You use a stereo cameras machine vision system when you need machines to see the world in 3D. Stereo cameras help machines gain depth perception, so they can judge how far away objects are. This ability makes a huge difference in robotics, automation, and other machine vision systems. Today, 3D vision and depth perception drive major changes in many sectors:

- Automation and robotics use stereo cameras for better depth perception.

- New 3D vision systems now offer higher resolution and smarter perception.

| Sector | Market Share |

|---|---|

| Automotive | 40% |

| Industrial | 30% |

| Consumer Electronics | 15% |

| Medical Robotics | 10% |

| Agriculture | 5% |

Key Takeaways

- Stereo cameras give machines real 3D vision by using two cameras to measure depth and distance, helping machines understand their surroundings better than regular 2D cameras.

- Accurate depth perception depends on proper calibration, the distance between cameras (baseline), sensor resolution, and good lighting conditions.

- Stereo vision systems work by comparing images from two cameras to calculate depth using disparity, allowing precise tasks like object placement, volume measurement, and navigation.

- Compared to other 3D technologies, stereo cameras offer a cost-effective solution with color and depth data, working well outdoors and in many environments, but they may struggle in low light or low-texture scenes.

- Stereo cameras are widely used in industries like automation, robotics, ADAS, and medical fields, providing real-time 3D data that improves safety, accuracy, and efficiency.

Stereo Cameras Machine Vision System

What Is a Stereo Vision Camera

You use a stereo vision camera when you want a machine to see the world in three dimensions. This camera type stands out because it uses two or more image sensors, much like your own eyes. These sensors capture images from slightly different angles. By comparing these images, the camera can figure out how far away things are. This process gives machines the ability to understand depth perception, which is crucial for many tasks.

Stereo cameras machine vision system setups often use either CCD or CMOS sensors. CCD sensors give you good image quality and work well in steady lighting. CMOS sensors offer faster speeds and use less power, which helps in fast-moving environments. Some systems use microbolometer sensors for thermal imaging, but you mostly find CCD and CMOS in standard setups. These sensors help the system collect detailed 3D information without sending out extra signals, making them reliable for many machine vision tasks.

You will notice that stereo cameras machine vision system designs can be passive or active. Passive systems use only the light already in the scene. Active systems add their own light, such as infrared, to help with depth sensing in dark or low-texture areas. Unlike regular 2D cameras, stereo cameras machine vision system setups give you 3D data. This makes them perfect for jobs like measuring volumes, checking assemblies, or placing objects with high precision.

Tip: If you need a machine to measure how far away something is, choose a stereo vision camera over a regular 2D camera.

How Stereo Vision Works

Stereo vision works by copying the way your eyes see the world. Each camera in the system takes a picture from a slightly different spot. When you look at these two images, you see that objects appear in different places. This difference is called disparity. The system uses disparity to figure out depth.

Here is how the process works:

- The stereo cameras machine vision system captures two images at the same time.

- The system finds matching points in both images.

- It measures the horizontal difference between these points. This is the disparity.

- Using the disparity, the system calculates the depth of each point.

The math behind this uses a formula:

Z = (focal length × baseline) / disparity

Here, Z is the depth, the baseline is the distance between the cameras, and the focal length is how strongly the camera lens focuses light. When disparity is large, the object is close. When disparity is small, the object is far away. This method, called triangulation, lets the system build a depth map of the scene.

Stereo vision systems rely on careful calibration. You must align the cameras and know their exact positions. This ensures that the depth data is accurate. The baseline distance plays a big role. A larger baseline helps you measure depth for faraway objects, but it can make close-up measurements harder. A smaller baseline works better for nearby objects but limits how far you can see in 3D.

- A larger baseline increases disparity for distant objects, improving depth accuracy at longer ranges.

- A smaller baseline gives better results for close objects but reduces the range for depth perception.

- The choice of baseline depends on your application and the size of the area you want to scan.

Stereo vision systems use matching techniques like Sum of Squared Differences (SSD) or Sum of Absolute Differences (SAD) to find corresponding points in the images. These methods help the system create a reliable depth map.

Depth Perception in Stereo Vision

Depth perception is the main reason you use a stereo cameras machine vision system. With two images, the system can tell how far away every part of the scene is. This ability is called 3D depth perception. It lets machines understand the world in a way that 2D cameras cannot.

When the system matches points between the left and right images, it creates a depth map. This map shows the distance to every visible point. The system uses this depth data for many tasks, such as:

- Guiding robots to pick up objects.

- Checking if parts fit together in assembly lines.

- Measuring the volume of items in a box.

- Navigating drones or vehicles safely.

You get the best depth perception when the cameras are well-calibrated and the lighting is good. In industrial settings, stereo vision systems can reach depth accuracy as fine as 0.1 mm. This level of precision comes from careful calibration, high-quality optics, and sometimes the use of structured light to help with matching.

Depth perception depends on several factors:

- The baseline distance between cameras.

- The resolution of the sensors.

- The quality of the calibration.

- The lighting conditions.

A stereo cameras machine vision system gives you real 3D vision. It creates a depth map that helps machines make smart decisions. You can use this technology in robotics, automation, inspection, and many other fields. The system provides depth data that is reliable and accurate, making it a key part of modern machine vision.

Note: Depth perception from stereo vision is not just about seeing in 3D. It is about giving machines the power to interact with their environment safely and efficiently.

Features and Technology

Baseline and Calibration

You need to pay close attention to baseline and calibration when working with stereo camera technology. The baseline is the distance between the two cameras in your stereo system. A longer baseline helps you measure depth for objects that are far away, while a shorter baseline works better for close-up tasks. The choice of baseline affects both the range and the accuracy of your depth measurements.

Calibration is essential for maintaining accuracy in stereo systems. Photogrammetric calibration methods, such as Zhang’s method, use a checkered board to estimate camera parameters. This approach gives you high accuracy and is simple to use. You can further improve calibration by optimizing the distance and angle of your calibration images. Some advanced methods use circular targets or even laser trackers for sub-millimeter accuracy. In industrial settings, you should check calibration every few months. If your system moves often or faces harsh conditions, monthly recalibration keeps your depth measurement accuracy high.

Tip: Regular calibration corrects lens distortion and camera misalignment, which is crucial for reliable depth data.

Resolution and Accuracy

Sensor resolution plays a big role in the accuracy of stereo systems. Higher resolution lets you detect smaller changes in object position, which improves the accuracy of your 3D mapping. For example, commercial cameras now offer up to 4K and even 8K resolution, giving you detailed images for precise depth calculations. When you use high-quality sensors, you get clearer images and better feature matching between stereo pairs. This leads to more accurate depth estimation.

Accuracy in stereo systems depends on several factors:

- Sensor resolution

- Baseline distance

- Calibration quality

- Lighting conditions

You can also use sensor fusion to combine data from multiple sensors. This approach boosts the accuracy of your 3D maps, especially in large or complex environments. Sensor fusion works well with advanced algorithms and AI, helping you achieve reliable depth even in challenging scenes.

Real-Time Processing

Modern stereo systems offer real-time depth perception, which is vital for robotics and automation. Onboard processing technologies, such as FPGAs and AI chips, handle tasks like image rectification, stereo matching, and disparity calculation directly on the camera. For example, the OAK-D SR camera uses Intel’s Myriad X chip to run neural networks onboard. This setup allows you to perform object detection and classification without extra hardware.

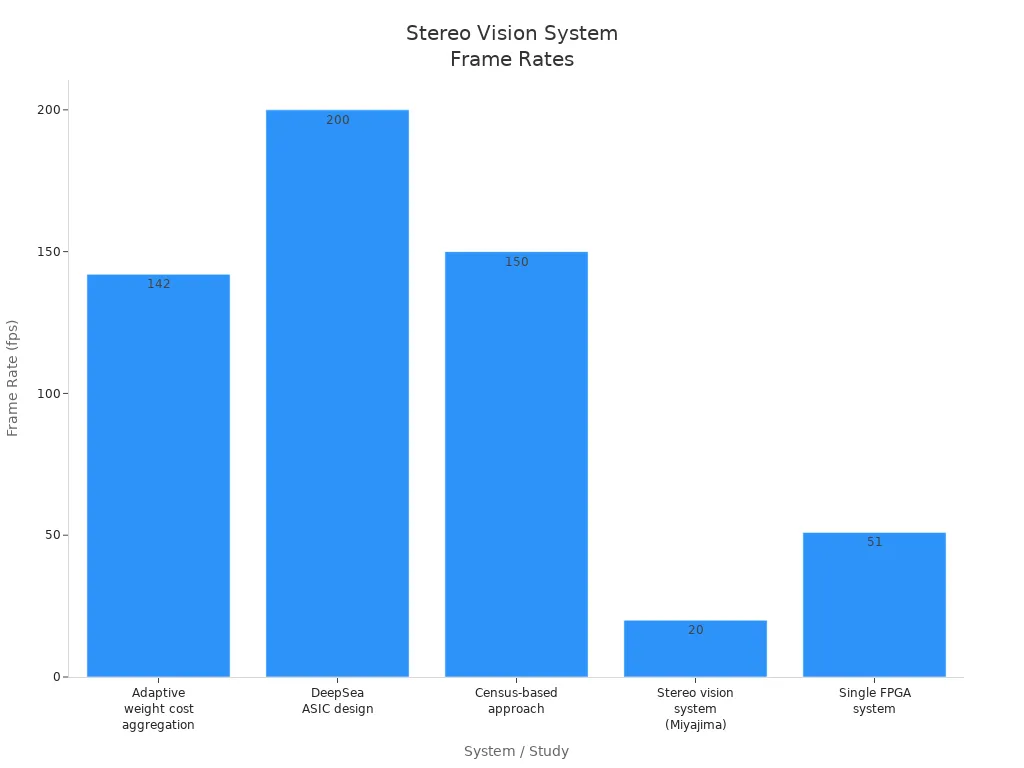

You can expect high frame rates from real-time stereo systems. The table below shows typical processing speeds:

| Video Size | Disparity Range | Frame Rate (fps) | Notes |

|---|---|---|---|

| 1920×1080 | 256 | 47.6 | FPGA optimized system |

| 1024×768 | 128 | 129 | FPGA optimized system |

Stereo cameras generate 3D point clouds, which you can use for mapping and measurement. While stereo point clouds are less dense than those from LiDAR, they still provide useful depth information at a lower cost. Sensor fusion can further enhance these results.

Most industrial stereo cameras support standards like GigE Vision. This feature ensures easy integration with your existing systems and fast data transfer.

Note: Real-time processing and industry standards help you deploy stereo camera technology quickly and reliably in your applications.

Stereo Vision vs. Other 3D Imaging

Stereo Vision vs. ToF

When you compare stereo vision to Time-of-Flight (ToF) cameras, you notice some key differences. Stereo vision uses two cameras to estimate depth by comparing images from different viewpoints. ToF cameras measure the time it takes for light to travel to an object and back, giving you direct depth data. This difference affects both accuracy and performance.

| Parameter | Stereo Vision | Time-of-Flight (ToF) |

|---|---|---|

| Depth Accuracy | Typically in the centimeter range (cm) | Higher accuracy ranging from millimeters to centimeters (mm~cm) |

| Principle | Calculates depth by comparing disparities between two images from different viewpoints | Measures the actual time light takes to travel to and from the object, providing direct depth measurement |

| Software Complexity | High (requires complex disparity matching algorithms) | Low (depth data provided directly by sensor) |

| Depth Range | Limited | Scalable |

| Low Light Performance | Weak | Good |

| Response Time | Medium | Fast |

You will find that stereo vision works best outdoors and in wide fields of view. It does not need special lighting, so you can use it in many environments. Stereo cameras are cost-effective and give you both color and 3D data at the same time. ToF cameras, however, offer better depth accuracy and work well in low-light settings. If you need fast, real-time 3D mapping with high precision, ToF may be the better choice.

Stereo Vision vs. LiDAR

Stereo vision and LiDAR both help you capture 3D information, but they use different methods. Stereo cameras are passive sensors. They rely on natural light and image texture to estimate depth. LiDAR systems send out laser pulses and measure how long it takes for the light to return. This gives you very accurate and reliable depth data, even at long distances.

- Stereo vision cameras give you color images and 3D perception at a lower cost. They work well for short to medium ranges.

- LiDAR provides high-resolution 3D maps with centimeter or even millimeter accuracy. It performs better for long-range detection and in complex environments.

- Stereo cameras may struggle as the distance increases, while LiDAR maintains strong performance over greater ranges.

| Technology | Hardware Cost |

|---|---|

| Stereo Vision | Low (e.g., $349-$5,000 depending on model) |

| LiDAR | Expensive (significantly higher than stereo vision) |

If you need detailed 3D spatial data for tasks like traffic management or crowd monitoring, LiDAR is often the top choice. For cost-sensitive projects where you still need good depth perception, stereo vision offers a practical solution.

Strengths and Limitations

Stereo vision stands out for its flexibility and environmental adaptability. You can use stereo cameras in outdoor settings, bright sunlight, or changing weather. Many models have rugged enclosures and filters that help reduce glare and improve depth estimation. You can also combine stereo vision with other sensors, like IMUs or thermal cameras, to boost perception reliability.

Tip: Stereo vision works well for robotics, autonomous vehicles, agriculture, and manufacturing. It gives you real-time 3D data and strong depth perception in many scenarios.

However, stereo vision has some limits. It struggles in low-light or low-texture environments, such as blank walls or shiny surfaces. In these cases, the system may not find enough features to match between images, leading to gaps in the 3D map. High-dynamic-range scenes can also cause problems, making it hard to get accurate depth data. While active stereo systems can add texture with projected patterns, this increases cost and complexity.

Stereo vision is one of the most popular depth perception technologies. It gives you a balance of cost, 3D perception, and flexibility. You should consider your needs for depth, accuracy, and environmental conditions when choosing between stereo, ToF, or LiDAR for your machine vision project.

Applications

Industrial Automation

You see stereo cameras used widely in industrial automation. These systems help machines measure distances and recognize objects on assembly lines. With depth perception, you can guide robotic arms to pick and place parts with high precision. Stereo cameras support quality control by checking if items fit together or if products meet size requirements. You also use them for volume measurement and bin picking, where robots need to find and grab items from a pile. In high-accuracy applications, stereo cameras give you reliable depth sensing, even in fast-moving environments. This technology helps factories run smoothly and safely.

Robotics and Drones

Stereo cameras play a key role in robotics and drone navigation. You use them for:

- Autonomous navigation and trajectory planning, thanks to real-time depth perception.

- Obstacle avoidance in dynamic places like warehouses.

- Pick and place tasks that need precise 3D object detection.

- Integration with AI for smarter depth sensing in complex scenes.

- Crop monitoring and agricultural automation with drones.

- SLAM (Simultaneous Localization and Mapping) for mapping and moving without GPS.

Stereo cameras capture both visual and depth information, so robots and drones can see and react to obstacles quickly. Onboard processing in some cameras reduces delay, which is important for fast decision-making. You benefit from small, lightweight cameras that use little power but still provide rich data for safe movement.

ADAS and Medical

In Advanced Driver Assistance Systems (ADAS), stereo cameras help vehicles see the road in 3D. You get depth perception by triangulating images from two cameras, much like human vision. This allows cars to detect objects, estimate distances, and recognize lane boundaries. Stereo cameras support features like Automatic Emergency Braking and Lane Keep Assist. They work well in tough conditions, such as at night or in fog, and offer a cost-effective alternative to LiDAR for depth sensing.

In medical imaging, stereo cameras improve surgical navigation and 3D visualization. You find them in AR surgical systems, where they track anatomical features and overlay 3D images onto the patient. This gives surgeons real-time depth perception and helps them perform safer, more accurate procedures. Stereo cameras also appear in stereo endoscopes and microscopes, making complex surgeries easier and faster.

Tip: Stereo cameras give you a powerful tool for depth sensing and 3D mapping in many fields, from factories to hospitals.

Stereo cameras give you accurate 3D vision and strong depth perception for many machine vision tasks. You benefit from high frame rates, wide field of view, and robust performance in tough environments. However, you must watch for challenges like lighting changes, calibration drift, and higher computational needs.

- When choosing a system, consider factors such as synchronization, resolution, baseline, lens type, and housing rigidity.

- Calibration and image rectification remain critical for reliable results.

For more guidance, industry articles from Teledyne Vision Solutions and UnitX Labs offer practical tips on hardware, software, and deployment strategies.

FAQ

What is the main advantage of using stereo cameras in machine vision?

Stereo cameras give you real 3D vision. You can measure depth and distance. This helps machines understand their surroundings and make better decisions.

How do you keep stereo cameras accurate over time?

You should calibrate your stereo cameras regularly. Calibration fixes lens distortion and camera misalignment. This keeps your depth measurements reliable.

Can stereo cameras work in low-light conditions?

Stereo cameras need enough light to see details. In low-light, you may get poor depth results. You can use active stereo systems with extra lighting to help.

What data do stereo cameras provide?

Stereo cameras give you both color images and depth maps. You can use this data for object detection, measurement, and navigation.

See Also

Understanding The Use Of Cameras In Machine Vision

Essential Insights Into Computer And Machine Vision Technologies

A Beginner’s Guide To Metrology In Machine Vision Systems