Introduction: The Complexity of the Cap

In Lithium-ion cell production, the Top-Cap is not just a lid; it is a complex assembly of safety features. It contains the explosion-proof vent, the electrode poles, and critical seal points.

Because of this complexity, the variety of things that can go wrong is staggering. From weld breaks and membrane misalignment to oxidation and simple scratches, the defect list is massive. For human inspectors, memorizing and spotting over 100 different defect types across various materials and product sizes is a cognitive overload. This leads to fatigue, missed defects, and ultimately, end-customer complaints.

The challenge for this project was not just “automation,” but “versatility.” The client needed a system that could handle extreme defect variety and diverse materials, and they needed it fast.

The Challenge: 100+ Defects, One Failing Solution

The scope of this project was daunting and it aimed to replace the traditional “one solution”—manual inspection—which had reached its breaking point. The vision system needed to reliably identify over 100 distinct types of defects, including:

- Welding Issues: Breaks, voids, pinholes, and discontinuity.

- Component Failures: Explosion-proof vent deformation, membrane misalignment.

- Surface Flaws: Oxidation, scorching, burn marks, and physical damage.

Furthermore, the production line handles diverse materials and product sizes, meaning the system couldn’t be a “one-trick pony.” It had to adapt to different reflective properties and geometries without constant re-tuning.

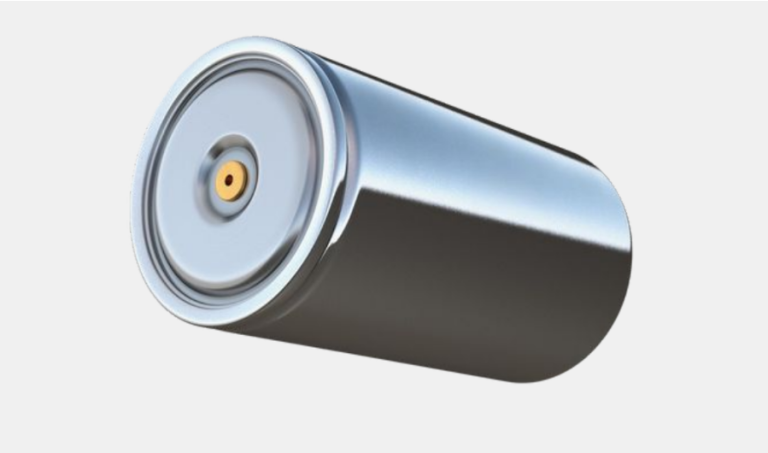

A prismatic battery top-cap. Ensuring the integrity of the vent and welds is critical for safety.

The Solution: A Robust, AI-Driven Vision Platform

UnitX delivered a high-performance inspection station engineered to “digest” extreme complexity at line speed.

The UnitX inspection station, capable of handling variable product sizes and materials.

System Power: Precision Engineering Meets Neural Intelligence.

- Multi-Angle Imaging (OptiX): The station utilizes a proprietary OptiX configuration designed for total visibility. The multi-camera array is set at strategic angles to provide comprehensive coverage of the part’s entire geometry. This setup clearly identifies structural flaws—such as vent deformations and pinholes—from multiple perspectives.

- AI Central Processing (CorteX): The “brain” of the system is the UnitX CorteX deep learning engine. CorteX is engineered to navigate the nuances of top-cap production, empowering it to distinguish between critical failures and harmless environmental variables. It ensures a “burn mark” is never confused with a shadow, and oxidation is never mistaken for a material reflection.

Results: Speed in Deployment, Savings in Labor

The results of this deployment highlight not just technical capability, but operational agility.

1. Rapid Deployment (2 Weeks)

Industrial automation projects often drag on for months.

- Result: Full line deployment and customer acceptance in just 2 weeks.

- The pre-trained capabilities of the UnitX AI platform allowed for an incredibly fast integration, minimizing downtime for the manufacturer.

2. High ROI: 66% Labor Reduction

The system didn’t just assist inspectors; it replaced the need for a large team.

- Before: 6 quality inspection personnel per shift.

- After: 2 personnel per shift.

- This reduction from 6 to 2 represents a massive saving in operational costs, delivering a rapid Return on Investment (ROI).

3. Quality Assurance

- False Acceptance Rate (FA): 0%.

- False Rejection Rate (FR): ≤ 5%.

- Impact: The client reported a confirmed decrease in end-customer complaints following the installation, proving that the machine was catching defects that human inspectors were missing.

Defect Gallery

The following images demonstrate the system’s ability to capture widely different defect types under the same inspection logic.

From welding voids to chemical oxidation, the UnitX system classifies over 100 defect types.

Conclusion

Complexity doesn’t have to be a barrier to automation. Even with a catalog of 100+ potential defects and varying product sizes, UnitX’s AI solution proved that it can be deployed quickly (2 weeks) and deliver immediate ROI (66% labor reduction).

Struggling with complex, multi-defect inspection?

Contact UnitX to see how quickly we can deploy on your line.