Project Overview:

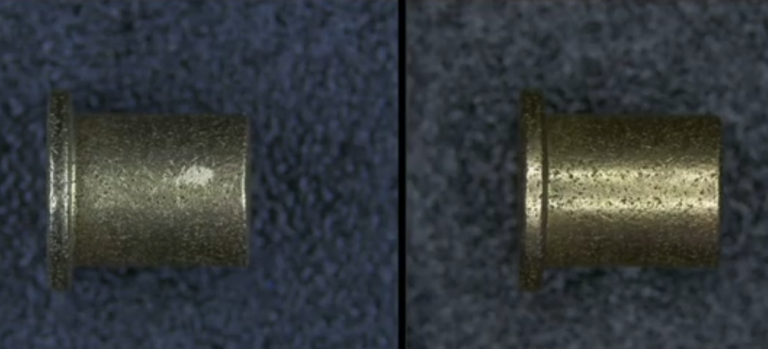

- Product: Pump Housing (Size: 60×60×70mm)

- Project Goal: save labor costs and enhance product quality through AI-driven inspection. Remote update modules are needed for future projects.

- Defect Types: Scratches, pits, material loss, incomplete machining, peeling, color variations, porosity, dents, etc.

Solution:

Housings travel on a servo-driven conveyor beneath four 4 inspection stations, where Cortex Edge instantly analyzes high-contrast images to spot sub-millimeter flaws and route good parts to the pallet carousel while diverting rejects for rework.

Vision System Components:

- AI Central: CorteX Central *1

- Imaging System: OptiX *4

- Inspection Cell: CorteX Edge *1

Results:

- The system delivers fully automated inspections with False Acceptance Rate (FA) =0 for critical defects and an overall False Acceptance Rate (FA)≤0.5% for all other defects.

- False Rejection Rate (FR) ≤5%

- Cycle Time: 5s/each