Introduction: The High Stakes of the Final Weld

In Lithium-ion battery manufacturing, the ultrasonic welding of electrode tabs is a pivotal moment. This process creates the electrical path for the cell. If the joint is weak, resistance rises. If resistance rises, heat generates. In the worst-case scenario, a poor weld becomes the catalyst for thermal runaway, leading to cell failure or explosion.

Despite these high stakes, many manufacturers still rely on manual sampling for quality control. The problem? Manual inspection is slow, inconsistent, and lacks data traceability. In a mass-production environment, checking “some” of the batteries isn’t enough—you need to check ALL of them in real-time.

The Challenge: Tiny Defects, Massive Consequences

Ultrasonic welding defects are often subtle, multi-factor in nature, and difficult to detect through conventional inspection methods. A “bad weld” isn’t just about strength; it involves a variety of visual indicators that are hard to standardize for human inspectors:

- Structural Issues: Tab tearing, folding, or burrs (sharp edges that can puncture separators).

- Process Issues: Weld-mark misalignment, insufficient fusion, or burn marks.

The project goal was clear: Replace labor-intensive sampling with an AI-driven system capable of 100% inline inspection to ensure no defective unit ever moves forward.

The Solution: A Value-Added Retrofit

UnitX approached this challenge not by demanding a new production line, but by upgrading the existing one. We designed a value-added retrofit for the ultrasonic welding machine.

This compact integration fits seamlessly into the welding station. It captures high-resolution images immediately after the weld is formed.

- The Brains: Powered by UnitX CorteX (AI Central & Inspection Cell) for rapid processing.

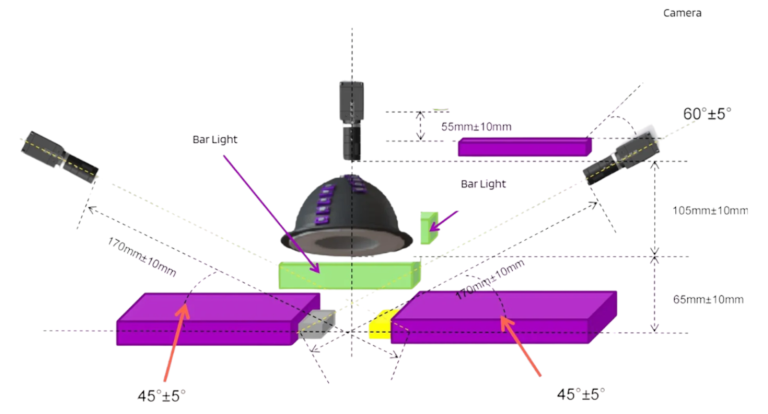

- The Eyes: A UnitX OptiX imaging system, specifically angled (as shown in the schematic) to highlight texture differences between a good weld pattern and defects like metal burrs or folds.

AI Defect Detection in Action

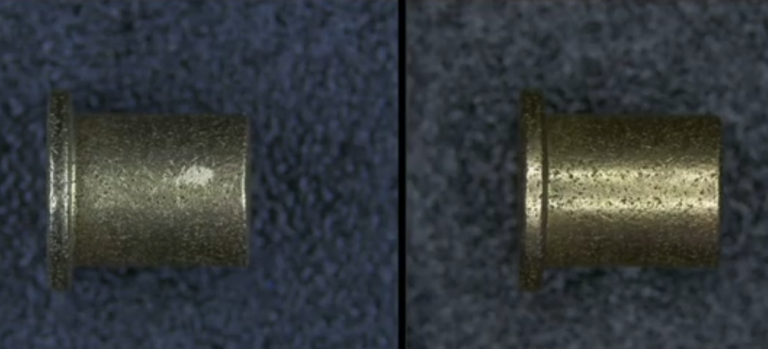

CorteX was trained to detect specific morphological changes in the metal tabs. Unlike traditional rule-based vision that might get confused by the natural texture of a weld, the UnitX AI distinguishes between the normal “roughness” of a weld and actual damage.

Reliability at Scale

The deployment of this system delivered immediate improvements in both quality assurance and operational stability.

- Guaranteed Safety (FA = 0%)

For a critical process like welding, “mostly good” isn’t good enough,UnitX achieves:

- False Acceptance Rate: 0%.

- Every single unit with a critical defect (like a tear or burr) was correctly identified and rejected.

- Operational Stability

A unique highlight of this deployment was the system’s robustness.

- Downtime: ≤ 0.1%.

- The system operates with extreme reliability, ensuring that the inspection process does not become a cause for line stoppages.

- Efficiency and Speed

- Cycle Time: < 4.3 seconds.

False Rejection Rate: ≤ 1%.

- The system keeps up with the welding cycle while minimizing the waste of good materials, saving significant labor costs previously dedicated to manual checking.

Conclusion

The transition from manual sampling to 100% AI automated inspection is the only way to guarantee the safety of modern Lithium-ion batteries. By retrofitting existing ultrasonic welders with UnitX’s visual inspection system, manufacturers can close the gap on quality control, ensuring that every weld is strong, clean, and safe.

Upgrade your welding process today.

Contact UnitX to learn about our retrofit solutions for battery manufacturing.