Introduction: The Critical Connection

In the architecture of a cylindrical battery pack—a format spanning from power tools to electric vehicles—the Nickel Tab serves as the lifeline. It connects the battery lugs to the wider system.

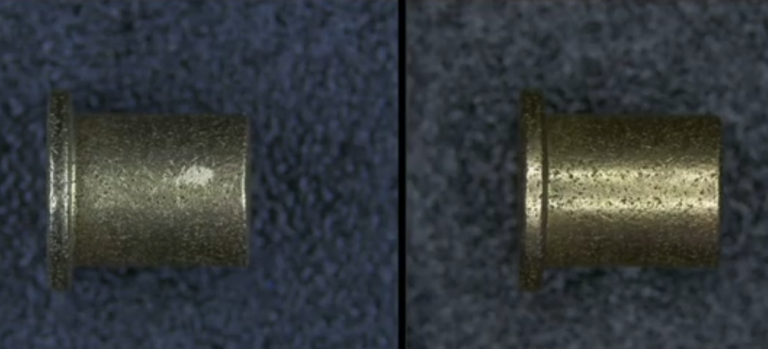

The process of joining these tabs—Resistance Welding—is a delicate balancing act.

- Too weak (Cold Weld): The connection fails, creating high electrical resistance and heat.

- Too strong (Over-fusion): You risk piercing the battery shell, causing leaks or shorts.

With thousands of cells in a single EV battery pack, a single bad weld is a potential failure point. Ensuring 100% quality control isn’t a luxury; it’s a necessity for preventing downstream failures and ensuring user safety.

The Challenge: Two Welding Methods, One Quality Standard

Our client needed a solution that could handle the high-volume nature of cylindrical cell production while addressing the specific complexities of two different welding techniques:

- Flat-Needle Welding: Prone to issues like “needle pull,” blackened spots, and crooked tabs.

- Projection Welding: Susceptible to micro-fusion, over-fusion, and sticky needles.

The goal was ambitious: Detect a massive variety of defect types (over 18 specific categories) without slowing down the line or disrupting the flow of 4x4pcs battery trays.

The Solution: On-the-Fly Tray Inspection

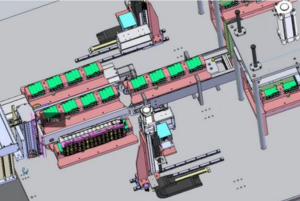

UnitX deployed a high-speed, dual-workstation solution designed for batch processing.

How it works:

- Speed: The system utilizes on-the-fly photography, capturing images while the camera moves at 120 mm/s. It doesn’t need to stop for every single cell, which drastically improves cycle time.

- Batch Processing: It examines an entire 4×4 tray (16 cells) at a time.

- Smart Integration: Beyond just “seeing” defects, Unit’s system integrates directly with the customer’s MES (Manufacturing Execution System). This allows for intelligent data collection, ensuring that every specific battery’s weld quality is recorded and traceable.

Hardware Configuration:

- Imaging: 1x UnitX OptiX system.

- Compute: 2x UnitX CorteX units (AI Central & Inspection Cell) to handle the heavy image processing load.

100% Recognition of Agreed Defects

The core of this solution is the ability to distinguish between a “messy” good weld and a “functional” bad weld. UnitX Visual Inspection system was trained to identify a comprehensive list of defects including:

- Structural: Missed welds, absence of nickel tabs, double tabs.

- Quality: Cold welds, over-fusion, offset spots, and spot bursts.

The Results: Stability and Precision

The deployment proved that AI can handle the nuance of welding inspection better than traditional rule-based systems.

- Adaptable Defect Detection: The system maintained a 100% recognition rate across all inspection criteria. It demonstrated remarkable flexibility, identifying every trained defect type even as lighting modes varied—a scenario that typically confuses traditional rule-based systems.

- A Constant Safety : UnitX reached the ultimate benchmark of 0% False Acceptances. By ensuring no faulty welds escape to the next stage, and protects the final battery pack from the high-resistance issues that lead to dangerous overheating.

- Synchronized Batch Velocity: The system processes the entire batch in just 14 seconds. This “whole-tray” perspective ensures that every weld spot is scrutinized with the same level of intensity, keeping the production speed steady and reliable.

Conclusion

In cylindrical battery manufacturing, the weld is where the power meets the road. UnitX’s surface inspection solution provides the assurance that this connection is solid, safe, and traceable. By combining on-the-fly imaging with deep learning, we help manufacturers maintain high throughput without compromising on safety.

Need reliable weld inspection?

Contact UnitX to see how we integrate with your MES and production line.