Imagine a factory where machines detect defects in products instantly. A mobile deployment machine vision system makes this possible. It uses advanced technologies like artificial intelligence and 5G to inspect and optimize processes in real-time. These systems, when integrated with mobile robots, offer unmatched flexibility. You can now achieve higher efficiency across manufacturing tasks with ease.

By using these systems, you reduce errors, improve quality, and redefine industrial automation.

Key Takeaways

-

Mobile machine vision systems help by automating checks and reducing mistakes.

-

They keep product quality steady and improve work efficiency.

-

These systems are very flexible and can handle many tasks.

-

They let factories quickly change how production lines work.

-

Real-time data helps businesses decide better and save time.

-

AI and new tech make these systems more accurate.

-

They find tiny defects that people cannot see.

-

Training workers is important to use these systems well.

-

It ensures teams can run and fix these smart tools.

Understanding Mobile Deployment Machine Vision Systems

Definition and Core Components

A mobile deployment machine vision system is a cutting-edge solution designed to perform visual inspection tasks in dynamic environments. Unlike stationary systems, these systems are integrated into mobile platforms, such as autonomous robots, to provide flexibility and adaptability in industrial settings. They combine hardware and software to capture, process, and analyze images for tasks like defect detection, quality control, and process optimization.

The core components of these systems include:

|

Component |

Description |

|---|---|

|

Lighting |

Illuminates the object being inspected to highlight its features for clear camera capture. |

|

Lens |

Captures the image and focuses the light onto the sensor. |

|

Image Sensor |

Converts the captured light into a digital representation, similar to how our eyes process light. |

|

Vision Processing (VPU) |

The brain of the system, analyzing images, extracting data, and making decisions. |

|

Communications |

Transmits information to other devices for logging or further action. |

These components work together to create a customized inspection system capable of handling complex tasks with precision.

Key Technologies Driving Machine Vision Systems

Advancements in machine vision technology have revolutionized how industries approach visual inspection. Several key technologies drive the evolution of these systems:

|

Technology |

Impact on Mobile Machine Vision Systems |

|---|---|

|

Edge Computing |

Enables real-time decision-making and processing at the source of data. |

|

AI-Enhanced Vision Models |

Improves pattern recognition and supports sophisticated applications. |

|

Hyperspectral Imaging |

Expands application areas by allowing detailed material analysis. |

|

Neuromorphic Vision Sensors |

Mimics human vision processing, enhancing speed and efficiency. |

|

Sensor Integration Advancements |

Simplifies the use of diverse sensors, making systems more versatile. |

|

High-Speed Networking |

Supports high-resolution imaging and real-time data processing. |

|

MIPI Standard |

Reduces complexity and improves performance in mobile and embedded applications. |

|

Nvidia Jetson |

Powers advanced machine vision systems with embedded processing capabilities. |

These technologies enable machine vision systems to deliver high-resolution imaging, faster image analysis, and greater adaptability in industrial environments.

Differences Between Mobile and Traditional Vision Systems

Mobile deployment machine vision systems differ significantly from traditional computer vision systems. While traditional systems are fixed and rely on external computers for processing, mobile systems integrate all components into a compact design. This integration reduces latency and enhances real-time performance.

|

Metric |

Mobile Machine Vision Systems |

Traditional Machine Vision Systems |

|---|---|---|

|

Data Processing Speed |

Processes data within the camera, reducing latency. |

Relies on external computers, which can slow down operations. |

|

Cost |

Lower total cost of ownership due to compact design. |

Higher costs due to additional hardware and software requirements. |

|

Flexibility |

Highly flexible, ideal for dynamic tasks. |

Less flexible, better suited for stable environments. |

Mobile systems excel in environments requiring adaptability and speed, making them ideal for modern industrial automation.

Applications of Machine Vision Systems in Industrial Automation

Comprehensive Inspection Automation Solution for Quality Control

A mobile deployment machine vision system offers a comprehensive inspection automation solution that ensures consistent quality control across industries. These systems excel in visual inspection tasks, identifying defects with precision and speed. By automating the inspection process, you can eliminate human error and achieve standardized defect detection. This is particularly crucial in industries like pharmaceuticals and food production, where compliance with strict regulations is non-negotiable.

Machine vision systems also enhance inspection speed, allowing you to process more products in less time. For example, Landing AI’s LandingLens platform has revolutionized product quality inspection by reducing validation times while improving reliability. The integration of AI and advanced algorithms further boosts accuracy, enabling real-time defect detection and process monitoring. This immediate feedback helps you correct issues before they escalate, saving time and resources.

|

Evidence |

Description |

|---|---|

|

Market Demand |

Growing industries like steel and consumer durables are driving demand. |

|

Regulatory Impact |

Stringent food and packaging regulations in North America fuel adoption. |

|

AI Integration |

Enhances image processing accuracy and decision-making. |

|

Industry Applications |

Vital in pharmaceuticals, food, and electronics for quality and safety. |

|

Recent Innovations |

LandingLens reduces validation times and improves inspection reliability. |

By leveraging these systems, you can ensure product quality inspection meets the highest standards while maintaining efficiency and compliance.

Process Optimization and Workflow Automation

Mobile machine vision systems play a pivotal role in optimizing processes and automating workflows. These systems capture real-time data during production, enabling you to monitor operations continuously. With this data, you can identify inefficiencies, detect deviations, and implement corrective actions swiftly.

Here’s how these systems streamline workflows:

-

Pre-Production Configuration: You can set up the system with specific guidelines and calibrate it to capture essential data points.

-

Real-Time Production Monitoring: The system observes production processes and processes data instantly to ensure compliance.

-

Deviation Detection: It identifies anomalies and sends alerts to the relevant personnel for immediate action.

-

Root Cause Analysis and Resolution: Detailed reports allow you to assess issues and resolve them quickly.

-

Continuous Feedback Loop: The system updates its models based on new data, improving future monitoring and decision-making.

These capabilities not only enhance speed and accuracy but also support data-driven decision-making. For instance, automated visual inspections provide real-time insights that help you identify trends and predict potential issues. This allows you to make timely adjustments, ensuring smooth workflows and maintaining product quality.

Real-Time Inventory Management and Logistics

Managing inventory efficiently is a critical challenge in industrial settings. Mobile machine vision systems simplify this task by providing real-time object detection and counting capabilities. These systems capture images of inventory items, analyze them instantly, and update stock levels automatically. This eliminates the need for manual counting, saving you time and reducing errors.

Comparative studies highlight the efficiency improvements these systems bring. For example, Sam’s Club uses an inventory scan system to capture shelf images in real-time, improving stock management across 600 stores. Similarly, Gather AI employs drones for automated inventory counting, achieving speeds 15 times faster than manual methods. These advancements not only enhance speed but also deliver significant cost savings.

|

Company |

System Used |

Efficiency Improvement Description |

Speed Improvement |

Cost Savings |

|---|---|---|---|---|

|

Sam’s Club |

Inventory Scan |

Real-time collection and processing of shelf images, improving stock management and reducing labor. |

Improved speed and accuracy across 600 stores |

Significant ROI expected |

|

Gather AI |

Gather AI |

Uses drones for real-time image analysis, counting inventory automatically and alerting on issues. |

15x faster than manual counting |

Substantial cost savings due to eliminated manual counting |

By adopting these systems, you can streamline inventory management and logistics, ensuring accurate stock levels and reducing operational costs.

Predictive Maintenance with Mobile Robots

Predictive maintenance has become a game-changer in industrial automation. By using mobile robots equipped with advanced sensors and machine vision systems, you can monitor equipment health and predict failures before they occur. This proactive approach minimizes downtime and extends the lifespan of machinery.

Mobile robots excel in predictive maintenance because they can navigate complex environments with ease. Their navigation system allows them to move autonomously through factories, warehouses, or production lines. These robots collect data from machines, such as temperature, vibration, and noise levels, using their onboard sensors. The data is then analyzed to identify patterns that indicate potential issues.

Here’s how predictive maintenance with mobile robots works:

-

Data Collection: The mobile robot moves through your facility, gathering real-time data from various machines.

-

Data Analysis: The robot’s onboard system processes the data or sends it to a central server for analysis.

-

Issue Detection: The navigation system ensures the robot reaches all critical areas, enabling it to detect anomalies like overheating or unusual vibrations.

-

Actionable Insights: The system generates alerts or recommendations, helping you address problems before they escalate.

For example, a mobile robot with a robust navigation system can inspect conveyor belts in a manufacturing plant. It identifies wear and tear early, allowing you to schedule repairs during non-peak hours. This reduces unexpected breakdowns and keeps your operations running smoothly.

The benefits of predictive maintenance extend beyond cost savings. You also improve workplace safety by addressing equipment issues before they become hazardous. Additionally, the mobility of these robots ensures comprehensive coverage, even in hard-to-reach areas.

By integrating mobile robots into your maintenance strategy, you gain a reliable and efficient solution. Their advanced navigation systems and data analysis capabilities make them indispensable for modern industrial automation.

Benefits of Mobile Machine Vision Systems

Enhanced Flexibility and Scalability

Mobile machine vision systems provide unmatched flexibility and scalability, making them ideal for dynamic industrial environments. You can adapt these systems to various product categories and production demands with ease. For instance, mobile robots equipped with machine vision systems can handle diverse manufacturing tasks, from inspecting small electronic components to analyzing large automotive parts. This adaptability ensures that your operations remain efficient, even when product specifications or order volumes change.

Scalability is another significant advantage. These systems allow you to reconfigure production lines quickly, enabling you to scale operations as needed. Whether you need to increase output during peak seasons or introduce new product lines, mobile machine vision systems simplify the process. The integration of AI and smart technologies further enhances scalability by enabling rapid deployments and upgrades.

|

Key Features |

Description |

|---|---|

|

Flexibility |

Mobile robots and machine vision enable flexible manufacturing processes that can adapt to various product categories and order fluctuations. |

|

Scalability |

The systems allow for rapid adjustments and reconfigurations of production lines, enhancing the ability to scale operations as needed. |

|

Intelligent Manufacturing |

Integration of AI and smart technologies facilitates quick deployments and technological upgrades, significantly reducing time to market. |

By leveraging these features, you can create a more agile and responsive manufacturing environment, ensuring that your business stays competitive in a fast-changing market.

Cost Savings and Operational Efficiency

Mobile machine vision systems significantly reduce operational costs while improving efficiency. By automating inspections, you eliminate the need for manual labor in repetitive and time-consuming tasks. This not only reduces labor costs but also minimizes the risk of human error, ensuring consistent quality across your products.

These systems also optimize resource utilization. For example, they can identify defects early in the production process, preventing waste and reducing material costs. Additionally, their ability to perform real-time inspections allows you to address issues immediately, avoiding costly delays and rework. The streamlined processes and automated workflows enabled by these systems contribute to faster production cycles and higher throughput.

Consider the long-term benefits as well. Although the initial investment in a machine vision system may seem high, the cost savings from reduced waste, improved productivity, and fewer errors quickly offset the expense. Over time, these systems deliver a substantial return on investment, making them a cost-effective solution for modern industrial automation.

Improved Accuracy and Reduced Downtime

Accuracy is a cornerstone of mobile machine vision systems. These systems use advanced imaging technologies and AI algorithms to detect even the smallest defects with precision. Whether you are inspecting intricate circuit boards or large mechanical components, the system ensures that no flaw goes unnoticed. This level of accuracy enhances product quality and reduces the likelihood of customer complaints or recalls.

Reduced downtime is another critical benefit. Mobile machine vision systems perform inspections and data analysis in real-time, allowing you to identify and resolve issues before they escalate. For example, if a system detects a misalignment on a production line, it can alert operators immediately, enabling quick corrective action. This proactive approach minimizes disruptions and keeps your operations running smoothly.

Furthermore, the mobility of these systems ensures comprehensive coverage of your facility. They can move autonomously to inspect equipment, monitor production lines, and collect data from hard-to-reach areas. This versatility not only improves accuracy but also enhances overall operational efficiency.

By adopting mobile machine vision systems, you gain a reliable solution that boosts accuracy, minimizes downtime, and ensures consistent performance across your operations.

Real-Time Data Collection and Analysis

Real-time data collection and analysis have become essential in modern industrial automation. Mobile machine vision systems excel in this area by capturing and processing data instantly, enabling you to make informed decisions without delays. These systems use advanced imaging technologies and AI algorithms to monitor production lines, detect anomalies, and optimize workflows in real time.

One of the key advantages of these systems is their ability to handle automated data capture with precision. Unlike traditional methods, which often rely on manual input or delayed processing, mobile machine vision systems collect data continuously. This ensures that you always have access to the most up-to-date information about your operations. For example, event-based imaging technology mimics biological systems by processing data asynchronously. This innovation significantly improves the speed and accuracy of data collection, allowing you to respond to changes in production conditions immediately.

To understand the impact of real-time data collection, consider the following metrics that validate improved operational performance:

|

Metric |

Description |

|---|---|

|

Throughput |

The amount of product produced in a given time period. |

|

Jitter |

The variability in time delay in data transmission. |

|

Delay |

The time taken for data to travel from source to destination. |

|

Bandwidth |

The maximum rate of data transfer across a network. |

|

Availability |

The percentage of time the system is operational and available for use. |

|

Error Rate |

The frequency of errors occurring in the data transmission process. |

|

Overall Equipment Effectiveness (OEE) |

A composite metric that assesses manufacturing efficiency based on availability, performance, and quality. |

These metrics highlight how mobile machine vision systems enhance operational efficiency. For instance, reduced delay and jitter ensure smoother data transmission, while high availability guarantees that your system remains functional when you need it most.

Recent advancements in industrial streaming cameras further demonstrate the capabilities of mobile machine vision systems. These cameras enable real-time data streaming without requiring centralized processing. This shift aligns with the principles of Industry 4.0, where interconnected smart devices work together to optimize operations. By integrating these cameras into your workflow, you can achieve faster data analysis and improved decision-making.

Another groundbreaking innovation is the use of neuromorphic vision sensors. These sensors process visual data in a way that mimics the human brain, enhancing the system’s ability to detect patterns and anomalies. This capability is particularly useful in applications like predictive maintenance, where early detection of equipment issues can prevent costly downtime.

The benefits of real-time data collection extend beyond operational efficiency. By leveraging automated data capture, you can also improve product quality and customer satisfaction. For example, real-time analysis allows you to identify defects during production, ensuring that only high-quality products reach your customers. Additionally, the continuous feedback loop provided by these systems helps you refine your processes over time, leading to long-term improvements in performance.

Incorporating mobile machine vision systems into your operations not only streamlines data collection but also empowers you to act on insights immediately. This proactive approach ensures that your business remains competitive in an increasingly data-driven world.

Challenges in Mobile Deployment Machine Vision Systems

Integration Complexities with Existing Systems

Integrating mobile machine vision systems into your existing infrastructure can be a daunting task. These systems often require significant adjustments to ensure smooth operation. For example:

-

The high computational power needed for these systems can strain your current hardware, leading to performance issues.

-

AI-based vision systems may not align with your existing software or communication protocols, creating compatibility challenges.

-

The large volumes of data generated by these systems can overwhelm your data handling and storage solutions.

-

Extensive training is often required to fine-tune AI models, which can delay deployment.

-

Operational environments may need modifications to accommodate the system’s requirements.

-

Deployment and maintenance demand higher technical expertise, which might not be readily available in your workforce.

These complexities highlight the importance of planning and preparation when adopting mobile machine vision systems.

Hardware and Software Compatibility Issues

Compatibility between hardware and software is another significant challenge. Mobile machine vision systems rely on seamless communication between their components to function effectively. However, mismatched hardware and software can disrupt this harmony. For instance, older systems in your facility may not support the advanced features of modern machine vision technologies.

You may also encounter issues with integrating third-party software or sensors. These problems can lead to delays, increased costs, and reduced system efficiency. Ensuring compatibility requires careful evaluation of your existing setup and the new system’s requirements. This step is crucial for achieving regulatory compliance and maintaining operational efficiency.

High Initial Investment Costs

The upfront costs of mobile machine vision systems can be prohibitive, especially for small and medium-sized enterprises. These expenses include hardware, software, and the infrastructure needed for deployment. Market analyses reveal the following insights:

|

Source |

Evidence |

|---|---|

|

North America Machine Vision Systems Market Size & Trends |

High initial investment costs are a significant challenge in the adoption of mobile machine vision systems, particularly in the North American market. These costs are associated with both hardware and software, making it difficult for small and medium-sized enterprises to justify the investment. |

|

Machine Vision Market Worth USD 33.2 Billion by 2033 With CAGR of 7.7%. |

The setup of advanced machine vision systems often requires significant upfront investments in equipment, software, and infrastructure. Small and medium-sized businesses may find it difficult to justify these costs, particularly if they do not have the resources to support ongoing maintenance and upgrades. |

|

Machine Vision Market Size, Share, Trends, Growth & Forecast |

High initial investment costs associated with the technology and its integration are anticipated to deter small and medium-sized enterprises from implementing machine vision solutions. |

While the long-term benefits of these systems are undeniable, the initial financial burden can slow down adoption. Exploring financing options or phased implementation strategies can help you overcome this hurdle.

Workforce Training and Skill Development

Adopting mobile machine vision systems requires you to invest in workforce training and skill development. These systems introduce advanced technologies like AI, IoT, and robotics, which demand new competencies from your team. Without proper training, your workforce may struggle to operate, maintain, and optimize these systems effectively.

Why Training Matters

Training ensures your team understands the system’s functionality and capabilities. It equips them to troubleshoot issues, interpret data, and make informed decisions. A well-trained workforce improves operational efficiency and reduces errors.

Tip: Start with foundational training on machine vision basics before advancing to AI-driven applications.

Key Areas for Skill Development

Focus on these areas to prepare your workforce:

-

Technical Skills: Teach employees how to operate and maintain hardware components like cameras, sensors, and processors.

-

Data Analysis: Train them to interpret real-time data and use insights for decision-making.

-

AI and Machine Learning: Provide knowledge on how AI models work and how to fine-tune them for specific tasks.

-

System Integration: Help them understand how to integrate machine vision systems with existing workflows.

Training Methods

You can use various methods to train your team:

-

Workshops: Conduct hands-on sessions to familiarize employees with system components.

-

Online Courses: Offer flexible learning options for AI and machine vision concepts.

-

On-the-Job Training: Let employees practice with the system during live operations.

-

Vendor Support: Collaborate with system providers for specialized training programs.

Benefits of Workforce Training

Investing in training delivers long-term benefits:

|

Benefit |

Description |

|---|---|

|

Increased Productivity |

Skilled employees complete tasks faster and with fewer errors. |

|

Reduced Downtime |

Trained staff quickly resolve system issues, minimizing disruptions. |

|

Enhanced Job Satisfaction |

Employees feel empowered when they master new technologies. |

By prioritizing workforce training, you ensure a smooth transition to mobile machine vision systems while fostering a culture of innovation and growth.

Future Trends in Machine Vision Systems

Advancements in AI and Machine Learning

Artificial intelligence (AI) and machine learning are transforming the capabilities of machine vision systems. These technologies enable faster image processing, improved pattern recognition, and more accurate decision-making. For example, advancements in AI frameworks now allow you to develop applications more quickly, while sophisticated algorithms enhance activity recognition.

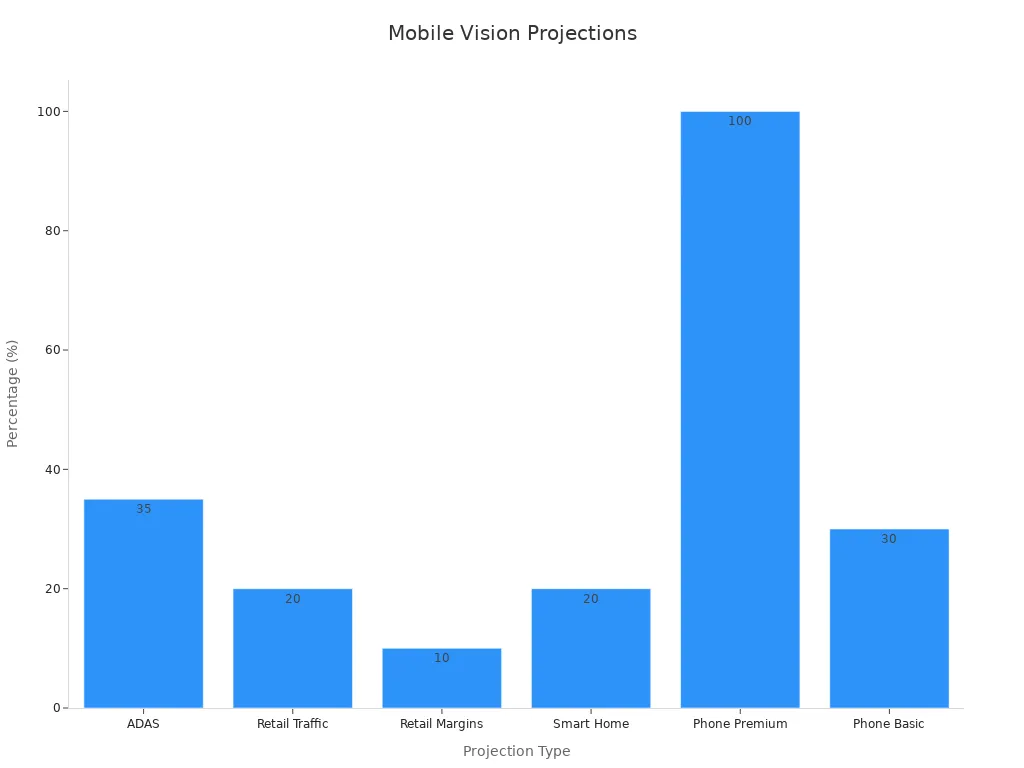

The integration of machine vision systems into various sectors is also accelerating. By 2025, advanced driver assistance systems (ADAS) in automobiles will grow from 10% to 35%. In retail, machine vision applications are projected to increase customer traffic by 20% and store margins by 10%. Additionally, 20% of smart home appliances will feature machine vision technology, and nearly all premium smartphones will include facial or gesture recognition capabilities.

IoT and Edge Computing Integration

The integration of IoT and edge computing with machine vision systems is revolutionizing data processing. Edge AI allows you to process data locally, eliminating delays caused by cloud-based systems. This real-time processing is crucial for dynamic environments like autonomous driving. Local data processing also reduces operational costs by minimizing the need for expensive cloud infrastructure.

Moreover, edge computing enhances data security. Sensitive information is processed locally, reducing the risk of breaches during transmission. This approach ensures compliance with data protection regulations while maintaining high AI performance. By adopting edge computing, you can achieve faster responses and lower costs without compromising security.

Autonomous Mobile Robots in Industrial Automation

Autonomous mobile robots equipped with machine vision systems are reshaping industrial automation. These robots navigate complex environments, collect real-time data, and optimize workflows. By 2025, over 50% of these robots will use advanced AI for improved navigation and efficiency. In logistics and manufacturing, 70% of mobile robots will integrate IoT technology by 2026, enabling real-time data sharing.

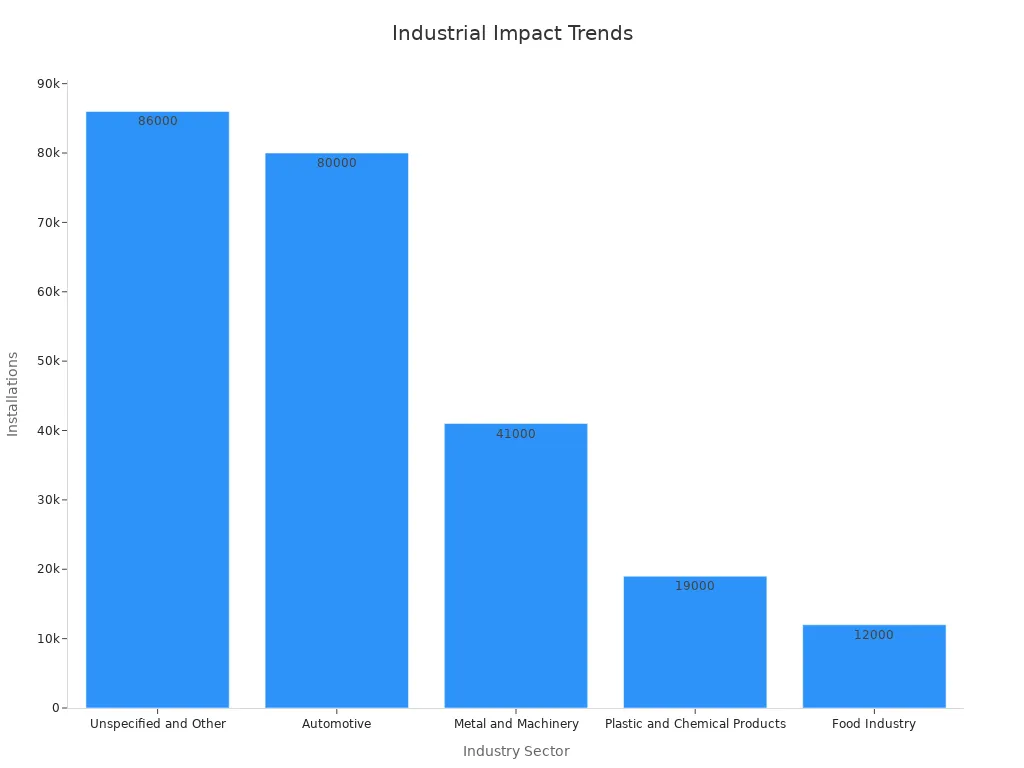

The adoption of these robots is growing across industries. For instance, the automotive sector installed 80,000 units, while the food industry deployed 12,000. Their ability to operate autonomously and adapt to changing conditions makes them indispensable for modern factories.

Expanding Use Cases Across Diverse Industries

Mobile machine vision systems are transforming industries by enabling automation and improving efficiency. You can find these systems in manufacturing, healthcare, and automotive sectors, where they perform tasks that were once impossible to automate. Their ability to deliver real-time visual inspection and quality control makes them indispensable in modern industrial applications.

In manufacturing, these systems streamline production lines. They detect defects in products, ensuring consistent quality. For example, they inspect electronic components for flaws or verify the dimensions of automotive parts. Their adaptability allows you to use them across different product categories, making them a versatile solution for dynamic production environments.

Healthcare is another sector benefiting from machine vision systems. These systems assist in analyzing medical images, identifying abnormalities, and supporting diagnostics. For instance, they help detect irregularities in X-rays or monitor surgical procedures with precision. Their accuracy reduces human error and enhances patient outcomes.

The automotive industry uses machine vision systems to improve safety and efficiency. You can see them in advanced driver assistance systems (ADAS), where they monitor road conditions and detect obstacles. They also play a role in assembling vehicles, ensuring parts are correctly aligned and functioning. This technology supports faster production and higher-quality vehicles.

A report highlights the growing demand for machine vision systems due to advancements in AI and automation. These technologies enable the systems to perform complex tasks, further expanding their applications. As industries continue to adopt automation, the role of machine vision systems will only grow, driving productivity and innovation.

By integrating machine vision systems into your operations, you can enhance accuracy, reduce costs, and stay ahead in a competitive market. Their expanding use cases across diverse industries demonstrate their potential to revolutionize how you approach automation.

Mobile deployment machine vision systems are transforming industrial automation by delivering flexibility, efficiency, and accuracy. These systems adapt to diverse inspection needs, ensuring operational agility. Their high-speed inspections improve productivity in fast-paced environments, while advanced imaging detects defects invisible to the human eye, safeguarding product quality. By 2033, the market for these systems is projected to reach $26.7 billion, reflecting their growing impact.

|

Benefit |

Description |

|---|---|

|

Flexibility |

Machine vision systems can adapt to various inspection needs, enhancing operational flexibility. |

|

Efficiency |

Capable of high-speed inspections, essential in fast-paced production environments. |

|

Accuracy |

Detects defects invisible to the human eye, ensuring product safety and quality. |

|

Safety |

Inspects for foreign particles and contamination, ensuring safe products for consumers. |

|

Uniformity of Containers |

Detects deformities in containers, maintaining brand perception and product quality. |

|

Packaging |

Ensures seals are intact and products are defect-free, preventing loss of business. |

|

Labels |

Validates correct label placement and printing, crucial for consumer safety regarding allergies. |

While challenges like integration and cost exist, the benefits far outweigh the drawbacks. As AI, IoT, and robotics advance, these systems will unlock new possibilities, driving the future of industrial automation.

FAQ

What is a mobile machine vision system used for?

Mobile machine vision systems perform tasks like defect detection, quality control, and process optimization. They help you automate inspections and improve efficiency in industries such as manufacturing, healthcare, and logistics.

How does a mobile machine vision system differ from a traditional one?

Mobile systems integrate all components into a compact, portable design. This allows you to use them in dynamic environments. Traditional systems, on the other hand, are fixed and rely on external computers for processing.

Are mobile machine vision systems expensive to implement?

The initial investment can be high due to advanced hardware and software. However, these systems reduce long-term costs by improving efficiency, minimizing waste, and lowering labor expenses.

Can mobile machine vision systems work in low-light conditions?

Yes, these systems often include advanced lighting components. These ensure clear image capture even in challenging environments, allowing you to maintain inspection accuracy.

Do I need special training to use these systems?

Yes, training is essential. It helps your team understand system operations, troubleshoot issues, and analyze data effectively. Many vendors offer workshops and online courses to simplify the learning process.

Tip: Start with basic training and gradually introduce advanced concepts like AI and machine learning.

See Also

A Detailed Overview of Machine Vision in Automation

Essential Features and Advantages of Medical Vision Systems

Exploring Inspection Machine Vision Technologies for 2025

Comparing Firmware Machine Vision to Conventional Systems

Defining the Role of Automotive Machine Vision Systems