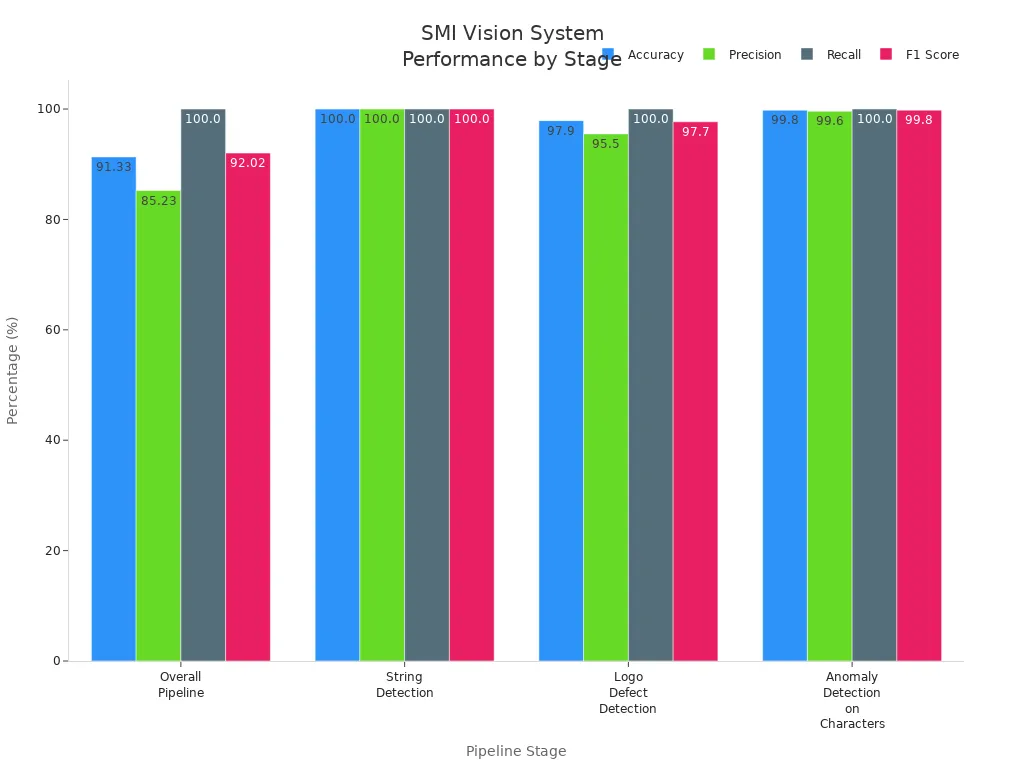

The smi machine vision system, developed by SensoMotoric Instruments, uses advanced computer vision and eye-tracking technology for industrial tasks. This system inspects, measures, and detects defects with high accuracy. Companies rely on the smi machine vision system to improve quality and reduce manual errors. According to recent studies, this system reaches an overall accuracy of 91.33% and perfect recall in defect detection.

The global machine vision system market shows strong growth, driven by automation and quality control needs. The smi machine vision system helps industries achieve reliable results and streamline production.

Key Takeaways

- SMI machine vision systems use advanced cameras and sensors to detect defects with high accuracy, helping companies improve product quality and reduce errors.

- The system combines eye tracking and 3D inspection technologies to provide precise and fast inspections, even in tough industrial environments.

- Flexible hardware and AI-powered software allow easy integration with existing factory equipment and quick adaptation to changing production needs.

- Using SMI systems can speed up inspections, lower manual labor costs, and increase reliability, making production lines more efficient and safer.

- These systems support modern industry trends like Industry 4.0 by enabling real-time data use, predictive maintenance, and smarter manufacturing processes.

SMI Machine Vision System

Overview

The smi machine vision system comes from SensoMotoric Instruments, a company known for its expertise in computer vision and eye tracking. This system uses advanced machine vision systems to automate inspection and defect detection in many industries. Each system uses a combination of camera, sensors, and software to capture and analyze images. The camera collects visual data, while sensors help with precise acquisition of information. The system then processes this data to find defects or measure objects.

Many industries use machine vision systems for inspection and measurement. These systems help companies reduce errors and improve product quality. The smi machine vision system stands out because it supports integration with other devices and platforms. For example, it works with VR environments and uses CMOS sensors for better image acquisition. Scanning Moiré Interferometry is another unique feature. This technology allows the system to detect tiny defects that are hard to see with the naked eye.

Note: Machine vision systems play a key role in modern factories. They help companies find defects early and keep production lines running smoothly.

Eye Tracking Technology

SensoMotoric Instruments specializes in eye tracking, which is a core part of the smi machine vision system. Eye tracking uses a camera and sensors to follow the movement of a person’s eyes. The system captures data through fast acquisition and then analyzes where the person is looking. This technology helps in quality control and inspection tasks. For example, operators can use eye tracking to guide robotic arms during inspection. The system records eye movements and uses this data to improve accuracy in defect detection.

Machine vision systems with eye tracking can also help in training and safety. By tracking where workers look, the system can spot unsafe behavior or missed inspection steps. The camera and sensors work together to provide real-time feedback. This makes the inspection process faster and more reliable. Eye tracking also supports integration with other machine vision systems, making it easier to add new features or connect with existing equipment.

3D Inspection

3D inspection is a major strength of the smi machine vision system. The system uses advanced 3d vision systems like the SMI-3DBL-500-01. This device is lightweight and fits easily on a robotic arm. It allows flexible positioning and a wide scanning range. The camera uses a line laser solution, which resists interference from ambient light. This means the system works well in different lighting conditions, even outdoors.

The smi machine vision system can handle close-distance, high-precision inspection tasks. It can identify and position objects that are dark, black, or highly reflective. The hardware is shock-resistant and shock-proof, so it stays stable in tough industrial settings. The system supports flexible installation, allowing multi-directional scanning and positioning. The sturdy metal case has IP65 protection, making it suitable for harsh environments. The camera connects easily through an Ethernet interface, which helps with intelligent operation and integration with robotic systems.

- Key features of the SMI-3DBL-500-01 3D inspection system:

- Lightweight design for robotic arm installation

- Line laser solution for reliable acquisition in various lighting

- High-precision inspection for close-distance tasks

- Ability to detect defects on challenging surfaces

- Shock-resistant and shock-proof hardware

- Flexible installation for multi-directional scanning

- Sturdy metal case with IP65 protection

- Easy Ethernet connection for integration with robots

Machine vision systems use these features to improve defect detection and inspection accuracy. The camera and sensors work together to provide fast acquisition and detailed analysis. This helps companies find defects quickly and keep production lines efficient. The smi machine vision system supports integration with other machine vision systems, making it a flexible choice for many industries.

Components

Hardware

The hardware of a machine vision system includes several important parts. The camera acts as the main image acquisition unit. It captures images of products on the production line. Most systems use an industrial camera with high resolution. These cameras work with sensors that help with fast and accurate acquisition. The sensors detect light and movement, making sure the system collects clear images every time. The image acquisition unit often uses CMOS sensors. These sensors give the system better low-light performance and high dynamic range. The hardware also includes lighting, lenses, and a frame grabber. Each part helps the system reach high accuracy in inspection and measurement. The hardware supports real-time processing and works well in tough industrial settings.

Software

Software controls the processing and analysis in machine vision systems. The software receives data from the camera and sensors. It uses image processing to find defects and measure objects. The image processing system checks each image for quality and accuracy. Processing software uses AI to improve inspection speed and accuracy. The software can adjust to different products and inspection needs. It also connects with other systems in the factory. This makes it easy to share data and results. The software helps operators track quality and make quick decisions. Good software keeps the system running smoothly and supports high-quality production.

Unique Features

SMI machine vision systems offer several unique features that improve industrial inspection.

- Integration of CMOS sensor technology gives the system superior low-light performance and ultra-fast frame rates.

- High-performance image sensors with global shutter architectures allow precise defect detection and consistent inspection.

- AI-powered image processing supports real-time inspection, measurement, and decision-making.

- Smart ROI features and low power consumption help optimize operational efficiency.

- Extended vision technologies, such as LiDAR and SWIR, expand the system’s ability to map and detect objects in 3D.

Note: These features make the machine vision system smarter, faster, and more reliable. They help companies reach higher accuracy and better quality in every inspection.

Machine Vision System Applications

Defect Detection

Many industries use a machine vision system for defect detection. The system uses a camera and advanced acquisition methods to find defects in products like BGA, CSP, and LGA devices. The machine vision system scans each item and uses defect detection algorithms to spot even the smallest flaws. This process improves accuracy and reduces the chance of missing defects. The system can inspect surfaces, measure dimensions, and check for missing parts. Companies rely on machine vision systems to meet strict inspection requirements and maintain high quality. The system works quickly, so production lines do not slow down. Operators see fewer errors, and the system helps reduce manual inspection costs by up to 40%.

The machine vision system uses real-time acquisition and analysis to catch defects early, keeping production quality high.

Quality Control

Quality control becomes more reliable with machine vision systems. These systems use 3D inspection to check every product for quality. The camera captures detailed images, and the system analyzes them for defects. The table below shows how SMI machine vision systems improve quality control outcomes:

| Metric | Improvement/Value |

|---|---|

| 3D vision system evaluation | 70.4% (better than 2D at 57.4%) |

| Assembly task consistency | 97% consistency rate |

| Cycle time reduction | 26 seconds less per cycle |

| Operators reduced | From 3 to 1 |

| Manual inspection cost reduction | 40% reduction |

| Accuracy improvement | Up to 100 times better |

Case studies show that companies like DS Smith and Kawasaki Robotics use these systems for automated inspection and assembly. The result is higher accuracy, better quality, and faster production.

Measurement

Measurement tasks in factories require high accuracy. SMI machine vision systems use active triangulation and structured light patterns for precise 3D surface reconstruction. The system uses a camera with high-resolution sensors for fast acquisition. The mandrel-target-based calibration method achieves 0.002 mm absolute accuracy, matching CMM probe results. The system also handles vibrations by using multiple laser stripes and advanced data processing. This ensures accurate inspection even when products move or bounce. The table below highlights key aspects of measurement accuracy:

| Aspect | Description |

|---|---|

| Measurement Principle | Active triangulation with structured light |

| Calibration Technique | Mandrel-target-based, 0.002 mm accuracy |

| Error Reduction | Handles bouncing and flapping during acquisition |

| Sensor Technology | High-resolution CMOS/CCD sensors for line detection |

| Data Processing | Converts raw data into calibrated 3D point clouds |

| System Benefits | Reliable, high-speed inline inspection |

| Vibration Handling | Multiple laser stripes remove vibration effects |

These features help companies meet strict inspection requirements and deliver products with top quality.

Fitting Machine Vision System

Integration

A fitting machine vision system must support seamless integration with both new and legacy industrial setups. Many factories use older equipment that relies on different communication protocols, such as RS-422/485, Modbus, or PROFIBUS. This diversity can make integration complex. Companies often need adapters, gateways, or standardization tools like OPC-UA or MQTT to achieve seamless integration. The fitting machine vision system addresses these challenges by offering modular hardware and software that connect easily to existing lines.

| Challenge Category | Description | Example |

|---|---|---|

| Financial Constraints | High costs for new equipment and training can slow adoption. | Small businesses may lack funds for upgrades. |

| Knowledge Gaps | Many teams do not understand how to start with Industry 4.0 solutions. | Staff may need extra training. |

| Technological Complexity | Integrating new vision systems with old machines can be difficult. | Different protocols and terms create confusion. |

| Protocol Heterogeneity | Legacy systems use many incompatible protocols. | Adapters and gateways are often required. |

| Cybersecurity Concerns | Connecting machines increases the risk of hacking and safety issues. | Early IT involvement helps design secure systems. |

| SME-specific Challenges | Small companies have fewer resources and less digital experience. | They may need outside help for integration. |

A fitting machine vision system uses flexible design to overcome these barriers. The system supports accurate fitting with various industrial robots and inspection stations. Seamless integration ensures that production lines can upgrade without major downtime. This approach helps companies improve quality and efficiency while keeping costs under control.

Tip: Early planning and IT involvement can make seamless integration smoother and safer for all types of factories.

Adaptability

Adaptability is a key strength of a fitting machine vision system. Modern production lines change quickly, so the system must adjust to new products and inspection needs. SMI machine vision systems use AI and deep learning to adapt without manual reprogramming. Unlike traditional systems, they handle changes in raw materials, tools, and environments with ease.

- AI vision systems adapt to dynamic industrial conditions.

- Different system types (PC-based, smart camera-based, compact) offer flexibility for many tasks.

- Benefits include higher throughput, less scrap, fewer errors, lower costs, and better safety.

The fitting machine vision system uses a human-guided learning approach. When the AI model faces new conditions, human experts help correct mistakes in real time. This process improves accurate fitting and keeps the system reliable as production changes. Flexible hardware and software allow quick reconfiguration for different products. Features like modular cameras, lighting, and grippers support seamless integration with new tasks.

Digital twins and CAD-based tools help operators adjust settings virtually. The system creates reconfiguration files that update both hardware and software. This method has worked well in real factories, such as automotive parts inspection, for several years. The fitting machine vision system maintains accurate fitting and seamless integration, even when production requirements shift rapidly.

Note: Adaptable machine vision systems help companies stay competitive by responding quickly to market changes.

Advantages of Machine Vision Systems

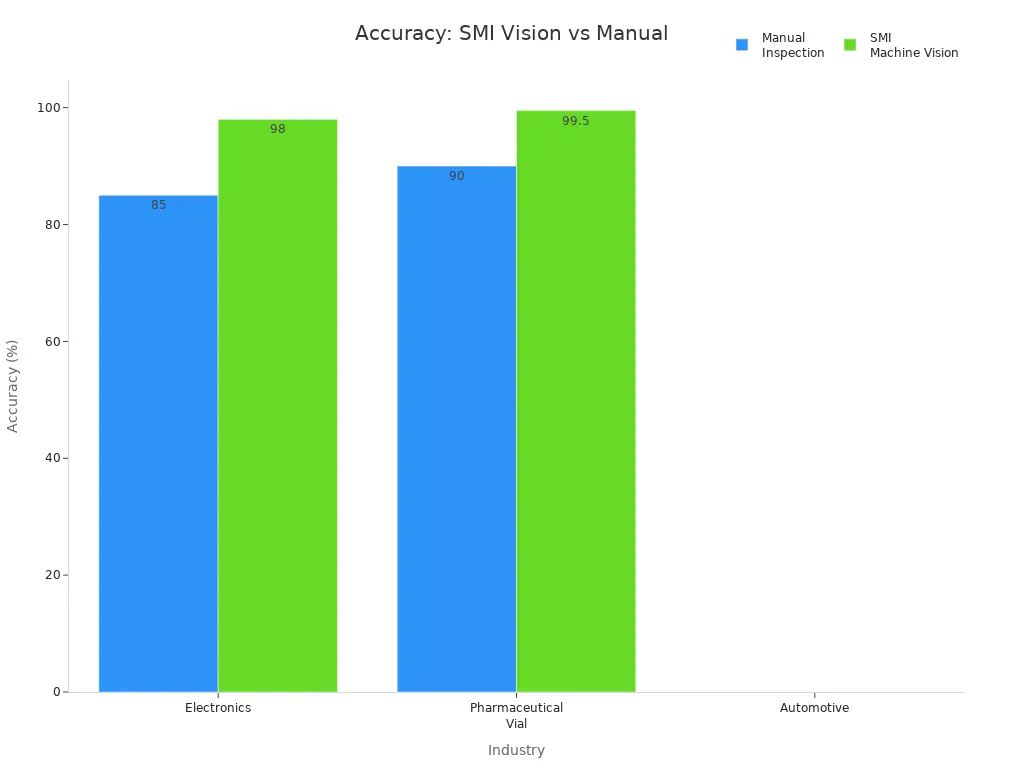

Accuracy

SMI machine vision systems deliver high accuracy in industrial inspection. These systems use advanced cameras and sensors to capture detailed images. The technology improves defect detection by finding small flaws that humans might miss. In electronics, SMI systems reach 98% accuracy, while manual inspection only achieves 85%. In pharmaceutical vial inspection, the system achieves 99.5% accuracy, which is much higher than manual checks. Automotive factories see a 30% increase in accuracy over manual methods. The table below shows these improvements:

| Industry | Manual Inspection Accuracy | SMI Machine Vision Accuracy | Improvement (%) |

|---|---|---|---|

| Electronics | 85% | 98% | +13 |

| Pharmaceutical Vial | 90% | 99.5% | +9.5 |

| Automotive | N/A | +30% increase over manual | +30 (relative) |

Over the past decade, SMI systems have improved accuracy through better noise reduction and signal restoration. New methods like Cycle-GAN and advanced fringe counting help lower errors. These improvements lead to better quality and fewer mistakes in defect detection.

Speed

Machine vision systems increase inspection speed in high-volume production. The system automates image capture and processing, which allows for fast and consistent quality checks. Here is how the process works:

- Cameras capture images quickly at fixed points.

- The system uses noise filtering and image restoration to prepare images for analysis.

- Feature extraction finds important details for defect detection.

- Decision modules classify products based on quality standards.

- Specialized hardware speeds up processing tasks.

- The system adapts to changing conditions, keeping quality high and reducing errors.

This fast processing means factories can check more products in less time. Real-time processing and real-time adaptive processing help maintain high throughput and quality.

Reliability

SMI machine vision systems offer strong reliability in harsh industrial settings. The hardware uses IP65 or IP67-rated enclosures to protect against dust and water. These systems work well in temperatures from –10 °C to 50 °C. Advanced sensor technology, such as CMOS with ROCC, ensures accurate 3D measurements. The table below highlights key features:

| Feature | Description |

|---|---|

| Enclosure rating | IP65/67 for dust and water protection |

| Temperature range | –10 °C to 50 °C |

| Sensor technology | CMOS with ROCC for high 3D accuracy |

| Data transmission | Gigabit Ethernet for fast, reliable data |

| Factory calibration | No need for on-site recalibration |

| High scan speed | Up to 45,000 profiles per second |

These features support error reduction and consistent quality. The system’s modular design and built-in algorithms handle different lighting and surface conditions. This reliability ensures that factories maintain high accuracy and quality in every inspection.

SMI machine vision systems deliver strong benefits for modern industries. Key strengths include:

- Advanced eye tracking for precise inspection

- 3D defect detection for higher product quality

- Fast and reliable automation in production lines

SMI technology will continue to grow with Industry 4.0. Integration with IoT, cloud computing, and AI will help factories use real-time data and predictive maintenance. These advances will make manufacturing smarter, more flexible, and more efficient.

FAQ

What is an image acquisition unit?

An image acquisition unit uses a camera and sensors to capture pictures of products. This unit collects data for the image processing system. It helps operators see small details during inspection and supports real-time processing in factories.

How do sensors improve inspection accuracy?

Sensors detect light, movement, and position. They help the system find defects quickly. Sensors also support error reduction by sending clear signals to the processing software. This leads to better accuracy and reliable quality control.

Why is seamless integration important in factories?

Seamless integration lets new systems connect with old machines. This process saves time and money. Operators can use the fitting machine vision system with different robots and tools. It helps factories meet inspection requirements and keep production running smoothly.

What role does software play in defect detection?

Software runs defect detection algorithms. It checks images for defects and measures objects. The software uses real-time adaptive processing to find problems fast. Operators trust the software to keep quality high and reduce mistakes.

How does accurate fitting help with quality control?

Accurate fitting means the system matches tools and parts correctly. This process uses 3d vision systems and industrial cameras. Accurate fitting helps operators meet strict quality control standards. It also supports error reduction and improves production results.

See Also

Comprehensive Overview Of Semiconductor Vision Systems

Demystifying Image Processing In Machine Vision Technology

Complete Insights Into Machine Vision For Industrial Automation

Exploring Inspection Vision Systems Trends For 2025

Comparing Firmware-Based And Conventional Machine Vision Systems