Defect detection machine vision systems revolutionize how you identify and address flaws in production processes. These systems use advanced computer vision technologies to inspect products with exceptional precision, ensuring consistent quality while minimizing waste. Industries benefit from reduced defective products by 99%, faster inspections, and a 40% boost in productivity compared to manual methods. With object detection accuracy reaching 98.5%, you can rely on these systems to deliver reliable results in complex environments. The global computer vision market, projected to grow from $13.45 billion in 2022 to $48.6 billion by 2026, highlights the transformative role of automated quality assurance in modern manufacturing.

Key Takeaways

-

Machine vision systems find defects using smart tools to check products. They cut defective items by 99%.

-

AI systems adjust to new rules without needing reprogramming. This makes them great for changing work environments.

-

Good lighting and clear cameras are key to spotting defects. They help find even tiny problems.

-

Automated systems work fast, checking items in seconds. This saves money and reduces waste.

-

Using AI defect detection helps businesses stay strong. It keeps quality steady and adapts to competition.

Overview of Machine Vision Systems

What is a machine vision system?

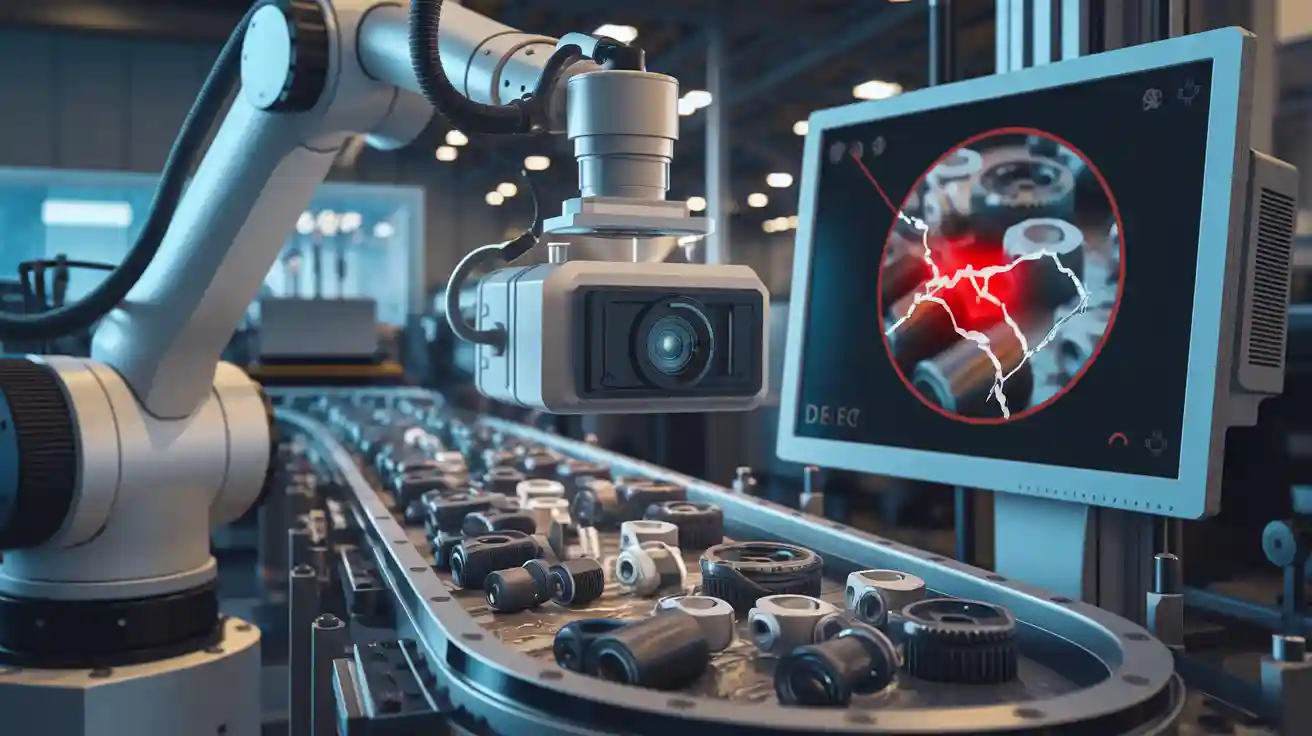

Machine vision systems use advanced technology to extract information from images automatically. Unlike traditional image processing, which modifies images, these systems analyze visual data to identify patterns, anomalies, or defects. They rely on components like cameras, sensors, and software to capture and interpret images. For example, area scan cameras capture images in a single frame, making them ideal for inspecting objects of uniform size. Line scan cameras build images pixel by pixel, which works well for moving objects or irregular shapes.

Performance metrics validate the efficiency of machine vision systems. Accuracy measures how often the system correctly identifies defects. Precision evaluates the correctness of positive detections. Recall assesses the system’s ability to detect all defects, while the F1 score combines precision and recall into a single metric. These metrics ensure reliable defect detection and consistent quality control.

Types of machine vision systems for defect detection

Different types of machine vision systems cater to various defect detection needs. Traditional machine vision systems rely on predefined rules and parameters, requiring meticulous programming. While effective for specific tasks, they lack flexibility and adaptability. AI-driven machine vision systems, on the other hand, use advanced algorithms to analyze visual data dynamically. These systems excel at real-time defect detection and can adapt to changing inspection criteria.

You can also choose between 2D and 3D vision systems. 2D systems use area scan cameras and are cost-effective and easy to deploy. However, they may struggle with complex tasks. 3D systems add depth information, often using lasers for precise measurements. These systems are essential for tasks requiring high precision, such as robotic manipulation, but come with increased complexity and cost.

Applications of machine vision in defect detection

Machine vision systems play a vital role in defect detection across industries. Automated visual inspections maximize product quality and throughput by inspecting hundreds or thousands of parts per minute. Pharmaceutical companies use these systems to identify defects in products, ensuring compliance with stringent quality standards. In manufacturing, machine vision systems enhance efficiency by detecting flaws in casting components and metal surfaces.

Other applications include print defect identification, where systems detect anomalies like color inconsistencies that manual inspections might overlook. Barcode scanning improves categorization efficiency and reduces errors. Machine vision systems also analyze inspection data to identify production trends, enabling you to optimize processes and reduce waste.

Comparing Rule-Based and AI-Powered Defect Detection

How rule-based systems work in defect detection

Rule-based systems rely on predefined parameters and algorithms to identify defects. These systems operate by comparing captured images against a set of established rules or templates. For example, if a product deviates from a specified size or shape, the system flags it as defective. This approach works well for tasks with clear and consistent criteria, such as detecting scratches on flat surfaces or verifying barcode alignment.

However, rule-based systems struggle with adaptability. They require manual reprogramming whenever inspection criteria change. For instance, if a new product design introduces subtle variations, the system may fail to detect defects accurately. Traditional methods like statistical quality control also face limitations in identifying sporadic or unpredictable defects. While effective for straightforward tasks, rule-based systems lack the flexibility needed for dynamic production environments.

The role of AI in modern defect detection systems

AI-powered systems revolutionize defect detection by leveraging advanced computer vision techniques. These systems use machine learning models to analyze visual data and identify patterns that may indicate defects. Unlike rule-based systems, AI models learn from data, enabling them to adapt to new scenarios without manual intervention. For example, AI-powered visual inspection systems in automotive manufacturing can detect tiny imperfections in paint quality that human inspectors might miss.

AI enhances defect detection rates significantly. A systematic review of 152 peer-reviewed articles highlights the use of AI techniques in additive manufacturing, improving defect detection rates by an average of 22%. AI-powered systems also integrate multimodal data, such as combining thermal imaging with visual data, to identify defects that are invisible to the naked eye. Drones equipped with AI cameras can scan construction sites to detect structural flaws, while thermal imaging cameras pinpoint heat leaks or insulation gaps.

Real-time detection is another advantage of AI-powered systems. These systems process data instantly, allowing you to identify and address defects during production. This capability reduces downtime and ensures consistent quality. AI excels in complex, data-rich environments, making it ideal for industries like pharmaceuticals, where precision and compliance are critical.

Pros and cons of rule-based vs. AI-powered approaches

|

Feature |

Rule-Based Systems |

AI-Powered Systems |

|---|---|---|

|

Adaptability |

Limited adaptability to new defects |

Highly adaptable to complex scenarios |

|

Accuracy |

Effective for known defects |

Higher accuracy in detecting subtle defects |

|

Real-Time Detection |

Limited real-time capabilities |

Excellent real-time detection capabilities |

|

Complexity Handling |

Best for well-defined tasks |

Excels in complex, data-rich environments |

|

Flexibility |

Rigid, based on predefined rules |

Flexible, can learn from new data |

Rule-based systems offer simplicity and reliability for well-defined tasks. They are cost-effective and easy to implement, making them suitable for small-scale operations. However, their rigidity limits their ability to handle complex or evolving inspection criteria. AI-powered systems, on the other hand, provide unparalleled adaptability and accuracy. They excel in detecting subtle defects and processing large volumes of data in real time.

Despite their advantages, AI-powered systems come with higher implementation costs and require significant computational resources. Training AI models demands substantial data and expertise, which may pose challenges for smaller businesses. However, the long-term benefits of improved defect detection and operational efficiency often outweigh these initial investments.

Tip: When choosing between rule-based and AI-powered systems, consider your production complexity, budget, and scalability needs. AI-powered systems may be ideal for industries requiring high precision and adaptability, while rule-based systems work best for straightforward tasks.

Hardware Components in Defect Detection Machine Vision Systems

Cameras and their role in capturing product images

Cameras form the backbone of defect detection systems, capturing high-resolution images that enable precise analysis. In manufacturing plants, these cameras detect small abnormalities in safety-critical products. Food production facilities use them to monitor packaging and ingredient quantities, ensuring compliance with industry standards. Vehicle manufacturers rely on cameras to inspect assembly processes and identify defects in real time.

Companies like BMW and Nestlé demonstrate the transformative power of cameras. BMW uses high-speed cameras paired with image analysis software to inspect vehicle components, reducing production costs and enhancing quality. Nestlé employs high-resolution cameras to inspect packaging and product appearance, minimizing waste. Intel leverages image processing for wafer inspection, identifying minute defects in microchips to maintain high standards.

Cameras also improve accuracy and reduce human error. By automating inspections, they minimize oversight risks and save costs associated with rework or recalls. High-resolution imaging ensures even the smallest metal defects are detected, enhancing overall product quality.

Importance of lighting and illumination techniques

Proper lighting is critical for accurate defect detection. Illumination techniques highlight surface irregularities, ensuring defects are visible to the system. For example, diffuse integrating-sphere lighting improves defect identification on reflective surfaces, reducing false negatives. Dark-field angled lighting achieves an 82% detection rate for shallow scratches, outperforming bright-field lighting.

Shadowless ring lights deliver over 90% classification accuracy by eliminating glare and highlighting defects on cylindrical metal parts. Combined lighting techniques provide near-comprehensive detection, as seen in scalpel blade inspections where multiple lighting types effectively reveal defects.

Lighting impacts detection rates and false positives significantly. Uniform and targeted illumination ensures the system can identify metal defects accurately, even on challenging surfaces like polished metals.

Other essential components like lenses and sensors

Lenses and sensors play a pivotal role in defect detection systems. Lenses focus light onto the camera sensor, ensuring sharp and detailed images. The choice of lens affects the system’s ability to detect metal defects, especially in intricate or small components. Wide-angle lenses cover larger areas, while telecentric lenses maintain consistent magnification, crucial for precise measurements.

Sensors convert light into electrical signals, enabling the system to process visual data. Advanced sensors with high dynamic range capture details in varying lighting conditions, ensuring accurate inspection results. Paired with the right lenses, these sensors enhance the system’s ability to identify metal defects across diverse applications.

Together, cameras, lighting, lenses, and sensors form a cohesive system that ensures reliable defect detection. By optimizing these components, you can achieve higher inspection accuracy and efficiency.

The Role of Software in Defect Detection

How image analysis software identifies defects

Image analysis software plays a pivotal role in defect detection by processing visual data to identify anomalies. It uses algorithms to analyze captured images, pinpointing defects that may compromise product quality. For instance, software can detect scratches, dents, or misalignments by comparing images against predefined standards or training data. This process ensures consistent and accurate identification of defects across various industries.

Studies highlight the effectiveness of image analysis software in outperforming human inspectors. Machines achieve an average recall of 0.842 and precision of 0.837, surpassing human recall (0.804) and precision (0.790). Additionally, machines complete defect detection tasks in just 27 seconds, compared to 2440 seconds for humans. This performance improvement of over 80 times underscores the efficiency of software in defect detection.

Modern systems integrate high-resolution imaging with deep learning models to enhance sensitivity. These models detect anomalies smaller than a pixel, enabling the identification of defects that traditional methods might overlook. This combination of advanced imaging and software ensures reliable defect detection, even in complex environments.

Features of defect detection software

Defect detection software offers a range of features that optimize quality assurance processes. These features ensure efficient and accurate identification of defects, contributing to improved production outcomes. Key metrics describing the capabilities of defect detection software include:

|

Metric |

Description |

|---|---|

|

Defect detection percentage |

Evaluates how effectively testing uncovers defects relative to those reported. |

|

Test case execution time |

Crucial for understanding testing efficiency and identifying slow test cases. |

|

Requirements coverage |

Assesses whether all stakeholder requirements have been adequately tested. |

|

Defect density |

Indicates software quality by assessing defects relative to the size of the software. |

|

Defect removal efficiency |

Measures the team’s ability to handle and remove valid defects before they reach production. |

|

Test execution coverage |

Evaluates the ratio of executed test cases to the total number of test cases planned. |

|

Defect severity index |

Prioritizes testing efforts based on defects’ potential impact on product quality. |

These metrics highlight the software’s ability to detect defects efficiently, prioritize testing efforts, and ensure comprehensive coverage of requirements. By leveraging these features, you can streamline quality assurance processes and enhance production reliability.

Real-world examples of software applications

Defect detection software has transformed operations across industries, delivering tangible benefits in quality assurance. Here are some practical applications:

-

Aviation: Computer vision systems detect surface defects like scratches and structural issues such as cracks. These systems improve inspection speed and accuracy while reducing human error.

-

Manufacturing: Object detection technology automates quality assurance, identifying defects in products and raw materials. This approach minimizes manual labor and ensures consistent quality.

-

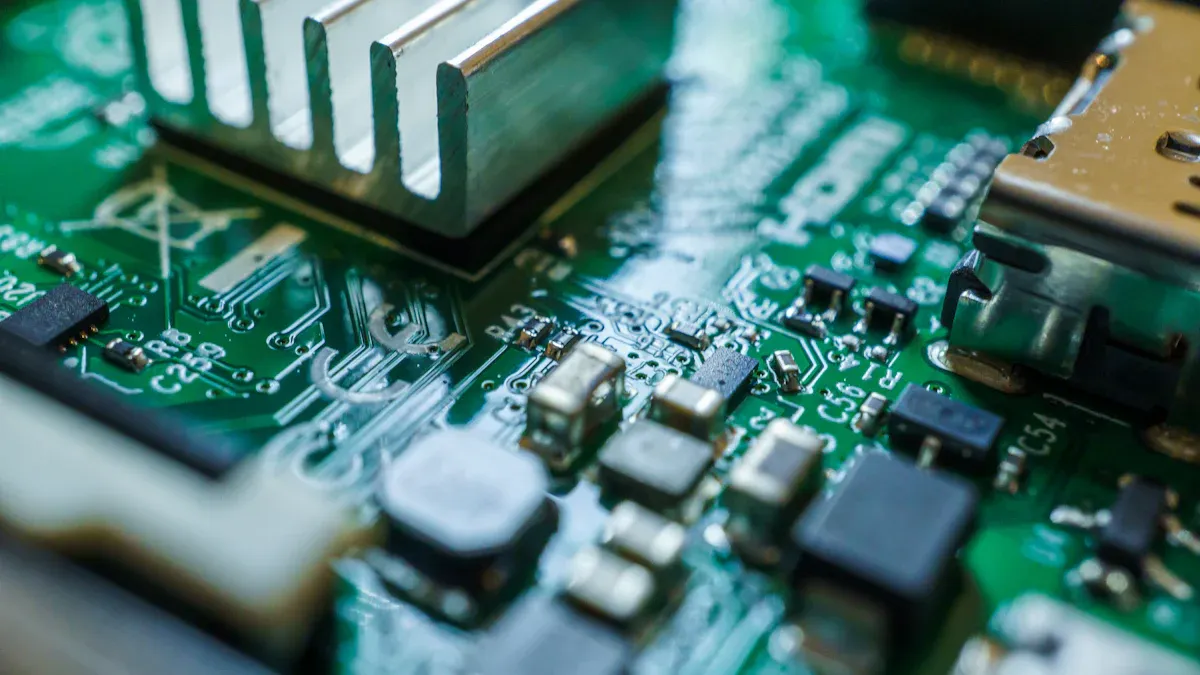

Electronics: A global manufacturer improved defect detection in circuit boards by 25% using ML-powered visual inspection. This advancement reduced faulty products and enhanced production efficiency.

These examples demonstrate the versatility of defect detection software in addressing industry-specific challenges. By integrating advanced models and imaging systems, companies achieve higher accuracy and efficiency in their final inspection processes.

Benefits and Future of Defect Detection in Machine Vision Systems

Advantages of automated defect detection

Automated defect detection systems offer unparalleled benefits for quality assurance. These systems eliminate human error, ensuring consistent and accurate inspections. By leveraging computer vision, you can detect even the smallest anomalies that manual inspections might overlook. For example, high-resolution imaging paired with advanced models identifies defects smaller than a pixel, enhancing precision in industries like electronics and automotive manufacturing.

Automation also accelerates inspection processes. Traditional methods often require hours of manual labor, while machine vision systems complete the same tasks in seconds. This speed boosts productivity and reduces operational costs. Additionally, automated systems improve scalability. Whether you manage a small production line or a large-scale operation, these systems adapt to your needs without compromising accuracy.

Note: Automated defect detection not only enhances efficiency but also minimizes waste. By identifying flaws early, you prevent defective products from reaching consumers, safeguarding your brand reputation.

Emerging trends in computer vision for defect detection

Advancements in computer vision continue to reshape defect detection. Modern systems integrate AI and machine learning to analyze visual data with remarkable precision. These technologies enable real-time defect detection, allowing you to address issues during production rather than after completion. For instance, automotive assembly lines use AI-powered models to identify faulty components instantly, preventing delays and reducing costs.

Emerging trends include the use of edge computing for faster analysis. By processing data locally, edge computing reduces latency and enhances operational efficiency. Vision systems increasingly integrate with IIoT and Industry 4.0 frameworks, enabling predictive maintenance and improved data collection. In the food industry, computer vision categorizes items based on visual properties, ensuring uniformity and compliance with standards.

-

Key advancements driving innovation:

-

Integration of AI and machine learning in defect detection.

-

Development of advanced software solutions for better user experience.

-

Enhanced data analysis capabilities through edge computing.

-

The future of AI and machine learning in defect detection

AI and machine learning will play a pivotal role in the future of defect detection. These technologies enable systems to learn and adapt, improving accuracy over time. As models evolve, they will handle increasingly complex tasks, such as detecting defects in intricate designs or multi-layered products. For example, AI-powered systems in electronics manufacturing already identify circuit board flaws with 25% higher accuracy than traditional methods.

The integration of computer vision with predictive analytics will further enhance defect detection. By analyzing historical data, these systems predict potential issues before they occur, reducing downtime and maintenance costs. Real-time monitoring combined with AI-driven insights ensures optimal production efficiency.

Tip: Investing in AI-powered defect detection systems positions your business for long-term success. These systems not only improve quality but also adapt to future challenges, ensuring sustained growth in competitive markets.

Defect detection in machine vision systems plays a critical role in ensuring product quality and operational efficiency. Studies demonstrate their reliability, with systems achieving a recall of 100% and an F1 score of 92.02%. These metrics highlight their ability to identify defects consistently, even in complex manufacturing environments.

The synergy between hardware and software components enhances precision and adaptability. Cameras, sensors, and lenses work seamlessly with advanced algorithms to detect even minor deviations. These systems conduct multi-faceted inspections, maintain consistency, and reduce human error. Real-time monitoring ensures immediate corrective actions, improving overall production reliability.

AI-powered systems promise a transformative future. They enable early defect detection, reducing waste and costs. Continuous monitoring and root cause analysis enhance real-time quality control. For instance, NTT DoCoMo achieved a 34% improvement in defect detection by integrating AI into its processes. As these technologies evolve, they will redefine quality assurance, ensuring your operations remain efficient and competitive.

Tip: Investing in AI-driven defect detection systems positions your business for long-term success, offering unmatched precision and adaptability in an ever-changing market.

FAQ

What industries benefit the most from defect detection systems?

Industries like automotive, electronics, pharmaceuticals, and food production gain the most from defect detection systems. These systems ensure product quality, reduce waste, and improve compliance with industry standards. For example, automotive manufacturers use them to identify assembly flaws, while food producers ensure packaging consistency.

How do machine vision systems handle complex defects?

Machine vision systems use AI algorithms and high-resolution imaging to detect complex defects. These systems analyze patterns and anomalies invisible to the human eye. For instance, they identify microscopic cracks in metal or subtle color inconsistencies in printed materials.

Are AI-powered systems difficult to implement?

AI-powered systems require initial setup and training, but they adapt quickly to production environments. You’ll need quality data and computational resources to train models. Once implemented, these systems streamline defect detection and reduce manual intervention, saving time and costs.

Can machine vision systems work in real-time?

Yes, modern machine vision systems process data instantly, enabling real-time defect detection. This capability allows you to address issues during production, minimizing downtime and ensuring consistent quality. Industries like electronics and automotive rely on this feature for efficiency.

What is the cost of implementing defect detection systems?

Costs vary based on system complexity and features. Rule-based systems are more affordable but less adaptable. AI-powered systems require higher investment due to advanced hardware and software. However, their long-term benefits, such as improved accuracy and reduced waste, often outweigh initial expenses.

See Also

Grasping Defect Identification Through Machine Vision Technologies

Analyzing Flaw Identification Using Machine Vision Techniques

Investigating Machine Vision Solutions for Instant Anomaly Recognition

Always Identify Defects with Verification Machine Vision Tools

Harnessing Deep Learning for Enhanced Defect Detection