A quality inspection machine vision system uses cameras and software to check product quality during manufacturing. This automated technology replaces manual inspection, helping companies improve accuracy and speed. Manufacturers rely on these systems for automated quality control because they deliver consistent results and reduce human error. Industry surveys show that automated vision inspection can detect microscopic defects, improve workplace safety, and save costs by reducing faulty products. Companies achieve higher accuracy in inspection, better product quality, and meet strict quality standards through automated inspection.

Key Takeaways

- Quality inspection machine vision systems use cameras and software to check products automatically, improving speed and accuracy over manual inspection.

- These systems come in 1D, 2D, and 3D types, each suited for different inspection tasks like surface checks or complex shape measurements.

- Machine vision inspection works by capturing images, processing them with advanced software, and making fast decisions to accept or reject products.

- Using these systems boosts product quality, reduces defects, saves costs, and helps manufacturers meet strict industry standards.

- Choosing the right system involves considering product type, production speed, lighting, and integration to get the best results and future growth.

What Is a Quality Inspection Machine Vision System?

Purpose and Value

A quality inspection machine vision system is an automated solution that uses cameras, lighting, and advanced software to check products during manufacturing. These systems capture images of products or components and analyze them for defects, size, shape, and other important features. They play a key role in quality control by making sure every item meets strict standards before leaving the factory.

Vision inspection systems help manufacturers achieve high product quality. They work much faster than manual inspection and do not get tired or distracted. By using sensors and smart algorithms, these systems can spot even the smallest defects. They measure dimensions, check for missing parts, and verify labels or codes. This reduces waste and prevents faulty products from reaching customers.

Note: Vision inspection systems support real-time monitoring and provide instant feedback to production teams. This helps keep the production line running smoothly and ensures consistent quality.

Manufacturers use machine vision inspection to reduce human error and improve consistency. These systems can operate 24/7, providing the same level of accuracy at all times. They also help companies save money by lowering labor costs and reducing the need for rework. Machine vision inspection supports compliance with industry regulations and helps avoid costly recalls.

The value of a quality inspection machine vision system goes beyond just finding defects. It also provides data for process optimization and supports Industry 4.0 goals. Companies can use this data to improve workflows, increase efficiency, and introduce new products faster. The payback period for these systems is often between 6 and 18 months, making them a smart investment for many manufacturers.

Types of Vision Inspection Systems

Vision inspection systems come in several types, each designed for specific tasks in manufacturing and industrial automation. The main types include 1D, 2D, and 3D systems. Each type uses different technology to capture and analyze images.

| Vision System Type | Image Capture Method | Key Features | Typical Applications | Depth Information | Accuracy & Precision | Cost & Complexity |

|---|---|---|---|---|---|---|

| 1D Vision System | Line-by-line laser scanning | Scans moving items on conveyor belts; less detail | Dimensional measurement, barcode reading, label checks | No depth | Lower precision | Lower cost, simple setup |

| 2D Vision System | Single camera captures flat images | Detects surface defects, patterns, and labels | Surface inspection, defect detection, pattern matching | No depth | Moderate accuracy | Moderate cost, moderate |

| 3D Vision System | Multiple cameras or lasers for 3D | Measures depth, volume, and angles | Complex shape inspection, robotic guidance, 3D scanning | Yes | High precision | Higher cost, complex |

- 1D Vision Systems: These use line-scan cameras to capture images one line at a time. They work best for inspecting items moving quickly on conveyor belts, such as checking the length of cables or reading barcodes. They offer high speed but do not provide depth information.

- 2D Vision Systems: These systems use area-scan cameras to take flat images of products. They are ideal for surface inspection, defect detection, and pattern recognition on flat surfaces. Manufacturers use them to find scratches, discolorations, or missing labels.

- 3D Vision Systems: These advanced systems use multiple cameras or lasers to create three-dimensional models. They measure depth, volume, and angles, making them perfect for complex shape inspection and robotic guidance. 3D systems are more expensive and complex but provide the highest accuracy for tasks like checking the shape of automotive parts or guiding robots.

Manufacturers choose the type of vision inspection system based on their specific needs. For example, 2D systems are common for surface inspection, while 3D systems are used for precise dimensional measurement and complex shapes. Each system helps improve quality control by automating inspections that are too fast or detailed for manual checks.

Vision inspection systems are essential in industries such as electronics, automotive, food and beverage, and pharmaceuticals. They help companies maintain high product quality, reduce defects, and meet strict regulatory standards. By using the right type of machine vision inspection, manufacturers can ensure every product meets their quality goals.

How Machine Vision Inspection Works

Machine vision inspection follows a clear sequence of steps to ensure product quality on manufacturing lines. Each step uses advanced technology to capture, process, and analyze images in real-time. This process helps manufacturers detect defects, maintain high accuracy, and deliver consistent inspection results.

Image Capture

The first step in machine vision inspection is image capture. The system uses high-speed cameras and special lenses to take pictures of products as they move along the production line. Sensors detect when an object arrives, and the cameras snap images at the perfect moment. Lighting plays a critical role in this step. Proper lighting, such as LED, ring, or dome lights, improves image clarity by reducing shadows, glare, and reflections. Consistent illumination ensures that every image looks the same, which is important for reliable inspection. Manufacturers often use different lighting techniques, like backlighting or multispectral lighting, to highlight specific features or defects.

Tip: Stable and controlled lighting setups help the system avoid errors caused by changes in the environment, such as dust or vibrations.

The captured images are then sent to the vision controller for further analysis. High-quality image capture forms the foundation for accurate inspection and real-time data analysis.

Image Processing

After capturing the image, the system begins image processing. This step uses software algorithms to improve image quality and extract important details. The software may adjust brightness, remove noise, and correct distortions. Advanced preprocessing techniques, such as denoising and illumination enhancement, help the system see even the smallest defects.

Modern machine vision inspection systems often use deep learning models, like convolutional neural networks, to analyze images. These models can detect, classify, and locate defects with high accuracy. The software looks for features such as color, shape, and texture. It compares these features to known standards and highlights any differences. Real-time data analysis allows the system to process images quickly and provide instant feedback to the production team.

Note: AI-powered algorithms improve defect detection and help manufacturers maintain consistent quality, even in challenging conditions.

Decision Making

The final step is decision making. The system compares the extracted features from the image to predefined quality standards. If the product meets all requirements, the system marks it as a pass. If it finds defects or measurements outside the allowed range, it marks the product as a fail. Some systems can even trigger alarms or remove defective items from the production line automatically.

Machine vision inspection systems make these decisions without human input. They use AI classifiers and real-time data analysis to ensure objective and repeatable results. This automation reduces human error and increases inspection speed. Many systems achieve up to 99% accuracy in defect detection, which helps manufacturers deliver high-quality products and avoid costly recalls.

Manufacturers also use inspection data to monitor trends and improve their processes. Real-time feedback helps teams fix problems quickly and keep quality levels high.

Summary Table: Steps in Machine Vision Inspection

| Step | Description | Importance for Quality |

|---|---|---|

| Image Capture | Cameras and lighting capture clear images of products | Foundation for accuracy |

| Image Processing | Software enhances images and detects features and defects | Enables precise inspection |

| Decision Making | System compares features to standards and classifies products (pass/fail) | Ensures consistent quality |

| Real-Time Analysis | Data is analyzed instantly for immediate feedback and process improvement | Supports process control |

Machine vision inspection transforms quality control by providing fast, accurate, and real-time inspection. This technology helps manufacturers detect defects early, maintain high standards, and use real-time data analysis to optimize production.

System Components

Hardware Overview

A machine vision inspection system uses several important hardware parts. Each part helps the system capture and analyze images for quality control.

- Image Sensors (CCD and CMOS): These sensors turn light into electrical signals. They help the cameras capture clear images for inspection.

- Cameras: Area scan cameras take pictures of whole objects at once. Line scan cameras capture images one line at a time, which works well for fast-moving items.

- Lenses: Lenses focus light onto the sensors. Different types, like telecentric or zoom lenses, help control image quality and measurement accuracy.

- Lighting: LED lights provide steady and bright illumination. Good lighting makes defects easier to see during inspection.

- Processing Units: CPUs and GPUs process the images quickly.

- Hardware Interfaces: These connect cameras, sensors, and computers so the system works together smoothly.

- Calibration Tools: These tools keep measurements accurate and reliable.

Camera and lens choices affect how well the system finds defects. High-quality lenses reduce image distortion. The right camera resolution helps spot small flaws without slowing down inspection.

Software and Algorithms

Software controls how the system analyzes images. Traditional rule-based software checks for simple patterns or measurements. Today, many systems use advanced AI and deep learning. These models learn from data and improve over time. They can spot tiny or hidden defects that older methods might miss. Deep learning also helps the system adapt to changes in lighting or product shape.

AI-powered image processing algorithms boost inspection accuracy and reduce mistakes. Real-time software lets the system make fast decisions, keeping up with high-speed production lines.

Integration in Production Lines

Manufacturers need inspection systems that fit into their existing lines without causing delays. Most systems use standard communication protocols, so they connect easily to robots, PLCs, or other machines. Compact hardware and auto-calibration tools allow quick setup.

- Systems can log image data for traceability.

- They detect defects and send alerts or remove faulty products automatically.

- Edge computing processes data locally, reducing delays.

These features help keep production running smoothly while improving inspection speed and accuracy.

Benefits of Quality Assurance Machine Vision System

Accuracy and Consistency

A quality assurance machine vision system delivers high accuracy and consistent results in manufacturing. These systems process images in milliseconds, allowing rapid inspection of every product. They detect tiny defects, such as scratches or color changes, that human inspectors often miss. By using automated inspection, manufacturers remove the risk of human error and fatigue. The system applies the same quality standards to every item, ensuring uniform product quality across all batches.

Real-time feedback from the system allows immediate adjustments, reducing downtime and defective output.

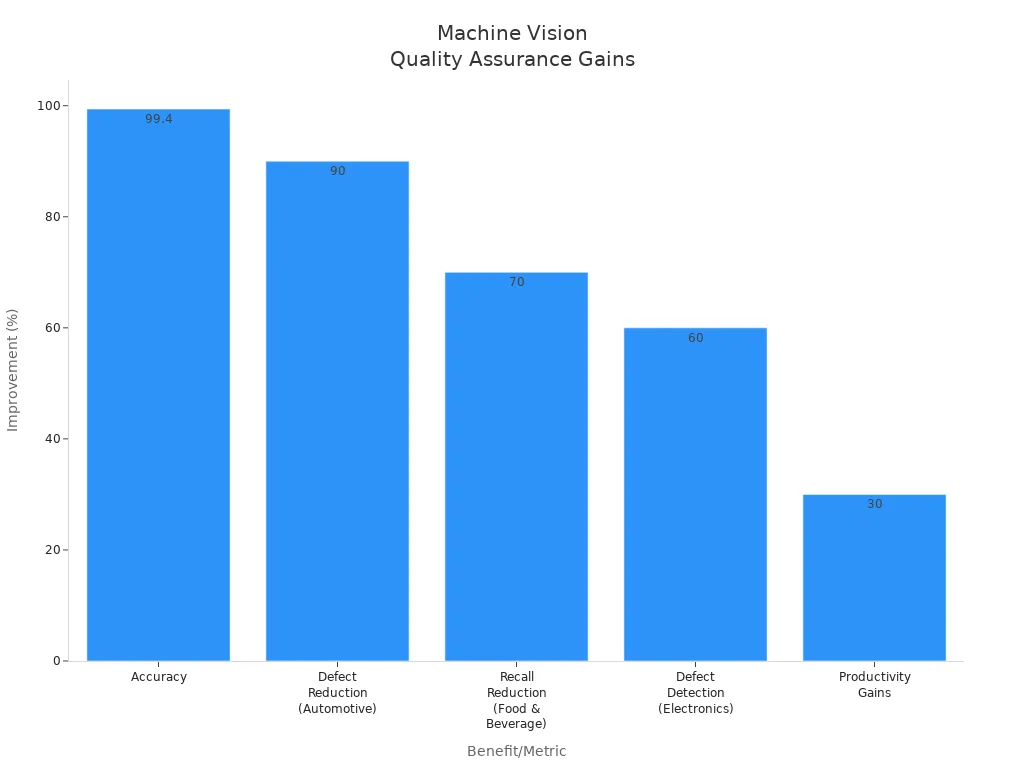

| Benefit/Metric | Description | Improvement/Result |

|---|---|---|

| Accuracy | Machine vision systems achieve up to 99.4% accuracy in defect detection. | High precision in identifying defects. |

| Consistency | Automated inspections eliminate human error and fatigue, ensuring uniform quality standards. | Consistent product quality across batches. |

| Defect Reduction (Automotive) | Up to 90% reduction in defects compared to manual inspections. | Significant decrease in faulty products. |

Manufacturers in electronics and automotive industries have seen up to 60% better defect detection and 90% fewer faulty products after adopting these systems.

Productivity and Efficiency

A quality assurance machine vision system increases productivity and efficiency on the production line. These systems operate 24/7 without fatigue, maintaining high inspection speed and quality. Automated inspection reduces scrap rates and rework, which saves time and resources. Real-time defect detection helps remove faulty products quickly, minimizing waste. AI-driven monitoring also detects early signs of equipment failure, supporting predictive maintenance and reducing downtime.

- Inspection time drops from six minutes to one minute, an 83% reduction.

- Inspection accuracy improves from 60% to 95%.

- Start-up time becomes 80% faster.

These improvements lead to increased efficiency, higher product quality, and lower operational costs.

Compliance and Cost Savings

A quality assurance machine vision system helps manufacturers meet industry regulations and save money. Automated inspection ensures every product meets strict quality and safety standards. The system provides traceability by reading barcodes and serial numbers, supporting audits and regulatory checks. Real-time error detection and assembly verification prevent defects and recalls.

- Early defect detection prevents costly rework and scrap.

- Labor cost reductions often pay for the system within a year.

- Increased production efficiency and fewer returns protect brand reputation.

Manufacturers also benefit from reduced training needs, improved data accuracy, and enhanced customer satisfaction.

A quality assurance machine vision system offers a strong return on investment, with average payback periods of one year or less. Lower system costs make this technology accessible for many manufacturers.

Applications & Selection Tips

Manufacturing Use Cases

Manufacturers use vision inspection systems for many tasks in production. These systems automate quality checks and improve defect detection. They help with product verification by checking labels, barcodes, and serial numbers. Vision inspection systems also support flaw detection by finding scratches, cracks, or missing parts.

Common uses include:

- Quality inspection of products, such as checking tablets in pharmaceuticals.

- Supply chain optimization through inventory monitoring.

- Equipment monitoring for predictive maintenance.

- Real-time barcode reading to avoid manual errors.

- Automated assembly using 3D models for precise part placement.

- Packaging inspection to count items and detect damage.

- COVID-19 safety monitoring, like mask detection.

Vision inspection systems also guide robots for sorting and picking. Advanced 3D vision improves picking accuracy and handles up to 10,000 parts per hour. Deep learning algorithms analyze shape and texture for better flaw detection and product verification. These systems adapt to changing environments using real-time data.

Industry Examples

Many industries rely on vision inspection systems for quality control. In the food industry, these systems check product size, shape, and packaging integrity. The pharmaceutical sector uses them for flaw detection in tablets and bottles, meeting strict standards. Beverage companies monitor fill levels and label accuracy to prevent defects.

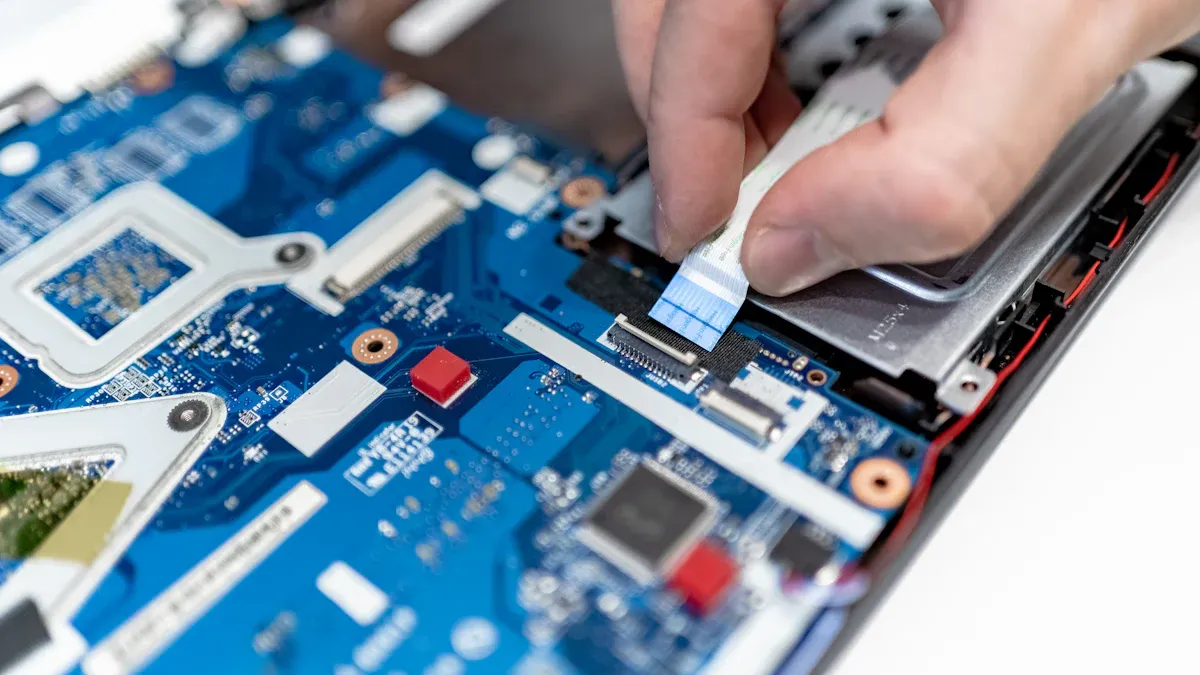

Tesla uses vision inspection systems to find scratches and cracks in cars. Electronics manufacturers use 3D vision for defect detection in circuit boards. Packaging lines use real-time inspection to verify seals and labels, reducing waste. These examples show how vision inspection systems improve quality and speed in manufacturing and industrial automation.

Choosing Vision Inspection Systems

Selecting the right vision inspection system requires careful planning. Manufacturers should define their inspection needs, such as volume, speed, and precision. They must check system accuracy for defect detection and flaw detection.

Key factors include:

- Product type: Choose area scan, line scan, or 3D cameras based on inspection needs.

- Production speed: High-speed lines need cameras with fast frame rates.

- Integration: Ensure the system works with existing equipment and software.

- Lighting: Select lighting that highlights defects for reliable inspection.

- Scalability: Pick systems that allow future production optimization and production optimisation.

- Vendor support: Training and support help with smooth setup and ongoing use.

A good vision inspection system supports real-time quality checks, reduces defects, and helps with production optimization. Manufacturers who plan for future needs get the most value from their investment.

A quality assurance machine vision system transforms quality control processes by delivering precise, consistent inspections and reducing operational costs. Manufacturers benefit from higher productivity, improved product quality, and fewer recalls. These systems address the need for accuracy, efficiency, and compliance across industries.

- Increase inspection speed and reliability

- Detect subtle defects missed by manual checks

- Support real-time data analysis for process improvements

Manufacturers should review their current quality control processes, define clear goals, and consult experts to select the right quality assurance machine vision system.

FAQ

What products can machine vision inspection systems check?

Machine vision inspection systems can check many products. They work with electronics, food, automotive parts, and medicine. These systems find defects, measure sizes, and read labels on different shapes and materials.

How accurate are machine vision inspection systems?

Most machine vision systems reach up to 99% accuracy. They spot tiny defects that people often miss. The system’s accuracy depends on camera quality, lighting, and software.

Can machine vision systems work with fast production lines?

Yes, these systems inspect products moving at high speeds. High-speed cameras and fast processors help them keep up with busy production lines. They do not slow down the process.

Do machine vision systems need special lighting?

Proper lighting is important for clear images. Many systems use LED lights or special setups to reduce shadows and glare. Good lighting helps the system find defects more easily.

Are machine vision inspection systems hard to install?

Most systems fit into existing production lines. Many use standard connections and software. Some systems need expert setup, but many vendors offer training and support.

See Also

Improving Product Quality Through Surface Inspection Vision Technology

Defining Machine Vision Systems For Quality Assurance Purposes

A Comprehensive Guide To Inspection Vision Systems In 2025