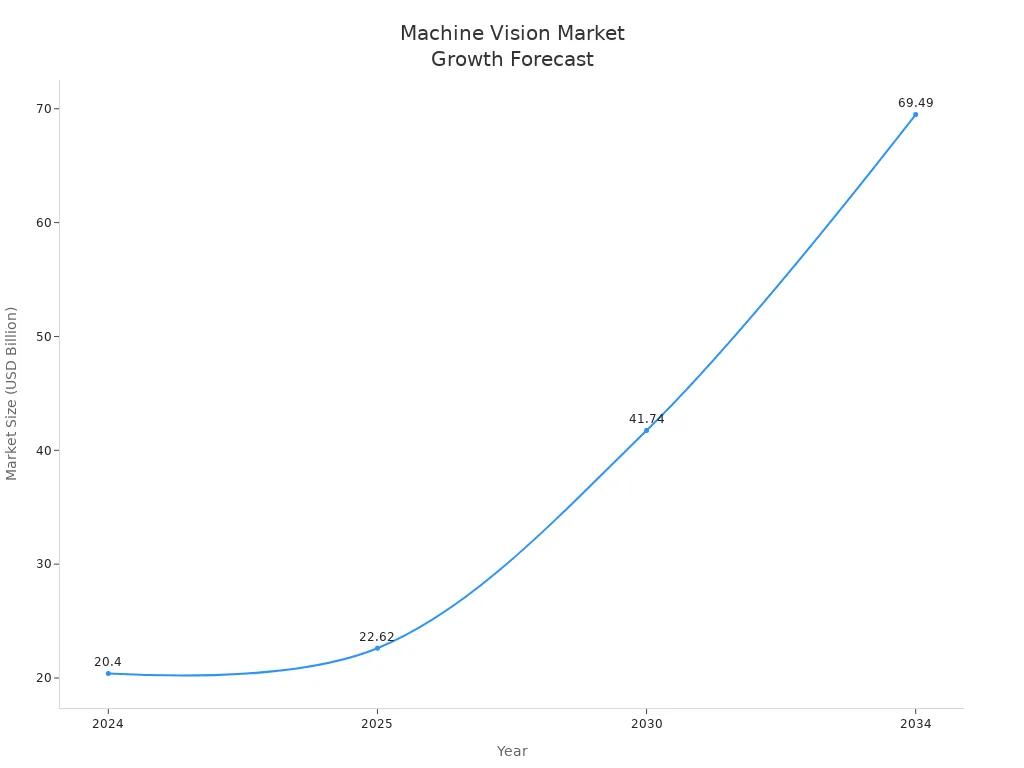

A tp machine vision system uses advanced cameras, sensors, and artificial intelligence to inspect products automatically. High true positive detection rates ensure these systems catch nearly every defect, which leads to better quality control and fewer faulty items reaching customers. For example, some methods achieve almost perfect detection, improving reliability and reducing downtime in factories. Machine vision now offers user-friendly interfaces and deep learning tools, making it practical for many industries. The global market for these systems is growing rapidly, as shown below:

Key Takeaways

- TP machine vision systems use advanced cameras and AI to find defects automatically, improving product quality and reducing errors.

- These systems perform many inspection tasks quickly and consistently, cutting down human mistakes and speeding up production.

- High true positive rates mean the system catches most real defects, helping factories avoid sending faulty products to customers.

- Good lighting, cameras, and AI-powered processing work together to detect even tiny flaws that humans might miss.

- Machine vision systems save costs by reducing labor, lowering defect rates, and supporting fast, reliable quality control across industries.

TP Machine Vision System Overview

Definition and Purpose

A tp machine vision system uses advanced technology to inspect products and parts with high accuracy. This vision system combines cameras, sensors, and artificial intelligence to find defects and measure features. The main goal is to improve quality control and reduce errors in manufacturing. Many industries, such as automotive manufacturing, rely on these systems to keep products safe and reliable.

Machine vision systems stand out from traditional inspection methods because they use AI-driven machine learning algorithms. These algorithms adapt and improve over time, unlike older rule-based systems that need manual updates. The vision system learns from data, which helps reduce false positives and lowers costs. It also scales easily for different production needs. Regular calibration and retraining keep the system accurate and prevent errors. Performance metrics like precision, recall, and F1 score help balance false positives and false negatives, ensuring high product quality. Advanced features, such as subpixel processing and environmental controls, further boost detection accuracy.

Note: A tp machine vision system can handle complex inspection tasks that humans might miss, especially in fast-paced environments like automotive manufacturing.

Role in Automated Inspection

A tp machine vision system plays a key role in automated solutions for quality control. It performs many tasks during the inspection process, making it essential for industries like automotive and electronics. The vision system captures images, processes data, and makes decisions without human help. This process ensures that only products meeting strict standards reach customers.

Key tasks performed by machine vision systems during automated inspection include:

- Image acquisition: The vision system uses cameras and sensors to capture multiple images of each product.

- Image transfer: It sends these images to a processing unit for analysis.

- Image preprocessing: The system removes noise and enhances images to prepare them for inspection.

- Feature extraction: Algorithms identify edges, colors, shapes, and patterns.

- Analysis: The vision system uses AI or rule-based methods to detect defects, measure dimensions, and check surface quality.

- Decision-making: Based on the analysis, the system decides if a product passes, needs reinspection, or should be rejected.

- Communication: Results go to control systems and robots for further action.

- User interface update: The system displays inspection results, highlighting any defects.

Machine vision systems help reduce human error in inspection. The table below shows how these systems outperform manual inspection in several ways:

| Aspect | Explanation |

|---|---|

| Hybrid 2D/3D Deep Learning System | Combines 2D imaging and 3D laser triangulation, improving defect detection accuracy beyond human levels (over 95% TP accuracy). |

| Reduction of Human Error | Automates repetitive tasks, limiting human involvement to supervision and ambiguous cases, reducing errors from fatigue. |

| Inspection Speed and Inline Usability | Cuts inspection time by about 20%, manages hardware, and enables faster inline inspection. |

| Consistency and Robustness | Provides more consistent defect detection than human inspectors, who may get tired or lose focus. |

| Operator Role Shift | Operators focus on rework and final decisions, reducing error-prone activities. |

| Accuracy Metrics | Achieves true positive and true negative rates above 90%, better than most human inspection. |

Advancements in artificial intelligence have made machine vision systems even more accurate. High-quality sensors, subpixel processing, and careful calibration allow these systems to detect tiny defects that humans might miss. Environmental controls, such as optimized lighting and temperature management, help maintain reliable measurements. In automotive manufacturing, these features ensure that every part meets safety and quality standards.

Machine vision systems now offer user-friendly interfaces and scalable solutions. This makes them practical for many industries, from automotive to electronics. Automated solutions using these systems can inspect thousands of products per hour, reducing costs and improving efficiency. As a result, machine vision has become a vital part of modern inspection systems, supporting automatic inspection and quality control across many sectors.

Machine Vision Systems Components

Cameras and Lenses

Machine vision systems rely on specialized cameras and lenses to capture clear images for inspection. The main camera types include:

- Area cameras: Capture 2D images in one shot, ideal for checking part presence and reading labels.

- Line scan cameras: Build images one row at a time, perfect for inspecting long materials at high speed.

- 3D vision cameras: Use structured light or stereo imaging to measure height and profile surfaces.

Selecting the right lens is just as important. Fixed focal length lenses work well for standard tasks, while variable magnification lenses allow real-time adjustments. Telecentric lenses provide constant magnification and eliminate parallax errors, making them essential for precise measurements. Specialty lenses, such as macro or ruggedized types, solve unique challenges in harsh environments.

Resolution plays a key role in defect detection. Higher resolution allows the vision system to spot smaller defects, but it also increases image data size and processing time. Engineers must balance resolution, frame rate, and cost to ensure the image sensor captures enough detail without slowing down the image processing system. Proper lens choice and calibration help maintain measurement accuracy.

Lighting and Sensors

Lighting determines image quality in machine vision systems. Good lighting improves clarity, contrast, and defect visibility. Techniques like dome, coaxial, ring, and backlighting adapt to different surfaces and inspection needs. Adaptive lighting, synchronized with high frame rate cameras, enhances defect detection. The image sensor must match the lighting setup to capture high-quality images.

Vision-based sensors, especially those using deep learning and machine learning, outperform traditional sensors in detecting surface defects. Advanced image sensors with specific wavelength sensitivities highlight important features and reduce false positives. These sensors, combined with the right lighting, ensure reliable inspection and high throughput.

Industrial Computers and AI

Industrial computers form the backbone of modern machine vision systems. Leading manufacturers like Cognex, Omron, Neousys Technology, and National Instruments offer rugged computers and embedded AI solutions. These systems use CPUs, GPUs, and AI accelerators to process images in real time. Embedded AI processors enable fast, on-device image processing and decision-making, reducing latency and boosting reliability.

Lightweight deep learning models, such as YOLOv5, run efficiently on embedded hardware. These models improve inspection speed and accuracy, even in complex environments. Vision software and machine learning algorithms allow the vision system to adapt to new tasks and maintain high performance. Local image processing lowers costs and supports scalable deployment in industrial automation.

Machine Vision System Process

Image Acquisition

Inspection systems begin with image acquisition. Engineers define what features or defects the system must detect. They build an image database of both defective and acceptable parts. Next, they select lighting that highlights product features and reduces shadows or glare. Material-handling devices position each item for consistent imaging. Engineers choose cameras and lenses based on resolution and field-of-view needs. High-resolution cameras and specialized lenses capture clear images, revealing even microscopic defects. Proper lighting, such as LED arrays or backlighting, ensures images are suitable for analysis. Environmental controls, like dust management, help maintain image quality. The team calibrates the inspection systems and tests them under different conditions. Finally, they develop user-friendly interfaces for operators to adjust or retrain the machine vision systems as needed.

Note: High-quality image acquisition directly affects the accuracy and reliability of inspection systems. Poor lighting or camera settings can cause false alarms or missed defects.

Processing and Analysis

After capturing images, machine vision systems use advanced image processing to analyze them. Convolutional Neural Networks (CNNs) extract features and detect defects. Some inspection systems use hybrid models that combine CNNs with Recurrent Neural Networks (RNNs) for analyzing video or time-series data. Data preprocessing, such as normalization and augmentation, improves model performance. Deep learning and machine learning algorithms help the system adapt to new defect types and changing conditions. Engineers use Python and libraries like TensorFlow or PyTorch to implement these models. High-quality image data allows inspection systems to measure product features and identify flaws with high precision.

Decision and Action

Once analysis is complete, the machine vision system makes decisions in real time. It checks if products meet quality standards by evaluating shape, size, color, and surface condition. If the system detects a defect, it triggers automated actions. These actions include rejecting faulty items, sorting products, or guiding robotic arms for rework. Inspection systems use predefined rules or adaptive machine learning models to decide when to act. Integration with industrial automation equipment ensures fast and accurate responses. Real-time feedback and continuous monitoring allow inspection systems to support automatic inspection, reduce downtime, and maintain product quality.

True Positive Metrics in Machine Vision

What Are True Positives

In machine vision inspection, a true positive happens when the system correctly finds a defect or anomaly in a product. The model identifies a defective part as defective, which means it makes the right call. This correct detection is important for quality control because it helps factories catch problems before products reach customers. For example, in defect detection, true positives show that the system can spot real issues on a production line. True positives form the basis for measuring how well a machine vision system works. They help engineers understand if the system can find defects when they exist. High true positive counts mean the system supports strong quality control and reduces the risk of faulty products leaving the factory.

Evaluating Performance

Engineers use several metrics to check how well a machine vision system performs in quality control. The most important ones include precision and recall. Precision measures how many of the detected defects are actually real defects. Recall shows how many real defects the system finds out of all the defects present. The formula for recall is:

Recall = True Positive / (True Positive + False Negative)

A high recall means the system catches most defects, which is critical in quality control to avoid missing faulty items. Precision is also key because it tells how often the system makes correct positive calls, reducing unnecessary rework. The F1 score combines precision and recall to give a balanced view of performance. Engineers also look at true negatives, false positives, and false negatives to get a full picture.

In quality control, factories often aim for high recall to make sure no defective products slip through, even if it means accepting more false positives. This trade-off helps protect customers and brand reputation.

The table below summarizes key metrics:

| Metric | What It Measures |

|---|---|

| Precision | Correctness of defect detections |

| Recall | Ability to find all real defects |

| F1 Score | Balance between precision and recall |

| True Positive | Correctly found defects |

| False Positive | Incorrectly flagged defects |

| False Negative | Missed real defects |

By tracking these metrics, companies can tune their machine vision systems for better quality control and more reliable production.

Quality Control Benefits and Challenges

Accuracy and Efficiency

Machine vision systems transform quality control by delivering unmatched precision and recall. These automated solutions use advanced image processing and deep learning to spot even the smallest defects, which often escape human inspectors. In industries such as automotive manufacturing, these systems reduce inspection errors by over 90% and defect rates by up to 80%. The table below highlights key improvements compared to manual inspection:

| Improvement Aspect | Improvement Magnitude Compared to Manual Inspection |

|---|---|

| Inspection errors | Over 90% reduction |

| Defect rates | Up to 80% reduction |

| Labor costs for quality assurance | Approximately 50% reduction |

| Cycle time | Up to 20% reduction |

Automated solutions enable real-time systems to inspect thousands of products per hour, ensuring high quality and consistency. Companies in automotive and electronics report faster diagnostic times, improved repair efficiency, and significant cost savings. Machine vision also supports continuous monitoring, allowing immediate adjustments to maintain quality control requirements.

Integration and Tuning

Integrating machine vision into existing production lines presents several challenges. Compatibility with current equipment, seamless communication with robotics, and adapting to different lighting conditions require careful planning. Automotive manufacturing facilities often need to customize solutions to meet unique quality control needs. Calibration and maintenance demand expertise to achieve sub-pixel precision and reliable recall. Operators and technicians benefit from standardized training and intuitive interfaces, but advanced tuning still requires expert support. Thorough testing and phased deployment help identify issues early, ensuring smooth integration and optimal performance.

Overcoming Barriers

To minimize false results, manufacturers focus on several strategies:

- Enhancing training data quality and diversity improves the system’s ability to distinguish true defects, boosting both precision and recall.

- Continuous model refinement and retraining maintain accuracy as production conditions change.

- Dynamic thresholding allows real-time systems to adapt to environmental shifts, reducing false positives.

- Combining traditional algorithms with deep learning increases defect detection accuracy.

- Regular audits and performance monitoring track false positive rates and support ongoing optimization.

These approaches help machine vision systems deliver high quality, reliable quality control, and robust production efficiency across automotive and other industries.

TP machine vision systems drive major improvements in automated inspection and quality control. True positive metrics help engineers measure and boost system performance. Advancements in AI and user-friendly interfaces make these systems more efficient and easier to use.

- AI integration increases defect detection accuracy and adaptability.

- User-friendly solutions and IoT connectivity lower technical barriers.

- Everyday smart devices now support machine vision, expanding access.

Machine vision will continue to evolve, making automated quality control smarter, faster, and more accessible for every industry.

FAQ

What industries use TP machine vision systems?

Automotive, electronics, food processing, and pharmaceuticals use TP machine vision systems. These industries need fast, accurate inspection to maintain product quality and safety. Machine vision helps companies meet strict standards and reduce the risk of faulty products reaching customers.

How does a TP machine vision system reduce costs?

A TP machine vision system lowers costs by automating inspection. It reduces labor needs, catches defects early, and prevents expensive recalls. Companies save money on rework and waste. Automated systems also speed up production and improve overall efficiency.

Can machine vision systems adapt to new defects?

Yes. Modern machine vision systems use AI and machine learning. These systems learn from new data and adjust to changing defect types. Engineers can retrain models quickly, so the system stays accurate as products or defects change.

What is the difference between true positive and false positive in inspection?

- True positive: The system correctly finds a real defect.

- False positive: The system marks a good product as defective.

High true positive rates mean better quality control. Fewer false positives reduce unnecessary rework and costs.

See Also

Comprehensive Overview Of Inspection Vision Systems In 2025

Essential Tips For Positioning Equipment In Vision Systems

Detailed Explanation Of Image Processing In Vision Systems