A dome light machine vision system uses a special lighting device to create soft, even light from all directions. This system helps cameras inspect objects by removing shadows and reflections, making it easier to see small details. Many industries, such as automotive, electronics, and packaging, rely on dome light machine vision systems to check parts with shiny or curved surfaces. The importance of lighting stands out in these inspections because even light means fewer errors and better quality control.

Key Takeaways

- Dome lights provide soft, even light from all directions, removing shadows and glare for clearer images.

- They work best on shiny, curved, or uneven surfaces, helping detect small defects and improve inspection accuracy.

- Compared to ring, bar, and backlights, dome lights excel at reducing reflections on complex shapes.

- Uniform lighting from dome lights supports reliable, repeatable inspections and boosts quality control.

- Dome light systems need close placement and enough space, and they require training and maintenance for best results.

How It Works

Key Parts

A dome light machine vision system uses several important components that work together to create clear, detailed images for inspection. Each part plays a unique role in the setup:

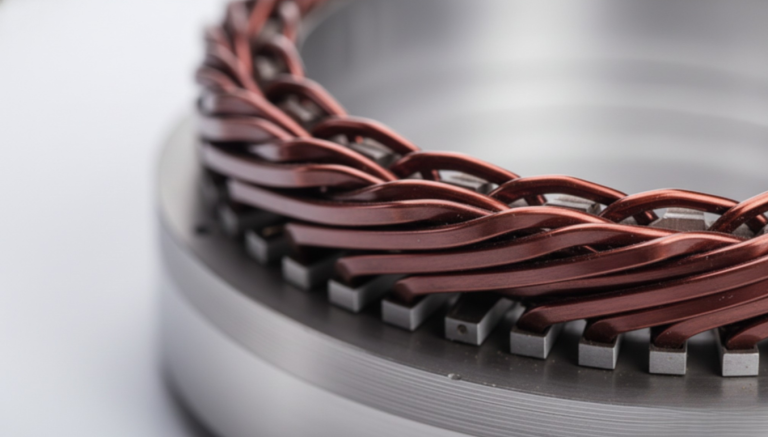

- Dome Lighting: This component surrounds the object and provides uniform illumination from many angles. It removes glare and shadows, which is especially important for inspecting curved or shiny surfaces.

- Polarizers: These filters sit in front of the camera lens and the LEDs. They reduce glare and hot spots, making it easier to see fine details by improving contrast.

- Color Filters: These filters help highlight certain features by making them lighter or darker. This makes it easier to spot differences or defects on the object.

- Optics (Lenses and Optical Elements): The camera uses lenses to focus and capture the image. Good optics ensure the image is sharp and clear, which is necessary for accurate inspection.

This setup improves image quality by reducing unwanted reflections and ensuring the machine vision system collects consistent, detailed data.

Even Illumination

Dome lighting creates a special kind of light that covers the object from all directions, much like the soft, even light on a cloudy day. The design uses a dome or a flat dome with a dense array of tiny micro-reflectors. These micro-reflectors spread the light evenly across the object, removing any bright spots or shadows. The camera looks through a clear section of the dome, so it can capture the image without any mechanical barriers.

Note: This setup works best when the dome light sits close to the object. The close distance ensures the light covers every part of the surface, even if the object is curved or shiny.

Light from the dome hits the object from every angle. This indirect, multidirectional illumination prevents dark spots and reflections that can hide important details. The latest flat dome designs improve image quality even more by removing dot patterns and making the light even brighter and clearer. This helps the system inspect shiny, uneven, or transparent surfaces without missing any features.

Dome lights work especially well for objects with curved, specular, or mixed reflectivity surfaces. They help the machine vision system detect features that might be hard to see with other lighting setups. By providing even illumination, dome lights make it easier to find defects or read small codes, even on challenging surfaces.

Lighting Problems

Shadows and Glare

Traditional machine vision systems often struggle with lighting problems that affect inspection accuracy. Shadows can hide important details on an object, making it hard for the camera to detect small defects. Glare and reflections can distort images, especially when inspecting shiny or curved surfaces. These issues become worse when the light source is too direct or uneven. Inconsistent light intensity can cause some parts of the image to appear too bright while others remain too dark. This makes it difficult for the system to recognize objects or spot flaws.

Shadows and glare do more than just make images look unclear. They also reduce the system’s ability to find defects and can lead to false alarms. For example, glare can wash out parts of an image, causing the camera to miss scratches or dents. Shadows can cover up cracks or other problems, leading to missed defects. In high-speed applications, finding the right lighting solution becomes even more important because motion blur can add to these challenges. The importance of lighting stands out in these situations, as poor lighting can lead to more errors and lower product quality.

Dome Light Solutions

A dome light machine vision system offers a powerful lighting solution for these common problems. The dome shape spreads light evenly over the object, much like a cloudy sky softens sunlight. This even, diffuse light reduces both shadows and glare, making it easier for the camera to capture clear images. Photographic comparisons show that dome lighting removes most reflections and hot spots, which standard lighting strategies cannot achieve.

The dome light machine vision system works especially well for complex or reflective surfaces. Uniform illumination from all directions helps the system see fine details and shapes that other lighting solutions might miss. This approach improves defect detection rates and lowers the chance of false positives. By using advanced lighting strategies, such as dome lighting, industries can achieve more reliable inspections and better quality control.

Applications in Machine Vision System

Typical Uses

Dome light illumination plays a vital role in many machine vision applications. Engineers often select dome lights when they need to inspect objects with curved, shiny, or uneven surfaces. The uniform, non-directional lighting from a dome light helps the camera see every detail, even on tricky surfaces. This approach works well for tasks such as:

- Surface inspection for cracks, chips, stains, or marks

- Solder and substrate inspection in electronics

- Checking printing quality on shiny metal or plastic packaging

- Authentication of security features on banknotes, pharmaceuticals, or luxury goods

- Fluorescence inspection, where even lighting is critical

Dome lights create a "cloudy day" effect, which means the light covers the object from all directions. This effect helps the machine vision system detect defects that might hide under shadows or glare with other lighting types. Many machine vision applications benefit from this even illumination, especially when the object has a complex shape or a glossy finish.

Tip: Dome lights work best for machine vision applications that involve curved, reflective, or mixed-material surfaces.

Industries

Many industries rely on dome light illumination to improve inspection accuracy. The following table shows where dome lights fit best:

| Lighting Type | Application | Characteristics |

|---|---|---|

| Dome Lights | Inspection of objects with complex shapes or reflective surfaces | Provide diffuse illumination that reduces shadows and glare, ideal for uniform lighting on irregular or glossy surfaces |

Electronics manufacturing uses dome lights for solder and substrate inspection. The packaging industry depends on dome lights to check printing on shiny materials. Automotive factories use dome lights to inspect metal and glass parts. Pharmaceutical companies and luxury goods manufacturers use dome lights to verify security features and ensure product authenticity.

Dome lights help these industries achieve reliable results in machine vision applications. They support quality control by making it easier to spot flaws, even on challenging surfaces.

Choosing the Right Lighting

Selecting the right lighting is essential for successful machine vision inspections. Different lighting techniques work best for different objects and inspection goals. Understanding the strengths of each option helps engineers achieve lighting optimization and reliable results.

Dome Light vs. Ring Light

Dome lights and ring lights both aim to reduce shadows, but they excel in different situations:

- Dome lights scatter light from all directions, creating diffuse illumination. This approach works well for shiny, curved, or irregular surfaces. Dome lights minimize glare and shadows, making them ideal for complex shapes.

- Ring lights provide uniform, shadow-free lighting, especially on flat or simple surfaces. They deliver precise illumination that enhances defect detection and image clarity. Ring lights are cost-effective and easy to use.

- Dome lights outperform ring lights when inspecting objects with mixed reflectivity or uneven surfaces. Ring lights work best for edge detection and brightfield imaging on flat parts.

Tip: Choose dome lights for curved or reflective items. Use ring lights for flat, simple surfaces where uniformity is key.

Dome Light vs. Bar Light

Bar lights offer directional lighting from one side or multiple sides. This method highlights surface features and textures. However, bar lights can create shadows and glare on shiny or uneven objects. Dome lights, in contrast, provide even illumination from all angles. This makes dome lights the right lighting choice for reducing unwanted reflections on complex parts. Bar lights suit applications where highlighting topographic details matters more than minimizing glare.

Dome Light vs. Backlight

Backlights shine light from behind the object, creating a silhouette. This technique works well for detecting holes, gaps, or edges. However, backlighting does not reveal surface texture or reflective details. Dome lights excel at inspecting shiny, curved, or textured surfaces by minimizing glare and providing even illumination. When the inspection requires surface detail and glare reduction, dome lights offer the right lighting solution.

| Lighting Type | Best For | Limitations |

|---|---|---|

| Dome Light | Curved, shiny, or complex surfaces | Needs close placement, less suited for fine detail on flat parts |

| Ring Light | Flat, simple surfaces, edge detection | Less effective on irregular shapes |

| Bar Light | Highlighting textures, topography | Can cause shadows/glare on shiny surfaces |

| Backlight | Silhouette, edge, hole detection | No surface detail, not for reflective surfaces |

Selecting the right lighting depends on surface shape, reflectivity, and inspection needs. Dome lights provide the best results for curved or shiny objects, while other lighting techniques may suit flat or textured parts. Careful lighting optimization ensures accurate inspections and high-quality images.

Dome Light Machine Vision System Benefits

Main Advantages

A dome light machine vision system offers several important benefits for industrial inspection. The most significant advantage is its ability to provide uniform, diffuse illumination. This lighting covers the object from every angle, which reduces shadows, glare, and reflections. As a result, cameras can capture clear images, even on shiny or curved surfaces.

Uniform lighting improves defect detection rates in automated inspection processes. For example, when using advanced dome lights such as the VL-D430W, automated optical inspection systems can spot defects more accurately. The consistent, homogeneous light helps deep learning models like YOLOv8 find small flaws that might otherwise go unnoticed. This setup increases recall rates and reduces false negatives, which means fewer missed defects and better quality control.

Consistent lighting also supports reliable image-based analysis. When the lighting does not change, inspection results stay accurate over time.

Dome lights help prevent ambient light problems that can affect machine vision accuracy. By creating a stable lighting environment, they reduce errors and increase productivity in industrial settings. The energy efficiency and steady performance of modern dome lights support repeatable inspections, which is critical for high-speed production lines.

Emerging technologies can make dome light systems even more powerful. Adaptive lighting control can adjust brightness based on the object’s reflectivity. Polarized illumination can further reduce unwanted reflections. Multi-spectral imaging can reveal surface features that standard lighting might miss. These advancements, when combined with dome lighting, create robust and adaptable inspection solutions.

A summary of the main advantages appears below:

| Benefit | Description |

|---|---|

| Uniform Illumination | Even light from all directions eliminates shadows and glare |

| Improved Defect Detection | Higher accuracy for finding flaws, especially on reflective surfaces |

| Reliable Inspection | Consistent lighting ensures repeatable results |

| Enhanced Image Quality | Clearer images support advanced AI and software analysis |

| Productivity Boost | Fewer errors and false alarms increase efficiency |

| Adaptability | Works well with new technologies like adaptive and polarized lighting |

Limitations

Despite many strengths, dome light machine vision systems have some limitations that users must consider. The physical size of the dome light often presents challenges. Dome lights must be much larger than the area being inspected—sometimes nearly twice as large. This requirement can make the system bulky and difficult to fit into tight spaces.

The setup needs the dome light to sit very close to the object. If machine parts or fixtures block the light, image quality drops. Clearance issues for both lighting and camera placement can complicate installation. In some cases, the workpiece holder may obstruct the light, making integration harder.

Note: Dome lights typically max out at about 300 mm in size. This limit restricts the field of view and may not suit large objects.

Cost is another important factor. Dome lights are often more expensive than other lighting options. The need for a larger light and precise placement increases both material and installation costs.

Operating and maintaining these systems requires specialized knowledge. Teams need training in illumination, optics, and filters to optimize performance. Vendors often provide hands-on and online training, but regular updates and maintenance remain necessary. Hardware components such as cameras and lights may need replacement over time. Partnering with vendors who offer strong support services can help keep the system running smoothly.

A summary of the main limitations appears below:

- Dome lights must be much larger than the inspection area.

- The system requires close placement to the object, which can be difficult in crowded setups.

- Physical constraints and fixtures may block the light or camera.

- Dome lights are more expensive than many other lighting types.

- Maximum size limits the field of view for large parts.

- Specialized training and ongoing maintenance are necessary for best results.

| Limitation | Impact |

|---|---|

| Large Physical Size | Hard to fit in tight spaces |

| Close Placement Needed | May not work with bulky fixtures or large objects |

| High Cost | Increases project expenses |

| Integration Challenges | Fixtures and machine parts can block light |

| Training Requirements | Operators need expert knowledge and regular updates |

Dome light machine vision systems deliver uniform, diffused illumination that reduces shadows and glare. Their hemispherical design surrounds objects with light, making them ideal for inspecting reflective or curved surfaces. Key benefits include:

- Consistent, high-quality images

- Fewer shadows and highlights

- Reliable detection of defects

When choosing lighting, users should match the technique to part size, shape, and inspection goals. Dome lights often provide the best results for complex surfaces. Selecting the right lighting ensures accurate inspections and supports quality control. 😊

FAQ

What is the main purpose of a dome light in machine vision?

A dome light provides even, shadow-free illumination. This lighting helps cameras capture clear images of objects, especially those with shiny or curved surfaces. Uniform light improves inspection accuracy and reduces errors.

Can dome lights work with all types of surfaces?

Dome lights perform best on curved, glossy, or uneven surfaces. They may not suit flat parts that need detailed edge detection. For those cases, engineers often choose ring or backlighting solutions.

How close should the dome light be to the object?

The dome light should sit as close as possible to the object. This placement ensures the light covers every part of the surface. If the dome sits too far away, shadows and glare may appear.

Are dome light systems difficult to install?

Installation can be challenging in tight spaces. Dome lights require enough room around the object. Proper placement and alignment are important for best results. Many vendors offer support and training for setup.

Do dome lights need regular maintenance?

Yes. Dome lights and cameras need cleaning and occasional checks. Operators should inspect for dust or damage. Regular maintenance keeps the system working well and ensures high-quality inspections.

See Also

Understanding The Role Of Cameras In Vision Systems

A Comprehensive Guide To Electronics In Vision Systems

Defining Illumination Techniques In Machine Vision Systems