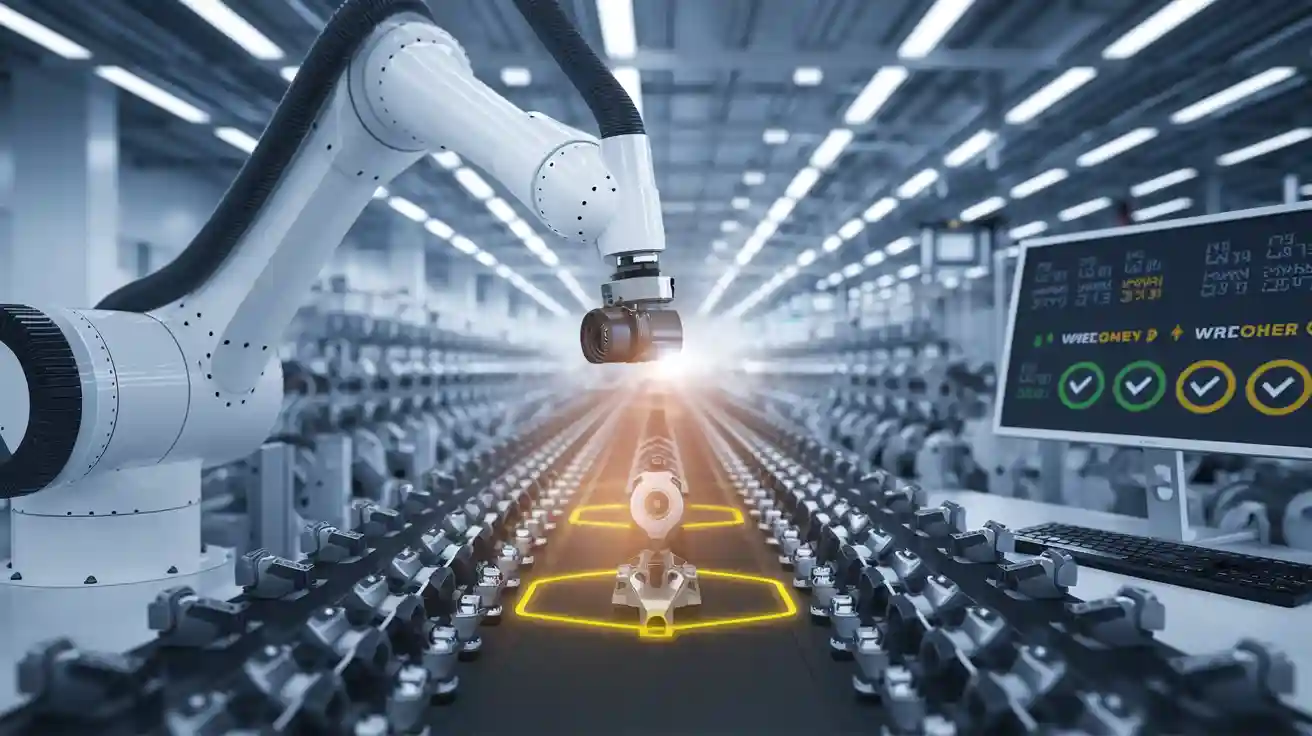

An assembly verification machine vision system uses cameras and AI to check if each assembly step meets strict quality standards. Companies in manufacturing rely on these systems to catch errors and improve quality control during assembly. Machine vision helps automate inspections, reducing mistakes that people might miss. Market data shows the assembly verification market reached $13.7 billion in 2024, with rapid growth expected as AI and deep learning become more common in assembly verification.

| Aspect | Details |

|---|---|

| Market Size 2024 | $13.7 billion |

| Key Application | Assembly verification in manufacturing (automotive, electronics, pharmaceutical sectors) |

| Technology Trends | AI, deep learning, smart factories |

Key Takeaways

- Assembly verification machine vision systems use cameras and AI to check products quickly and accurately during manufacturing.

- These systems combine cameras, lighting, lenses, and software to detect missing parts, defects, and misalignments in assemblies.

- Machine vision improves quality by reducing human errors, speeding up inspections, and providing consistent results around the clock.

- AI and deep learning help these systems learn from past inspections, making defect detection smarter and more reliable over time.

- Using machine vision lowers costs, reduces waste, and supports continuous quality improvement in many industries like automotive and electronics.

Assembly Verification Machine Vision System

Components

An assembly verification machine vision system checks products during manufacturing to make sure every part is present and correctly assembled. Many industries use these systems to improve quality and reduce errors. Some common assembly verification applications include automotive, electronics, medical devices, packaging, and food production.

Assembly verification tools help companies find defects early and prevent faulty products from reaching customers.

The main components of a verification machine vision system work together to inspect assemblies:

- Cameras: These capture images of the assembly. Area cameras with high resolution and fast frame rates are popular in manufacturing. For example, the Keyence XG-X series works well in harsh environments, while Imaging Source 38 series is used for electronics inspection.

- Lighting: Proper lighting makes features stand out and helps the camera see defects. Bar lighting gives even illumination, dark field lighting highlights scratches, and dome lighting removes glare from shiny surfaces.

- Lenses: Lenses focus light onto the camera sensor. They determine how much of the assembly is visible and how sharp the image appears.

- Sensors and Capture Boards: These convert the image into digital data for analysis.

- Vision Software: Software algorithms process the images. They reduce noise, enhance contrast, and detect edges. The software checks for missing parts, misalignment, and defects.

- Communication Systems: These connect cameras, lighting, and computers. They allow the system to send inspection results to other machines or operators.

| Component | Function | Example Application |

|---|---|---|

| Camera | Captures images of assemblies | PCB inspection, brake pad verification |

| Lighting | Illuminates parts for clear imaging | Detecting scratches on metal surfaces |

| Lens | Focuses image onto sensor | Ensuring label position on packaging |

| Software | Analyzes images for defects and errors | Checking for missing electronic parts |

| Communication | Shares results with other systems | Alerting operators about faulty products |

Lighting and camera integration play a key role in assembly verification. The right lighting type, color, and geometry must match the assembly and camera for reliable inspection. Testing camera-lighting integration during setup helps ensure the verification machine vision system works well in real production.

Operation

A verification machine vision system follows a step-by-step process to inspect assemblies in manufacturing:

- A detector senses when an assembly moves into position.

- The system sends signals to the camera and lighting to start inspection.

- The camera scans the assembly and captures an image.

- Lighting turns on at the right moment to highlight features.

- The camera outputs the image to the computer.

- The system stores the digital image in memory.

- Vision software analyzes the image. It checks for correct part placement, orientation, and defects.

- The system decides if the assembly passes or fails.

- If the assembly fails, the system can remove it or alert an operator.

Software algorithms help the verification machine vision system work quickly and accurately. They clean up images, adjust brightness, and find edges. The system compares each assembly to a set standard. Machine learning and AI algorithms allow the system to learn from past inspections and improve defect detection.

Assembly verification applications use these systems to check for missing components, misaligned parts, and surface defects. In electronics, the system inspects circuit boards for tiny flaws. In automotive manufacturing, it verifies brake pads and gears for safety. Medical device makers use assembly verification to ensure tools and implants meet strict standards.

Machine vision systems help companies catch errors early, reduce recalls, and improve product quality.

Assembly verification machine vision system technology continues to advance. New cameras, lighting, and software make inspections faster and more reliable. As manufacturing grows more complex, these systems play a bigger role in quality control.

Inspection and Defect Detection

Image Analysis

A vision inspection system uses high-resolution cameras and advanced sensors to capture detailed images of assemblies. These systems perform inspection by checking for the presence or absence of parts, verifying correct placement, and identifying surface defects. During assembly verification inspections, the inspection system analyzes each image in real time. The system uses auto-focus calibration and real-time monitoring to adapt to changes on the production line.

- Presence inspections confirm that every part is in the correct place and that the quantity matches the design.

- Surface inspection detects scratches, dents, or other defects that may affect product quality.

- Feature recognition helps the inspection system identify labels, connectors, and other important details.

AI plays a key role in image analysis. AI-powered inspection systems learn from examples and recognize subtle patterns that humans might miss. Deep learning models, such as convolutional neural networks, increase defect detection accuracy by identifying complex patterns and subtle defects. These models provide consistent and reliable inspection results, even when lighting or part orientation changes. Once trained, AI models can scale across multiple production lines, enabling automated inspections with high speed and accuracy.

In electronics and automotive manufacturing, the inspection system detects common defects such as soldering errors, misaligned components, improper cable routing, and incorrect label placement. Early defect detection reduces costly rework and prevents faulty products from reaching customers.

Error Prevention

Assembly verification inspections rely on error prevention strategies to reduce false positives and negatives. The inspection system uses advanced algorithms and machine learning to learn from large datasets, improving defect detection accuracy over time. This approach helps the inspection system adapt to product variations and changing environments.

AI-driven inspection systems perform multi-faceted inspections, assessing several quality parameters at once. Real-time monitoring allows immediate corrective actions, which reduces human error and ensures consistent quality control. The inspection system follows a structured process: image acquisition, illumination, preprocessing, analysis, and pattern recognition. This process ensures precision and consistency in defect detection.

Barcode verification and validation processes further reduce errors. The inspection system checks barcodes for quality and compliance, which is critical in many industries. Expanding training data for AI models improves defect detection rates, as seen in cases where false rejects dropped by 65% after more training.

A vision inspection system, when combined with AI and deep learning, provides reliable, automated inspection and defect detection. These systems help manufacturers maintain high standards, reduce waste, and deliver safe, high-quality products.

Quality in Assembly Verification

Accuracy

Assembly verification machine vision systems play a vital role in improving accuracy during quality control. These systems use advanced cameras, lighting, and software to check each assembly step. They compare every product to a set standard, making sure each part is present and correctly placed. This process helps companies achieve enhanced accuracy and reduce the risk of missing a defect.

A comparison between machine vision systems and manual inspection shows a clear advantage for automated solutions:

| Metric | Machine Vision System Performance | Manual Inspection Performance |

|---|---|---|

| Accuracy Rate | Approximately 99% | Lower due to human error and inconsistency |

| Defect Rate Reduction | 30% reduction | N/A |

| Inspection Time per Unit | Reduced from 1 minute to 2.2 seconds | 1 minute |

| Cost Savings | 30-fold reduction | Baseline |

Manual inspections often suffer from human error, fatigue, and inconsistency. Human inspectors may miss subtle defects, especially in high-volume manufacturing. Machine vision systems use artificial intelligence and machine learning to detect even the smallest defect. These systems can achieve up to 95% accuracy with minimal training data, making them adaptable to new assembly types.

In the automotive industry, a leading car seat manufacturer replaced manual inspection with an AI-powered assembly verification system. The new system detected 99% of defects, reduced inspection time from 1 minute to 2.2 seconds, and cut defect rates by 30%. The company also saw a 30-fold reduction in inspection costs. This example shows how accuracy in final assembly verification leads to better quality and lower expenses.

Electronics manufacturers also benefit from high accuracy. Machine vision systems check for missing components, soldering errors, and misaligned parts. As electronic devices become smaller, the need for precise inspection grows. These systems ensure that even the tiniest assembly meets strict quality standards.

Note: Machine vision systems provide more consistent and reliable quality control compared to manual inspection, helping companies deliver safe and high-quality products.

Consistency

Consistency is essential for maintaining high quality in assembly verification. Machine vision systems operate 24/7 without fatigue, ensuring the same level of accuracy across all production shifts. Unlike human inspectors, these systems do not experience tiredness or changes in judgment. They use precise measurements and pre-programmed tolerances to evaluate each assembly.

Machine vision inspection systems use industrial cameras and specialized lighting to capture images. Algorithms analyze these images in real time, comparing them to predefined standards. This process ensures unbiased, repeatable pass or fail decisions for every assembly, regardless of the time of day or shift.

Manufacturers in the automotive sector use machine vision to measure drive shaft parallelism, check door assembly gaps, and detect gear notch angles. These tasks require consistent accuracy to prevent assembly errors and ensure product safety. In electronics, machine vision systems inspect circuit boards and connectors, maintaining quality even as product designs change.

Machine vision systems also support continuous improvement in quality control. They collect and analyze data from every inspection, providing valuable insights for process optimization. Companies use artificial intelligence, machine learning, and predictive maintenance to monitor equipment and prevent defects before they occur. Integration with IoT and smart manufacturing allows real-time feedback and remote monitoring, helping teams address issues quickly.

| Data-Driven Method | Description and Impact |

|---|---|

| Artificial Intelligence (AI) | Detects small defects with high accuracy; reduces defect rates and inspection time. |

| Machine Learning & Transfer Learning | Adapts to new assembly types with minimal data, improving inspection quality. |

| Predictive Maintenance | Monitors equipment to prevent defects and minimize downtime. |

| IoT Integration | Enables real-time data sharing and corrective actions. |

| Advanced Imaging | Provides detailed data for precise defect detection. |

Final assembly verification benefits from this consistency. Companies can trust that every product meets the same high quality standards, no matter when or where it was made. This reliability is especially important as manufacturing moves toward smaller, more complex assemblies. Consistent inspection results help reduce recalls, improve customer satisfaction, and support continuous quality improvement.

Benefits and Challenges

Advantages

Assembly verification machine vision systems bring many benefits to manufacturing. These systems increase speed by performing inspections in milliseconds. They help factories avoid bottlenecks and keep production moving quickly. Machine vision systems work without breaks, so they inspect products faster and more accurately than people. This leads to higher inspection capacity and better quality. Automation reduces labor costs because fewer workers are needed for inspection. Early defect detection stops bad products from moving forward, which reduces waste and rework. Companies save money by avoiding recalls and lowering overhead costs. Machine vision systems also collect large amounts of data during inspections. This data helps improve quality by finding patterns and root causes of defects. Over time, factories use this information to make better decisions and improve quality control.

- Rapid image processing for faster inspections

- Continuous operation without fatigue

- Lower labor costs and less waste

- Real-time defect detection for better quality

- Data collection for process optimization

Integration

Integrating machine vision systems into existing production lines can be challenging. Many factories have old equipment that needs updates before new systems can work. Products often vary in size, shape, and color, so the system must adapt to these changes. Managing large amounts of data in real time is important to avoid slowdowns. High initial costs and the need for skilled workers can make integration harder. Regular maintenance is needed to keep the system reliable. Workers must clean lenses, protect cameras from dust, and adjust lighting as needed. Training staff on calibration and troubleshooting helps maintain accuracy. Factories must also balance preventive and reactive maintenance to reduce downtime and keep quality high.

Future Trends

The future of assembly verification machine vision systems looks bright. Deep learning will make inspections smarter and more flexible. These systems will learn from images and improve accuracy without extra programming. Three-dimensional vision will help check complex assemblies and improve quality. Virtual prototyping will let engineers test designs before making real products, which helps catch problems early. Machine vision systems will become smaller, easier to use, and better at sharing data with other machines. As factories use more AI and advanced imaging, quality control will keep getting better. Experts expect strong growth in machine vision technology, especially in industries that need high accuracy and quality.

Assembly verification machine vision systems have become essential for maintaining high quality in modern manufacturing. These systems automate inspection, reduce errors, and ensure every assembly meets strict quality standards. Companies see improved defect detection, faster inspection, and lower costs. To maximize quality, experts recommend collecting diverse training data, using high-performance hardware, and following best practices.

Staying informed about new technologies and best practices helps manufacturers adapt quickly and maintain top quality in every assembly.

FAQ

What is an assembly verification machine vision system?

An assembly verification machine vision system uses cameras and software to check if products are built correctly. It finds missing parts, misaligned pieces, or defects. Many factories use these systems to improve quality and reduce errors.

How does machine vision help prevent defects?

Machine vision systems spot problems early. They check each product for mistakes like missing screws or scratches. The system alerts workers or removes bad products. This process helps companies avoid recalls and keep customers safe.

Which industries use assembly verification machine vision systems?

Many industries use these systems. Automotive, electronics, medical device, and food packaging companies rely on machine vision for quality control. These systems help ensure products meet strict standards.

Can machine vision systems work with different product types?

Yes. Machine vision systems adapt to many shapes, sizes, and colors. Engineers program the system for each product. The system can learn new items using artificial intelligence.

What are the main benefits of using machine vision for assembly verification?

| Benefit | Description |

|---|---|

| Speed | Inspects products quickly |

| Accuracy | Finds small defects |

| Consistency | Gives the same results every time |

| Cost Savings | Reduces waste and labor costs |

See Also

Understanding Machine Vision Systems For Quality Assurance

Ensuring Accurate Part Identification Using Machine Vision

Advancing Assembly Verification Through Machine Vision Innovation

Detect Every Defect Using Verification Machine Vision Systems

Improving Product Quality With Surface Inspection Vision Systems