A structured light systems machine vision system uses patterns of light to scan objects and create detailed 3D models. This technology captures 3D data quickly, making it important for modern machine vision systems. The global machine vision market is expected to reach $15.83 billion in 2025 as industries demand better automation. Recent advances in 3d structured light include:

- Parallel structured light captures 3D images of moving objects in a single shot.

- New sensors allow high-speed, high-accuracy scanning, even for fast-moving items.

These improvements help structured light systems machine vision system deliver reliable 3d results in real time.

Key Takeaways

- Structured light systems use projected light patterns and cameras to create fast, accurate 3D models of objects without touching them.

- These systems excel in industries like automotive, electronics, healthcare, and cultural heritage for quality control, reverse engineering, and medical imaging.

- Advanced algorithms and high-speed cameras improve scanning speed and accuracy, even for moving or complex objects.

- Structured light scanners offer high precision and non-contact measurement, protecting delicate items and enabling detailed inspections.

- Compared to laser scanning, structured light is faster and better for small, detailed tasks, making it ideal for close-range 3D scanning.

Structured Light Systems Machine Vision System

Principle of Structured Light

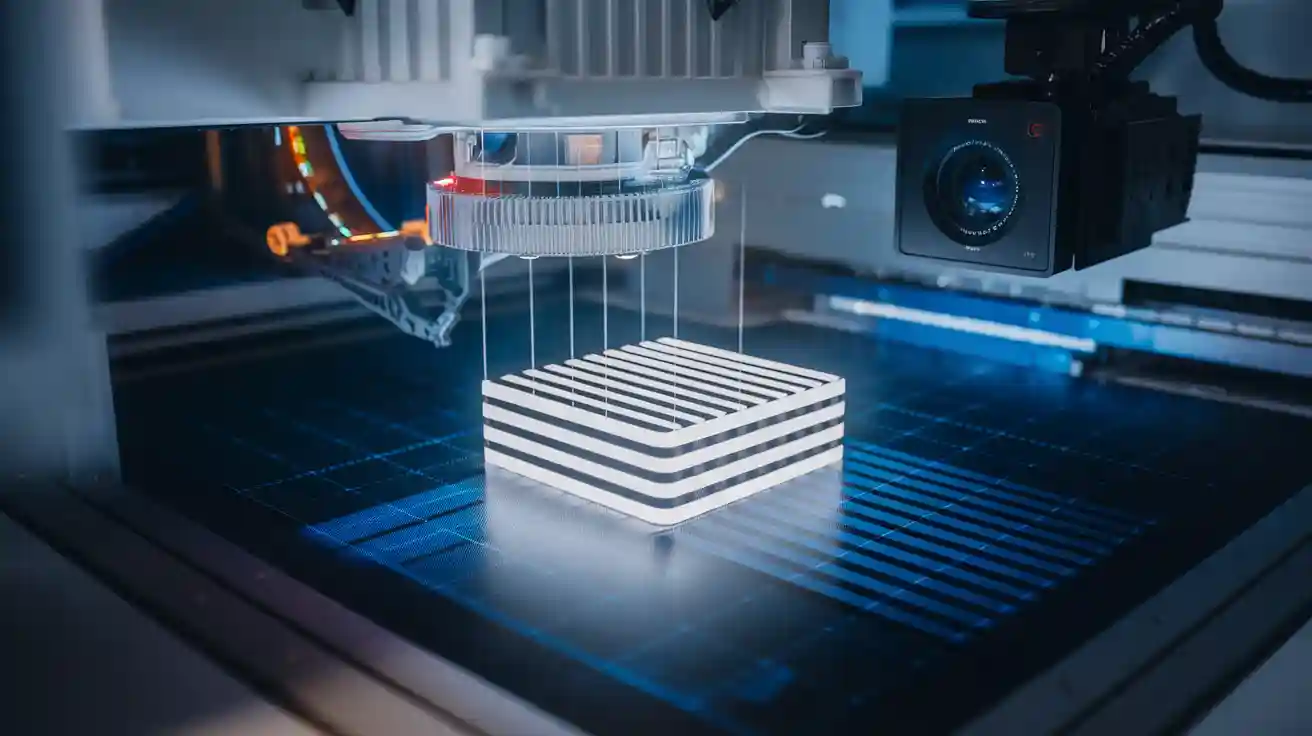

A structured light systems machine vision system uses a simple but powerful method to capture the shape of objects. The system projects a known pattern, such as stripes or grids, onto the surface of an object. The pattern bends and changes shape when it hits the object’s surface. Cameras or sensors then capture images of these deformed patterns from different angles. The system uses advanced algorithms to analyze the changes in the pattern. This process allows the system to create a detailed 3D model of the object’s surface.

Structured light scanners rely on this principle to deliver fast and accurate 3d structured light measurements. The main components of a structured light system include:

- A projector that emits structured light patterns.

- Cameras that record how the patterns change on the object.

- Software that processes the images and reconstructs a 3d point cloud.

The workflow of a structured light systems machine vision system follows these steps:

- The projector shines a coded light pattern onto the object.

- The object’s surface causes the pattern to deform.

- Cameras capture the deformed pattern from one or more viewpoints.

- The system analyzes the distortions using triangulation algorithms.

- The software reconstructs a precise 3d model of the object.

Structured light scanners achieve high accuracy and speed. Calibration methods, such as digital image correlation, help keep errors low. For example, some systems show less than 1% error when measuring a cylinder’s radius. Optimized lighting can improve accuracy by over 12% and reduce processing time. Structured light technology often outperforms other 3d scanning methods, such as laser triangulation, by providing full 3d point clouds quickly and efficiently.

3D Structured Light Technology

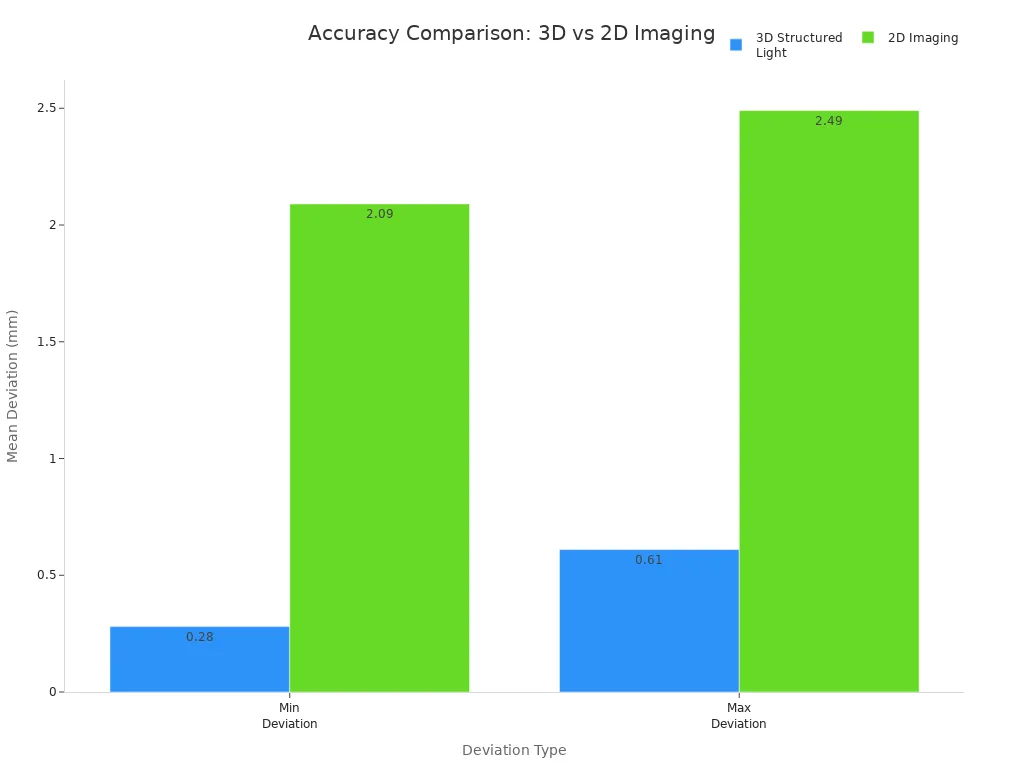

3d structured light technology stands out from traditional 2D imaging. It produces rich 3d data, not just flat pictures. The table below compares 3d structured light technology with standard 2D photography:

| Aspect | 3D Structured Light Technology (Dual-Structured Light Facial Scanner) | Traditional 2D Imaging (Photography) |

|---|---|---|

| Data Output | Produces a 3D virtual facial representation with volumetric data, high-resolution color, and no radiation. Enables integration with intraoral scanners and CAD software for comprehensive digital workflows. | Captures flat, 2D images lacking depth information; susceptible to perspective errors; limited in analyzing complex facial dynamics like smile and lip-tooth relationships. |

| Accuracy (Mean Deviation) | Ranges approximately from 0.28 mm to 0.61 mm, within clinically acceptable limits; no statistically significant differences compared to manual measurements. | Higher discrepancies, often exceeding clinically acceptable limits; mean deviations around 2.09 mm to 2.49 mm; statistically significant differences from manual measurements. |

| Clinical Applicability | Allows facial reconstructions in a single procedure; supports accurate diagnosis, treatment planning, and long-term follow-up. | Limited by lack of depth and perspective distortion; less reliable for detailed facial anthropometry. |

| Limitations | Possible volume distortions depending on technology used but generally more accurate and reliable. | Inherently limited by 2D nature; cannot capture dynamic or volumetric facial data. |

3d structured light scanners create 3d models with high accuracy. They can capture detailed color and shape information in a single scan. This makes them useful for medical imaging, reverse engineering, and quality control. The technology supports integration with other digital tools, such as CAD software, for a complete digital workflow.

Advanced algorithms and high-speed cameras play a key role in modern 3d structured light systems. New imaging algorithms improve the accuracy and quality of 3d point clouds. They reduce missing or distorted points, even on shiny or dark surfaces. High-speed cameras capture data quickly, allowing the system to scan moving objects or perform real-time inspections. These improvements help structured light scanners deliver reliable results in demanding environments.

| Aspect | Role of Advanced Algorithms | Role of High-Speed Cameras |

|---|---|---|

| Accuracy & Resolution | New algorithms increase accuracy and resolution, reducing errors on difficult surfaces. | High-speed cameras provide rapid, detailed 3d data capture. |

| Handling Reflective & Dark Surfaces | Algorithms reduce glare and noise, making it easier to scan shiny or dark objects. | Cameras support real-time processing for automation tasks. |

| Impact on Automation Efficiency | Robots can recognize and handle complex objects with more precision. | Faster data acquisition supports tasks like bin picking and inspection. |

| Integration & Support | Integrated into 3d structured light cameras for smart manufacturing. | Used in electronics, automotive, and battery industries for fast inspection. |

3d structured light technology continues to evolve. Fewer projection patterns and smarter algorithms make scanning faster and more efficient. Structured light scanners now handle complex surfaces and challenging materials with ease. As a result, structured light systems machine vision system remains a top choice for industries that need accurate, fast, and reliable 3d reconstruction.

Applications

Industrial Quality Control

Factories use structured light scanners to inspect products with high accuracy. These systems project patterns onto items moving along production lines. Cameras capture the deformed patterns, and software performs 3d imaging to check for defects or measure dimensions. Workers rely on structured light scanners for fast, non-contact inspection. This technology helps companies maintain strict quality standards and reduce waste. In 2025, many industries, such as electronics and automotive, use 3d scene reconstruction to ensure every product meets exact specifications.

Structured Light Scanner for Reverse Engineering

Engineers often need to recreate parts that lack digital designs. A structured light scanner captures millions of points from an object’s surface in seconds. The table below shows key benefits of using structured light scanners for reverse engineering:

| Key Benefit | Explanation |

|---|---|

| Non-contact scanning | Avoids physical contact, improving accuracy. |

| High-speed data capture | Collects detailed 3d data rapidly. |

| Full-field scanning | Scans large areas efficiently. |

| Easy automation and minimal setup | Integrates into automated workflows with little setup. |

| High accuracy and detail | Delivers precise measurements for complex parts. |

These features make structured light scanners essential for creating digital twins and supporting 3d reconstruction in manufacturing.

Medical and Healthcare Uses

Doctors and researchers use structured light scanners for 3d imaging of faces and body parts. This method maps soft tissues, such as ears and lips, with high accuracy. Some scanners, like the EINSTAR, match the precision of traditional tools but avoid tissue distortion. Medical teams use 3d scans for planning surgeries, tracking healing, and storing patient data for future reference. Structured light scanners allow repeated measurements without needing the patient present. Although scanning may take longer, the benefits in accuracy and flexibility are significant.

- Structured light scanners support detailed surface mapping for maxillofacial surgery and orthodontics.

- 3d imaging helps with pre-surgical planning and post-operative evaluation.

- Portable scanners make 3d reconstruction accessible in clinics and research.

VR, AR, and Artifact Digitization

Structured light scanners play a key role in creating digital worlds. They project patterns to capture the shape and color of real objects. Artists and developers use these scans for VR and AR experiences, game design, and digital exhibitions. Scanners like the 3DMakerpro Moose offer real-time feedback and high precision, making 3d imaging of artifacts easy. Museums use structured light scanners for 3d reconstruction of cultural heritage items, preserving them as digital twins. This technology provides the detail and accuracy needed for interactive digital models.

- Structured light scanners create reliable 3d models for VR, AR, and cultural heritage.

- 3d scanning spray improves results on shiny or transparent surfaces.

- Artists refine scanned models for animation or 3d printing.

Benefits and Drawbacks

Precision and Speed

Structured light systems offer high precision and fast 3d imaging. These systems scan entire areas at once, which makes them much faster than laser scanning technologies that work line-by-line. The table below compares structured light systems with laser scanning:

| Aspect | Structured Light Systems | Laser Scanning Technologies |

|---|---|---|

| Speed | Faster; scans entire areas at once, suitable for efficiency | Slower; scans line-by-line, especially slower for complex objects |

| Precision (Accuracy) | High accuracy capturing fine details within working area under controlled lighting | Accurate for large-scale objects; depends on laser color and scan pattern |

| Object Complexity | Excels at capturing complex geometries and intricate details | Better suited for large, simpler objects or environments |

| Environmental Impact | Sensitive to ambient light; best in controlled environments | Performs well in various lighting conditions, including outdoors |

| Material Sensitivity | May require scanning sprays for reflective or transparent surfaces | Can scan any surface regardless of material |

Structured light systems excel at capturing complex shapes and fine details. They deliver reliable depth accuracy and high data quality, especially in controlled environments. Many industries choose these systems for tasks that require both speed and precision.

Non-Contact Measurement

Structured light systems use non-contact measurement. These measurement devices project patterns of light onto objects and analyze the reflected light. This method avoids touching the object, which protects sensitive or delicate items from damage or contamination. Non-contact measurement offers several advantages:

- Reduces the risk of harming fragile materials.

- Provides high precision for 3d imaging.

- Works well for objects that are hard to reach or cannot be moved.

This approach makes structured light systems ideal for measuring valuable artifacts, medical models, or soft tissues.

2025 Improvements and Challenges

In 2025, structured light systems continue to improve. New encoding methods and multi-sensor fusion help address issues with reflective or transparent surfaces. However, some challenges remain:

- Non-contact measurement struggles with transparent or shiny objects, which can lower data quality.

- Complex optical components make some systems hard to assemble and limit miniaturization.

- Physical limits in light field transmission restrict the range of emission angles and hardware design.

Engineers work on solutions like UV structured light and compressed sensing to improve 3d imaging of difficult materials. Despite these efforts, precision and reliability can still drop when scanning certain surfaces.

Alternatives to Structured Light

Structured Light vs. Laser Scanning

Structured light and laser scanning both help machines see in 3D, but they work best in different situations. Structured light scanners use patterns of light to capture shapes quickly and with high detail. Laser scanning systems use a focused laser beam to measure surfaces, often line by line. The table below shows how these two systems compare:

| Aspect | Laser Scanning Systems | Structured Light Scanners |

|---|---|---|

| Accuracy | High accuracy, suitable for complex, shiny, or dark surfaces | High resolution and accuracy |

| Surface Compatibility | Versatile: works well on complex, shiny, dark surfaces; struggles with transparent or highly reflective materials | Sensitive to light; challenges with outdoor scanning |

| Application Scope | Wide range: from small components to large industrial spaces; optimal for close-range scanning | Primarily close-range; capable of capturing large areas |

| Portability | Available in handheld, arm-based, CMM, and long-range systems | Portable and eye-safe |

| Scan Speed | Generally slower compared to structured light | Quick scan times |

| Safety | Not specified | Eye-safe, suitable for scanning humans and animals |

| Environmental Limitations | Limited by material transparency and reflectivity | Light sensitivity limits outdoor use |

Laser scanning works best for large or distant objects. Factories often use laser scanning for big machines or buildings. Structured light scanners shine in close-range tasks, like checking small parts or making digital models of faces. Laser scanning can cost more, especially for high-precision jobs. Smaller research groups may find structured light more affordable and easier to use.

Laser scanning is the top choice when measuring large spaces or objects far away. Structured light fits best for small, detailed, and fast tasks.

Structured Light vs. Light Field Systems

Light field technology offers another way to capture 3D information. These systems record not only the light intensity but also the direction of light rays. Light field technology can capture a scene from many angles at once. This allows users to refocus images after taking them or create 3D models from a single shot.

Structured light scanners provide high accuracy and fast results for objects at close range. Light field technology, on the other hand, works well for capturing complex scenes with many layers or transparent materials. Some researchers use light field technology to scan objects that structured light cannot handle, such as glass or water. Light field technology also helps in virtual reality and robotics, where understanding depth and texture is important.

Light field technology continues to improve, but structured light remains the top choice for fast, precise 3D scanning in industry.

- Structured light systems use projected patterns and cameras to measure height and volume with high precision.

- In 2025, industries like automotive, electronics, and healthcare use these systems for quality control, defect detection, and robot guidance.

- AI and machine learning help improve accuracy and reduce errors.

- Real-time data transfer supports flexible and scalable automation.

3D structured light continues to grow in machine vision. New hardware and smarter software will make these systems even more powerful. Companies looking for reliable and fast 3D inspection should consider structured light for their future needs.

FAQ

What is a structured light system in machine vision?

A structured light system projects patterns onto objects. Cameras capture the pattern changes. The system uses this data to create a 3D model. This method helps machines "see" shapes and surfaces with high accuracy.

Can structured light scanners work on shiny or transparent objects?

Structured light scanners may struggle with shiny or transparent surfaces. Engineers use scanning sprays or special algorithms to improve results. Some new systems use UV light or multi-sensor fusion for better performance.

How fast can a structured light system scan an object?

Modern structured light systems scan objects in seconds. High-speed cameras and advanced algorithms allow real-time 3D imaging. This speed makes them ideal for production lines and moving objects.

Are structured light systems safe for scanning people?

Yes, structured light systems use eye-safe light. Doctors and researchers use them for medical imaging, including faces and soft tissues. The process does not harm people or animals.

What industries use structured light systems the most?

Industries such as automotive, electronics, healthcare, and cultural heritage rely on structured light systems. They use these systems for quality control, reverse engineering, medical imaging, and artifact digitization.

See Also

Exploring The Future Of Inspection Vision Systems In 2025

The Role Of Structured Light In Improving Vision Systems

Comprehensive Overview Of Semiconductor Vision Systems Technology