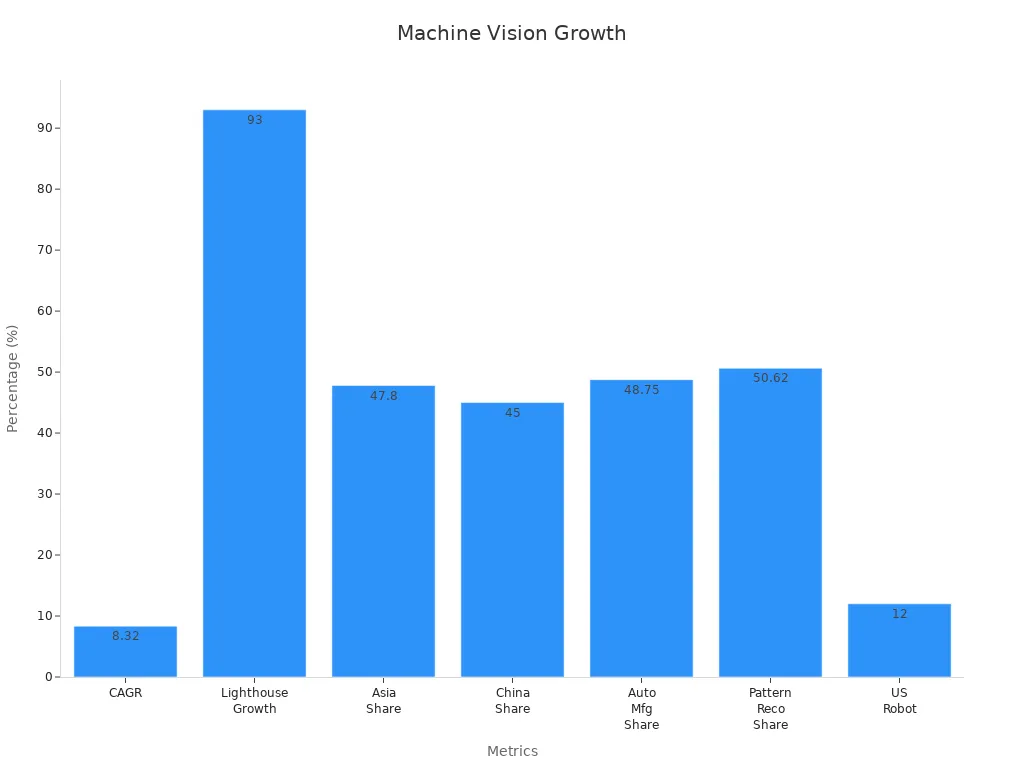

Boosting machine vision system performance in 2025 starts with understanding its growing power in manufacturing. You see more connected devices—rising from 4.9 billion in 2015 to 25 billion by 2025—driving smarter factories. Machine vision helps you spot defects, speed up inspection, and cut waste. In manufacturing, robots will handle up to 25% of tasks, making your production line faster and more reliable. The machine vision market will reach $13.95 billion in 2025, and pattern recognition will cover over 50% of all applications. As you explore new technologies, focus on real steps that improve productivity. The rapid evolution of machine vision makes 2025 a turning point for manufacturing worldwide.

The Asia-Pacific region leads in machine vision adoption, with China holding 45% of the regional market share.

Key Takeaways

- Machine vision is growing fast and transforming manufacturing with smarter hardware and AI, boosting accuracy and speed.

- Upgrading cameras, sensors, and lighting improves image quality and helps spot defects early, increasing production efficiency.

- Advanced algorithms and fine-tuning models raise inspection accuracy and reduce training time for better quality control.

- A clear automation roadmap and careful system integration ensure smooth adoption and maximize machine vision benefits.

- Using machine vision speeds up inspections, lowers defect rates, cuts labor costs, and supports safer, more reliable production.

Machine Vision in 2025

Key Trends

You will see machine vision transform manufacturing in 2025. The market is growing fast, with a projected value of USD 1,949 million in 2025 and a CAGR of 5.5% through 2033. This growth comes from new hardware, smarter image processing, and more advanced AI. Companies like Cognex, Keyence, Basler, OMRON, and ISRA Vision lead the way with innovations that boost accuracy and speed. For example, Keyence’s next-gen 3D vision system improves accuracy by 25% using AI, while Basler’s high-speed cameras increase automotive automation by 20%.

| Aspect | Details |

|---|---|

| Market Size Growth | USD 1,847.4 million in 2024 to USD 1,949 million in 2025; CAGR 5.5% through 2033 |

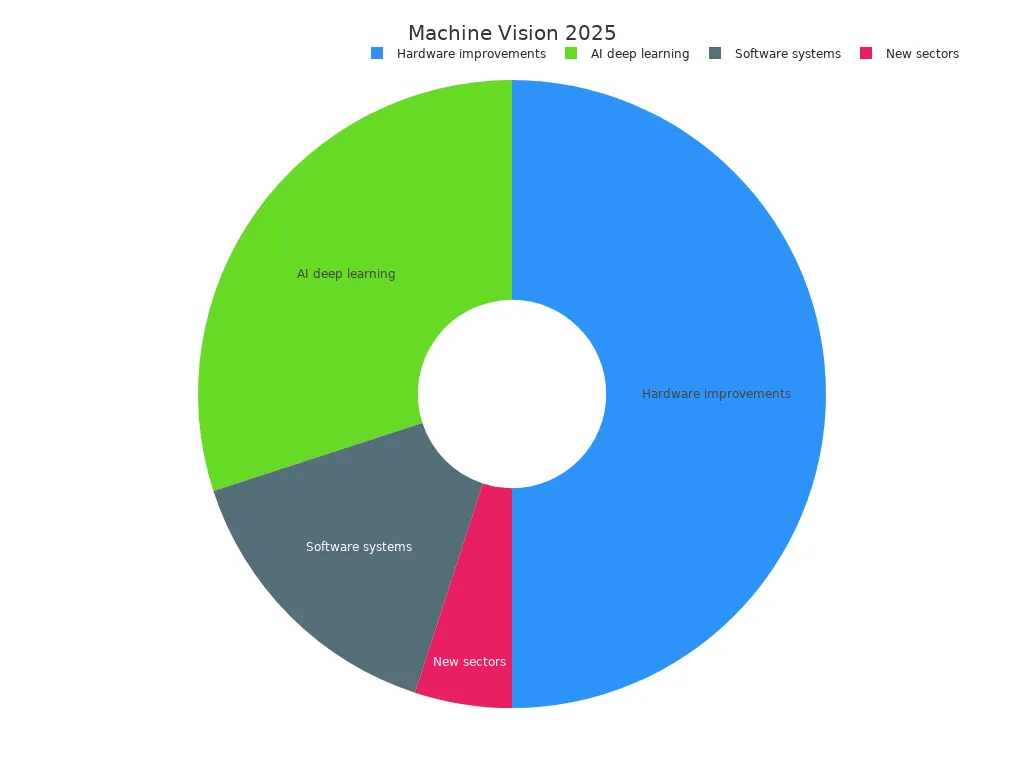

| Market Segmentation of New Product Development (2025) | 50% hardware improvements (cameras, lenses, sensors), 30% AI and deep learning integration, 15% software and systems integration, 5% expansion into new sectors (e.g., healthcare) |

| Key Company Innovations (2025) | Cognex: New vision sensor reducing processing time by 30% Keyence: Next-gen 3D vision system improving accuracy by 25% with AI integration Basler: High-speed industrial cameras with increased frame rates, enhancing automotive automation by 20% OMRON: Vision processing unit with machine learning for real-time defect detection, improving quality control in food & beverage ISRA Vision: Machine vision system for packaging, reducing waste by 15% and increasing production efficiency by 10% |

| Regional Insights | Asia Pacific expected to hold largest market share in 2025, driven by manufacturing hubs like China and Japan |

| Emerging Applications | Expansion into healthcare, agriculture, logistics with applications such as surgical robotics, crop monitoring, and package sorting |

| Market Drivers | Increasing automation demand, AI integration, improved hardware capabilities, and adoption in diverse industries |

You will notice more use of edge computing and 3D sensing. These trends help you process images faster and make real-time decisions. Edge AI reduces latency and improves data privacy. Miniaturization and better sensors allow you to use machine vision in more places, from automotive production to healthcare and logistics.

Industry Impact

Machine vision changes how you manage manufacturing and industrial automation. You can use it for quality control, making sure every product meets your standards. In 2025, you will see machine vision systems in automotive, food and beverage, and packaging. OMRON’s vision processing unit uses machine learning for real-time defect detection, improving quality control and reducing waste.

You will also see machine vision in new areas. For example, AI-powered marine drones called “Sentinels” collect plastic waste from oceans. These drones removed over 1,800 metric tons of plastic in the first quarter of 2025, making collection 48% more efficient than manual methods. This shows how machine vision supports environmental sustainability.

In factories, you can use machine vision for predictive maintenance and smart machines. This helps you avoid downtime and keep production running smoothly. Policy-driven image analysis improves safety by checking for proper PPE use and monitoring worker behavior. Studies show a 13% boost in safety compliance and a 4% increase in worker identification accuracy.

You will find that machine vision not only improves quality control but also increases production efficiency. As you adopt these systems, you help your business stay competitive in a fast-changing world.

Boosting Machine Vision System

Hardware Upgrades

You can boost your machine vision system by upgrading hardware components. Start with cameras that use advanced sensors and faster interfaces like USB 3.0 or GigE. These upgrades help you capture images at frame rates over 500 fps, which is important for high-speed inspection tasks. When you increase processing power, you handle more image data and reduce dropped frames. This leads to better real-time analysis and higher accuracy in quality control.

Tip: Balance frame rate with CPU and GPU performance, memory, storage, and interface bandwidth. This prevents bottlenecks and keeps your image capture consistent.

You should also consider industrial PCs for your machine vision setup. These PCs process images quickly and support advanced image processing algorithms. When you optimize exposure time and adjust resolution, you tailor performance to your needs. Upgrading hardware not only improves accuracy but also increases efficiency in your production line.

- Upgrading cameras and sensors improves frame rates and data transfer speeds.

- Faster processors allow better image processing and reduce latency.

- Hardware upgrades help maintain high accuracy in quality control tasks.

Lighting and Filters

Lighting and filters play a big role in boosting machine vision system performance. You need to match the lighting source to your camera’s sensitivity. For example, CCD cameras work best with lighting near 580 nm, while CMOS cameras need different lighting because they are less sensitive to light. Using LED spotlights with up to 300,000 lux gives you higher intensity and stability than older halogen lights.

| Aspect | Numerical Comparison / Detail | Impact / Validation |

|---|---|---|

| TDI technology sensitivity increase | Up to 100 times more sensitive than traditional line scan cameras | Enables use of LED technology in line scan applications |

| CMOS vs CCD camera sensitivity | CMOS cameras are 10-20% less sensitive to light than CCD cameras | Requires different lighting specifications |

| CCD camera peak sensitivity wavelength | Around 580 nm | Lighting matched to this wavelength maximizes camera performance |

| Use of narrow wavelength sources & filters | Example: Red 660 nm LED with red bandpass filter | Effectively blocks ambient light, improves contrast |

| LED spotlight intensity | Up to 300,000 lux (HLV Series LED Spotlights) | Replaces halogen lights with higher intensity and stability |

You can use narrow wavelength LEDs with matching bandpass filters, such as a red 660 nm LED with a red filter. This setup blocks ambient light and improves contrast in your images. When you optimize lighting and filters, you get clearer images, which helps your image processing algorithms find defects and improve quality control.

Note: Matching the spectral output of your lighting to your camera’s peak sensitivity is key for the best inspection results.

Advanced Algorithms

Advanced image processing algorithms are essential for boosting machine vision system performance. You can fine-tune pre-trained models to reduce training time by up to 90%. This approach improves task-specific performance by 10-20%, which means higher accuracy and efficiency in quality control. Fine-tuning works well when you have limited labeled data and need to adapt to special tasks.

You should use evaluation metrics like accuracy, precision, recall, F1-score, Intersection over Union (IoU), and mean Average Precision (mAP) to check how well your image processing algorithms perform. Visualization tools such as confusion matrices and ROC curves help you understand model results and guide improvements.

| Metric | Definition / Interpretation | Formula / Range | Successful Performance Indicator |

|---|---|---|---|

| Accuracy | Proportion of correctly classified samples over total samples | Accuracy = Correct / Total | Close to 1 (or 100%) means high correct classification |

| Precision | Ratio of true positives to total predicted positives | Precision = TP / (TP + FP) | Close to 1 means few false positives |

| Recall | Ratio of true positives to total actual positives | Recall = TP / (TP + FN) | Close to 1 means few false negatives |

| F1-score | Harmonic mean of precision and recall | F1 = 2 * (Precision * Recall) / (Precision + Recall) | High f1-score indicates good overall classification |

You can choose between two-stage detectors and single-stage detectors for your image processing algorithms. Two-stage detectors, like Faster R-CNN, reach about 70% accuracy and work well for small objects and complex scenes. They use region proposal networks to reduce computational costs and latency by up to 10 times. Single-stage detectors, such as YOLO, offer faster real-time processing but slightly lower accuracy at around 63.4%. For quality control in industries like medical imaging or manufacturing, two-stage systems are often the best choice.

- Fine-tuning models speeds up training and adapts to new tasks.

- Using the right evaluation metrics helps you track improvements in accuracy and quality control.

- Advanced image processing algorithms supported by industrial PCs and digital imaging boost both accuracy and efficiency.

Remember: Continuous evaluation and adjustment of your image processing algorithms keep your machine vision system reliable and ready for changing production needs.

Integration of Machine Vision Systems

Automation Roadmap

You need a clear automation roadmap to get the most from machine vision in manufacturing. Start by choosing tools that help you plan and track progress, such as Jira or Trello. These tools let you set goals, assign tasks, and monitor each step. Use data from different sources to build a complete picture of your process. AI-driven insights can show you patterns and trends in your inspection results.

Predictive modeling helps you see what might happen in the future. You can use market trend analysis tools like Google Trend to spot changes in demand. Track what your competitors do to find gaps in your own process. Create a visual roadmap with clear timelines and milestones. Update your plan often using feedback from your team and real-time data.

A good roadmap moves through stages. At first, you may rely on manual work. As you grow, you add forecasting and data analysis. Later, you use AI and automation to make decisions faster. This staged approach helps you build a strong foundation for integrating machine vision into automated systems.

System Integration Steps

You can follow a step-by-step process to make integration of machine vision systems successful in manufacturing and inspection. First, analyze your needs. Look at your operation, the parts you handle, and your production flow. Next, define what you want the system to do and how you will measure success.

Design the vision technology early. Make a project plan with clear tasks and use project management tools to stay organized. Install the system and test it before full deployment. Write a validation plan and repeat tests after installation to make sure everything works.

You may need skills from different fields, such as mechanical and computer engineering. If you lack resources, work with experienced integrators. Train your staff so they can use and maintain the system well.

Here is a table showing real-world examples of successful integration in manufacturing and inspection:

| Company / Alliance | Application / System Description | Integration Success / Benefits |

|---|---|---|

| Basler AG | AI-enabled vision for retail checkout | Faster checkout, better accuracy, lower labor costs |

| Cognex Corporation | Deep learning defect detection | Fewer false positives, better quality control, higher productivity |

| Ericsson & ABB Alliance | 5G-enabled vision for automotive manufacturing | Real-time image transmission, faster and more precise inspection |

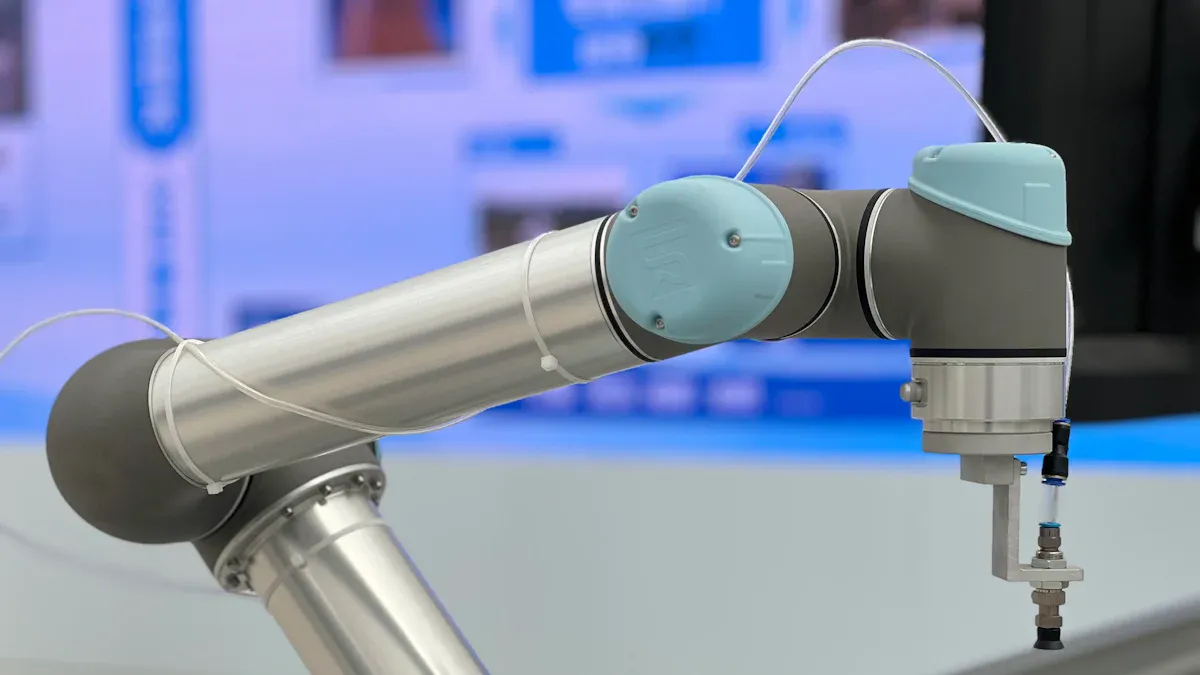

| Universal Robots | Collaborative robots for welding, painting, and assembly | Higher precision, improved efficiency, cost savings |

| Headwall Photonics | Hyperspectral imaging for food safety | Finds contaminants invisible to the human eye, better food quality |

| Keyence Corporation | 3D vision for electronics and aerospace inspection | Accurate inspection, ensures compliance with specifications |

You can see that these companies improved speed, accuracy, and efficiency by following a careful integration process. When you plan well and use the right steps, you help your automated systems reach their full potential in manufacturing and inspection.

Increase Productivity with Machine Vision

Quality Control

You can achieve strong quality control with machine vision. These systems give you automated inspection that works faster and more accurately than manual checks. When you use machine vision, you get consistent, repeatable results. This means you spot defects early and reduce waste on your production line. AI-driven machine vision systems often lower defect rates to below 1%. In one case, a system found a 22% failure rate, which led to quick repairs and prevented customer complaints.

Machine vision helps you track every product as it moves through production. Real-time inspections let you catch problems right away. You can use tracking data to improve processes and keep your quality control strong. Machine learning models in machine vision systems detect even small flaws that humans might miss. Over time, these systems learn and get better at defect detection, which helps you reduce waste and save money.

Tip: Use machine vision to monitor your production line for early signs of trouble. This helps you improve safety and avoid costly recalls.

Speed and Efficiency

Machine vision increases the speed and efficiency of your production. Automated inspection lets you check up to 10,000 parts per hour. You can reduce inspection cycle times by 40%. This means your production line moves faster and you get more products out the door.

Here is a table showing how machine vision improves production:

| Productivity Benchmark | Measurable Impact |

|---|---|

| Automated inspection speed | Up to 10,000 parts per hour |

| Inspection cycle time reduction | 40% decrease |

| Accuracy improvement | Over 99.5% with AI-driven systems |

| Labor cost reduction | About 50% |

| Energy consumption reduction | Over 38% |

You also see improvements in exposure time and image quality. For example, exposure time can drop from 40-50 microseconds to just 12, which removes motion blur and gives you clearer images. Machine vision systems help you track production and spot trends. This allows you to make changes quickly and improve processes. When you use advanced inspection and real-time inspections, you increase productivity and keep your production running smoothly.

You can boost your machine vision system by upgrading hardware, optimizing lighting, and using advanced algorithms. New technologies drive rapid growth across industries. The global market will reach over USD 41 billion by 2030, with quality assurance and inspection leading adoption.

| Segment | Key Insight |

|---|---|

| Market Size (2030) | USD 41,744 million |

| Fastest Growth | Software, smart cameras, identification |

| Leading Application | Quality assurance and inspection |

Assess your current setup. Explore upgrades or consult experts to stay ahead in automation. 🚀

FAQ

What is the most important upgrade for my machine vision system in 2025?

You should upgrade your cameras and sensors first. Newer models capture clearer images and process data faster. This helps you find defects quickly and improve quality control.

How does lighting affect machine vision accuracy?

Lighting changes how well your system sees details. Good lighting reduces shadows and glare. You get sharper images and better results. Try using LED lights and filters that match your camera’s sensitivity.

Can I use machine vision for small batch production?

Yes, you can. Machine vision systems now adapt to different products and batch sizes. You can reprogram them quickly. This makes them useful for both large and small production runs.

What skills do I need to maintain a machine vision system?

You need basic computer skills and some knowledge of cameras and lighting. Learning how to use software for image analysis helps. Many systems come with training and support.

See Also

The Impact Of Deep Learning On Machine Vision

Essential Insights Into Computer And Machine Vision

Understanding Image Processing In Machine Vision Systems