A flat light machine vision system uses a thin, uniform light source to deliver high-intensity, shadow-free illumination across inspection surfaces. In a busy electronics factory, a technician notices that poor lighting causes missed defects on circuit boards. When the team installs a flat light machine vision system, detection rates increase as lighting exposes scratches and contaminants with greater clarity. The importance of lighting becomes clear—advanced lighting now drives growth in machine vision solutions, with the market expected to double by 2032. The importance of lighting lies in its ability to reveal defects that cameras alone cannot detect.

Key Takeaways

- Flat dome lights provide even, shadow-free lighting that reveals small defects on shiny or curved surfaces, improving inspection accuracy.

- These lights use advanced coatings and controllers to reduce glare and allow flexible brightness control, ensuring clear and consistent images.

- Compared to ring and dome lights, flat dome lights reduce shadows and reflections better, making them ideal for large or reflective objects.

- Flat light systems enhance inspections in electronics, packaging, and surface defect detection by improving contrast and reducing glare.

- New technologies in 2025 include brighter LEDs, integrated 3D sensors, and AI features that boost speed, accuracy, and adaptability in inspections.

Flat Light Machine Vision System Basics

What Is a Flat Light?

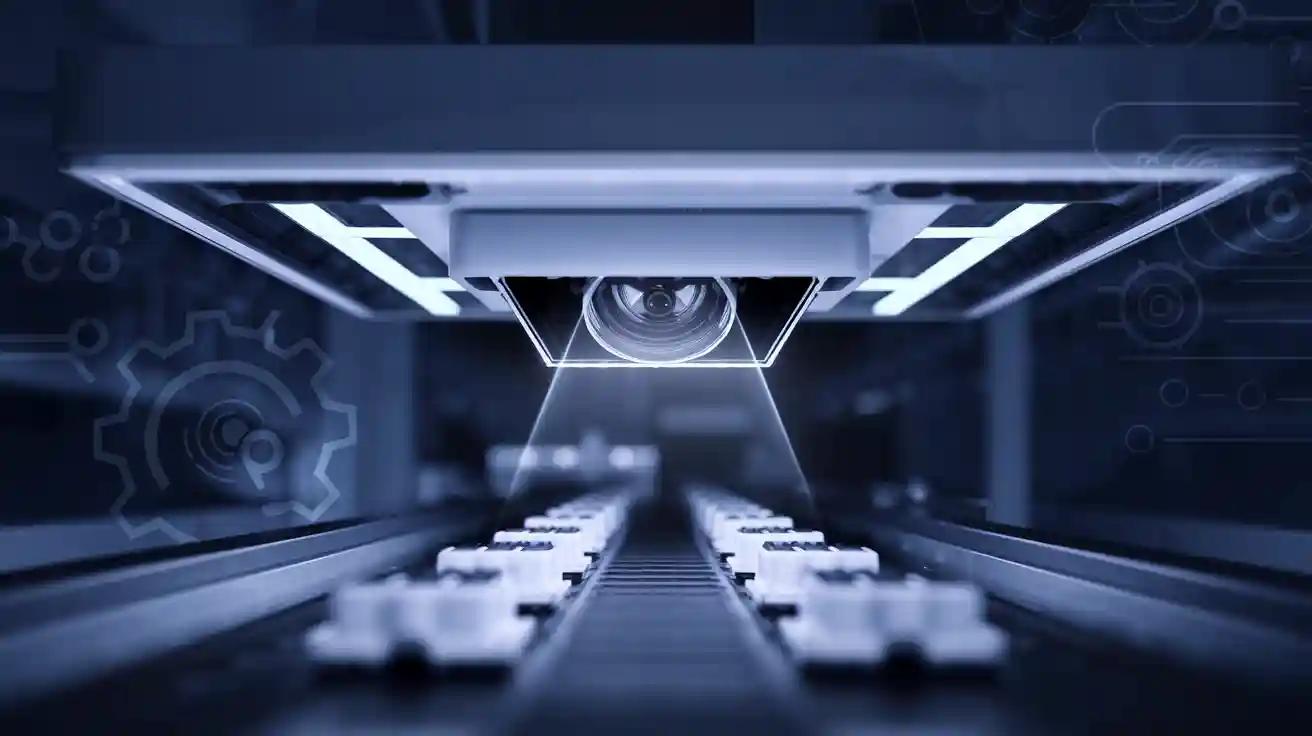

A flat dome light is a specialized lighting device used in machine vision. This type of lighting provides uniform, shadow-free illumination across flat and slightly curved surfaces. Flat dome lights help sensors in a flat light machine vision system detect small details that other lighting types might miss. These lights create even contrast without shadows or vignetting. Flat dome lights do not require close mounting to the part, which gives flexibility in system setup. Compared to other types of illumination, such as high-angle ring lights or coaxial lights, flat dome lights deliver superior image quality by avoiding poor contrast and unwanted shadows. Many industries prefer flat dome lights for enhancing image quality and reducing errors, especially on challenging surfaces.

- Flat dome lighting offers:

- Uniform, shadow-free illumination

- Enhanced detection of fine details

- Even contrast without vignetting

- Flexible mounting options

- Superior performance on reflective or curved surfaces

Core Features

Flat dome lights in a flat light machine vision system use advanced panel designs and anti-reflection systems. The CCS LFXV Series White Flat Dome Light is a common example. It provides bright, uniform white light with a color temperature near 5,500K. Manufacturers apply anti-reflection, oleophobic, and hydrophobic coatings to the diffusive window. These coatings protect the lens and improve image clarity by reducing unwanted reflections.

| Aspect | Description |

|---|---|

| Panel Design | Flat dome light with high uniformity (>90%) and camera holes for system integration |

| Anti-Reflection System | Anti-reflection coating on the diffusive window to absorb unwanted reflections |

| Additional Features | Built-in dimming controller, available in multiple sizes and camera hole diameters |

| Benefits | Improved image quality by reducing reflections, easy integration into production lines |

Flat dome lights often include on-sensor polarization technology. This feature captures polarized light from four angles in a single frame, reducing glare and reflections dynamically. The technology simplifies system design and improves performance in difficult lighting conditions, such as shiny or reflective surfaces. Flat dome lights also use analog controllers. These controllers regulate illumination by adjusting voltage or current supplied to LEDs. They ensure consistent and uniform lighting, which is critical for high uniformity illumination.

- Analog controllers offer:

- Adjustable intensity for LED brightness

- Trigger inputs to synchronize light flashing with camera triggers

- Programmable parameters for intensity, pulse width, and delay

- Support for multiple channels and communication protocols

Flat dome lights typically have a slim profile, with thicknesses ranging from 10mm to 30mm. Manufacturers use high-quality light-guide materials to achieve uniform illumination. The design ensures that the flat light machine vision system delivers reliable results in demanding environments.

How It Works

Flat dome lights achieve uniform illumination by using diffuse illumination. This method emits light from multiple directions, reducing shadows and glinting. Diffuse lighting comes from dome-shaped surfaces that scatter light evenly across the inspection area. Coaxial illumination directs light along the camera’s line of sight, providing uniform lighting that minimizes shadows and reflections. Both diffuse and coaxial lighting techniques create a consistent, shadow-free illumination field over the inspection area.

- The process includes:

- Emitting light from a dome-shaped surface for even coverage

- Scattering light to highlight subtle surface features without glare

- Using fluorescent lamps or LEDs as sources for diffuse lighting

- Combining direct illumination and diffuse techniques for optimal results

Flat dome lights support different types of illumination, including direct illumination and diffuse lighting. This flexibility allows the flat light machine vision system to adapt to various inspection tasks. The system produces high uniformity illumination, which is essential for detecting defects and ensuring product quality.

Tip: Choosing the right flat dome light and controller can improve inspection accuracy and reduce false detections.

Lighting Types Compared

Flat Light vs. Ring Light

Flat dome light and ring light represent two common types of machine vision lighting. Flat dome light creates very diffuse and even illumination. This lighting reduces glare and shadowing, making it ideal for inspecting shiny or large objects. Ring light, on the other hand, provides uniform illumination only at specific working distances. It can cause circular glare on reflective surfaces and works best for matte objects. The table below highlights the differences:

| Illumination Type | Illumination Uniformity | Glare and Shadowing | Working Distance | Key Application |

|---|---|---|---|---|

| Ring Light | Uniform at proper distances | Can cause circular glare | Short working distances | Inspection of matte objects, reduces shadowing |

| Flat Dome Light | Very diffuse and even illumination | Greatly reduces glare and shadowing | Large working distances | Imaging large, shiny objects, measurements |

Note: Flat dome light provides better results for reflective surfaces and larger inspection areas.

Flat Light vs. Dome and Coaxial

Flat dome light stands out among other types of illumination, such as traditional dome lights and coaxial lighting. Flat dome light eliminates dark spots caused by camera holes and offers diffuse illumination from all angles. This lighting works well on shiny, specular, or uneven surfaces, including metallic cylinders, wire mesh, and PCBs. Traditional dome lights and coaxial lighting often struggle with reflections and shadows, especially on uneven surfaces. Flat dome light also allows flexible working distances and easy integration due to its compact design.

| Feature/Aspect | Flat Dome Light | Dome and Coaxial Lighting |

|---|---|---|

| Shadow Reduction | Eliminates dark spots, minimizes shadows | Camera hole causes dark spots, needs extra lighting |

| Surface Compatibility | Effective on shiny, uneven, or specular surfaces | Less effective on reflective or uneven surfaces |

| Mechanical Constraints | Compact, no camera hole, easy integration | Camera hole limits design, adds bulk |

| Imaging Examples | Clear plastic, blister packs, metallic cylinders, wire mesh, wrinkled foil, PCBs | Struggles with reflections, shadows, and surface texture |

Pros and Cons

Flat dome light offers several advantages over other types of machine vision lighting. It provides superior shadow reduction, uniformity, and surface compatibility. Flat dome light works with ordinary factory automation lenses and balances between diffuse and collimated lighting. However, it emits light over a range of angles, so it may require longer working distances. Dome lights and ring lights often need to be larger than the field of view and must be placed close to the part. Collimated backlights offer parallel rays but are heavy and expensive.

| Lighting Type | Advantages | Disadvantages |

|---|---|---|

| Flat Dome Light | Superior shadow reduction, uniformity, works on shiny/uneven surfaces | Requires longer working distances, not perfectly collimated |

| Dome Light | Very diffuse, minimal shadows, suppresses glare | Large size, needs close proximity |

| Ring Light | Common, reduces shadowing on matte objects | Can cause glare, limited to short working distances |

| Collimated Backlight | Parallel rays, high accuracy | Large, heavy, expensive, limited lens compatibility |

Tip: Choosing the right types of machine vision lighting depends on the object’s surface, required uniformity, and available space. Flat dome light often delivers the best results for challenging surfaces.

Applications

Electronics Inspection

Flat light systems play a critical role in electronics inspection. They provide uniform illumination across printed circuit boards (PCBs) and electronic components. This uniformity removes uneven brightness and sensor noise, which often hide small defects. Flat-field correction techniques work with these systems to eliminate lighting artifacts. As a result, the inspection process produces clear images that reveal fine defects such as missing components, soldering issues, or surface contamination. Machine vision applications in electronics rely on this clarity for accurate detection. Flat light systems also improve edge detection, making it easier to spot irregularities along component boundaries. These benefits increase workflow efficiency and reduce the need for manual adjustments.

Packaging and Labels

Flat dome lighting improves machine vision applications in packaging and label inspection. The diffuse and uniform illumination removes reflections and glare from shiny packaging materials. This lighting enhances contrast and makes printed codes easier to read. The thin design of flat lights, often just 10 mm thick, allows installation in tight spaces on production lines. These features help inspection systems detect defects and read codes accurately, even on fast-moving conveyors. Flat light systems also support edge detection, which is important for verifying label placement and alignment.

- Flat dome lighting removes glare and reflections.

- It improves contrast and readability of printed codes.

- The slim form factor fits into limited inspection spaces.

- These features boost detection accuracy and image quality.

Surface Defect Detection

Surface inspection in industries such as automotive, medical devices, and print relies on flat light systems for reliable results. These systems provide diffuse illumination that reduces glare and enhances contrast. This lighting makes it easier to detect scratches, dents, or contamination on surfaces like painted panels, headlamp lenses, or aluminum castings. Machine vision applications benefit from consistent lighting, which supports multiple inspection tasks at a single station. Real-world case studies show that dome lights minimize reflections and shadows, improving the performance of deep learning-based defect detection systems. The table below highlights common industrial uses:

| Industry Sector | Common Applications and Benefits |

|---|---|

| Automotive | Surface inspection during assembly, detecting scratches on painted panels, quality control of parts like headlamp lenses and air brake components. |

| Consumer Electronics | Fault detection on PCBs, including missing components, soldering defects, and surface contamination. |

| Food and Beverage | Contamination detection and defect inspection on conveyor belts, ensuring product safety and quality. |

| Pharmaceuticals | Automated inspection of packaging and production lines, detecting defects and ensuring compliance with safety standards. |

| Medical Devices | Surface defect detection such as scratches or contamination on devices, using LED ring lights to reduce glare and highlight details. |

| Print and Web Inspection | Detection of print defects, missing text, color issues on labels, packaging, and newspapers. |

Note: Flat light systems enable robust surface inspection by reducing glare and improving contrast, which leads to more accurate detection in machine vision applications.

Selection Guide

Size and Shape

Selecting the right size and shape for a flat light system ensures optimal performance in any inspection environment. Several factors guide this choice:

- Geometry: The spatial relationship among the sample, light, and camera determines the best fit. The light must match the physical constraints of the workspace.

- Structure or Pattern: The projected light shape should complement the sample’s geometry. This maximizes contrast and feature visibility.

- Inspection Environment: Robotic arms, support structures, or tight spaces may limit the available size and shape.

- Sample Characteristics: The object’s size, surface reflectivity, and color influence how light interacts with it.

- Consistency in Placement: Stable part positioning allows for more tailored lighting, while variable placement may require larger or more diffuse lights.

- Lighting Robustness: The system should handle changes in part size, orientation, or environmental conditions.

Tip: Adjusting the light’s shape and size can help avoid glare and hotspots, improving image quality for reliable detection.

Color and Intensity

The choice of LED color and intensity plays a crucial role in inspection accuracy. White LEDs with different color temperatures affect how the system perceives colors and subtle shades. A high Color Rendering Index (CRI) ensures realistic color reproduction, which is vital for tasks like matching automotive interior panels. Matching the LED’s spectral output to the camera’s sensitivity enhances performance, especially in low-light conditions. High-intensity LEDs, used in short bursts or strobes, freeze motion and prevent image blur during high-speed inspections. Proper synchronization between strobe timing and camera exposure ensures sharp, high-contrast images, which is essential for precise detection.

Integration Tips

Integrating flat light systems with cameras and controllers requires careful planning. The table below summarizes lighting techniques and their effects:

| Lighting Technique | Effect | Suitable Inspection Type |

|---|---|---|

| Frontlighting | Uniform illumination, reduces shadows | Surface inspection, barcode reading |

| Darkfield Lighting | Highlights imperfections, reduces shadows | Reflective or specular surfaces |

| Ring Lighting | Even illumination, minimizes glare | Flat or cylindrical surfaces |

| Diffuse Lighting | Softens shadows, reduces reflections | Textured or irregular surfaces |

| Coaxial Lighting | Eliminates shadows, highlights features | Highly reflective surfaces |

| Backlighting | Creates silhouette effect | Transparent or translucent materials |

- Select the right color temperature to enhance model accuracy.

- Use dimmers or PWM controllers to adjust intensity and coordinate with camera exposure.

- Test lighting setups under different conditions for consistent results.

Flat light systems offer continuous, analog, and strobe modes. Continuous mode provides steady illumination for general imaging. Strobe mode synchronizes pulsed lighting with camera exposure, reducing motion blur. Analog control allows fine-tuning of brightness and pulse length, giving flexibility for various inspection scenarios.

Trends for 2025

New Technologies

Flat dome light systems in 2025 will feature several technological breakthroughs. Manufacturers now use high-power models and dual LED arrays to deliver intense, wide-area illumination. These upgrades allow flat dome light units to maintain high brightness and stability, even in challenging industrial environments. The following table highlights how these features improve inspection:

| Feature | PRO-400 Series | PRO-500 Series |

|---|---|---|

| Maximum Intensity at 15" | 5,000 µW/cm² | >14,000 µW/cm² |

| Beam Diameter at 15" | 10" (>1,000 µW/cm²) | 10" (>1,000 µW/cm²) |

| LED Configuration | Dual LED (UV-A/Visible) | Ultra-high spot |

| Ruggedness | Waterproof, IP65 | Waterproof, IP65 |

| Cooling | No fan, stays cool | No fan, stays cool |

Flat dome light systems now integrate advanced image sensors, such as Time-of-Flight and 3D imaging sensors. These sensors enable depth measurement and object recognition. Global shutter CMOS sensors provide high-speed, low-distortion imaging. Some flat dome light models use short-wave infrared detectors for specialized inspections. Manufacturers also embed AI processing in smart cameras, allowing real-time analysis and faster defect detection. Innovations in Contact Image Sensor technology combine camera, lens, and flat dome light into compact modules, ideal for tight production lines. The trend toward combining 2D and 3D vision systems continues, improving inspection accuracy and enabling robotic guidance.

Evolving Needs

Industrial inspection demands continue to evolve. Flat dome light systems must adapt to new requirements for object shape, texture, and material. Inspection lines now require tailored lighting strategies. For example, backlighting works best for flat surfaces, while dome lighting suits curved objects. Controlling the angle and placement of flat dome light units helps highlight surface flaws and improve defect visibility. Color wavelength selection, such as red for general imaging or blue for material-specific details, enhances contrast.

Lighting stability and brightness must remain consistent for reliable results. Flat dome light systems offer flexible form factors and mounting options, supporting diverse industrial needs. AI-powered pose estimation and advanced 2D/3D alignment techniques now play a key role. These features help flat dome light systems detect object position and orientation in real time. Manufacturers also introduce innovations in anti-reflection and light-guide materials. Integrated analog controllers allow precise dimming. Anti-reflection systems absorb stray light, while light guiding diffusion plates project patterns for defect detection. Thin, compact housings and multiple LED colors make flat dome light systems versatile for many applications.

Note: Flat dome light technology now meets higher standards for accuracy, speed, and adaptability, supporting the future of automated inspection.

Flat light machine vision systems deliver unique advantages for modern inspection tasks:

- Eliminate dark spots and reduce glare, especially on reflective surfaces.

- Save space with slim, see-through LED designs.

- Offer adjustable working distances and flexible wavelength options.

- Adapt to various applications and improve inspection quality.

Manufacturers should assess their inspection needs, object characteristics, and integration requirements. The Practical Guide to Machine Vision provides a strong framework for matching lighting to inspection goals, ensuring robust and efficient system implementation in 2025.

FAQ

What makes flat light systems better for shiny surfaces?

Flat light systems use diffuse illumination. This reduces glare and shadows on reflective surfaces. Cameras capture more detail, which improves defect detection. Many industries choose flat lights for inspecting metal, glass, or plastic parts.

Can flat light systems work with any camera?

Most flat light systems support standard industrial cameras. Users should check compatibility with camera mounts and controllers. Some systems offer adjustable camera holes for easy integration.

How do users control the brightness of flat light systems?

Analog controllers let users adjust LED brightness. Many systems support both continuous and strobe modes. This flexibility helps match lighting to different inspection needs.

Are flat light systems energy efficient?

Yes, flat light systems use LEDs, which consume less power than traditional lamps. Efficient designs also reduce heat, which extends system life and lowers maintenance costs.

What maintenance do flat light systems require?

Users should keep the diffusive window clean and check for dust or scratches. Regular inspection ensures consistent lighting. Most systems need little maintenance due to durable LED technology.

Tip: Always follow the manufacturer’s cleaning guidelines to avoid damaging coatings or lenses.

See Also

A Comprehensive Look At Inspection Vision Systems In 2025

Breaking Down Machine Vision Systems For Electronics Industry

How Cameras Function Within Machine Vision Systems Overview

Essential Guide To Machine Vision Systems For Semiconductors