Robotics actuators machine vision system gives robots the power to see and move with purpose. Vision and movement work together, allowing robots to sense objects and react quickly. Computer vision helps robots understand their surroundings, while actuators let them act on this information. Vision-based control guides each motion and checks accuracy. Recent studies show that combining robotic actuators with machine vision systems improves efficiency and quality in automation. Vision-based control and computer vision make robots flexible and precise, helping them solve new tasks every day.

Key Takeaways

- Robotic actuators act like muscles, moving robot parts precisely to perform tasks such as picking, placing, and assembling.

- Machine vision systems give robots the ability to see and understand their environment using cameras and sensors, enabling real-time feedback.

- Combining robotics actuators with machine vision allows robots to adjust movements quickly and handle complex tasks with high accuracy.

- Vision-based control helps robots adapt to changes, improve precision, and perform tasks like inspection, navigation, and assembly efficiently.

- Robotics actuators and machine vision systems are widely used in industries like manufacturing, agriculture, and logistics to boost productivity, safety, and quality.

Robotics Actuators and Machine Vision System

What Are Robotic Actuators?

Robotic actuators serve as the muscles of robotics. They move and control robotic arms, grippers, and other parts. These actuators change energy into motion, allowing robots to pick, place, or assemble objects. Different types of actuators exist, each with unique features. The table below shows the main types used in robotics actuators machine vision system:

| Actuator Type | Working Principle | Key Characteristics | Suitability in Machine Vision Applications |

|---|---|---|---|

| Electric Actuators | Use motors to convert electrical energy | High speed, precise, easy to control, can get hot | Best for fast, accurate movements and positioning |

| Hydraulic Actuators | Use pressurized fluid | Strong force, scalable, manages heat well | Good for heavy-duty tasks needing strong force |

| Pneumatic Actuators | Use compressed air | Simple, light, cost-effective, less precise | Useful for simple, repetitive tasks |

| Smart Material Actuators | Respond to stimuli (electric, magnetic, thermal) | Precise, small, responsive, includes shape-memory alloys | Great for micro-manipulation and precision positioning |

| Soft Robotic Actuators | Use flexible, soft materials | Adaptable, gentle, inspired by biology | Ideal for delicate object handling and changing environments |

Robotic actuators play a key role in moving robotic arms with accuracy and speed. They help robots perform tasks in factories, labs, and even hospitals.

What Is a Machine Vision System?

A machine vision system gives robots the ability to see and understand their environment. It uses cameras and vision sensors to capture images. The system then processes these images using computer vision. The main components of a machine vision system include:

- Lighting: Improves image quality and helps robots detect details.

- Lenses: Focus light to create clear images.

- Image sensors: Convert light into digital signals for analysis.

- Cameras: Capture images for inspection or guidance.

- Vision processing: Turns images into data robots can use.

- Communications: Connects all parts for smooth operation.

Machine vision systems help robots find objects, check quality, and guide movements. Vision sensors and computer vision work together to give robots real-time feedback.

How They Work Together

Robotics actuators machine vision system forms the core of advanced robotics. Vision sensors and computer vision detect objects and send information to the robot. Robotic actuators then move robotic arms based on this data. This teamwork allows robots to adjust their actions quickly. For example, if a vision system spots a part out of place, the actuators can move the robotic arm to fix it. This integration makes robots smarter and more flexible. Robotics actuators machine vision system enables robots to handle complex tasks, adapt to changes, and improve accuracy in many industries.

Computer Vision and Robotic Actuators

Image Processing and Object Detection

Computer vision gives robots the ability to see and understand their surroundings. Cameras and sensors capture images, which computer vision techniques process to extract useful information. These techniques help robotic actuators perform tasks with accuracy and speed.

Some of the most common image processing methods in robotics include:

- Image enhancement improves image quality, making it easier for robots to interpret what they see. For example, increasing contrast helps robotic arms spot small parts on a conveyor belt.

- Image restoration removes noise or corrects blurry images. This step ensures that computer vision systems work well even in poor lighting or dusty environments.

- Image segmentation separates objects or regions of interest from the background. Robots use this to find and pick up specific items.

- Object recognition uses advanced machine learning algorithms to classify and identify objects. Robots can tell the difference between a screw and a bolt, or between ripe and unripe fruit.

- Scene understanding helps robots interpret the layout of their environment. This skill is important for navigation and motion planning.

Computer vision also supports object detection, which allows robots to locate items in real time. Vision-based control uses this information to guide robotic arms and actuators. When a robot sees an object, it sends the data to its controller. The controller then tells the actuators how to move. This process lets robots adjust their actions quickly and accurately.

Tip: Advanced machine learning algorithms, such as deep learning-based visual servoing, help robots improve their vision and movement over time. These systems learn from experience, making them smarter and more flexible.

Motion Control and Feedback

Robotic actuators rely on computer vision to guide their movements. The feedback loop between vision and motion is essential for precise automation. When a robot moves its arm, computer vision checks if the movement matches the goal. If not, the system sends new instructions to the actuators. This process repeats until the robot completes the task correctly.

In industrial robotics, sensors such as cameras and encoders provide real-time visual feedback. Controllers process this feedback and adjust the actuators, such as motors or pneumatic cylinders, to keep robotic arms on track. This closed-loop system ensures high accuracy and flexibility.

Many factories use 3D machine vision techniques, including stereo vision, structured light, and laser triangulation. These systems give robots depth perception, helping them avoid obstacles and position objects with care. No single vision system fits every job, so engineers often combine several types for the best results.

The table below shows some common control techniques used with computer vision and robotic actuators:

| Control Technique | Characteristics | Applications |

|---|---|---|

| PID Control | Simple, robust to disturbances | Industrial robotics, process control |

| State-Space Control | Handles complex systems, optimal control | Aerospace, robotics |

| MRAC | Adaptive, robust to uncertainties | Robotics, autonomous systems |

Vision-based control plays a key role in modern robotics. It allows robots to adapt to changes, work with humans, and perform complex tasks. Learning from visual data helps robots improve their skills and handle new challenges. As computer vision advances, robotic actuators and robotic arms become even more precise and reliable.

Note: Real-time visual feedback is vital for safety and efficiency in robotics. It helps robots react to unexpected changes and avoid mistakes.

Vision-Based Control in Robotics

Vision-based control gives robots the ability to adapt to new situations and changing environments. This approach uses computer vision to guide robotics actuators, allowing robots to see, understand, and react to what happens around them. Vision-based control forms the core of modern robotics, supporting tasks like bin picking, assembly, inspection, and navigation. By combining computer vision, robotics actuators, and advanced learning algorithms, robots achieve greater autonomy and handle complex jobs that once seemed impossible.

Positioning and Alignment

Precise positioning and alignment are essential for robots to perform tasks accurately. Computer vision captures images and video frames, then uses deep learning algorithms to detect an object’s position and orientation. Robots use both 2D and 3D alignment. In 2D alignment, robots position objects on flat surfaces, such as placing labels or aligning parts for inspection. In 3D alignment, robots account for depth and orientation in space, which is vital for navigation and object handling.

| Aspect | 2D Alignment | 3D Alignment |

|---|---|---|

| Focus | Positioning on flat surfaces, orientation in 2D plane | Positioning and orientation in three-dimensional space |

| Use Cases | Simple inspections like label placement | Complex robotic navigation and object handling |

| Precision | Good for planar tasks | Gold standard for spatial accuracy |

Advanced image processing tools measure angles and distances with high precision. Laser-based systems calculate exact distances, while angle measurement tools check if components are oriented correctly. These technologies allow robots to adjust their actions instantly, reducing errors and improving productivity. AI-powered pose estimation helps robots align objects even in cluttered or messy environments. Real-time feedback from computer vision lets robots correct misalignments as soon as they happen.

Note: Machine vision systems use smart cameras, fast data processing, and proper lighting to detect even small misalignments. This reduces human error and boosts productivity in manufacturing and robotics.

Real-Time Adjustment

Vision-based control enables robots to make real-time adjustments during tasks. Computer vision provides continuous feedback, so robots can spot changes or mistakes right away. This feedback loop helps robots stay accurate, even when conditions change quickly. For example, if lighting shifts or shadows appear, the vision system adapts by adjusting image processing settings.

Robots face several challenges when making real-time adjustments. Environmental changes, such as fluctuating lighting, can affect image quality. Robots need efficient algorithms to process visual data quickly without losing accuracy. Proper calibration of cameras and sensors is critical for accurate perception. Managing large datasets for machine learning also presents difficulties, as robots need high-quality data to interpret what they see. Integrating hardware and software into a single vision-based control system can be complex. Sometimes, robots need extra feedback, like force sensors, to handle tasks that vision alone cannot solve.

Despite these challenges, vision-based control allows robots to adapt quickly. In automated assembly, robots use computer vision to detect, pick, and place parts with high accuracy. In inspection, robots find defects or misalignments and correct them on the spot. Technologies like Zivid 3D cameras help robots handle shiny or reflective parts, reduce errors from occlusions, and capture complete scenes for reliable picking.

Dynamic Response

Dynamic response means robots can react to unpredictable events in real time. Vision-based control systems use computer vision to monitor the environment and adjust robot actions as needed. Real-time visual feedback lets robots adapt to changes like occlusions, lighting shifts, or unexpected obstacles. Image-Based Visual Servoing (IBVS) compares live images to reference data, forming a closed-loop system that keeps robots on track even if the camera model changes.

Hybrid approaches combine reinforcement learning and model-free control with IBVS. These methods let robots learn from experience, improving their ability to handle surprises. Deep learning techniques help robots extract features and deal with uncertainties that traditional methods might miss. Vision-based control architectures can move the robot or camera to keep objects in view, solving problems with visibility and disturbances.

Different camera setups, such as eye-in-hand or eye-to-hand, give robots various perspectives for better control. Reinforcement learning controllers help robots anticipate and correct for disturbances, improving tracking and stability in dynamic settings. In bin picking, robots use high-resolution 3D cameras to detect and pick objects from cluttered bins, even when items are stacked or hidden. Artifact Reduction Technology helps robots handle shiny or polished parts, while compact depth sensors reduce missed picks by capturing more of the scene.

Vision-based control, powered by computer vision and robotics actuators, enables robots to perform complex tasks like defect detection, grasping, and manipulation. This integration leads to greater autonomy, improved safety, and higher productivity in industries such as manufacturing, logistics, and healthcare.

Benefits and Challenges

Improved Accuracy and Flexibility

Vision-based control gives robotics systems the ability to adapt and improve performance. Robots use vision to see objects, measure positions, and check for errors. This approach increases accuracy in tasks like assembly, inspection, and picking. Vision-based control helps robots adjust to new products or changes in the environment without needing major reprogramming. Factories benefit from this flexibility because robots can switch between tasks quickly. Vision-based control also reduces human error and improves product quality. When robots use vision-based control, they can handle complex jobs that require careful alignment or real-time adjustments.

Integration Challenges

Combining robotics actuators machine vision system with vision-based control presents several challenges. Teams must ensure all parts work together smoothly. Some common issues include:

- Synchronizing cameras, sensors, and actuators, which can be difficult due to different response times and communication delays.

- Making sure new systems fit with existing equipment and control software.

- Planning the project carefully to avoid delays and extra costs.

- Keeping production lines running smoothly by balancing workloads and avoiding bottlenecks.

- Setting up strong communication protocols so all parts of the system share information quickly and accurately.

Note: Achieving proper synchronization and compatibility is critical. If teams do not address these issues, system performance may drop, and errors can occur.

Solutions and Best Practices

Teams can overcome integration challenges by following best practices. They should:

- Use tools like encoders, camera triggers, and real-time operating systems to keep all parts in sync.

- Select cameras, lenses, and accessories that match the needs of each application.

- Develop a clear project plan that defines the scope and identifies possible risks.

- Choose robust communication protocols to ensure fast and reliable data sharing.

- Apply advanced technologies, such as AI and computer vision, to improve adaptability and performance.

Vision-based control works best when all components communicate well and respond quickly. Careful planning and the right technology help robotics systems achieve high accuracy and flexibility. Teams that follow these steps can build reliable systems that handle complex tasks and adapt to changing needs.

Applications of Robotics Actuators Machine Vision System

Industrial Automation

Industrial automation uses robotics actuators machine vision system in many real-world applications. These systems help factories and warehouses work faster and safer. Some common applications include:

- Robot arms use motors or compressed air to move with precision. They handle welding, assembly, and material transport.

- Machine vision systems inspect parts and check for defects. AI helps these systems find problems quickly, making quality control easier.

- Collaborative robots, or cobots, work next to people. Safety sensors protect workers and let robots handle tasks that need human oversight.

- Autonomous Mobile Robots (AMRs) use AI-based vision to move heavy loads across factory floors. They reduce the need for manual labor.

- Robots with machine vision automate inspection, increasing accuracy and letting people focus on more complex jobs.

These real-world applications improve productivity by making work faster and more accurate. They also boost safety and allow factories to run longer with less waste.

Note: The accuracy of machine vision systems depends on calibration, resolution, and the needs of each industry. For example, the automotive and electronics sectors use 3D vision for high-precision tasks, while healthcare often uses 2D vision for simpler inspections.

Autonomous Navigation

Autonomous navigation is one of the most exciting real-world applications of robotics actuators machine vision system. Robots use sensors and cameras to see their surroundings and move safely. In warehouses, AMRs deliver goods by following paths and avoiding obstacles. In self-driving vehicles, machine vision systems read road signs, detect other cars, and help the vehicle stay in its lane. These applications show how robotics and automation work together to increase autonomy and safety.

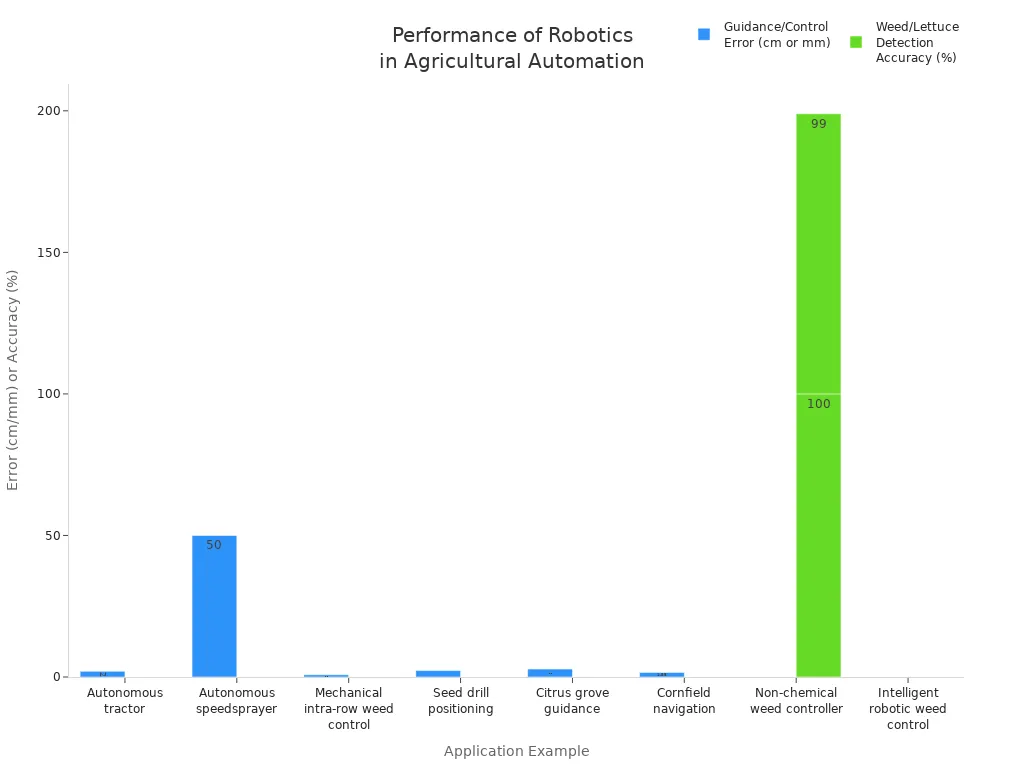

Agriculture and Inspection

Agriculture has seen many real-world applications of robotics actuators machine vision system. The table below shows some important applications:

| Application Example | Role of Robotics Actuators | Role of Machine Vision Systems | Outcome/Performance |

|---|---|---|---|

| Autonomous tractor | Precise steering and control | Row detection and localization | Route following within centimeters |

| Autonomous speedsprayer | Controls spraying | Obstacle detection | Avoids obstacles, accurate spraying |

| Mechanical weed control | Controls weed knives | Guides positioning | Centers weed control with 0.8 cm error |

| Non-chemical weed controller | Executes weed removal | Detects and locates weeds | Removes 100% of small weeds |

| Seed drill positioning | Positions seed drills | Guides alignment | 23 mm error in seed placement |

| Citrus grove guidance | Controls navigation | Precise localization | 2.8 cm average guidance error |

| Cornfield navigation | Controls movement | Navigation between rows | 15.8 mm max guidance error |

These applications help farmers save time and reduce labor. Machine vision and robotics actuators machine vision system make farming more precise and efficient. They also improve inspection by finding problems early and reducing waste.

Robotics actuators machine vision system work together to create smarter, more flexible robots. Vision-based control and computer vision help robots see, learn, and act with precision. Experts expect big changes in robotics soon, including:

- AI-powered vision for real-time quality checks and scene understanding

- Bionic grippers and tactile sensors for safer, more precise handling

- Robots that learn from data and adapt to new tasks

- Growth in Robotics-as-a-Service, making advanced robotics easier to access

These trends will shape the future of automation across many industries.

FAQ

What is the main benefit of using a robotics actuators machine vision system?

A robotics actuators machine vision system helps robots see and move with accuracy. This system allows robots to find objects, check quality, and complete tasks faster. Factories use these systems to improve safety and reduce mistakes.

How do robotics actuators and machine vision systems work together?

Robotics actuators move robot parts, while machine vision systems help robots see. The vision system sends information to the robot. The actuators then move based on what the robot sees. This teamwork lets robots adjust quickly to changes.

Can robotics actuators machine vision system improve product quality?

Yes. Robotics actuators machine vision system checks products for defects and measures parts with high precision. Robots can spot small errors and fix them right away. This process helps companies make better products and reduce waste.

Where can robotics actuators machine vision system be used?

Robotics actuators machine vision system works in many places. Factories use them for assembly and inspection. Farms use them for planting and harvesting. Warehouses use them for sorting and moving goods. These systems help many industries work better.

See Also

A Comprehensive Look At Robotic Vision Guidance In 2025

How Machine Vision Guidance Shapes Modern Robotics Today

Breaking Down The Fundamentals Of Electronics Vision Systems

Transforming Aerospace Production With Advanced Machine Vision Technology

Comparing Firmware-Based Vision To Conventional Machine Systems