Modern manufacturing demands precision and speed. Automated optical inspection plays a vital role in ensuring the quality of products while maintaining efficiency. You can rely on these systems to detect defects that human eyes might miss. By using an Automated Optical Inspection (AOI) machine vision system, manufacturers achieve consistent results and reduce errors. Industries turn to these systems because they enhance productivity and minimize waste, making them indispensable in today’s competitive landscape.

Key Takeaways

-

Automated Optical Inspection (AOI) systems help find product flaws quickly. They are more accurate than human inspectors.

-

Buying AOI technology lowers mistakes and waste in factories. This saves money and makes production better for the environment.

-

2D AOI systems check surfaces, while 3D systems find harder-to-see problems. 3D systems work well for detailed tasks.

-

Adding AI to AOI systems makes finding defects easier. It also reduces wrong alerts, keeping product quality steady.

-

AOI systems make production faster and smoother. Factories can grow without losing quality.

Understanding Automated Optical Inspection Systems

What is an AOI machine vision system?

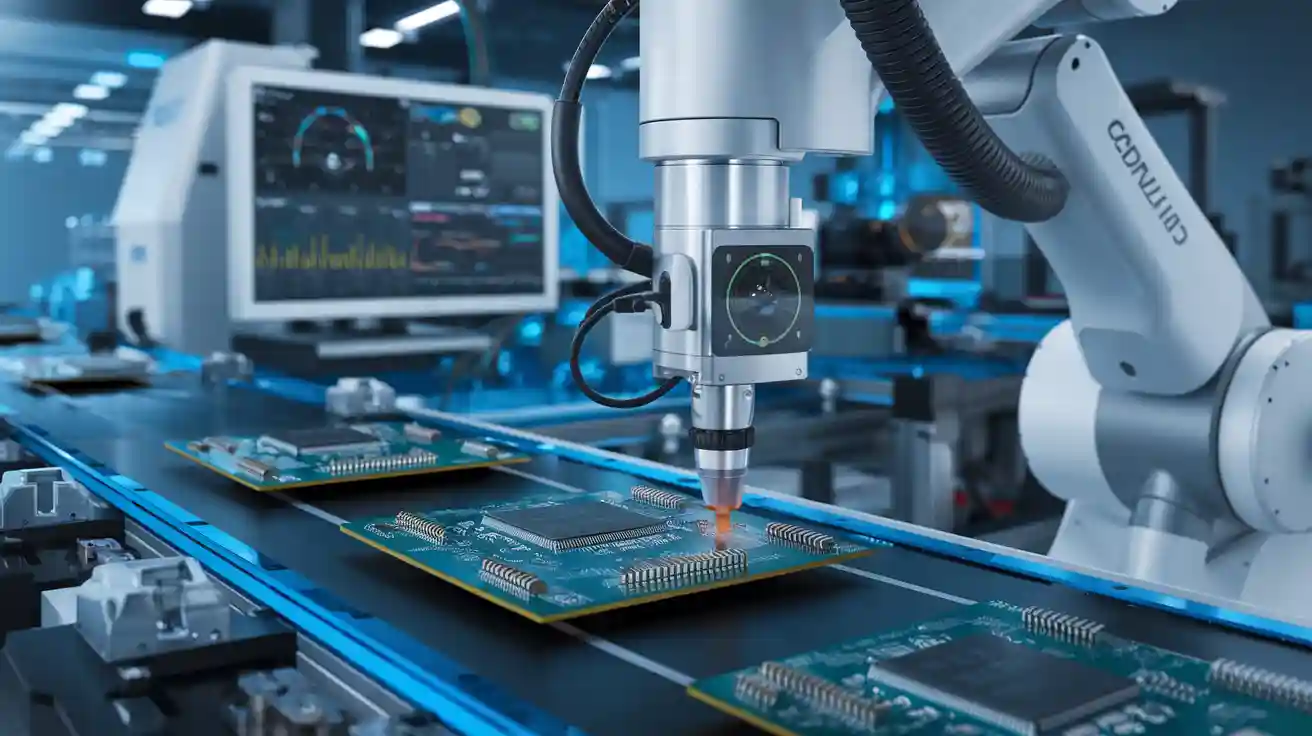

An automated optical inspection (AOI) machine vision system is a cutting-edge tool used in manufacturing to ensure products meet strict quality standards. It uses advanced cameras and software to inspect items for defects, such as missing components or incorrect alignments. Unlike manual inspections, which rely on human judgment, AOI systems provide consistent and accurate results. You can think of it as a highly efficient “visual inspector” that never tires or makes mistakes.

These systems are widely used in industries like electronics, automotive, and medical devices. For example, in electronics manufacturing, an AOI machine vision system checks printed circuit boards (PCBs) for issues like soldering errors or misplaced parts. By automating this process, manufacturers can achieve higher levels of quality assurance while reducing production delays.

Components of an automated optical inspection system

An AOI system consists of several key components that work together to perform inspections:

-

Cameras: High-resolution cameras capture detailed images of the product being inspected. Some systems use multiple cameras to provide different angles.

-

Lighting: Proper lighting ensures that the cameras can clearly capture the product’s features. LED lights are commonly used for their precision and reliability.

-

Image Processing Software: This software analyzes the captured images and compares them to predefined standards. It identifies any defects or irregularities.

-

Conveyor System: Many AOI systems include a conveyor to move products through the inspection process automatically.

-

User Interface: The interface allows operators to set inspection parameters and review results.

Each component plays a vital role in ensuring the system performs accurate and efficient inspections. For instance, the combination of cameras and lighting ensures that even tiny defects are visible, while the software processes this data in real time.

How AOI systems detect defects using machine vision

Automated optical inspection systems use machine vision technology to detect defects with remarkable precision. The process begins when the system captures high-resolution images of the product. These images are then analyzed by sophisticated algorithms that compare them against a set of predefined standards. Any deviation from these standards is flagged as a defect.

For example, AOI systems can identify issues like misaligned components, incorrect polarity, or faulty soldering. Both 2D and 3D imaging technologies are used to enhance defect detection. While 2D imaging captures surface-level details, 3D imaging provides depth information, making it easier to spot subtle irregularities.

Machine vision technology has revolutionized defect detection in manufacturing. By automating this process, you can achieve faster inspections without compromising accuracy.

In one study, AOI systems demonstrated their ability to detect defects that human inspectors often missed. This included identifying tiny soldering errors on PCBs and ensuring components were correctly placed. Such capabilities make AOI systems an essential tool for maintaining high-quality standards in modern production lines.

Comparing 2D and 3D Automated Optical Inspection Systems

Applications of 2D AOI systems in manufacturing

You’ll find 2D AOI systems widely used in industries where surface-level inspections are sufficient. These systems excel in electronics manufacturing, where they verify component placement and soldering accuracy. High-resolution cameras and image processing software ensure that defects like missing components or soldering errors are quickly identified.

Manufacturers often use stop-and-go or continuous scanning techniques to achieve precise camera positioning and stable image capture. For example, in PCB production, 2D AOI systems inspect boards for alignment issues and surface defects. Their speed and simplicity make them ideal for high-volume production lines.

|

Application Area |

Technology Used |

Benefits |

|---|---|---|

|

Electronics Manufacturing |

High-resolution cameras and image processing |

Verifies component placement and soldering accuracy |

|

Inspection Techniques |

Stop-and-go and continuous scanning approaches |

Achieves precise camera positioning and stable image capture |

Advantages of 3D AOI systems for high-precision inspections

When you need to detect complex defects like volume or shape irregularities, 3D AOI systems are the go-to solution. These systems use advanced imaging technology to capture depth information, allowing them to identify issues that 2D systems might miss. For example, they can measure the height of solder joints or detect warping in components.

3D AOI systems perform well under varying lighting conditions, making them more reliable in challenging environments. Although they process data more slowly due to their complexity, their precision ensures fewer errors in high-stakes industries like automotive and medical device manufacturing.

Tip: If your production line requires high precision and handles intricate components, investing in 3D AOI systems can significantly enhance quality control.

Key differences between 2D and 3D AOI systems

Understanding the differences between 2D and 3D AOI systems helps you choose the right solution for your manufacturing needs. While 2D systems focus on surface-level defects, 3D systems analyze depth and volume. This makes 3D systems better suited for detecting complex issues.

Here’s a comparison of key features:

|

Feature |

2D AOI Systems |

3D AOI Systems |

|---|---|---|

|

Image Quality |

Good image quality, but limited in 3D defect detection |

Highly precise, capable of detecting complex defects |

|

Inspection Speed |

Generally faster and less complex |

Slower due to complexity and data processing needs |

|

Cost |

Less expensive |

More complex and costly |

|

Defect Detection |

Limited to 2D defects |

Can detect 3D defects like volume and shape issues |

|

Lighting Variability |

Struggles with certain lighting conditions |

Less affected by lighting variations |

|

Computational Power |

Requires less computational power |

Requires more computational power |

2D systems offer faster inspections and lower costs, making them ideal for simpler applications. On the other hand, 3D systems provide unmatched precision, especially for products requiring intricate quality checks.

The Impact of AOI Systems on Manufacturing Processes

Enhancing product quality in high-speed production lines

In high-speed production lines, maintaining consistent product quality can be challenging. Automated optical inspection systems help you overcome this challenge by providing precise and reliable defect detection. These systems inspect every product on the line, ensuring that no faulty items reach the next stage of the manufacturing process. Unlike manual inspections, which can miss subtle issues, AOI systems excel at identifying even the smallest defects.

For example, in electronics manufacturing, an AOI system can verify the placement of components on a printed circuit board (PCB) within seconds. This ensures that each PCB meets quality standards before moving forward. By integrating AOI systems into your production line, you can maintain high-quality output without slowing down operations.

Tip: Using AOI systems in high-speed environments not only improves quality but also boosts customer satisfaction by delivering defect-free products.

Reducing manufacturing errors and waste

Errors and waste can significantly impact your manufacturing process, both financially and environmentally. Automated optical inspection systems minimize these issues by detecting defects early in the production cycle. When you identify problems at an early stage, you can address them before they escalate, reducing the need for costly rework or scrapping.

For instance, AOI systems can detect soldering errors, misaligned components, or surface irregularities in real time. This immediate feedback allows you to make adjustments on the spot, preventing defective products from accumulating. As a result, you save resources and reduce material waste, contributing to a more sustainable manufacturing process.

Note: Reducing waste not only lowers costs but also aligns with eco-friendly manufacturing practices, which are increasingly important in today’s market.

Improving scalability and efficiency with AOI systems

As your business grows, scaling up production can become a complex task. Automated optical inspection systems simplify this process by enhancing efficiency and adaptability. These systems can handle large volumes of products without compromising on quality, making them ideal for scaling up your manufacturing process.

With AOI systems, you can also customize inspection parameters to suit different product types. This flexibility allows you to adapt quickly to changing production demands. Additionally, the automated nature of AOI systems reduces the need for manual labor, freeing up your workforce for other critical tasks. By improving both scalability and efficiency, AOI systems enable you to meet growing market demands with ease.

Callout: Investing in AOI technology ensures that your manufacturing process remains efficient and adaptable, even as production volumes increase.

Automated Inspection vs. Manual Inspection

Challenges of manual inspection methods

Manual inspection methods often struggle to meet the demands of modern manufacturing. Human inspectors can only work for limited hours and are prone to fatigue, which increases the likelihood of errors. Identifying tiny defects, such as misaligned components or surface irregularities, becomes difficult when relying solely on human vision. This inconsistency can lead to faulty products slipping through the inspection process.

Another challenge is the speed of manual inspections. In high-speed production lines, keeping up with the pace while maintaining accuracy is nearly impossible for human inspectors. The repetitive nature of the task also makes it harder to sustain focus over time. These limitations make manual inspection less reliable for industries requiring precision and efficiency.

Benefits of automated optical inspection in accuracy and speed

Automated optical inspection systems revolutionize the way you approach quality control. These systems operate at speeds far beyond human capability, ensuring that every product is inspected thoroughly. Unlike manual methods, automated systems maintain consistent accuracy without being affected by fatigue. They can detect even the smallest defects, such as soldering errors or shape irregularities, with remarkable precision.

Technical studies have shown that automated optical inspection systems significantly enhance the inspection process. They work continuously, making them ideal for inline operations in industries like electronics and automotive manufacturing. By integrating an AOI system, you can achieve high throughput while maintaining strict quality standards. This combination of speed and accuracy makes automated inspection indispensable in today’s competitive market.

Cost-effectiveness and long-term advantages of AOI systems

Investing in an industrial inspection machine like an AOI system may seem costly upfront, but the long-term benefits outweigh the initial expense. Automated systems reduce the need for manual labor, lowering operational costs over time. They also minimize waste by identifying defects early in the production cycle, preventing defective products from advancing further.

The scalability of automated systems is another advantage. As your production volume grows, AOI systems can adapt to handle larger workloads without compromising quality. Inline integration ensures seamless operation, saving time and resources. Over time, these systems pay for themselves by improving efficiency, reducing errors, and enhancing product quality.

Tip: Choosing an automated inspection system not only improves your bottom line but also positions your business for long-term success in a competitive industry.

Innovations and Future Trends in AOI Technology

AI-powered advancements in automated optical inspection

Artificial intelligence (AI) is transforming automated optical inspection systems. By integrating AI, these systems can analyze data faster and deliver more accurate results. Machine learning algorithms allow AOI systems to adapt to new defect patterns over time. This means you can rely on them to improve their performance as they process more data.

For example, AI-powered AOI systems can identify subtle defects that traditional systems might miss. They also reduce false positives, ensuring that only genuine issues are flagged. This leads to high-quality results and fewer interruptions in your production line. With AI, you can achieve better efficiency and maintain consistent quality standards.

Tip: Adopting AI-driven AOI systems can give your business a competitive edge by enhancing both speed and precision.

Expanding applications of AOI systems across industries

The use of AOI systems is no longer limited to electronics manufacturing. Today, industries like automotive, aerospace, and medical devices are adopting these systems to ensure high-quality results. For instance, in the automotive sector, AOI systems inspect components for defects like surface irregularities or misalignments. In medical device manufacturing, they verify the precision of intricate parts, ensuring safety and reliability.

The growing demand for high-quality manufacturing processes has driven this expansion. According to market reports, advancements in imaging technologies and AI have made AOI systems more versatile. This adaptability allows you to use them in diverse applications, from inspecting tiny electronic components to evaluating large mechanical parts.

Note: As industries continue to prioritize quality assurance, the role of AOI systems will only grow.

The role of AOI systems in shaping the future of manufacturing

AOI systems are at the forefront of modern manufacturing. They help you meet the increasing demand for precision and efficiency. Inline AOI equipment, for example, enables real-time inspections, ensuring that defects are caught early. This reduces waste and improves overall productivity.

Future trends suggest that AOI systems will become even more advanced. Reports highlight the integration of 3D imaging and AI as key drivers of innovation. These technologies enhance the accuracy and speed of inspections, making AOI systems indispensable for manufacturers aiming to stay competitive. By adopting these innovations, you can position your business for long-term success in an evolving market.

The evolution of AOI technology reflects changing consumer preferences and the need for operational excellence. Staying ahead of these trends ensures your manufacturing process remains efficient and reliable.

Automated optical inspection (AOI) systems have become essential in modern industries. They ensure high-quality standards by detecting defects with unmatched speed and precision. You can rely on these systems to handle the increasing complexity of products, especially in sectors like electronics and automotive manufacturing.

AOI systems outperform manual inspections by eliminating human error and maintaining consistent accuracy. Studies show that 3D AOI systems, in particular, excel at identifying defects in miniaturized components, making them indispensable for advanced manufacturing.

The future of AOI technology looks promising. With advancements like AI and 3D imaging, you can expect even greater efficiency and precision. These innovations will help you meet the growing demand for high-quality products while staying competitive in an evolving market.

FAQ

What industries benefit the most from AOI systems?

AOI systems are widely used in electronics, automotive, aerospace, and medical device manufacturing. These industries require high precision and quality assurance. For example, AOI systems inspect printed circuit boards in electronics and verify intricate components in medical devices.

How do AOI systems improve production efficiency?

AOI systems automate defect detection, reducing the need for manual inspections. They work faster than humans and provide consistent results. By identifying defects early, you can prevent delays and minimize waste, ensuring smoother production processes.

Are 3D AOI systems worth the investment?

If your production involves intricate components or requires high precision, 3D AOI systems are worth it. They detect complex defects like volume irregularities and ensure superior quality. Although they cost more upfront, their accuracy and long-term benefits outweigh the expense.

Can AOI systems adapt to different products?

Yes, AOI systems offer customizable inspection parameters. You can adjust them to suit various product types and manufacturing needs. This flexibility makes them ideal for industries with diverse production lines.

What role does AI play in AOI systems?

AI enhances AOI systems by improving defect detection accuracy. Machine learning algorithms allow the system to recognize new defect patterns over time. This reduces false positives and ensures better quality control, making your production line more efficient.

Tip: Consider AI-powered AOI systems for advanced manufacturing needs. They combine speed, precision, and adaptability.

See Also

Exploring Machine Vision Systems for Inspections in 2025

Defining Specialized Software for Automated Inspection Solutions

Improving Product Quality with Surface Inspection Vision Systems

Determining ROI for Automated Visual Inspection Systems in 2025

Essential Features and Advantages of Medical Device Vision Systems