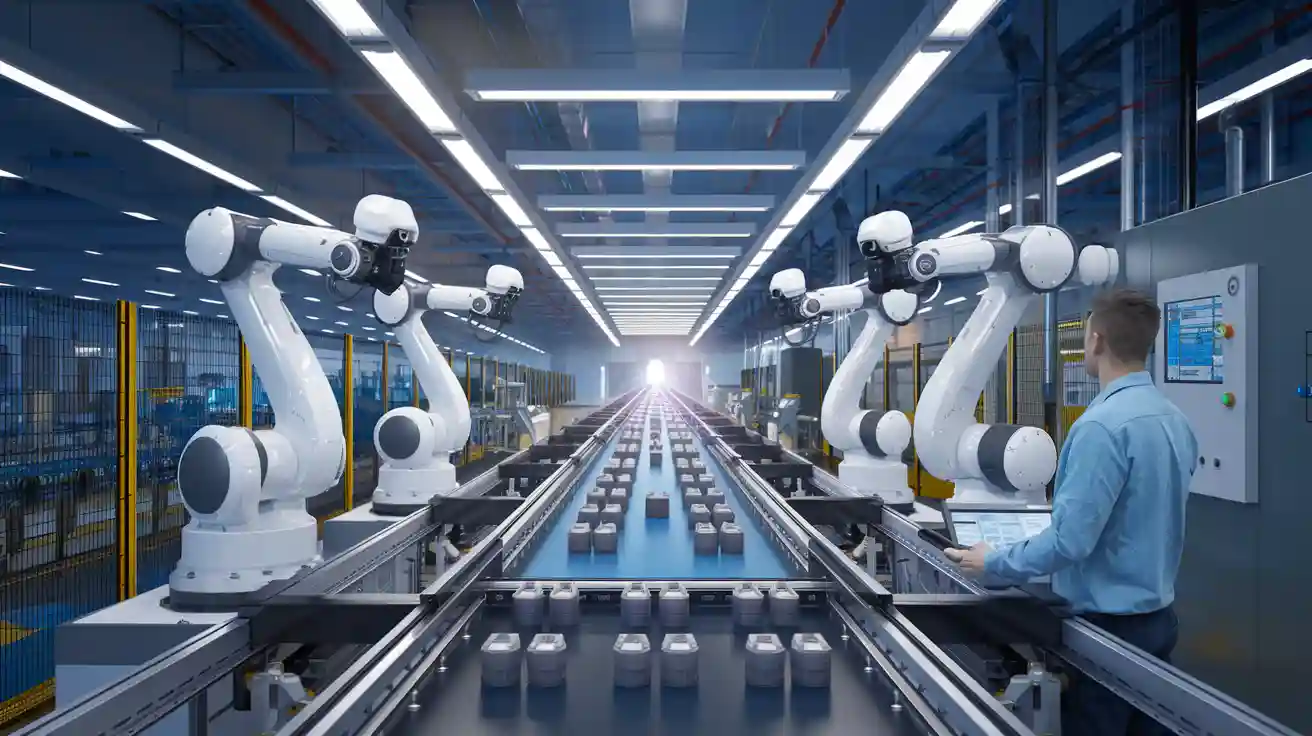

Production machine vision systems are transforming how you approach modern manufacturing. These systems use advanced cameras and software to perform tasks like inspecting products, detecting defects, and ensuring consistent quality. Unlike humans, they work tirelessly and with unmatched precision. By automating repetitive visual tasks, machine vision systems allow you to increase efficiency, reduce errors, and meet growing demands for accuracy. Whether you’re enhancing production lines or improving quality control, machine vision brings a new level of reliability to your operations.

Key Takeaways

-

Machine vision systems help factories work faster and make fewer mistakes.

-

These systems find over 99% of defects, keeping products high-quality and reducing waste.

-

Using machine vision can save businesses a lot of money, up to $200,000 each year per system.

-

Machine vision makes workplaces safer by replacing risky manual checks with automated ones.

-

Adding machine vision now helps your business stay strong and compete in the future market.

Understanding Production Machine Vision Systems

What Is a Production Machine Vision System?

A production machine vision system is a specialized technology designed to automate visual tasks in industrial environments. Unlike consumer-grade cameras, these systems are built for speed, precision, and durability. They excel in tasks like detecting defects, measuring dimensions, and sorting products. By integrating advanced imaging and processing capabilities, they help you maintain high standards of quality and efficiency in your operations.

Machine vision systems are becoming increasingly popular across industries. According to ABI Research, shipments of these systems are expected to reach 16.9 million by 2025. This growth reflects their critical role in industrial automation. For example, they can detect changes in product quality, analyze objects for accuracy, and even maintain a visual record of the production process. Whether you’re in manufacturing or logistics, these systems provide the tools you need to stay competitive.

Key applications of machine vision include:

-

Inspecting products for defects or inconsistencies.

-

Measuring and verifying dimensions to ensure precision.

-

Sorting items based on size, shape, or color.

By automating these tasks, you can reduce waste, improve quality control, and enhance overall productivity.

Core Components of Machine Vision Technology

A production machine vision system relies on several key components to function effectively. Each part plays a vital role in capturing, processing, and analyzing visual data. Here’s a breakdown of the main components:

|

Component Type |

Description |

|---|---|

|

Imaging Sensors |

Capture images of the objects being inspected. |

|

Cameras |

Acquire images, including smart cameras that process data directly. |

|

Optics and Lenses |

Focus and direct light onto the imaging sensors. |

|

Light Sources |

Illuminate objects to enhance visibility and contrast. |

|

Computers |

Process the captured images and run analysis software. |

|

Software |

Extract useful data from images to make decisions. |

These components work together to deliver accurate and reliable results. For instance, adequate lighting conditions account for up to 90% of a system’s performance. Optimized lighting strategies can improve defect detection rates by 30%. By ensuring each component is properly configured, you can maximize the effectiveness of your vision systems.

How Machine Vision Works in Industrial Settings

Machine vision systems operate by capturing and analyzing images to perform specific tasks. The process begins with imaging sensors and cameras, which take high-quality pictures of the objects being inspected. These images are then processed by software that identifies patterns, measures dimensions, and detects defects.

In industrial settings, machine vision plays a crucial role in improving efficiency and accuracy. For example, vision-guided robots use these systems to locate and manipulate objects with precision. Packaging lines rely on machine vision to verify the quality and integrity of products. By automating these processes, you can reduce cycle times and minimize errors.

Here are some common operational processes supported by machine vision:

-

Balancing production lines to improve efficiency.

-

Inspecting packaging for defects or missing labels.

-

Guiding robotic systems to perform tasks like assembly or sorting.

Machine vision systems also provide measurable benefits. For instance, Averroes.ai reduced weekly false rejects from 12,000 units to just 246 units, saving over $18 million annually per production line. These systems not only enhance productivity but also lower operational costs, making them an essential tool for modern manufacturing.

Benefits of Machine Vision in Production

Boosting Efficiency and Productivity

Machine vision systems revolutionize how you approach efficiency and productivity in manufacturing. By automating repetitive tasks, these systems allow you to streamline operations and focus on higher-value activities. For instance, vision-guided robots can process up to 10,000 parts per hour, significantly accelerating production lines. This speed ensures that you meet tight deadlines without compromising quality.

The integration of machine vision with automated systems also reduces human error and enhances throughput. AI-powered systems process images within milliseconds, enabling real-time monitoring and faster inspections. This capability maximizes production line capacity and minimizes downtime. For example, a bakery using machine vision saved $14,000 annually by automating quality control tasks.

Here’s a snapshot of measurable efficiency gains:

|

Efficiency Gain Description |

Measurable Impact |

|---|---|

|

Reduction in quality assurance labor costs |

Approximately 50% reduction |

|

Speed of vision-guided robots |

Up to 10,000 parts per hour |

|

Increase in classification accuracy |

20% increase over traditional algorithms |

|

Improvement in robotic part-picking efficiency |

Over 40% improvement |

Machine vision systems not only boost efficiency but also contribute to sustainability. By identifying inefficiencies, they help reduce electrical energy consumption by 38.24% and CO2 emissions by 38.17%. These improvements align with modern goals for greener manufacturing.

Enhancing Quality Control and Consistency

Maintaining consistent quality is critical in any production environment. Machine vision excels in this area by providing precise defect detection and real-time monitoring. Traditional methods often miss subtle defects, but AI-driven systems achieve an accuracy rate of over 99.5%. This ensures that your products meet the highest standards.

A global electronics manufacturer implemented machine vision technology and saw a 30% reduction in missed defects. Inspection cycle times decreased by 40%, leading to annual savings of over $2 million. These results highlight how machine vision can improve product quality while reducing costs.

Here’s a comparison of traditional methods versus AI-driven systems:

|

Metric |

Traditional Methods |

AI-Driven Systems |

|---|---|---|

|

Accuracy |

85-90% |

99.5%+ |

|

Speed |

2-3 seconds/unit |

0.2 seconds/unit |

|

Cost Efficiency |

$12K/month |

$4K/month |

By leveraging advanced image analysis software, you can detect even the smallest defects. This level of precision minimizes waste and ensures that every product leaving your facility meets customer expectations.

Improving Workplace Safety and Reducing Errors

Workplace safety is a top priority in manufacturing, and machine vision plays a vital role in creating safer environments. Automated systems reduce the need for manual inspections in hazardous areas, protecting workers from potential risks. For example, vision systems can monitor equipment in real time, identifying issues before they become safety hazards.

Machine vision also minimizes errors that could lead to accidents. By using object detection and processing and analysis capabilities, these systems ensure that machinery operates correctly. This reduces the likelihood of malfunctions and improves overall safety.

Additionally, automation supported by machine vision enhances ergonomic conditions. Workers no longer need to perform repetitive or physically demanding tasks, reducing the risk of injuries. This shift not only improves safety but also boosts morale and productivity.

Incorporating machine vision into your operations leads to safer, more efficient workplaces. It’s a win-win for both employees and your bottom line.

Solving Modern Manufacturing Challenges

Addressing Labor Shortages with Automation

Labor shortages in manufacturing have become a pressing issue, but automation offers a practical solution. Machine vision systems enable you to automate operations that previously required manual labor. For example, AI-powered robots can handle complex tasks like bolt torquing with nearly 100% accuracy, even under challenging conditions such as inconsistent lighting or component positioning. Each automated system saves over $200,000 annually, making it a cost-effective alternative to traditional methods.

By integrating machine vision into your manufacturing process, you can reduce dependency on human labor while maintaining high-quality standards. Automated inspections streamline workflows, allowing you to focus on process improvement and innovation. Predictive maintenance features further enhance efficiency by preventing costly downtime and repairs. These systems not only alleviate labor shortages but also improve overall productivity.

Meeting Precision and Scalability Demands

Precision and scalability are essential for modern manufacturing. Machine vision systems excel in defect detection, identifying even minute flaws that could compromise safety or performance. With accuracy rates of 99.8%, recall of 100%, and precision of 99.6%, these systems ensure reliable results across various industries. They also adapt to changing production needs without significant disruptions, making them ideal for scalable operations.

Cloud-based solutions enhance scalability by reducing upfront costs and offering flexible configurations. You can easily program machine vision systems for different inspection requirements, ensuring they meet evolving demands. Enhanced data analysis and real-time monitoring capabilities further support scalability, allowing you to optimize production lines and maintain consistent quality.

|

Metric |

Value |

|---|---|

|

Accuracy |

99.8% |

|

Recall |

100% |

|

Precision |

99.6% |

Reducing Costs and Maximizing ROI

Machine vision systems deliver significant cost savings and a high return on investment. By detecting defects early, they prevent faulty components from advancing through the production line, reducing material waste and lowering rework costs. For instance, a leading car seat manufacturer reduced inspection time from 60 seconds per seat to just 2.2 seconds, achieving a 30% decrease in defect rates and a 30-fold reduction in inspection costs.

These systems also improve production efficiency, cutting downtime by up to 50% and reducing safety incidents by 40–60%. Maintenance costs drop by 20–40%, further enhancing financial benefits. Automated processes powered by machine vision technology streamline operations, allowing you to maximize ROI while maintaining high standards of quality.

|

Cost Reduction Metric |

Industry Average Impact |

|---|---|

|

Maintenance Costs |

20–40% savings |

|

Production Efficiency |

20–30% increase |

|

Safety Incidents |

40–60% reduction |

|

Downtime |

30–50% reduction |

Applications of Machine Vision Across Industries

Manufacturing: Quality Control and Defect Detection

Machine vision has transformed manufacturing by automating quality control and defect detection processes. Industrial vision systems now handle over 50% of production workflows in leading companies like General Motors. These systems identify flaws with unmatched accuracy, ensuring consistent product quality while reducing waste. For example, automated optical inspection detects defects early, preventing faulty components from advancing through production lines.

The benefits of machine vision in manufacturing include improved accuracy, faster inspections, and significant cost savings. A comparison of traditional methods and machine vision systems highlights these advantages:

|

Improvement Aspect |

Description |

|---|---|

|

Accuracy |

Machine vision systems reduce human error in defect detection. |

|

Speed |

Automated inspection accelerates production cycles. |

|

Efficiency |

Quality control processes become more streamlined. |

|

Cost Savings |

Waste and rework costs decrease significantly. |

|

Customer Satisfaction |

Fewer defects lead to higher customer satisfaction. |

By integrating machine vision, you can enhance efficiency and maintain high standards in your production lines.

Logistics: Automated Sorting and Tracking

In logistics, machine vision systems optimize sorting and tracking processes. These systems automate tasks like inventory visibility, defect detection, and space optimization. For instance, automated inspection ensures accurate classification of items, reducing errors and improving operational efficiency. With accuracy levels reaching 99.4%, machine vision ensures reliable quality assurance.

Key metrics illustrate the impact of machine vision in logistics:

|

Metric |

Description |

|---|---|

|

Inventory Visibility |

Tracks stock accurately, minimizing losses. |

|

Sorting Automation |

Simplifies item classification for efficient placement. |

|

Space Optimization |

Predicts container configurations to maximize space utilization. |

By automating sorting and tracking, you can reduce operational costs and improve productivity.

Healthcare: Medical Imaging and Diagnostics

Machine vision plays a critical role in healthcare, particularly in medical imaging and diagnostics. AI-powered vision systems identify abnormalities that may not be visible to the human eye. This capability enables early detection of diseases, leading to timely treatment. For example, UC San Diego Health used AI to detect COVID-19 pneumonia, allowing for faster diagnosis and intervention.

These systems also enhance diagnostic accuracy. In one case, a heart failure patient’s chest x-ray revealed a potential infection, prompting immediate COVID-19 testing and treatment. By leveraging machine vision, healthcare providers can improve patient outcomes and streamline diagnostic workflows.

Machine vision in healthcare not only saves lives but also reduces the burden on medical professionals by automating complex imaging tasks.

The Future of Production Machine Vision Systems

Innovations in AI and Machine Learning Integration

Advancements in AI and machine learning are reshaping how you use machine vision systems. Deep learning models, such as convolutional neural networks (CNNs), now enable systems to recognize objects and patterns with exceptional accuracy. These models excel in tasks like image classification and object detection, making your production lines smarter and more efficient. Reinforcement learning further enhances these systems by allowing robots to adapt their actions based on real-time feedback, optimizing tasks like navigation and object manipulation.

Edge computing is another game-changer. By processing data locally, it reduces latency, enabling real-time monitoring and defect detection. For instance, robots equipped with edge AI can predict maintenance needs, preventing costly downtime. High-resolution cameras and advanced optics also improve image quality, ensuring that even the smallest defects are identified. These innovations not only enhance precision but also make your operations more adaptable to market changes.

Emerging Applications in New Industries

Machine vision is expanding beyond traditional manufacturing into new sectors. In the automotive industry, it supports autonomous vehicles by enabling precise object recognition and navigation. The food industry uses it for tasks like sorting produce and ensuring packaging integrity. Electronics manufacturers rely on it for inspecting intricate components, while the healthcare sector benefits from its role in diagnostics and medical imaging.

This technology is also proving its value in unstructured environments. For example, it enhances automation in industries where conditions are less predictable, such as agriculture and construction. Improved adaptability and accuracy in defect detection are driving this expansion, making machine vision a versatile tool across diverse applications.

The market for machine vision systems reflects this growth. By 2030, the industry is projected to reach $21 billion, with a compound annual growth rate (CAGR) of 7.5%. The Asia-Pacific region, with its strong customer base, is expected to lead this expansion.

Why Businesses Should Embrace Machine Vision Now

Adopting machine vision systems today positions your business for long-term success. These systems reduce costs by minimizing waste and improving efficiency. Predictive maintenance features help you avoid downtime, while real-time monitoring ensures consistent quality. With software advancements, you can quickly adapt to changing production needs, staying competitive in a fast-evolving market.

The demand for vision-guided robotic systems is also on the rise. These systems streamline operations, allowing you to scale production without compromising precision. As industries increasingly rely on automation, integrating machine vision into your processes ensures you remain ahead of the curve. Waiting to adopt this technology risks falling behind competitors who are already leveraging its benefits.

Production machine vision systems are transforming industries by improving efficiency, quality, and safety. These systems address critical challenges like labor shortages and rising demands for precision. Their ability to automate processes and reduce costs makes them an essential investment for your business.

💡 Tip: Adopting machine vision now ensures you stay ahead of competitors and prepare for future advancements in AI and automation.

By integrating this technology, you secure your place in the future of smart manufacturing and position your business for long-term success.

FAQ

What industries benefit the most from machine vision systems?

Industries like manufacturing, logistics, healthcare, and automotive benefit significantly. These systems improve quality control, automate sorting, enhance diagnostics, and support autonomous vehicles. Emerging sectors like agriculture and food processing are also adopting machine vision for tasks like defect detection and product sorting.

How do machine vision systems improve quality control?

Machine vision systems detect defects with over 99% accuracy. They analyze images in real time, ensuring consistent product quality. By automating inspections, you can reduce human error, minimize waste, and meet high-quality standards.

Are machine vision systems difficult to integrate into existing operations?

No, modern machine vision systems are designed for easy integration. Many offer plug-and-play setups and customizable software. You can adapt them to your production lines without significant disruptions or downtime.

What is the ROI for machine vision systems?

Machine vision systems deliver high ROI by reducing waste, improving efficiency, and lowering labor costs. For example, automated inspections can cut defect rates by 30% and reduce downtime by up to 50%, saving millions annually.

Can small businesses afford machine vision technology?

Yes, many affordable options exist for small businesses. Cloud-based solutions and modular systems reduce upfront costs. These technologies scale with your needs, making them accessible even for smaller operations.

💡 Tip: Start small with a single application, then expand as you see results.

See Also

The Impact of Machine Vision in Modern Agriculture

Transforming Aerospace Production with Machine Vision Technology

Comparing Firmware Machine Vision to Conventional Systems

Essential Features and Advantages of Medical Vision Systems

Understanding the Role of Cameras in Machine Vision