Introduction: The Final Lock on Battery Safety

In the assembly of Lithium-ion batteries, the “Sealing Rivet” (or sealing pin) is effectively the final lock on the energy capsule. Once the electrolyte is filled, this rivet is welded shut to hermetically seal the cell.

If this weld fails—even microscopically—the battery becomes a ticking time bomb. Electrolyte leakage, loss of pressure, and eventual failure are inevitable. For manufacturers, ensuring zero-defect weld quality at the sealing pin is paramount; it is the most critical quality gate in the assembly process, determining the long-term reliability of the entire battery pack.

The Problem: The “0.3mm” Blind Spot

Our client faced a dangerous quality gap with their existing inspection line.

- Inadequate Vision: Their existing CCD (Charge-Coupled Device) system had a hard limit: it could not reliably detect welding holes smaller than 0.3 mm. Consequently, leaking cells were slipping through to the product line.

- Unreliable Backup: They relied on a secondary Helium leak test to catch what the camera missed, but this method was also prone to errors, generating both False Acceptances (leaks passed) and False Rejections (good batteries scrapped).

The goal was clear: an inspection system capable of resolving the anomalies that eluded traditional vision, all while operating at full-rated line velocity..

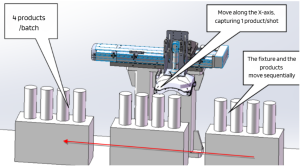

The Solution: A Flexible, 4-Cell Inspection Station

UnitX engineered a continuous 4-cell inspection station designed to handle high throughput while maintaining microscopic precision.

UnitX Visual Inspection SystemKey System Features:

- Multi-Height Capability: The station handles two different cell heights in a single pass, offering flexibility for mixed production lines.

- Rapid Changeover: In modern manufacturing, downtime is the enemy. This system enables format changeovers in under one hour without requiring any algorithm adjustments. The AI model is robust enough to handle the geometry changes instantly.

- Simplified Hardware: Utilizing just one UnitX OptiX imaging system and one CorteX AI unit, the solution remains lean yet powerful.

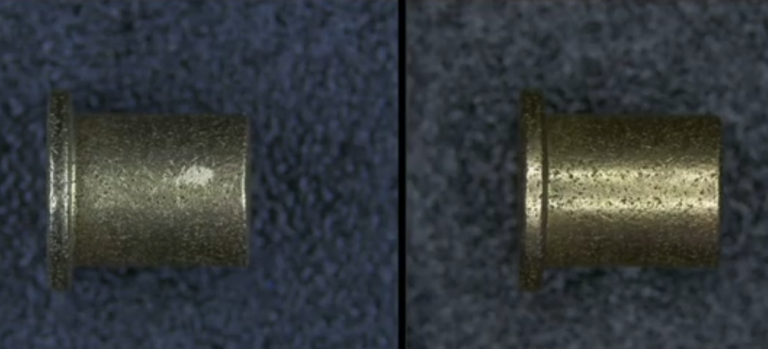

The Breakthrough: From 0.3mm to 0.05mm

The most significant achievement of this deployment was the dramatic increase in detection sensitivity.

By using UnitX’s optimized lighting patterns and AI algorithms, the system pushed the detection limit from the previous 0.3 mm down to 0.05 mm.

- The Impact: Pinholes that were previously “invisible” to the traditional CCD system are now glaringly obvious to the UnitX AI. This effectively closed the loophole that allowed compromised cells to proceed downstream.

Results: Speed and Safety Combined

The system is currently operating on the production line with metrics that far exceed the previous setup:

- 100% Detection Accuracy: Eliminated the risk of shipping compromised battery seals by achieving a zero percent False Acceptance Rate.

- Optimized Throughput (≤1.5s per cell): Sustained high-speed production with a total cycle time of ≤6 seconds for 4-cell consecutive inspections, matching the cadence of upstream welding machinery.

- Yield Optimization: Reduced False Rejection Rates to under 1%, significantly outperforming legacy Helium testing by minimizing “false fail” scenarios.

Conclusion

When it comes to battery sealing, “good enough” is not acceptable. A 0.3mm hole is enough to ruin a battery pack. By upgrading to UnitX’s AI vision system, manufacturers can improve their detection resolution by 500% (down to 0.05mm), ensuring that the final seal is as secure as promised.

Is your current inspection missing the micro-defects?

Contact UnitX to upgrade your weld inspection standards.