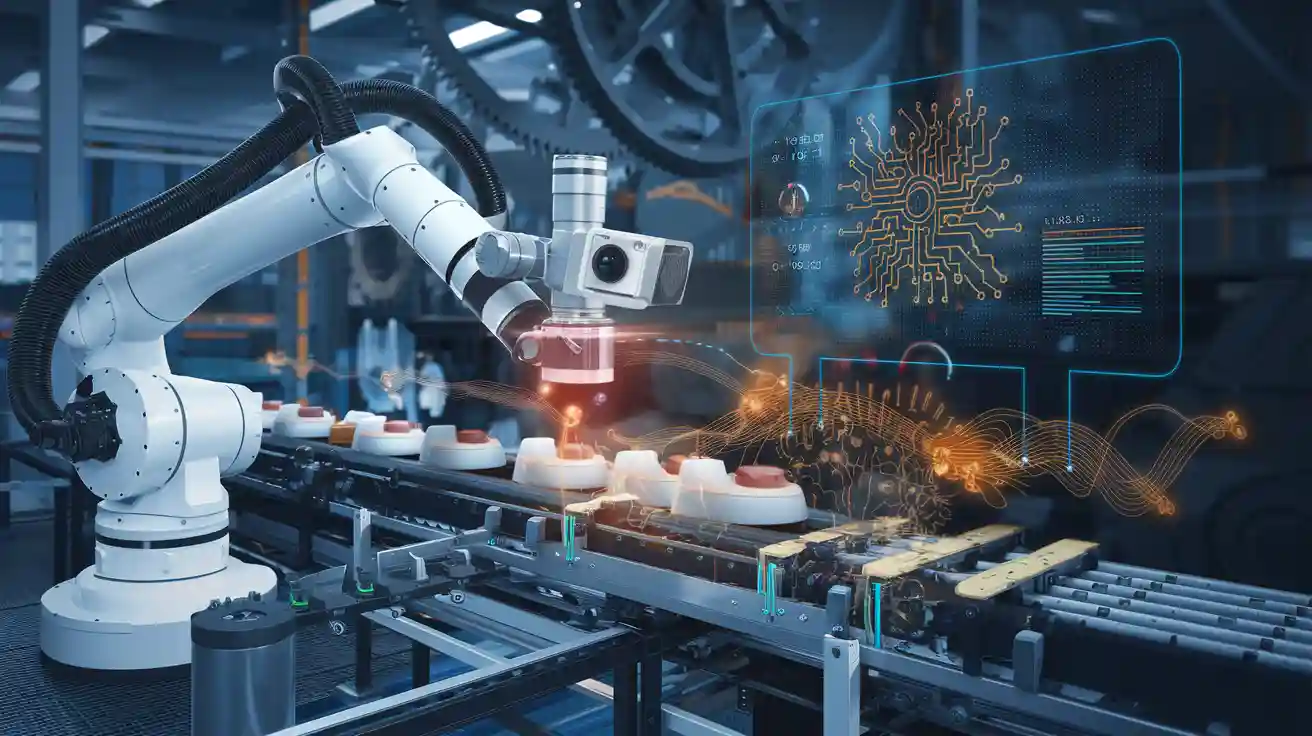

An action machine vision system uses a camera and advanced image analysis to help automated systems see objects and take action. In industrial automation, cameras and lighting capture images, which software then processes to guide machines. These systems inspect parts and products much faster and more accurately than human workers.

Automated systems with machine vision reduce errors and improve quality, while manual inspection can miss up to 40% of flaws. Real-time image feedback and motion control allow robots to sort, inspect, and assemble parts with high precision.

| Metric | Value |

|---|---|

| Market Size (2024) | USD 21.61 billion |

| Projected Market Size (2033) | USD 32.89 billion |

Camera improvements, such as better sensors and lighting, expand the reach of machine vision across many industries.

Key Takeaways

- Action machine vision systems use cameras and AI to help machines see, analyze, and act quickly with high accuracy.

- These systems improve product quality by detecting defects early and guiding robots for precise tasks.

- Key components include cameras, lighting, image processing software, and motion control that work together for fast, reliable automation.

- Machine vision systems speed up inspection and sorting while reducing errors and waste in many industries.

- AI-powered vision adapts to changing conditions and complex tasks, making automation more flexible and efficient.

What Is an Action Machine Vision System?

Definition

An action machine vision system is an advanced engineering solution that combines mechanics, optical tools, electromagnetic sensors, and digital image processing. This system captures and analyzes images to help machines understand and interact with the physical world. It uses cameras and lighting to collect digital images of objects or scenes. The system then processes these images using computers and specialized software. The goal is to give machines the ability to see, recognize, and make decisions, much like human vision but with greater speed and accuracy.

Industry experts describe a machine vision system as a non-contact optical sensing system. It automatically receives and interprets images from real scenes to gather information or control machines and processes. These systems play a key role in manufacturing and logistics. They allow automated equipment to locate, identify, inspect, measure, and sort objects. By using digital image analysis, the system provides rapid, consistent, and objective assessments. This technology helps improve quality and efficiency across many industries.

Core Function

The core function of an action machine vision system is to use imaging-based inspection and analysis to drive automated actions. The process starts when high-resolution cameras and optimized lighting capture clear digital images of products or components. The system uses advanced software to process these images. It analyzes features such as shape, size, and color, and checks for defects. AI and machine learning models help interpret the processed digital image data. They make real-time decisions, such as identifying defective items or confirming measurements.

Once the system makes a decision, it triggers automated mechanical actions. For example, it can reject defective products, sort items, or guide robotic arms during assembly. The system provides real-time feedback to the production line. This feedback prevents defective products from moving forward, which improves quality control and reduces waste.

Action machine vision systems offer several advantages over traditional machine vision systems. Traditional systems use fixed, rule-based algorithms and require manual updates when conditions change. Action machine vision systems use AI-driven models that adapt quickly to new tasks and environments. They handle complex, variable, and dynamic situations better than older systems. These systems also detect subtle defects and variations that traditional systems might miss.

| Aspect | Traditional Machine Vision Systems | Action Machine Vision Systems (AI-driven) |

|---|---|---|

| Workflow Steps | 1. Image acquisition via cameras and sensors | 1. Object detection triggers image capture |

| 2. Image processing using fixed, rule-based algorithms | 2. Synchronized image capture with lighting and exposure control | |

| 3. Decision-making based on predefined rules | 3. Digital conversion of images (if analog) | |

| 4. Action triggered based on decisions (e.g., removing defective items) | 4. Advanced processing using deep learning and neural networks | |

| Adaptability | Low; requires manual recalibration or updates when conditions change | High; AI models adapt quickly to new tasks and environments |

| Feature Engineering | Manual, fixed feature extraction | Automated feature learning via deep neural networks |

| Environment Suitability | Best for simple, stable, controlled environments | Effective in complex, variable, and dynamic environments |

| Hardware Requirements | Standard cameras, sensors, and processors | Requires powerful hardware, specialized cameras (e.g., telecentric lenses), and high-performance processors |

| Error Detection | Limited to predefined defects and patterns | Can detect subtle defects and variations |

| Flexibility | Limited; struggles with changes in lighting or part positioning | High; robust to lighting changes and part variations |

| Expertise Needed | Engineering knowledge for rule programming and system updates | AI expertise for model training, validation, and deployment |

| Typical Use Cases | Fast, consistent inspection in stable production lines | Complex inspection tasks like sorting visually similar parts, detecting missing ingredients, and guiding robotic actions |

A modern action machine vision system uses digital image processing to ensure dimensional accuracy and detect defects. Real-time feedback allows immediate corrective actions without stopping production. Automated decisions guide mechanical actions, such as rejecting defective products or adjusting robotic movements. Early defect detection reduces waste and prevents defective products from progressing. Consistent inspection quality surpasses human inspection by maintaining uniformity across all products.

Despite these benefits, implementing an action machine vision system presents challenges. Programming rule-based algorithms can struggle with complex inspections and unpredictable defects. The system must handle variability in scale, rotation, and surface textures. Environmental factors, such as lighting changes, dust, and temperature shifts, can disrupt performance. Selecting the right cameras, lenses, and sensors is critical for reliability. Proficiency in software platforms and industry-specific experience help address unique operational challenges and quality standards. Rigorous testing ensures the system meets its objectives and performs well in real-world conditions.

Machine Vision System Components

A machine vision system uses several key components to capture, process, and analyze images for automation. Each part plays a special role in helping machines see and act with precision.

Cameras and Lighting

- Cameras serve as the eyes of the machine vision system. They use image sensors like CCD or CMOS to capture digital images of objects. The choice of camera depends on the task. Area scan cameras take full 2D images, while line scan cameras capture one line at a time for moving materials. 3D cameras add depth information, which helps with robotic guidance.

- Lighting is just as important as the camera. Proper lighting ensures the camera captures clear images by highlighting edges and surface flaws. Techniques such as backlighting, diffuse lighting, and ring lighting help reduce shadows and reveal defects. The right lighting can improve defect detection rates and make image processing more accurate.

Image Acquisition Hardware

- Image acquisition hardware connects the camera to the rest of the system. This includes cables, interface peripherals, and hardware interfaces. Modern systems use fast connections like GigE Vision, Camera Link, and USB3 Vision. These allow high-speed transfer of image data from the camera to the computer. Newer hardware supports higher resolutions and faster frame rates, making real-time image processing possible. Embedded smart cameras now combine image capture and processing in one device, reducing setup time and complexity.

Software and Processing

- Software and processing units form the brain of the machine vision system. Image processing software analyzes the images captured by the camera. It uses advanced algorithms for pattern recognition, measurement, and defect detection. High-performance processors, GPUs, and FPGAs speed up image processing tasks. Real-time feedback from the software helps maintain quality and accuracy. AI and deep learning models now allow the system to adapt to new tasks and spot subtle defects that humans might miss.

Integration with Motion Control

- Integration with motion control makes machine vision systems truly powerful. Motion control synchronizes the movement of parts or cameras with image capture and processing. This allows the system to guide robots, sort items, and inspect products on moving lines. Vision-guided motion eliminates the need for fixed tooling, making automation more flexible and cost-effective. Real-time feedback between the vision system and actuators improves speed, accuracy, and throughput in automated tasks.

A well-designed machine vision system combines cameras, lighting, image sensors, hardware, software, and motion control. This integration allows machines to see, think, and act with high precision in many industries.

Types of Machine Vision Systems

1D and 2D Systems

Machine vision systems often start with 1D or 2D designs. A 1D system uses a single line of pixels in the camera. This setup scans objects as they move past the sensor. Factories use 1D systems for fast inspections on conveyor belts or for reading barcodes on bottles and cans. These systems work well for simple, linear tasks and cost less than other options.

A 2D system uses a camera with a sensor that captures images in two dimensions—length and width. This type of machine vision system checks surfaces for defects, reads labels, and verifies barcodes. Many industries use 2D systems for quality control. The camera captures flat images, and the software analyzes them for flaws or missing parts. However, 2D systems cannot measure depth.

2D vision systems offer fast, affordable inspection for flat surfaces, but they cannot detect height or shape.

| Dimension | Technology | Typical Applications | Key Characteristics |

|---|---|---|---|

| 1D | Line sensor, laser triangulation | Barcode scanning, conveyor inspection | Fast, simple, low detail |

| 2D | CCD/CMOS camera | Surface inspection, label verification | No depth, good for flat objects |

3D and Line Scan Systems

3D machine vision systems use multiple cameras or sensors to capture depth. These systems measure height, thickness, and shape. Factories use 3D vision systems to guide robots, inspect complex parts, and check assembly quality. The camera and sensor work together to create a 3D model of the object. This helps with tasks that need precise measurements.

Line scan systems use a camera that captures one line at a time. The system builds a full image as the object moves. Industries like plastics, textiles, paper, and metal manufacturing use line scan cameras for inspecting large or continuous surfaces. These cameras provide high resolution and avoid motion blur, even at high speeds. Line scan technology also works well for scanning large objects, such as aircraft wings or vehicle bodies.

Line scan cameras deliver detailed images for fast-moving items and large surfaces, making them ideal for web inspection and printing.

AI and Advanced Imaging

AI and advanced imaging have changed machine vision. AI models help machine vision systems detect defects, recognize objects, and understand textures. The camera captures images, and the AI software processes them in real time. Deep learning allows the system to spot subtle flaws and adapt to new tasks. Edge learning lets the system process data on the device, which speeds up inspection.

3D imaging and AI work together to solve complex inspection problems. Machine vision systems now handle tasks that were once too hard for rule-based software. These systems improve quality control, reduce costs, and make automation easier for many industries.

AI-powered machine vision systems learn from examples, making them flexible and accurate for many inspection and guidance tasks.

Applications of Action Machine Vision Systems

Inspection and Quality Control

Manufacturers use machine vision to improve inspection and product quality. A camera captures an image of each item on the production line. The system uses advanced algorithms for defect detection, measuring dimensions, and checking for surface flaws. Automated inspection finds tiny defects that people might miss. Electronics factories, for example, use machine vision to check wafers and components. This process ensures every product meets strict quality standards. Real-time feedback lets workers fix problems quickly, which keeps product quality high and reduces waste.

Machine vision systems help companies maintain consistent quality by detecting defects early and making fast, data-driven decisions.

Sorting and Identification

Sorting and identification are common applications in manufacturing and logistics. A camera takes an image of each part or package. The system uses object detection and counting to sort items by size, shape, or color. High-resolution cameras and multispectral sensors capture detailed images for accurate classification. Advanced image processing algorithms, such as pattern recognition and edge detection, help the system identify each object. Sorting mechanisms like robotic arms or conveyor belts then separate items based on the analysis. This speeds up operations and reduces errors.

| Technology Component | Role in Sorting and Identification | Key Characteristics and Benefits |

|---|---|---|

| High-Resolution Cameras | Capture detailed images for defect and feature detection | Up to 4K resolution, fast imaging |

| Multispectral Sensors | Analyze material composition | Quality insights across many wavelengths |

| Sorting Mechanisms | Physically separate objects | Air jets, conveyor belts, robotic arms |

Robotic Guidance

Robotic guidance uses machine vision to help robots see and act. A camera collects an image of the workspace. The system locates parts in 2D or 3D space, guiding robots to pick, place, or assemble items. Real-time processing allows robots to adjust their movements instantly. This improves accuracy and flexibility. Machine vision also checks for defects during assembly, which boosts product quality and reduces rework. Robots can handle different products without new programming, making production lines more efficient.

Image-Based Measurement

Image-based measurement is vital for continuous inspection applications. A camera captures an image of each part, and the system measures features like length, width, and diameter. High-resolution imaging and sub-pixel measurement techniques increase accuracy. The system uses object detection and counting to ensure the correct number of parts. Calibration and proper lighting help reduce errors. Machine vision provides reliable measurements, which supports product quality and compliance with design standards.

Machine vision systems convert images into actionable data. The process starts with image capture, followed by feature extraction and analysis. The system then makes decisions and triggers actions, such as sorting or alerting workers.

Benefits of Machine Vision

Speed and Accuracy

Machine vision systems bring a major boost to speed and accuracy in industrial automation. A camera can process images in less than 20 milliseconds, allowing real-time inspection of thousands of items every minute. This speed far exceeds what human inspectors can achieve. Unlike manual inspection, which suffers from fatigue and lower recall rates, automated systems maintain stable performance throughout long shifts. They also improve defect detection rates, with some systems increasing accuracy from 93.5% to 97.2%. In automotive manufacturing, advanced cameras and AI algorithms spot subtle defects in parts like ball bearings and glass. These systems adapt and learn over time, which means they keep getting better at finding problems and reducing errors.

Consistency and Scalability

Machine vision ensures consistent inspection results, even during high-volume production. In food processing, for example, cameras inspect products for size, shape, and color at high speeds. This automation reduces human error and keeps quality uniform. Companies can scale up operations easily because the systems adapt to different products and production stages. Modular designs let businesses add more cameras or upgrade software as needed. Real-time data analytics help optimize processes, and integration with production lines supports reliable operation during peak demand.

- Machine vision automates sorting, packaging, and labeling.

- Systems reduce waste by ensuring only products that meet standards reach consumers.

- Customizable setups allow for easy scaling as production grows.

Industry Value

Machine vision delivers strong value across industries by improving productivity and cutting costs. In packaging, cameras inspect more items than human workers, reducing waste and errors. Companies see quick returns on investment, with some reducing inspection time from 60 seconds to just over 2 seconds per unit. Maintenance costs drop, and downtime decreases by up to 50%. Machine vision also helps avoid expensive product recalls and lowers labor costs. Both 2D and 3D camera systems support high-speed inspection and advanced tasks like robotic guidance. As a result, businesses benefit from higher efficiency, better quality, and increased profitability.

| Benefit | Impact on Industry |

|---|---|

| Faster inspection | Higher throughput, less delay |

| Improved accuracy | Fewer defects, better compliance |

| Consistent results | Reliable product quality |

| Lower costs | Reduced waste and labor expenses |

| Scalability | Easy adaptation to growth |

Action machine vision systems help machines see, analyze, and act quickly. These systems boost productivity, improve quality, and support safer workplaces. Key benefits include fast defect detection, precise robot guidance, and real-time feedback for smooth operations. Anyone interested in learning more can explore training from Cognex, which offers courses for all skill levels, or review guides from UnitX Labs on topics like privacy and best practices. Machine vision continues to drive innovation in factories and beyond.

FAQ

What industries use action machine vision systems?

Manufacturing, automotive, electronics, food processing, and logistics companies use these systems. They help with inspection, sorting, and robotic guidance. Many factories rely on machine vision to improve quality and speed.

How does machine vision improve product quality?

Machine vision finds defects that people might miss. The system checks every item quickly and accurately. This helps companies deliver better products to customers.

Can machine vision systems work in low light?

Some cameras use special sensors and lighting to capture clear images in low light. Infrared and LED lights help the system see details even when the area is dark.

Are machine vision systems hard to set up?

Most modern systems come with user-friendly software. Many companies offer training and support. With the right setup, teams can install and use these systems without advanced programming skills.

See Also

Understanding How Image Processing Powers Machine Vision Systems

A Detailed Look At Electronics In Machine Vision Systems

The Role Of Cameras Within Machine Vision Technology

Exploring The Basics Of Automotive Machine Vision Systems

How Computer Vision Models Integrate With Machine Vision Systems