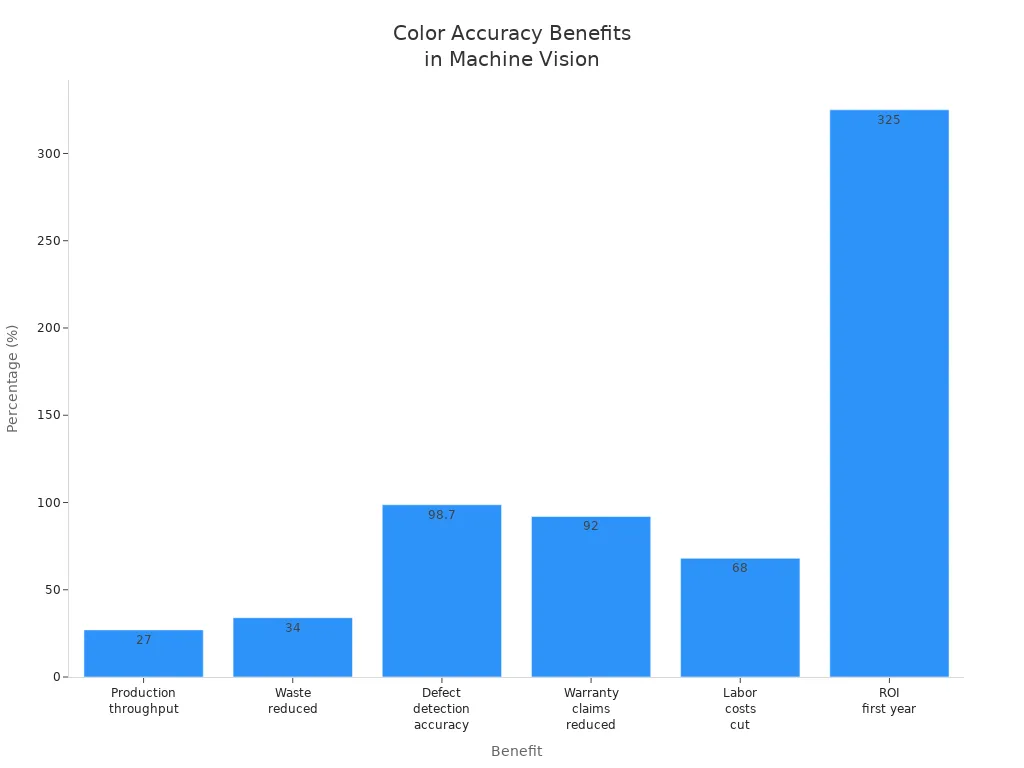

A chromaticity machine vision system uses advanced lighting and precise sensors to analyze color and ensure high product quality in 2025. Lighting from multiple led sources, including tunable led arrays, controls color temperature for consistent results. Proper lighting with adjustable color temperature reduces errors from environmental changes. The machine vision system depends on led lighting to capture true chromaticity, using color models to distinguish subtle differences. In factories, accurate lighting and calibrated led arrays help the machine vision system detect defects that grayscale imaging misses. The table below shows how color accuracy impacts effectiveness in industrial settings:

| Aspect | Impact of Color Accuracy on Machine Vision Effectiveness |

|---|---|

| Precise Color Detection | Enables identification of subtle color differences, improving defect detection and quality control beyond grayscale capabilities. |

| Lighting and Calibration | Proper lighting and regular calibration maintain consistent and accurate color detection, reducing errors caused by environmental variability. |

| Color Space Selection | Using HSV or LAB color spaces improves robustness against lighting changes and enhances detection accuracy. |

| Automation and Speed | Accurate color detection reduces human error, increases inspection speed, and supports real-time monitoring and automation. |

| Industrial Applications | Critical for quality control in automotive, electronics, pharmaceuticals, textiles, and food industries, ensuring product consistency and defect identification. |

| Measurable Benefits | – Production throughput increased by 27% – Waste reduced by 34% – Defect detection accuracy reached 98.7% – Warranty claims reduced by 92% – Labor costs cut by 68% – ROI of 325% within the first year |

| Advanced Technologies | Integration of AI and high-resolution imaging further enhances accuracy and adaptability in complex industrial environments. |

Key Takeaways

- Chromaticity machine vision systems use advanced lighting and sensors to analyze color accurately, improving product quality and defect detection.

- Proper LED lighting with the right color temperature and high Color Rendering Index (CRI) ensures consistent and true color capture in inspections.

- Separating color information from brightness using models like HSI helps maintain color accuracy even when lighting conditions change.

- Regular calibration and AI-driven algorithms keep the system reliable by adjusting to different environments and reducing errors.

- These systems boost manufacturing efficiency by increasing inspection speed, reducing waste, and supporting quality control across many industries.

Chromaticity in Machine Vision

What Is Chromaticity?

Chromaticity describes the quality of a color without considering its brightness. Scientists define chromaticity using two main parameters: hue and colorfulness, also called saturation or chroma. These parameters come from how human eyes see color. In color science, chromaticity is often shown in diagrams like the CIE 1931 xyY color space. Here, the x and y coordinates represent chromaticity, while Y stands for luminance or brightness. This separation allows a chromaticity machine vision system to measure color accurately, even when lighting changes. By focusing only on hue and saturation, the system can analyze colors without being affected by how bright the scene is.

Note: Chromaticity gives an objective way to describe color. It helps machine vision systems compare and process colors consistently, no matter the lighting conditions.

Color Models (RGB, HSI)

Machine vision systems use different color models to process and analyze images. The two most common models are RGB and HSI.

-

RGB Model

- Uses Red, Green, and Blue as primary colors.

- Forms colors by mixing these three channels in different amounts.

- Combines color and brightness in each channel.

- Device-dependent, so results can change with different cameras or lighting.

-

HSI Model

- Stands for Hue, Saturation, and Intensity.

- Separates color information (hue and saturation) from brightness (intensity).

- Hue shows the type of color, like red or blue.

- Saturation measures how pure or vivid the color is.

- Intensity shows how bright the color appears.

- Matches human color perception more closely.

The HSI model helps a chromaticity machine vision system analyze color more accurately. By separating color from brightness, HSI reduces the impact of lighting changes and device differences. RGB data often needs calibration to match device-independent color spaces, such as sRGB or CIE color spaces. This step ensures consistent results across different systems.

Why Chromaticity Matters

Chromaticity plays a key role in machine vision, especially for tasks that require precise color analysis. By using chromaticity coordinates, a system can focus on hue and saturation, ignoring brightness. This approach allows the system to:

- Distinguish between very similar colors with high accuracy.

- Maintain consistent color measurements, even when lighting changes.

- Improve quality control in industries like electronics, textiles, and food processing.

Chromaticity-based methods, such as those using the CIE xy chromaticity diagram, enable fast and accurate color texture recognition. These methods help detect defects that other systems might miss. For example, in solar cell inspection, chromaticity analysis highlights cracks and breaks that are hard to see with standard imaging. Combining chromaticity features with advanced image processing techniques, like Fourier transforms, further boosts defect detection rates.

Block Quote: Chromaticity allows machine vision systems to separate color from brightness, making it easier to spot subtle differences and improve inspection accuracy.

A chromaticity machine vision system uses these principles to deliver reliable and repeatable results. It ensures that products meet strict color standards and helps manufacturers reduce errors and waste.

Chromaticity Machine Vision System Components

Machine Vision Lighting

Machine vision lighting forms the foundation of any modern machine vision system. The choice of lighting type, such as white light or colored LEDs, directly affects chromaticity accuracy. White LEDs emit a broad spectrum and come in different color temperatures, measured in Kelvin. Lower color temperature LEDs produce warm light with red and yellow tones, while higher color temperature LEDs create cool, blue-toned light. Selecting the right color temperature ensures accurate color reproduction and reliable inspection results. High Color Rendering Index (CRI) values, often between 70 and 95 for white LEDs, indicate better color fidelity. In automotive manufacturing, for example, the correct color temperature helps the machine vision system distinguish subtle shades on interior panels. Colored LEDs, like red or blue, enhance contrast and reduce glare, making them useful for detecting defects or differentiating materials. However, using colored LEDs may compromise color accuracy, so engineers must balance color fidelity with contrast needs. Proper machine vision lighting, including advanced LED lighting arrays, supports consistent chromaticity analysis by minimizing the effects of environmental changes.

Note: The right combination of lighting, color temperature, and CRI ensures that the machine vision system delivers accurate and repeatable results.

Sensors and Cameras

Sensors and cameras play a critical role in capturing color information for chromaticity analysis. The spectral sensitivity of each sensor, determined by its design and calibration, affects how accurately it records color data. RGB sensors, for example, detect different color channels and operate in various modes to analyze reflected light or color proportions. Environmental factors, such as reflections and the angle of lighting, can influence the sensor’s performance. To address these challenges, engineers use calibration methods like gray balance and white balance. In-camera processing has minimal impact on chromaticity accuracy; instead, hardware components such as the color filter array and sensor spectral response determine color fidelity. The machine vision system relies on high-quality sensors to ensure that the captured images reflect true chromaticity, supporting precise defect detection and quality control.

Software and Processing

Software and processing algorithms transform raw sensor data into actionable insights for the machine vision system. Recent advancements include neural network–based color recovery and illumination correction models. These algorithms convert device-dependent RGB values into device-independent color spaces, such as CIE XYZ or sRGB, ensuring consistent color representation across different devices. For example, kernel partial least squares (KPLS) modeling accurately transforms RGB data, reducing color errors and improving chromaticity analysis. Advanced software also uses machine learning to optimize color correction, reducing average color differences and enhancing inspection reliability. By leveraging device-independent colorimetric images, the machine vision system maintains stable and accurate color data from acquisition to output. This approach supports rapid color correction and high-fidelity chromaticity analysis, even in complex industrial environments.

2025 Advancements and Standards

Color Accuracy and Calibration

In 2025, the machine vision system landscape features major breakthroughs in color accuracy and calibration. AI-driven white balance algorithms now use deep learning models, including convolutional neural networks and transformer-based architectures. These models analyze complex lighting environments and adjust exposure, contrast, and saturation in real time. As a result, the machine vision system maintains color constancy even in multi-illuminant scenes. New sensor technologies, such as multispectral sensors and multilayer monolithic perovskite photodetectors, capture a broader spectrum and improve quantum efficiency. These sensors reduce noise and enhance pixel response uniformity, which leads to more reliable color reproduction. Calibration practices now emphasize controlled lighting, regular use of neutral white cards, and color correction matrices. Both automatic and manual white balance modes play important roles. Automatic modes adapt to changing lighting, while manual modes provide precision in stable environments. Environmental control, iterative algorithm tuning, and hardware considerations like lens quality further support consistent results.

Industry Standards

Manufacturers follow rigorous calibration techniques to ensure chromaticity consistency in industrial environments. They define performance targets for white point, brightness, gamma, and color gamut during research and development. Engineers use precision instruments, such as spectroradiometers and high-end colorimeters, to calibrate prototype units. They verify calibration with chromaticity plots and luminance maps, refining hardware or firmware as needed. Production lines use automated calibration procedures, combining spot and 2D imaging colorimeters for global and uniformity checks. Calibration software adjusts display settings in real time, balancing speed and accuracy by measuring key points. Imaging colorimeters are calibrated against reference spectroradiometers or standard light sources. Flat-field calibration corrects sensor non-uniformity, and view angle corrections address lens errors. These steps ensure the machine vision system delivers reliable and traceable results over time.

Application Trends

The machine vision system market in 2025 shows rapid growth and diversification. Demand rises for high-resolution displays, such as OLED, mini-LED, and micro-LED, which require precise chromaticity analysis. Advanced lighting technologies and automotive lighting design also drive adoption. Augmented reality and virtual reality devices need accurate optical performance, making the machine vision system essential in their production. Manufacturers integrate these systems into automated production lines, using advanced CMOS sensors and user-friendly software for data analysis. New applications emerge in healthcare, agriculture, and smart home devices. The machine vision system now supports predictive analysis through AI and machine learning, enabling real-time data processing and quality control. Companies focus on sustainability, digital integration, and customization to meet industry needs. Regional growth in Asia-Pacific, North America, and Europe reflects strong innovation and manufacturing capabilities.

Machine Vision System Applications

Defect Detection

Machine vision system applications have transformed defect detection in modern manufacturing. These systems use advanced chromaticity analysis to spot flaws that traditional vision inspection methods might miss. For example, adaptive tone mapping based on color correction models improves image chromaticity, especially on reflective surfaces. This process reduces color shifts caused by brightness compression and enhances image quality. As a result, automated inspection systems can detect surface defects with greater accuracy, even when lighting and reflectivity present challenges. In industrial sewing machines, using the HSV color space allows the machine vision system to process chroma and brightness separately. This approach improves detection of defects in low-contrast or achromatic objects, making vision inspection more reliable. Automated color inspection also reduces human error and fatigue, ensuring consistent results across production lines.

Material Differentiation

Material differentiation is another key area for machine vision system applications. Chromaticity enables the system to distinguish between materials that look similar in brightness but differ in color quality. By focusing on chromaticity coordinates, the machine vision system can identify subtle differences in spectral reflectance. This capability proves essential in sorting, print analysis, and production verification, where materials may appear visually alike. Chromaticity diagrams and color spaces help the system ignore intensity and highlight color differences. This method supports general inspection tasks, allowing for accurate classification and separation of materials during vision inspection.

Quality Control

Quality control relies on precise color inspection and vision inspection to maintain product standards. Chromaticity analysis ensures color consistency and quality by measuring color purity and saturation as perceived by the human eye. Manufacturers use these systems to monitor large production batches, detect variations, and ensure compliance with industry standards. Chromaticity-based vision inspection detects defects or inconsistencies that human eyes might miss, improving manufacturing yield and reducing waste. In industries like textiles, food, and electronics, the machine vision system supports general inspection and quality control by providing fast, accurate, and repeatable results. This approach enhances product reliability and customer satisfaction.

Tip: Chromaticity analysis in machine vision system applications helps companies achieve higher inspection accuracy, better quality control, and improved production efficiency.

Selecting a Chromaticity Machine Vision System

Key Metrics (CRI, CCT)

When choosing a machine vision system, engineers focus on two main metrics: Color Rendering Index (CRI) and Correlated Color Temperature (CCT). CRI measures how accurately a light source, such as an led, shows colors compared to a reference source. A high CRI means the led lighting helps the system see true colors during inspection. Most industrial applications require a CRI above 80 for reliable results. CCT describes the color temperature of the led lighting, measured in kelvin. Lower color temperature values, like 3000K, create warm, reddish light, while higher values, such as 6500K, produce cool, bluish light. The right color temperature ensures the machine vision system matches the inspection environment. Engineers use the CIE color space to determine chromaticity coordinates and select the best led lighting for each task.

Tip: Always check that the chromaticity distance from the Planckian locus is within range to ensure CRI accuracy.

Evaluation Tips

Selecting the best machine vision system for inspection requires more than checking basic chromaticity plots. Modern systems use advanced metrics, such as the CIELab color space, which shows color differences in three dimensions. This method helps engineers see how led lighting and color temperature affect color accuracy. The Gamut Ring plot transforms this data into a clear, two-dimensional view, making it easier to compare different systems. When evaluating, teams should consider the specific inspection needs, the type of led lighting, and the required color temperature. Choosing between color and monochrome cameras depends on the inspection task. Outdated chromaticity plots can mislead buyers, so using CIELab and Gamut Ring plots gives a more accurate picture of system performance.

Use Cases

Manufacturers use chromaticity machine vision systems in many industries. In electronics, led lighting with the right color temperature helps detect small defects during inspection. Textile factories rely on high-CRI led arrays to ensure color consistency in fabrics. Food processing plants use machine vision systems with adjustable color temperature to inspect produce for ripeness and quality. Automotive assembly lines use led lighting to highlight paint differences and surface flaws. Each application depends on matching the led lighting and color temperature to the inspection environment for the best results.

Note: Matching the led lighting and color temperature to the inspection task improves accuracy and reduces errors.

A chromaticity machine vision system delivers precise color analysis for modern manufacturing in 2025. Lighting choices, advanced sensors, and improved color models all boost system performance. Engineers should evaluate lighting quality, calibration methods, and software features before implementation. Companies that adopt these systems gain better defect detection and higher product quality. Future applications will rely on chromaticity for even greater accuracy and efficiency.

FAQ

What is the main benefit of chromaticity in machine vision systems?

Chromaticity allows the system to separate color from brightness. This separation helps the system detect small color differences and improves inspection accuracy in many industries.

How does lighting affect chromaticity analysis?

Proper lighting ensures accurate color capture. LED lighting with the right color temperature and high CRI helps the system see true colors. Poor lighting can cause errors in color detection.

Why do manufacturers use device-independent color spaces?

Device-independent color spaces, like CIE XYZ or sRGB, provide consistent color results across different cameras and lighting setups. This consistency supports reliable quality control and reduces errors.

Can chromaticity machine vision systems work in changing environments?

- Yes, these systems use advanced calibration and AI-driven algorithms.

- They adjust to lighting changes and maintain color accuracy.

- This adaptability makes them useful in factories and other dynamic settings.

See Also

Understanding Pixel-Based Vision Technology In Contemporary Uses

An Overview Of Cameras Used In Vision Systems

Comparing Firmware-Based Vision With Conventional Methods

Comprehensive Guide To Semiconductor-Based Vision Technologies