An fpr machine vision system uses advanced cameras and software to inspect products and guide machines in real time. Manufacturers choose these systems to improve quality, reduce waste, and increase speed.

- Detects tiny defects invisible to humans

- Automates repetitive inspection tasks

- Reduces costs and human error

A machine vision system often delivers a return on investment in as little as seven months, making it essential for modern manufacturing.

Key Takeaways

- FPR machine vision systems use advanced 3D imaging and software to detect tiny defects and ensure high product quality in manufacturing.

- These systems automate inspections, reduce human error, and speed up production, leading to significant cost savings and faster return on investment.

- Key hardware includes cameras, lighting, lenses, and processing units, while software handles image analysis and decision-making with user-friendly interfaces.

- FPR systems offer unique features like autonomous calibration, real-time 3D reconstruction, and self-learning models that improve precision and reduce manual work.

- Successful implementation requires careful integration with existing equipment, attention to environmental factors, and training to overcome challenges and maximize benefits.

FPR Machine Vision System

Definition

An FPR machine vision system is a specialized technology used in manufacturing to automate the inspection, guidance, and tracking of products. This system combines high-resolution cameras, advanced lighting, and intelligent software to analyze images of products as they move through production lines. The main goal is to ensure that every item meets strict quality standards. Unlike manual inspection, an FPR machine vision system works quickly and accurately, even in challenging factory environments. It can identify defects, measure components, and verify assembly steps without slowing down production.

Manufacturers rely on this type of machine vision system to handle tasks that require precision and speed. The system can operate around the clock, providing consistent results and reducing the risk of human error. By using real-time image processing, the FPR machine vision system helps companies maintain high levels of quality and efficiency.

Purpose

The primary purpose of deploying an FPR machine vision system in manufacturing is to improve product quality, streamline operations, and support automation. Companies use these systems to guide, inspect, and track products during manufacturing, assembly, and packaging. The system integrates with existing automation equipment, such as programmable logic controllers (PLCs) and human-machine interfaces (HMIs), using industrial communication protocols like EtherNet/IP and PROFINET.

Key objectives of an FPR machine vision system include:

- Guiding, inspecting, and tracking products to meet quality standards.

- Integrating seamlessly with automation processes and equipment.

- Responding to external requests and providing timely results or output actions.

- Interacting with other automation equipment using industrial communication protocols.

- Supporting real-time inspection and control within manufacturing processes.

- Enhancing automation while maintaining or improving production speed.

- Ensuring ruggedness and reliability to withstand harsh factory conditions.

- Reducing costs and complexity, sometimes replacing PLCs in simpler installations.

- Providing facilities for interaction through discrete IOs for basic production processes.

- Enabling integration with operator interfaces for status updates, adjustments, and control inputs.

Cost is an important factor when choosing a machine vision system. The price depends on the type of system, its features, and the complexity of the application. The table below shows typical cost ranges for different types of machine vision systems:

| System Type | Cost Range (USD) | Key Cost Factors and Notes |

|---|---|---|

| 2D Vision Systems | Entry-Level: $200-$3,000 | Basic applications, standard resolution, basic software capabilities |

| Mid-Range: $3,000-$10,000 | Better resolution and speed, suitable for more complex industrial tasks | |

| High-End: $10,000-$25,000+ | Ultra-high resolution, sophisticated software, designed for high-speed automation and intricate checks | |

| 3D Vision Systems | Entry-Level: $3,000-$10,000 | Basic measurements and inspections, standard resolution and speed |

| Mid-Range: $10,000-$30,000 | Higher resolution and processing power, detailed inspections, precise robot guidance | |

| High-End: $30,000-$60,000+ | Top-tier resolution, rapid processing, complex applications like high-speed robot guidance and metrology |

Other important cost factors include:

- Understanding customer requirements and current system limitations.

- Selecting the right technology components, such as cameras, lighting, controls, and software.

- Conducting proof-of-concept and feasibility studies to reduce risk.

- Considering implementation, installation, training, and lifetime support.

- Collaborating closely with customers to ensure the system meets their needs, which may require dedicated engineering resources.

A well-designed FPR machine vision system helps manufacturers achieve higher productivity, lower costs, and better product quality. These systems play a vital role in modern manufacturing by supporting automation and ensuring that every product meets the required standards.

Machine Vision System Components

Hardware

A machine vision system relies on several key hardware components to deliver accurate results. Cameras serve as the eyes of the system, capturing images of products as they move through production. The image sensor inside each camera converts light into digital data, which determines the resolution and detail of every inspection. Lighting plays a critical role by illuminating objects and reducing shadows, making features easier to detect. The lens focuses light onto the image sensor, ensuring sharp and clear images. Vision processing units (VPUs) handle image processing tasks and run algorithms for real-time analysis. Communication interfaces connect the system to other equipment, allowing data and control signals to flow smoothly.

| Hardware Component | Contribution to System Performance |

|---|---|

| Lighting | Illuminates the object, highlights features, and reduces shadows for clear image capture. |

| Lens | Focuses light onto the image sensor for sharp and accurate images. |

| Image Sensor | Converts light into digital data, setting image resolution and detail level. |

| Vision Processing Unit | Runs algorithms for image analysis, enabling real-time inspection and decision-making. |

| Communications | Transmits data and control signals, ensuring reliable integration with other system components. |

Selecting the right hardware depends on the application and environment. For example, high-speed lines may require cameras with advanced camera features and fast image sensors. Calibration tools help maintain accuracy and reliability over time.

Software

Software forms the brain of machine vision systems. Image analysis software enhances images, detects edges, and classifies defects. Vision processing software runs algorithms such as pattern recognition, geometric search, and ocv. These tools transform raw images into actionable information. Machine vision software also supports pass/fail decision-making and integrates with data analytics for quality assurance. Configuration software, like In-Sight Explorer or EasyBuilder, provides user-friendly interfaces. Operators can set up vision applications, calibrate devices, and troubleshoot issues without programming skills. This approach makes machine vision systems accessible to users at all skill levels.

| Software Type | Main Functionalities |

|---|---|

| Machine Vision Software | Image enhancement, edge detection, morphological analysis, defect classification, ocv, and integration with analytics |

| Vision Processing Software (VPU) | Executes image processing algorithms, pattern recognition, ocv, and object detection |

| Vision System Configuration Software | User-friendly setup, calibration, communication with automation, troubleshooting |

System Types

Manufacturers use several types of machine vision systems, each suited to specific tasks. Area scan systems capture full 2D images in one frame, making them ideal for inspecting static or slow-moving objects. Line scan systems build images line-by-line, which works well for high-speed conveyor belts. 3D vision systems add depth information, using methods like stereo vision, structured light, or fringe pattern analysis. FPR, a type of 3D vision, projects shifting patterns onto objects and uses phase-shifted images to calculate precise 3D coordinates. This method provides higher resolution than other 3D techniques but requires more complex setup.

| System Type | Imaging Method | Ideal Applications | Key Advantages | Limitations/Notes |

|---|---|---|---|---|

| 2D Area Scan | Captures full 2D image in one frame | Electronics inspection, label verification | High resolution, simple setup | Less suited for fast-moving objects |

| 2D Line Scan | Captures images line-by-line | Web inspection, metal surface inspection | Optimized for speed, no motion blur | Requires precise synchronization |

| 3D Vision Systems | Adds depth via structured light, FPR | Robotic guidance, weld seam inspection, alignment | Accurate 3D data, multi-sensor input | More complex and costly |

Manufacturers choose the types of machine vision systems based on their needs. For example, 2D systems handle surface inspection and barcode reading, while 3D systems excel at volume measurement and assembly validation. Smart camera-based systems offer compact solutions for simple tasks, and AI-powered systems use computer vision models for advanced defect detection and pattern recognition.

Tip: Matching the right camera features, image sensor, and computer vision models to the application ensures the best performance from any machine vision system.

Applications in Quality Control

Defect Detection

Manufacturers rely on machine vision systems for precise defect detection. These systems use high-resolution cameras and advanced lighting to capture detailed images of products on the production line. Specialized image recognition software analyzes these images, identifying scratches, dents, misalignments, and other defects that human inspectors might miss. The process includes image acquisition, preprocessing, object detection, and decision-making. AI-powered algorithms such as convolutional neural networks and YOLO models enable real-time defect detection with accuracy rates above 99%. Some advanced models reach up to 99.9% accuracy, outperforming manual inspection.

Machine vision systems standardize quality control by automating grading and inspection tasks. They deliver consistent, objective results and eliminate fatigue-related errors. Human error accounts for over 60% of quality assurance defects in manufacturing. Fatigue can reduce inspection performance by up to 30% in fast-paced environments. Precision lenses and AI-driven image processing improve defect detection rates by more than 40% and reduce false positives by up to 25%. High-speed cameras operating at 1000 frames per second enable rapid inspection, increasing yield rates and reducing waste.

Machine vision systems provide real-time defect detection with unmatched precision and speed. They operate without fatigue or subjective bias, ensuring reliable quality control.

Inspection Tasks

Machine vision systems automate a wide range of inspection tasks in modern manufacturing. These tasks include:

- Defect detection for surface flaws, cracks, and contamination

- Dimensional checks to verify product measurements

- Surface quality inspection for texture and finish

- Packaging integrity verification to ensure seals and closures are intact

- Labeling accuracy and ocr for correct product information

- Assembly verification to confirm all components are present and correctly positioned

- Barcode reading for product tracking and traceability

- Object detection and counting for inventory management

Manufacturers in the automotive industry use machine vision systems to inspect welds, surface finishes, and assemblies. Electronics manufacturers rely on image recognition to check PCB solder quality, detect microcracks, and identify overlay misalignment. Medical device companies use automated inspection for dimensional accuracy and surface imperfections. Pharmaceutical companies depend on these systems for contamination detection, packaging seal integrity, and ocr-based labeling verification. Food and beverage producers use object detection and counting to spot foreign objects, packaging damage, and labeling errors.

Machine vision systems excel in repetitive, high-precision inspection tasks. They capture images, preprocess them, extract features, and analyze for defects. These systems make pass/fail decisions without human intervention. Automated machine vision reduces human error, improves inspection speed, and maintains consistent quality. AI-driven algorithms and advanced imaging technologies enable detection of microscopic defects and surface quality issues, even in fast-paced environments.

Real-World Examples

Many industries have adopted machine vision systems for quality control. The following examples highlight their impact:

- Automated sorting of defective products, fruit grading, parcel sorting, and pill sorting

- Real-time defect detection on manufacturing lines, identifying variations in color, texture, and labels

- Counting objects on conveyor belts to improve quality assurance and inventory management

- Flaw detection, including surface scratches, dents, and internal structural issues, using image recognition and object detection

- Advanced imaging techniques such as 3D vision and hyperspectral imaging for surface contour analysis, chemical composition detection, and contamination detection

ImpactVision’s hyperspectral imaging system operates in food processing facilities. It detects freshness levels and foreign objects in real time, reducing food waste and improving product quality. AI-powered machine vision systems support micro-defect detection, predictive maintenance, and flexible automation in high-mix, low-volume manufacturing environments. These systems adapt to frequent product changeovers and varying materials.

The following table shows measurable improvements after implementing FPR machine vision systems:

| Metric | Improvement |

|---|---|

| Defect Rate Reduction | 30% decrease in defect rates |

| Accuracy Rate | Up to 99% accuracy in defect detection |

| Inspection Time | Reduced from 1 minute to 2.2 seconds per unit |

| Cost Savings | 30-fold reduction compared to manual inspection |

| Return on Investment | Achieved in less than 2 years |

Manufacturers report that machine vision systems inspect gypsum boards at speeds up to 700 feet per minute, providing 100% surface inspection coverage. These systems detect surface variations as small as ¼” to ½”, replacing one quality control position per shift and reducing labor costs. Early defect detection reduces waste and rework, improving production efficiency and product quality.

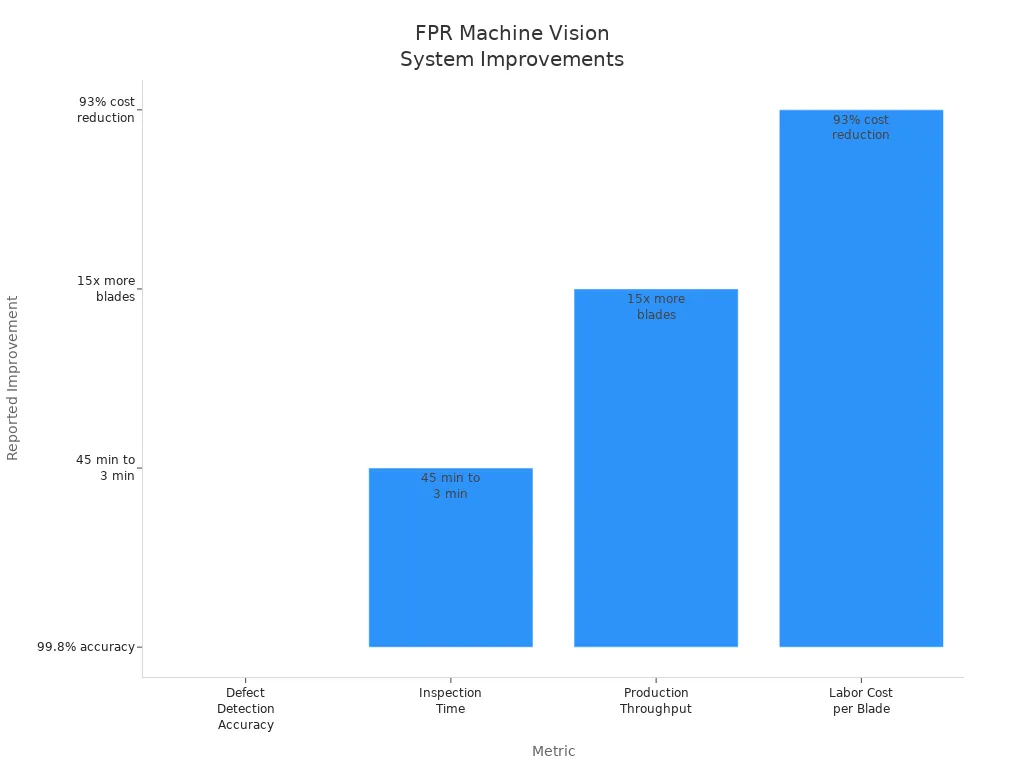

Another example comes from jet engine turbine blade inspection:

| Metric | Improvement |

|---|---|

| Defect Detection Accuracy | 99.8% accuracy in jet engine turbine blade inspection |

| Inspection Time | Reduced from 45 minutes to 3 minutes per blade |

| Production Throughput | 15 times more blades inspected with same labor |

| Labor Cost per Blade | Reduced by approximately 93% |

| Delivery Time | Engines shipped weeks earlier |

Machine vision systems also support compliance with industry standards and regulations. They provide end-to-end traceability, integrate with production management systems, and automate serialization, ocr, and barcode reading. Features such as audit trails, access control, and data integrity help manufacturers meet FDA 21 CFR Part 11 requirements and ensure secure, reliable electronic records.

Machine vision systems reduce human error by automating inspections with consistent, objective evaluations. They enable high-speed, accurate defect detection and provide real-time data for quick decision-making.

Comparing Machine Vision Systems

FPR vs. Other Systems

Manufacturers often compare FPR machine vision systems with other machine vision systems to select the best solution for their needs. FPR systems use advanced computer vision models to achieve high precision in 3D measurements. These systems excel in applications that demand autonomous operation and detailed inspection. Other machine vision systems, such as area scan and line scan, rely on 2D imaging and simpler computer vision models. These systems work well for basic inspection tasks but may not deliver the same level of precision or autonomous performance.

FPR machine vision systems stand out for their ability to process complex surfaces and shapes. They use computer vision models that analyze phase-shifted patterns, which increases precision. Autonomous inspection becomes possible even in challenging environments. Other machine vision systems may require manual adjustments or frequent recalibration. FPR systems reduce downtime and support continuous, autonomous quality control.

| Feature | FPR Machine Vision Systems | Other Machine Vision Systems |

|---|---|---|

| Imaging Dimension | 3D | 2D or basic 3D |

| Computer Vision Models | Advanced | Standard |

| Precision | High | Moderate to High |

| Autonomous Operation | Full | Partial |

| Application Scope | Complex, high-precision | General, less complex |

FPR machine vision systems provide unmatched precision and enable fully autonomous inspection, making them ideal for industries that require strict quality standards.

Unique Features

FPR machine vision systems offer several unique features that set them apart from other machine vision systems. These systems use specialized computer vision models to interpret 3D data with high precision. Autonomous calibration routines allow the system to adjust settings without human intervention. This capability ensures consistent performance and reduces the need for manual oversight.

Key unique features include:

- Real-time 3D reconstruction using advanced computer vision models

- Autonomous defect detection and classification

- High precision measurement of complex geometries

- Seamless integration with autonomous robots and production lines

- Adaptive lighting and focus control for changing environments

- Self-learning computer vision models that improve over time

- Robust performance in harsh or variable conditions

- Autonomous reporting and data logging for traceability

- Scalable architecture for expanding machine vision systems

These features enable manufacturers to deploy machine vision systems that deliver reliable, autonomous inspection with superior precision. Computer vision models in FPR systems adapt to new products and changing conditions, supporting flexible manufacturing. Autonomous operation reduces labor costs and increases throughput. Precision in measurement and defect detection ensures that only high-quality products reach customers.

Manufacturers who invest in FPR machine vision systems gain a competitive edge through autonomous, high-precision inspection powered by advanced computer vision models.

Implementation Considerations

Accuracy

Precision stands at the core of machine vision systems. Manufacturers demand high accuracy for every inspection. Computer vision models drive this precision by analyzing images with advanced image segmentation. These models detect even the smallest defects, ensuring only quality products move forward. AI-powered algorithms improve precision by learning from new data and adapting to changing conditions. Proper lighting, optics, and calibration also play a major role in maintaining accuracy. Environmental factors such as dust, vibration, and temperature can affect image segmentation and precision. Robust camera housings and specialized lighting help machine vision systems maintain efficiency and reliable results in harsh environments. Real-time recalibration and adaptive computer vision models further support consistent performance.

Integration

Seamless integration of machine vision systems with existing manufacturing processes ensures efficiency and productivity. Manufacturers must define clear objectives for each system. Compatibility with Manufacturing Execution Systems (MES) and other technologies is essential. The integration process involves several steps:

- Align machine vision systems with manufacturing goals.

- Ensure compatibility with MES and automation equipment.

- Analyze current operations to identify integration points.

- Design imaging setups for reliable image segmentation and precision.

- Select vendors with proven expertise in computer vision models and manufacturing.

- Plan for data integration and analytics to boost efficiency.

Advanced software capabilities allow direct communication between cameras and robots. This reduces programming time and increases efficiency. AI-driven computer vision models enable rapid adaptation to new products and inspection tasks. Scalable infrastructure, including cloud-based processing, supports growing data needs and maintains high efficiency as operations expand.

Challenges

Implementing machine vision systems presents several challenges. High initial costs and uncertainty about return on investment can slow adoption. Integrating new systems with legacy infrastructure may cause compatibility issues. Manufacturers often need specialized technical expertise and ongoing training to operate and maintain these systems. Data privacy and security remain important, especially as AI and computer vision models handle sensitive production data. Environmental conditions such as lighting, dust, and vibration can impact image segmentation and precision. Scalability also poses a challenge, as evolving product designs require flexible computer vision models and efficient data management. Transparency in AI decision-making is critical for regulatory compliance and building trust.

| Challenge Area | Impact on Machine Vision Systems |

|---|---|

| Project Scope | Poorly defined scope reduces efficiency and precision. |

| Synchronization | Latency affects accuracy and image segmentation. |

| Component Selection | Wrong cameras or optics lower precision and efficiency. |

| Integration | Compatibility issues disrupt workflows and reduce efficiency. |

| Environment | Dust, vibration, and lighting changes impact image segmentation. |

| Staff Training | Lack of expertise lowers system efficiency and precision. |

| AI Transparency | Opaque computer vision models hinder trust and compliance. |

Tip: Selecting mature, proven computer vision models and robust software ensures high precision, efficiency, and adaptability in machine vision systems.

FPR machine vision systems transform manufacturing by automating inspections, reducing human error, and increasing precision. These systems improve efficiency, lower costs, and deliver reliable quality control across industries.

Key benefits include:

- Detects defects invisible to the human eye

- Automates inspections for faster production

- Collects real-time data for process optimization

| Trend | Impact on FPR Machine Vision |

|---|---|

| Edge AI | Enables instant, on-device analysis |

| Advanced 3D Vision | Improves spatial accuracy |

| Deep Learning | Boosts defect detection performance |

Future advancements in AI, optics, and edge computing will make FPR machine vision even more powerful and adaptable.

FAQ

What does "FPR" stand for in machine vision systems?

FPR stands for "Fringe Pattern Recognition." This technology uses projected patterns and advanced algorithms to capture precise 3D measurements of objects on production lines.

How does an FPR machine vision system improve quality control?

An FPR system detects defects and measures products with high accuracy. It works faster than manual inspection and reduces human error. Manufacturers use it to ensure every product meets strict quality standards.

Can FPR machine vision systems integrate with existing factory equipment?

Yes. FPR machine vision systems connect with automation equipment, such as robots and PLCs. They use standard industrial protocols for seamless integration and real-time data exchange.

What industries benefit most from FPR machine vision systems?

Industries such as automotive, electronics, pharmaceuticals, and food processing gain the most. These sectors require precise inspection, fast production, and strict quality control.

Are FPR machine vision systems difficult to maintain?

Most FPR systems feature user-friendly interfaces and self-calibration routines. Operators can perform routine maintenance with basic training. Advanced support is available from system providers if needed.

See Also

Comparing Firmware-Based Vision With Conventional Systems

Understanding The Role Of Machine Vision In Steel Production

Transforming Aerospace Manufacturing Through Advanced Vision Systems

Complete Overview Of Machine Vision Applications In Automation

Essential Tips For Proper Equipment Placement In Vision Systems