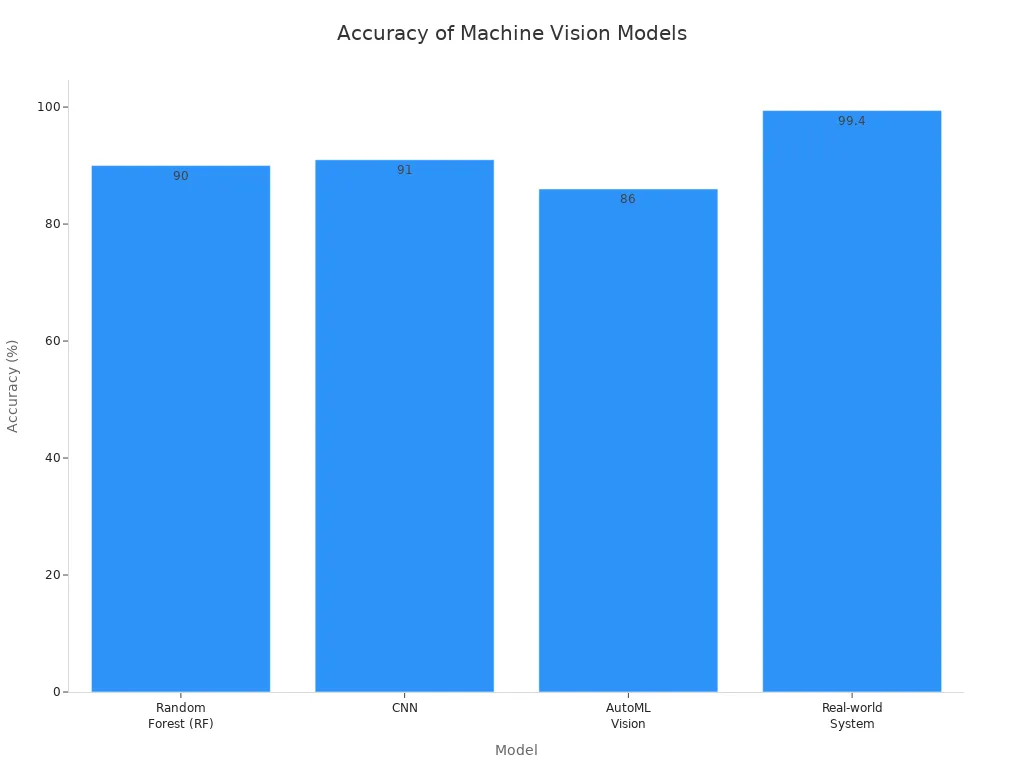

A two-stage detector machine vision system increases accuracy by first proposing potential object regions and then classifying and refining these areas. This approach reduces false positives and improves detection quality. In computer vision tasks, especially in autonomous vehicles, security, and medical imaging, high accuracy is critical. Leading algorithms like Faster R-CNN and Mask R-CNN outperform one-stage models by focusing on each object region in detail. In a real-world computer vision test, a two-stage detector machine vision system achieved 99.4% accuracy when inspecting 1,000 parts, showing its strength over other models.

Key Takeaways

- Two-stage detector systems improve accuracy by first finding possible object regions, then classifying and refining them carefully.

- These systems reduce false positives and detect small or overlapping objects better than one-stage detectors.

- Two-stage detectors work well in critical fields like medical imaging, security, and quality control where precision is essential.

- They require more computing power and run slower than one-stage detectors but offer higher reliability and detailed analysis.

- Including diverse training data, such as negative samples, helps improve the accuracy and robustness of two-stage detectors.

Object Detection in Computer Vision

What Is Object Detection?

Object detection stands as a core task in computer vision. It involves identifying and classifying each object within an image, then assigning a bounding box to show its location. Early approaches used handcrafted features, but deep learning now dominates the field. Modern models like Faster R-CNN, SSD, and YOLOv3 use large datasets to train neural networks that learn robust features. These models can recognize objects even when they appear in different shapes, sizes, or lighting conditions.

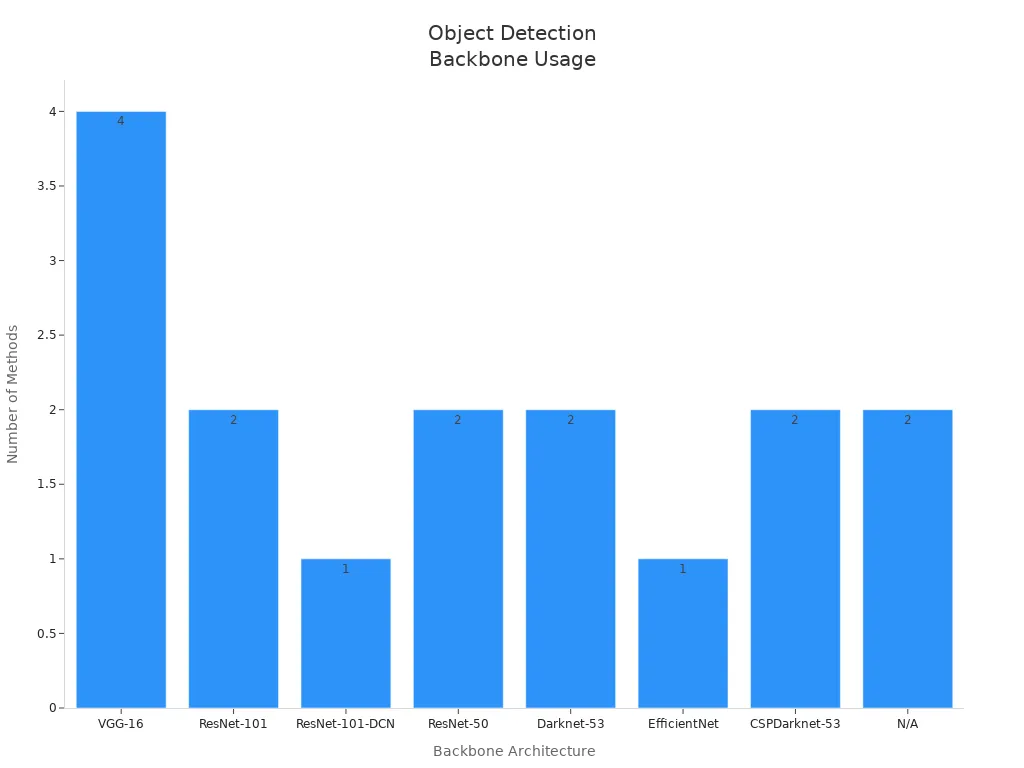

Researchers define object detection as the process of recognizing object categories and their positions in images. The field uses benchmark datasets such as COCO to evaluate performance. Standard metrics include true positives, false positives, and false negatives. The table below lists some of the most recognized object detection methods and their backbone architectures:

| Method | Backbone |

|---|---|

| Faster R-CNN | VGG-16 |

| Mask R-CNN | ResNet-101 |

| SSD | VGG-16 |

| RetinaNet | ResNet-50 |

| YOLOv3 | Darknet-53 |

| EfficientDet | EfficientNet |

Why Accuracy Matters

Accuracy in object detection plays a vital role in the reliability of computer vision systems. High accuracy ensures that each object is correctly identified and localized. In practical applications, accuracy reduces false positives and false negatives, which is crucial for safety and trust. For example, autonomous vehicles depend on precise object detection to avoid obstacles. Medical imaging systems require accurate detection to identify subtle anomalies.

Several challenges affect accuracy in object detection:

- Objects may appear different from various angles.

- Deformation changes the shape of objects.

- Occlusion hides parts of objects behind others.

- Lighting conditions can make objects hard to see.

- Cluttered backgrounds cause objects to blend in.

- Objects come in many shapes and sizes.

- Real-time applications demand both speed and accuracy.

Metrics such as mean Average Precision (mAP) and Intersection over Union (IoU) help measure how well a system detects and localizes objects. These metrics guide model selection and tuning, ensuring reliable performance in real-world computer vision tasks.

Two-Stage Detector Machine Vision System

How Two-Stage Detectors Work

A two-stage detector machine vision system uses a structured, step-by-step approach to improve accuracy in object detection. The process begins with a region proposal network that scans the input image and suggests regions likely to contain an object. This first stage acts as a filter, narrowing down the search space and focusing attention on promising areas. The second stage takes these proposals and applies a more detailed analysis. It classifies each region and refines the bounding boxes to better fit the detected object.

This workflow, often called "coarse-to-fine," allows the system to separate background from true objects early in the process. By focusing on fewer, high-quality regions, the two-stage detector reduces the risk of missing small or hard-to-see objects. Deep learning algorithms power both stages, enabling the system to learn complex patterns and features from large datasets. The use of a region proposal network is a key innovation, as it improves both efficiency and accuracy by generating candidate regions before classification.

Popular architectures such as Faster R-CNN, R-FCN, and feature pyramid network (FPN) have set benchmarks in the field. These models combine the strengths of region proposal and advanced feature extraction, making them suitable for demanding applications like industrial inspection and autonomous vehicles.

Note: Two-stage detectors achieve higher accuracy than one-stage models, especially when detecting small or overlapping objects. However, this comes with increased computational cost and slower processing times.

Region Proposal and Classification

The region proposal network plays a central role in the two-stage detector machine vision system. It uses anchor boxes and Intersection over Union (IoU) metrics to generate candidate regions. These proposals highlight where an object might be located. The system then applies roi pooling to extract fixed-size feature maps from each proposal. This step ensures that the next stage receives consistent input, regardless of the original region size.

In the second stage, the system assigns an objectness score to each proposal. This score helps filter out background regions and reduces false positives. The classifier then labels the object and refines the bounding box using bounding box regression. Roi pooling enables the system to reuse convolutional feature maps, which boosts both speed and accuracy.

Recent studies show that integrating roi pooling and improved loss functions, such as AIoU loss, leads to better localization and higher mean Average Precision (mAP). Pre-training the region proposal network also reduces localization errors, especially when labeled data is limited. These steps make the two-stage detector robust in real-world scenarios, from self-driving cars to medical imaging.

| Detector Type | Accuracy (mAP) | Notes |

|---|---|---|

| Faster R-CNN | ~72.3% | Two-stage detector with RPN, high accuracy |

| DSFSN | 81.6% | Advanced two-stage detector, higher mAP |

| YOLO (single-stage) | ~63.4% | Faster inference, lower accuracy |

Accuracy Advantages

Two-stage detectors stand out for their superior accuracy in object detection tasks. By separating region proposal from classification, these systems achieve higher precision and robustness. Empirical studies report a 10% improvement in detectability when the second stage refines low-confidence detections. This approach proves especially effective in applications where accuracy is more important than speed.

The use of roi pooling and feature pyramid network further enhances performance. Feature pyramid network builds multi-scale feature representations, allowing the system to detect objects of different sizes, including small or partially hidden ones. In industrial settings, two-stage detector machine vision systems have achieved detection accuracy rates as high as 96.3% and classification accuracy up to 98.9%. These results hold even in challenging conditions, such as low-light environments or when objects are surrounded by noise.

Two-stage detectors also offer flexibility for specialized tasks. For example, the DualSight Network and FocusFusion Module improve sensitivity to small objects, while denoising networks help in low-light or noisy settings. This adaptability makes the two-stage detector machine vision system a preferred choice for high-stakes applications, including medical imaging, security, and quality control.

Tip: Including negative samples—images without the target object—during training helps reduce false positives. This strategy teaches the model to distinguish between true objects and background clutter.

Two-Stage vs. One-Stage Detectors

Key Differences

Two-stage detectors and one-stage detectors use different workflows to detect objects in images. Two-stage detectors, such as Faster R-CNN, first generate region proposals using a region proposal network. They then classify and refine these proposals through ROI pooling and fully connected layers. This process increases computational overhead and training time. One-stage detectors, like RetinaNet, skip the proposal step. They predict class probabilities and bounding box coordinates in a single pass. This design makes one-stage detectors faster and simpler.

- Two-stage detectors use a sequential process: region proposal, then classification.

- One-stage detectors predict object classes and locations directly in one step.

- Two-stage detectors handle small or overlapping objects better.

- One-stage detectors use dense predictions on feature maps for speed.

- Two-stage detectors introduce more complexity due to extra processing steps.

Accuracy vs. Speed

Benchmark studies show that two-stage detectors achieve higher accuracy, especially for small or crowded objects. They use region proposal networks to focus on likely object locations, which improves precision. However, this comes at the cost of slower inference speed. One-stage detectors excel in real-time applications. They can process images up to 300 times faster than some two-stage detectors. For example, YOLO achieves about 63.4% accuracy, while Fast R-CNN reaches 70%. Two-stage detectors remain the top choice for tasks where accuracy is more important than speed.

Trade-Offs and Use Cases

Choosing between two-stage detectors and one-stage detectors depends on the application. Two-stage detectors work best in high-reliability scenarios, such as medical imaging or detailed object recognition. Their design allows for better localization and classification, even when objects are small or partially hidden. One-stage detectors fit real-time needs, like video surveillance or autonomous driving, where speed matters most. They require less hardware and can handle large objects well. In manufacturing, one-stage detectors help spot defects quickly, while two-stage detectors provide detailed analysis for quality control.

Note: Two-stage detectors are preferred for high-reliability applications because they offer robust decision-making and handle uncertainty better. Their layered approach improves accuracy and reliability, making them suitable for critical environments.

| Detector Type | Workflow | Speed | Accuracy | Best Use Cases |

|---|---|---|---|---|

| Two-stage detectors | Proposal + Classification | Slower | Higher | Medical imaging, quality control |

| One-stage detectors | Direct prediction | Faster | Slightly lower | Real-time, surveillance, driving |

Real-World Applications

Autonomous Vehicles

Two-stage detector machine vision systems play a vital role in autonomous vehicles. These systems use models like R-CNN, Fast R-CNN, and Faster R-CNN to detect objects such as pedestrians, vehicles, and road signs. Faster R-CNN, for example, uses a Region Proposal Network (RPN) to quickly generate possible object locations and then classifies them. This approach helps vehicles understand their surroundings with high accuracy. On datasets like KITTI, two-stage detectors show strong performance in recall and precision, even though they process images more slowly than one-stage models. Recent advancements include lightweight models and optimized encoders, which allow these systems to run on edge devices inside vehicles. This balance of speed and accuracy supports safer navigation and better decision-making.

Security and Medical Imaging

Security systems rely on two-stage detectors for tasks like facial recognition, anomaly detection, and access control. These systems focus on key features, such as faces or license plates, by isolating regions of interest (ROIs). This method improves detection accuracy and speeds up processing, making real-time security monitoring possible. In medical imaging, two-stage detectors help doctors find diseases like cancer by analyzing specific areas in scans. Studies show that AI-assisted methods using these detectors can increase diagnostic accuracy by up to 8.75% compared to traditional approaches. CNN-based two-stage frameworks also achieve high sensitivity and specificity in detecting conditions such as brain tumors and breast cancer. These improvements lead to better patient outcomes and more reliable security systems.

Robotics and Remote Sensing

Robotics and remote sensing benefit from the precise object localization offered by two-stage detectors. Robots use advanced vision systems to perform complex tasks, such as underwater inspections and automated construction. For example, underwater robots equipped with high-resolution cameras create detailed 3D models of submerged structures, improving safety and efficiency. In construction, robotic micro-factories use vision AI to cut and assemble materials with great accuracy. Researchers continue to develop lightweight and efficient models, enabling these systems to operate in real-time and on devices with limited memory. These advancements support safer operations and smarter decision-making in challenging environments.

Two-stage detector machine vision systems deliver superior accuracy and reliability by separating region proposal from classification. They excel in critical environments like medical imaging and quality control, where precision matters most. Decision-makers should compare system needs using the table below:

| Consideration | Two-Stage Detectors | One-Stage Detectors |

|---|---|---|

| Accuracy | Higher | Good |

| Speed | Slower | Faster |

| Resource Needs | High | Low |

| Best Use | Complex, high-precision | Real-time, resource-limited |

Key trends include smarter AI, adaptive learning, and better integration with robotics, making these systems even more valuable for future applications.

FAQ

What makes two-stage detectors more accurate than one-stage detectors?

Two-stage detectors first find possible object regions, then classify and refine them. This step-by-step process helps reduce mistakes and improves detection, especially for small or overlapping objects.

Can two-stage detectors work in real-time applications?

Two-stage detectors usually process images slower than one-stage models. Some new designs use lighter networks to speed up detection, but most real-time systems still prefer one-stage detectors for faster results.

Where do two-stage detector systems perform best?

Two-stage detector systems excel in high-stakes fields. Medical imaging, quality control, and security benefit from their high accuracy. These systems help find small defects, subtle changes, or hidden objects.

Do two-stage detectors need a lot of computing power?

Yes. Two-stage detectors use more memory and processing power than one-stage models. They often require powerful GPUs or cloud resources, especially for large images or complex tasks.

How can users improve the accuracy of a two-stage detector?

Tip: Users can improve accuracy by adding more labeled data, using data augmentation, and including negative samples during training. Fine-tuning the model on specific tasks also helps boost performance.

See Also

Do Filtering Techniques Improve Precision In Machine Vision?

Capabilities Of Machine Vision Systems In Detecting Defects

A Guide To Object Recognition Using Advanced Machine Vision

Analyzing How Machine Vision Identifies Product Flaws Effectively

Comparing Firmware-Based And Conventional Machine Vision Solutions