Lenses form the backbone of every lenses machine vision system. The right lens choice shapes image quality and measurement accuracy. In industrial settings, even small lens distortions can decrease reliability and performance. The table below shows how distortion affects accuracy in machine vision systems:

| Lens Distortion Impact | Effect on Machine Vision Performance |

|---|---|

| Up to 1.4 pixels | Decreases measurement accuracy |

| Small distortions | Impact system reliability |

When engineers match the lens to the sensor and specific application, lenses machine vision system can capture sharp, precise images. A well-chosen lens in a machine vision system prevents costly errors, while a poor choice may lead to blurry images and faulty results.

Key Takeaways

- Choosing the right lens is crucial for sharp images and accurate measurements in machine vision systems.

- Different lens types serve specific industrial tasks, with fixed and telecentric lenses offering the best precision.

- Matching the lens to the sensor size and application prevents image distortion and improves system reliability.

- Environmental factors like temperature and vibration affect lens performance, so rugged lenses help maintain accuracy.

- Poor lens selection leads to blurry images, measurement errors, and costly downtime, making careful choice essential.

Role of Lenses in Machine Vision Systems

Impact on Image Quality

Lenses play a central role in every lenses machine vision system. They focus light onto the sensor, which allows the camera to capture sharp and detailed images. This process forms the foundation of high-quality imaging and high-precision imaging. The optical design of a lens determines how well it can capture and transmit light, which directly affects image quality, image clarity, and the ability to see fine details.

- Lenses in machine vision optics control key factors:

- Field of view: how much of the scene the camera can see.

- Magnification: how large objects appear in the image.

- Image clarity and sharpness: how well the system can distinguish small features.

- Brightness: how much light reaches the sensor for clear image capture.

A high-quality lens ensures that the camera captures images with minimal distortion, vignetting, or blurriness. Proper lens selection, considering focal length, aperture, and sensor compatibility, is essential for enhancing image quality. The interaction between the lens and the sensor must match to prevent issues like dark edges or blurred areas. High-quality imaging depends on this match.

Tip: Using lenses designed for machine vision optics improves focus accuracy and image clarity, which is vital for tasks such as defect detection, object measurement, and color recognition.

The optical quality of the lens also impacts the Modulation Transfer Function (MTF), a measure of how well the lens can reproduce detail and contrast. A lens with a high MTF supports high-precision imaging and reliable image capture, which is critical for industrial applications.

Influence on Measurement Accuracy

Measurement accuracy in a lenses machine vision system depends on the optical precision of the lens. Any distortion or imperfection in the lens can lead to errors in object measurement and spatial analysis. The following table shows how different types of lens distortion affect measurement accuracy:

| Type of Lens Distortion | Description | Impact on Measurement Accuracy |

|---|---|---|

| Barrel Distortion | Straight lines curve outward, common in wide-angle lenses. | Objects appear bloated, disrupting precise measurements. |

| Pincushion Distortion | Straight lines bend inward, often in telephoto lenses. | Overestimates geometric parameters, reduces measurement precision. |

| Perspective Distortion | Objects shrink as they move away from the camera. | Degrades accuracy and affects object detection. |

Even small distortions, such as a maximum absolute distortion of 1.2 to 1.4 pixels, can significantly decrease measurement accuracy if not corrected. In practical machine vision optics, these distortions cannot be ignored. Calibration methods, such as using checkerboard patterns or software correction algorithms, help restore image geometry and improve measurement reliability.

Lenses for machine vision optics are engineered for precision and durability, especially in industrial environments. Manufacturers follow strict standards, such as ISO 14644 for cleanroom production and EN ISO 12312-1 for optical quality and robustness. These standards ensure that lenses maintain their optical performance and withstand harsh conditions, including temperature changes and vibration.

- Environmental factors that affect lens performance:

- Temperature swings can cause expansion or contraction of lens parts, shifting focus and reducing image quality.

- Vibration can move internal lens components, causing pixel shifts and loss of resolution.

- Ruggedized lenses use fixed apertures and glued elements to maintain stability and optical precision in industrial settings.

A well-chosen lens in a lenses machine vision system supports accurate image capture, high-quality imaging, and reliable performance. Poor lens selection can lead to measurement errors, image distortion, and system downtime. By focusing on optical precision and matching the lens to the sensor and application, engineers can achieve the best results in machine vision optics.

Key Machine Vision Lenses Types

Selecting the right lens type is essential for any machine vision camera. Each lens design serves a unique purpose in industrial settings. The table below shows common lens types, their features, and typical uses:

| Lens Type | Key Features | Typical Industrial Applications |

|---|---|---|

| Fixed Focal Length | Single focal length, high resolution, minimal distortion | Defect detection, assembly line inspection, barcode reading |

| Varifocal | Adjustable focal length, flexible but less precise | Surveillance, preliminary inspections |

| Telecentric | Constant magnification, eliminates perspective distortion | Precision measurement, gauging, metrology, component alignment |

| Autofocus | Automatic focus adjustment, real-time adaptability | Robotic inspection, varying object distance applications |

| Line Scan | For line scan cameras, high-resolution moving images | Surface inspection of sheets, textiles, metal |

Variable Magnification Lenses

Variable magnification lenses, also called zoom lenses, allow users to change the focal length and field of view. This flexibility helps when object sizes or positions change often. These lenses work well in dynamic environments, such as preliminary inspections or surveillance. However, zoom lenses can lose image sharpness and introduce distortion, especially at extreme settings. Image quality and brightness may also change as users adjust magnification. For high-precision tasks, engineers often prefer other lens types.

- Variable magnification lenses offer:

- High flexibility for changing tasks

- Quick adaptation to different object sizes

- Lower image quality and more distortion compared to fixed lenses

Fixed Magnification Lenses

Fixed magnification lenses, including fixed focal length and telecentric lenses, provide stable performance and sharp images. These lenses have a single focal length, which means they do not zoom. Fixed lenses deliver high resolution and minimal distortion, making them ideal for defect detection and barcode reading. Telecentric lenses, a special type, keep magnification constant even if the object moves closer or farther from the camera. This feature removes perspective errors and supports precise measurements.

- Fixed magnification lenses offer:

- Superior image quality and sharpness

- Consistent performance for industrial machine vision lenses

- Best choice for most machine vision lenses applications

Bi-Telecentric Lenses

Bi-telecentric lenses take precision to the next level. These lenses keep light rays parallel on both the object and image sides. This design ensures constant magnification, even if the object shifts or tilts. Bi-telecentric lenses work well for measuring thick or complex objects, such as bottles or containers. They provide very low distortion and even brightness across the entire image. These lenses can measure with tolerances as fine as 1 micron, making them perfect for high-accuracy tasks.

Note: Bi-telecentric lenses help maintain measurement accuracy even when objects are not perfectly aligned or when the camera vibrates.

C-Mount Lens Compatibility

C-mount lenses are a standard choice for many machine vision camera systems. These lenses fit most common industrial sensor formats, including sensors up to 1/2" in size. C-mount lenses can also be adapted for CS-mount cameras with a simple adapter ring. Many leading camera sensors, such as Sony’s IMX series, work well with C-mount lenses. This compatibility makes C-mount lenses a popular and practical option in industrial machine vision.

Lens Characteristics and Sensor Matching

Focal Length and Field of View

Focal length is a key factor in machine vision optics. It determines how much of a scene the lens can capture and how large objects appear on the image sensor. Shorter focal lengths create a wide field of view, which helps in applications like autonomous navigation or surveillance. These lenses allow the system to capture more of the environment in a single image. Longer focal lengths narrow the field of view and increase magnification. This setup works best for detailed inspection tasks, such as barcode reading or quality control, where capturing small features with high precision is important.

The field of view depends not only on focal length but also on sensor size and working distance. For example, a larger sensor paired with a short focal length lens will capture a very wide scene. The angular field of view can be calculated using the formula: AFOV = 2 × arctan(H / 2f), where H is the sensor size and f is the focal length. Adjusting the working distance also changes the field of view for a fixed focal length lens. In dynamic environments, engineers often select a field of view slightly larger than the object to ensure full visibility and reliable capture.

Tip: Choosing the right focal length ensures the system captures the entire object or area of interest, improving image quality and measurement accuracy.

Aperture and Light Sensitivity

Aperture controls how much light enters the lens and reaches the image sensor. In machine vision optics, the size of the aperture affects both image brightness and clarity. A larger aperture (lower f-number) allows more light to pass through, which increases light sensitivity and enables faster image capture. This is important in low-light industrial environments, where capturing clear images quickly can improve system performance. A smaller aperture (higher f-number) reduces the amount of light, which may require longer exposure times and can affect image quality.

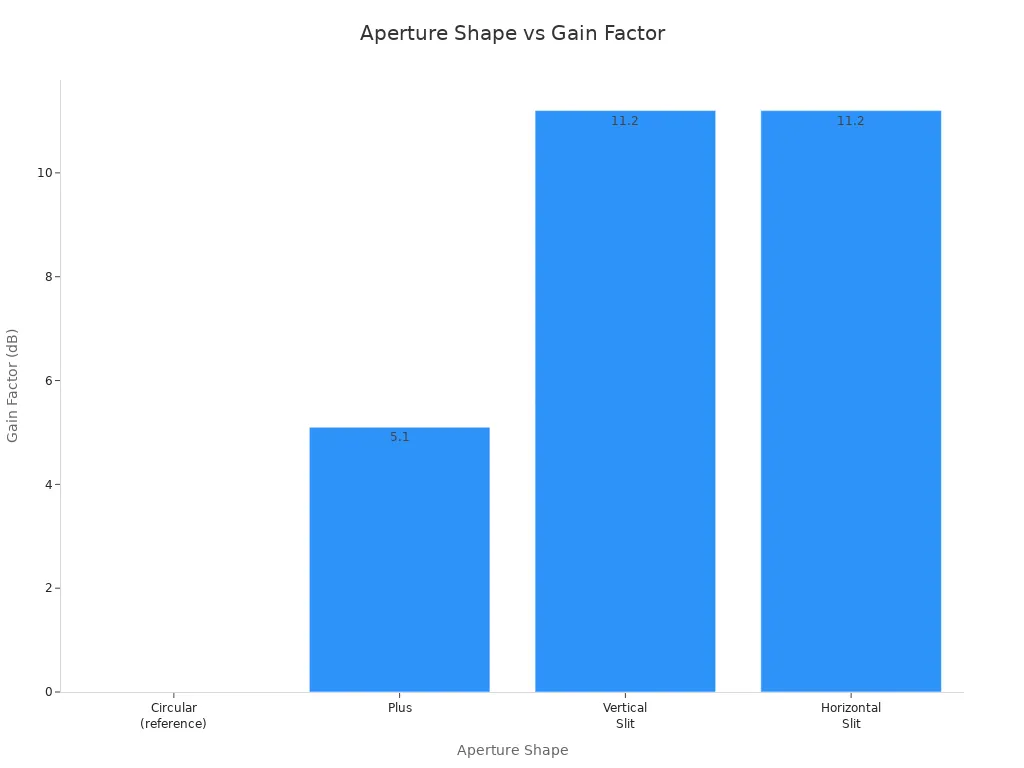

The table below shows how different aperture shapes and sizes impact light sensitivity and the required gain adjustment in industrial imaging:

| Aperture Shape | Aperture Area (mm²) | Relative Area Factor | Calculated f-number (f/#) | Gain Factor (dB) |

|---|---|---|---|---|

| Circular (reference) | 63.6 | 1.00 | 1.8 | 0.0 |

| Plus | 35.6 | 0.56 | 2.4 | 5.1 |

| Vertical Slit | 17.6 | 0.28 | 3.4 | 11.2 |

| Horizontal Slit | 17.6 | 0.28 | 3.4 | 11.2 |

A wider aperture improves light sensitivity, which helps the system capture sharp images even in challenging lighting. However, it also creates a shallow depth of field, so only a thin slice of the scene appears in focus. A smaller aperture increases the depth of field, making more of the scene sharp, but it reduces light sensitivity. Engineers must balance these factors to achieve the best image quality and measurement accuracy for each application.

Resolution and Sensor Coverage

Resolution describes how much detail a lens and image sensor can capture. In machine vision optics, matching lens resolution to sensor size is critical for optimal image quality and system performance. When the optical resolution of the lens matches the sampling resolution of the sensor, the system can capture sharp, detailed images without aliasing or pixelization.

- Matching lens resolution to sensor size ensures:

- The lens and sensor work together to capture fine details, improving image quality and measurement accuracy.

- The Modulation Transfer Function (MTF) of the system, which measures contrast and resolution, reaches its best value when both lens and sensor are balanced.

- If the lens resolution is lower than the sensor, the image appears blurry, and the sensor cannot capture extra detail.

- If the sensor resolution is lower than the lens, the system wastes optical precision and may introduce artifacts.

- Proper matching avoids issues like vignetting, color shading errors, and reduced sharpness.

Sensor size also affects the primary magnification needed in machine vision optics. Larger sensors require lenses with different magnification to achieve the desired field of view. The system must capture the necessary image detail and resolution for the application. Engineers define the smallest feature size to capture, convert it to the required spatial frequency, and select the lens and sensor accordingly.

Note: Matching lenses with sensors prevents problems like incorrect field of view, missing details, and compromised dynamic range.

Working distance, or the space between the object and the lens, also plays a vital role. It determines where the image comes into sharp focus. The right working distance ensures the system captures clear images with high precision. If the lens cannot resolve details as small as the sensor pixel size at the chosen working distance, the image becomes blurry, reducing measurement accuracy. Environmental factors, such as vibration and temperature changes, can further affect reliability, so stable system design is essential.

Application Fit and Common Pitfalls

Industrial and Automation Needs

Industrial applications demand careful lens selection to achieve reliable image processing and accurate results. Engineers often choose prime lenses with fixed focal lengths for automated visual inspection tasks. These lenses provide excellent image quality and low distortion, which is important for defect detection and non-contact inspection. Macro lenses work well for close-up imaging, allowing precise object measurement in electronics or medical device manufacturing. Telecentric lenses eliminate perspective errors, making them ideal for metrology and high-precision industrial applications. Vibration-resistant lenses support image processing in harsh environments, such as automotive assembly lines.

Matching the lens to the sensor size and pixel size helps avoid shading and vignetting. High optical resolution ensures that the system can resolve fine details during defect detection. In robotics, liquid lenses enable rapid focus changes, supporting flexible non-contact inspection as objects move or change size. Each lens type addresses specific needs, such as field of view, working distance, and lighting conditions, to optimize image processing for industrial tasks.

Tip: Selecting the right lens type for each industrial application improves image quality, reduces errors, and increases system reliability.

Consequences of Poor Lens Selection

Poor lens selection can cause many problems in industrial machine vision systems. Blurry details and image distortion often appear when the lens does not match the sensor or application. Vignetting, or darkened corners, results from mismatched sensor and lens sizes. Focus issues may occur if the lens mount or focal length is incorrect. These problems lead to unreliable image processing and missed defects during defect detection.

Common issues include:

- Localized image defects, such as bright spots or varying focus

- Underutilization of sensor resolution, reducing image detail

- Compromised accuracy in defect detection and object measurement

- Increased need for constant adjustments and maintenance

Image distortion bends straight lines and reduces detail, making measurements less accurate. These errors can cause mistakes in production, leading to rework or system downtime. Regular calibration and proper lens selection help maintain measurement accuracy and reliable image processing. When engineers skip these steps, the system may fail to deliver consistent results, affecting overall production efficiency in industrial applications.

Lenses shape every aspect of machine vision system performance. Engineers must select lens types and features that match sensor size, application needs, and environmental conditions.

- Experts recommend using telecentric or liquid lenses for precise tasks and matching the lens to the correct spectral range.

- Consider field of view, working distance, and lens mount for best results.

- Consult professionals and use knowledge bases for guidance.

To ensure accuracy, teams should:

- Test lenses with calibrated equipment.

- Validate results using statistical methods.

- Perform acceptance tests before deployment.

Ongoing evaluation keeps systems reliable as needs change.

FAQ

What is the most important factor when choosing a lens for machine vision?

Engineers consider sensor size, resolution, and application needs. The lens must match the sensor and task. This ensures sharp images and accurate measurements.

Why do telecentric lenses improve measurement accuracy?

Telecentric lenses keep magnification constant. They remove perspective errors. This helps the system measure objects with high precision, even if the object moves.

How does working distance affect image quality?

Working distance is the space between the lens and the object. If the distance is too short or too long, the image may blur. Proper distance gives clear, sharp images.

Can one lens fit every machine vision application?

No single lens fits all tasks. Each application needs a lens with specific features. Engineers select lenses based on field of view, resolution, and environment.

What problems can the wrong lens cause in a machine vision system?

The wrong lens can cause blurry images, distortion, and missed defects. It may also lead to system downtime and costly errors. Proper lens selection prevents these issues.

See Also

Understanding The Role And Function Of Lenses In Machine Vision

The Impact Of Structured Light On Improving Machine Vision

A Comprehensive Guide To Cameras Used In Machine Vision

The Effect Of Frame Rate On Machine Vision System Efficiency

Essential Camera Resolution Concepts For Machine Vision Applications