A f number machine vision system uses the f-number to control image brightness and clarity. The f-number, calculated by dividing focal length by aperture diameter, determines how much light enters the lens. In any f number machine vision system, the f number affects both depth of field and image quality. Proper understanding of the f number allows engineers to optimize a machine vision system for sharpness and accuracy.

Key Takeaways

- The f-number controls how much light enters a lens, affecting image brightness and clarity in machine vision systems.

- Lower f-numbers let in more light and allow faster imaging but reduce depth of field, making less of the object stay in focus.

- Higher f-numbers increase depth of field and reduce optical errors but require more light or longer exposure times.

- Choosing the right f-number balances brightness, focus range, and image sharpness to fit the specific needs of the application.

- Matching the f-number with the lens and sensor ensures clear, sharp images and reliable machine vision system performance.

F-Number Fundamentals

What Is F-Number?

The f-number, also known as the f-stop, describes the relationship between a lens’s focal length and the diameter of its aperture. In simple terms, the f-number tells how wide the lens opens to let light pass through. A lower f-number means a wider opening, which allows more light to reach the sensor. A higher f-number means a smaller opening, which lets in less light. This concept is essential in any f number machine vision system because it directly affects image brightness and clarity.

The f-number sequence follows a geometric pattern. Each step in the sequence changes the amount of light by a factor of two. The standard f-number sequence includes values like 1, 1.4, 2, 2.8, 4, 5.6, 8, 11, 16, and 22. For example:

- f/1 means the aperture diameter equals the focal length.

- f/2 means the aperture diameter is half the focal length.

- Each increase in f-stop halves the light entering the lens.

This sequence helps engineers control exposure and image quality in a machine vision system.

F-Number Formula

The f-number formula is simple but powerful. It is written as:

f-number (N) = focal length (f) / aperture diameter (D)

This formula shows that the f-number depends on both the focal length and the size of the lens opening. For a fixed focal length, increasing the aperture diameter lowers the f-number and increases light transmission. In contrast, decreasing the aperture diameter raises the f-number and reduces the light entering the lens.

In machine vision optics, engineers often use several formulas to calculate the f-number and related parameters:

| Formula/Concept | Expression/Description |

|---|---|

| Basic f-number (at infinite WD) | f/# (defined at infinite working distance where magnification m ≈ 0) |

| Working f-number (f/#)w | (f/#)w ≈ (1 + m) × (f/#), where m is magnification (image height/object height) |

| Relationship with Numerical Aperture (NA) | NA = 1 / (2 × f/#), showing inverse relationship between NA and f/# |

For example, a lens with a focal length of 50 mm and an aperture diameter of 25 mm has an f-number of 2 (f/2). If the aperture diameter decreases to 12.5 mm, the f-number becomes 4 (f/4). This change reduces the light entering the lens by a factor of four.

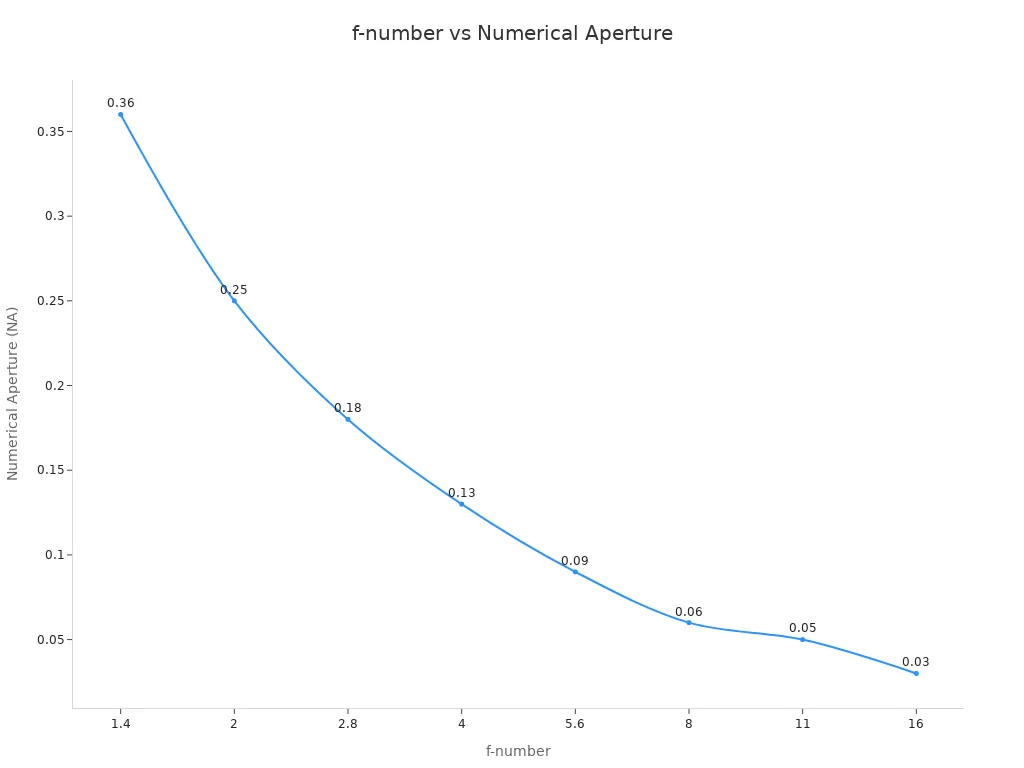

The table below shows how f-number and numerical aperture relate:

| f/# | 1.4 | 2 | 2.8 | 4 | 5.6 | 8 | 11 | 16 |

|---|---|---|---|---|---|---|---|---|

| NA | 0.36 | 0.25 | 0.18 | 0.13 | 0.09 | 0.06 | 0.05 | 0.03 |

The chart below illustrates the inverse relationship between f-number and numerical aperture, which is important in lens technology and camera technology:

F-Number in Machine Vision Systems

The f-number plays a central role in every f number machine vision system. It determines how much light reaches the sensor, which affects image brightness, exposure time, and the ability to capture fine details. In industrial settings, engineers must balance the f-number with the lens’s focal length to achieve the right depth of field and sharpness.

A lower f-number (wider aperture) allows more light to enter, which is useful in low-light environments or when fast exposure times are needed. However, a lower f-number can also reduce depth of field, making it harder to keep the entire object in focus. A higher f-number (narrower aperture) increases depth of field and reduces optical errors like spherical aberration, but it requires more light or longer exposure times.

Tip: Selecting the right f-number and lens combination is crucial for optimizing image quality and system performance in machine vision applications.

Impact on Image Quality

Light Throughput

The f-number plays a crucial role in determining how much light passes through the lens and reaches the sensor. Lower f-numbers, or wider apertures, allow more light to enter. This results in brighter images when the ISO and shutter speed remain constant. Higher f-numbers, or smaller apertures, restrict the amount of light, making images darker. This relationship forms the foundation for controlling exposure in a f number machine vision system.

When engineers adjust the f-stop, they directly influence the brightness of the image sensor output. For example, moving from f/2 to f/4 reduces the light by half, which can make the image appear much darker if other settings do not change. This principle is part of the exposure triangle, which includes f-number, shutter speed, and ISO. Each element must be balanced to achieve the desired image quality.

Note: Lowering the f-number increases light throughput, which is especially helpful in low-light environments or when fast imaging is required.

Depth of Field

Depth of field describes the range within the field of view that appears sharp and in focus. The f-number has a direct impact on this range. Increasing the f-number (using a smaller aperture) expands the depth of field, allowing more of the object to remain in focus from front to back. Decreasing the f-number (using a wider aperture) narrows the depth of field, which can make only a thin slice of the object appear sharp.

The relationship between f-number and depth of field can be described by the formula:

DOF ≈ (2 * u² * N * c) / f²

where DOF is depth of field, u is subject distance, N is the f-number, c is the circle of confusion, and f is the focal length.

In practical terms, a higher f-number helps keep more of the object in focus, which is important when inspecting parts with varying heights. However, increasing the f-number reduces the amount of light reaching the sensor, which may require longer exposure times or stronger illumination. This trade-off is a key consideration in machine vision applications.

- A low f-number (wide aperture) provides a shallow depth of field and faster exposure.

- A high f-number (narrow aperture) increases depth of field but may slow down imaging due to less light.

Tip: Engineers must balance the need for depth of field with the available lighting and required imaging speed.

Resolution & Contrast

The f-number also affects the ability of the lens and image sensor to resolve fine details and maintain contrast. Lowering the f-number increases the numerical aperture (NA), which improves the system’s ability to distinguish small features. This is critical in high-precision industrial image analysis, where resolving fine lines or small defects is essential.

However, using the lowest possible f-number does not always produce the best results. With the aperture fully open, images outside the depth of field can appear blurry and lose contrast. Partially closing the aperture (increasing the f-stop) often improves sharpness and makes features more legible. If the aperture becomes too small, diffraction can reduce both resolution and contrast, and the image sensor may not receive enough light.

The table below summarizes the impact of f-number on key imaging parameters:

| Parameter | Low f-number (Wide Aperture) | High f-number (Narrow Aperture) |

|---|---|---|

| Light Throughput | High | Low |

| Depth of Field | Shallow | Deep |

| Resolution | High (if in focus) | Moderate (diffraction limited) |

| Contrast | High (center), lower edges | Improved across field |

| Exposure Time | Short | Long |

A well-chosen f-number allows the lens and image sensor to capture sharp, high-contrast images with the right balance of depth of field and exposure. In a f number machine vision system, engineers often test different f-stop settings to find the optimal point for their specific field of view and inspection requirements.

Callout: Decreasing the f-number increases NA, which enhances resolution and contrast but reduces depth of field. Increasing the f-number improves depth of field but may lower resolution due to diffraction and reduce light throughput.

Practical Trade-Offs

High vs. Low F-Number

Choosing between a high or low f-number in a f number machine vision system depends on the application’s needs. Engineers often select a high f-number (small aperture) when they need to maximize depth of field. This approach works well for imaging objects with varying heights or when multiple planes must stay in focus. High f-numbers also help reduce optical aberrations, such as spherical aberration and coma, which improves image quality. However, using a high f-number means less light reaches the sensor, so the system may require stronger lighting or longer exposure times. Diffraction can also limit resolution at very high f-numbers, so engineers must balance these factors.

- High f-number is preferred when:

- Maximizing depth of field is critical.

- Reducing optical aberrations is important.

- Sufficient lighting or longer exposure times are available.

- Motion is minimal.

A low f-number (wide aperture) allows more light to reach the sensor, which is ideal for low-light conditions or when fast imaging is necessary. This setting provides a shallow depth of field and may introduce more optical aberrations, but it enables shorter exposure times.

Exposure Time & Motion

The f-number directly affects exposure time and the risk of motion blur. A low f-number, or wide aperture, lets in more light, allowing the system to use shorter exposure times. This reduces the chance of motion blur, which is essential in high-speed machine vision applications. High f-numbers restrict light, requiring longer exposures and increasing the risk of blur if objects move quickly. Studies show that shorter exposure times significantly reduce motion blur, even under different lighting conditions. Increasing illumination intensity can help maintain image sharpness by supporting faster shutter speeds. For fast-moving industrial processes, engineers recommend using lenses with low f-numbers to minimize motion blur, even if it means accepting a shallower depth of field.

Tip: For high-speed imaging, prioritize a low f-number and strong lighting to achieve sharp images with minimal blur.

Machine Vision Lenses Compatibility

Machine vision lenses must accommodate a range of f-numbers to suit different applications. Adjusting the aperture changes the f-stop, which influences both depth of field and the amount of light reaching the sensor. Lens mounts, such as C-mount or F-mount, have different maximum aperture sizes. Larger mounts support lower minimum f-numbers, allowing more light for larger sensors. Compatibility issues can arise if the lens does not match the sensor size. For example, using a lens designed for a smaller sensor can cause vignetting, where the image edges appear dark. Engineers should always select a lens that matches or exceeds the sensor size to ensure full coverage and optimal performance.

| Factor | Explanation |

|---|---|

| Application and Use Case | Determines lighting and focus needs. |

| Working Distance | Affects lens choice and compatibility with sensor size. |

| Resolution Requirement | Sensor resolution must match lens resolving power. |

| Depth of Field (DoF) | Controlled by f-number; smaller f-number means shallow DoF, larger f-number means deeper DoF. |

| Field of View (FOV) | Lens focal length and sensor size must align to avoid vignetting. |

| Operating Wavelength | Lens materials and coatings must suit sensor sensitivity. |

| Image Sensor Parameters | Pixel size and sensor format influence lens selection. |

| Lens Parameters | Includes focal length, f-number, image circle size, and back focal distance for compatibility. |

Selecting the right combination of f-number, lens, and sensor ensures the f number machine vision system delivers accurate and reliable results.

Choosing the Right F-Number

Application Guidelines

Selecting the right f-number for a machine vision system involves several key steps. Engineers should start by evaluating the application’s requirements, including lighting, object size, and inspection speed. These factors influence the amount of light needed and the depth of field required for clear images.

- High-speed inspection needs intense, well-timed lighting to freeze motion and avoid blur. If lighting is limited or not synchronized, a lower f-number (wider aperture) helps more light reach the sensor.

- The size of the object and the required resolution determine the necessary depth of field. Larger objects can use higher f-numbers for greater focus range, while smaller features benefit from lower f-numbers to maximize resolution and light throughput.

- The field of view must match the sensor and lens combination to avoid vignetting and ensure full coverage.

| f/# | Aperture Diameter (mm) | Relative Light Throughput |

|---|---|---|

| 1 | Largest aperture | Maximum light |

| 2 | Medium aperture | Reduced light (about 1/4) |

| 4 | Smaller aperture | Further reduced light |

Engineers should balance these factors to meet the application’s quality requirements without overspecifying components.

Example Use Cases

Low f-number settings (such as f/1 to f/2) are common in applications that demand maximum light throughput. These include uncooled infrared imaging, semiconductor inspection, and embedded cameras operating in low-light environments. Wide aperture lenses improve photon detection efficiency, which is critical for capturing weak signals or high-speed events.

- Short-Wave Infrared (SWIR) imaging uses low f-numbers to achieve high resolution in low-visibility conditions.

- Quality control tasks with fast-moving parts benefit from low f-numbers to reduce motion blur.

High f-number settings (such as f/5.6 or above) are preferred when depth of field and sharpness are more important than light throughput. For example, inspecting large objects with varying heights requires a higher f-number to keep the entire object in focus. In challenging environments, increasing the f-number reduces blur and improves image quality, but may require longer exposure times or brighter lighting.

Tips for Machine Vision Lenses

When selecting a machine vision lens, engineers should consider several practical tips:

- Understand the diffraction limit, which depends on the f-number and the wavelength of light. Calculate the Airy disk diameter to ensure the lens spot size matches the sensor’s pixel size.

- Adjust the effective f-number for the actual working distance using the finite f-number formula.

- Use lenses with low f-numbers to achieve sensor-limited resolution, especially as pixel sizes decrease.

- Consult lens manufacturers about performance at specific working distances and magnifications.

- Prefer machine vision lenses over repurposed photographic lenses for better manufacturing tolerances and alignment.

- Verify sensor-to-lens alignment to reduce defocusing risks, especially with high pixel density sensors.

- Recognize that as the f-number decreases, lens design becomes more challenging, so practical limits exist.

Tip: Matching the f-number with the sensor and application needs ensures optimal image quality and reliable system performance.

- The f-number controls how much light enters the lens, which affects exposure, depth of field, and image clarity.

- A small f-number gives more light and better contrast but reduces depth of field. A large f-number increases depth of field but can lower resolution due to diffraction.

- The best results come from choosing the largest aperture that still provides enough depth of field for the task.

Industry experts suggest balancing resolution and depth of field rather than only maximizing light. Testing the camera and lens together helps ensure the chosen f-number fits the application. Avoid common mistakes like ignoring working f-number at close distances or mismatching lens and sensor performance. By weighing these trade-offs, engineers can achieve reliable and sharp images in any machine vision system.

FAQ

What does the f-number control in a machine vision lens?

The f-number controls how much light enters the lens. It also affects the depth of field and the sharpness of the image. Engineers use it to balance brightness and focus.

How does a low f-number affect image quality?

A low f-number lets in more light and creates a brighter image. It also gives a shallow depth of field. This helps in low-light or high-speed applications but can make some parts of the image blurry.

Why is depth of field important in machine vision?

Depth of field keeps more of the object in focus. In machine vision, a deep depth of field helps inspect objects with different heights. A shallow depth of field may miss important details.

Can changing the f-number reduce motion blur?

Yes. Lowering the f-number allows more light, so the system can use a faster shutter speed. This reduces motion blur when inspecting moving parts.

How should engineers choose the right f-number?

Engineers should consider lighting, object size, and required sharpness. They test different f-numbers to find the best balance between brightness, depth of field, and resolution for the application.

Tip: Always match the f-number to the lens and sensor for the best results.

See Also

Understanding The Role Of Cameras In Vision Systems

Essential Camera Resolution Concepts For Machine Vision

Exploring Pixel-Based Machine Vision In Today’s Applications