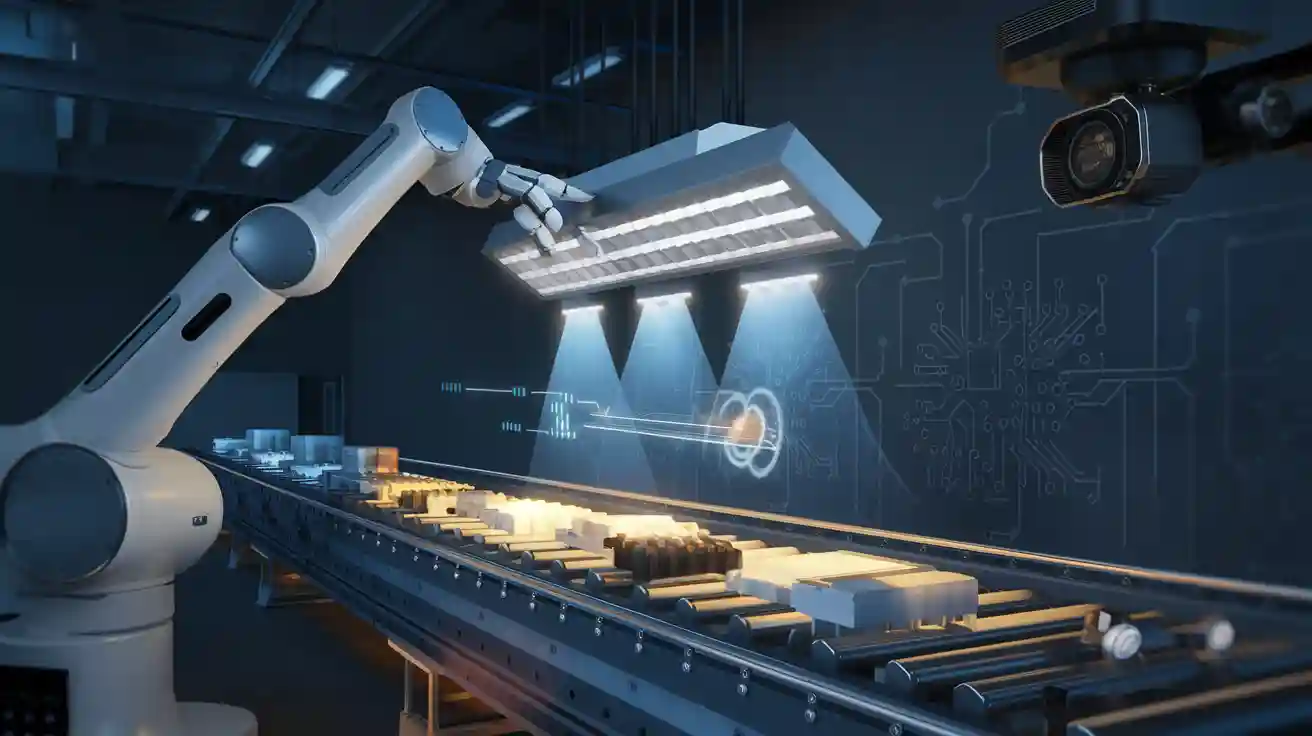

A production line worker inspects polished metal parts for scratches. He notices that some defects slip through when the lighting is uneven. After engineers install a structured LED system, defect detection rates rise by 30%. Uniform, targeted lighting helps the machine vision camera see even faint scratches. Techniques like dark-field lighting can achieve an 82% detection rate for shallow flaws, while shadowless ring lights push classification accuracy above 90%. These results show that light source control machine vision system choices directly impact image clarity, system reliability, and inspection performance.

Key Takeaways

- Proper light source control improves image quality, making defect detection more accurate and reliable.

- LED lighting is the preferred choice for machine vision due to its stability, energy efficiency, and long lifespan.

- Stable and flickerless lighting ensures consistent inspection results and prevents errors in image capture.

- Smart lighting controllers and feedback systems help adjust brightness and color in real time for different applications.

- Planning lighting early and choosing adjustable, protected light sources avoid common mistakes and improve system performance.

Importance

Image Quality

Lighting plays a key role in the performance of any machine vision system. Proper light source control improves image quality by enhancing contrast, reducing noise, and ensuring accurate color reproduction. When engineers optimize the light spectrum, machine vision systems can recognize objects more accurately. For example, using neural networks to adjust lighting can boost classification scores and reduce errors. In surface inspection, uneven or poor lighting leads to glare, shadows, and low contrast. These problems make it hard for cameras to capture clear images. As a result, defects may go undetected. Good lighting setups, such as ring lights or dark-field illumination, help reveal tiny scratches or flaws that would otherwise remain hidden.

Poor light source control can cause:

- Glare and bright spots on reflective surfaces

- Uneven illumination and reflections from ambient light

- Shadows that obscure parts of objects

- Low light conditions that distort images and reduce contrast

System Reliability

Stable lighting ensures that machine vision systems deliver repeatable and reliable results. Consistent illumination allows cameras to capture images that software can analyze with high accuracy. Inconsistent lighting introduces errors and makes defect detection unreliable. For instance, in pharmaceutical packaging, specialized lighting like UV or IR maintains image quality and traceability. LED lighting stands out for its stable output and long lifespan, which supports reliable surface inspection in industries such as electronics and automotive. Advanced lighting controllers help maintain steady illumination even when environmental conditions change. This stability reduces shadows and glare, improving defect detection and overall system reliability.

Application Demands

In 2025, machine vision faces new challenges as industries demand higher precision and faster inspection. Sectors like logistics, battery manufacturing, and agriculture require advanced light source control for tasks such as warehouse automation and bin-picking. The rise of smart factories and Industry 4.0 pushes for more efficient and programmable lighting solutions. Manufacturers now use specialized lighting for high-speed imaging and 3D vision, meeting the need for customized surface inspection. As automation grows, machine vision systems must adapt to higher resolution imaging and stricter quality standards. These trends drive the adoption of intelligent lighting that can adjust intensity and color for each application.

Light Source Types

LED Lighting

LED lighting dominates the illumination used by machine vision cameras in 2025. Engineers prefer LEDs because they offer stable and even light output. LEDs last much longer than halogen or fluorescent lamps. They use less energy and produce less heat, which helps keep systems cool. LEDs come in many colors and shapes, making them a good light source for different inspection tasks. Many vision experts choose LEDs for their ability to provide optimal illumination and precise control over brightness and color. LEDs can switch on and off instantly, which is important for high-speed inspections. Their long lifespan means less maintenance and fewer replacements. These features make LEDs the most common and reliable choice for modern machine vision systems.

Tip: LEDs can create ring lights or colored lighting to highlight specific features or defects. This flexibility helps engineers design systems for tasks like surface inspection or barcode reading.

Halogen and Fluorescent

Halogen and fluorescent lights still appear in some machine vision setups, but their roles are shrinking. Halogen lamps provide very bright light and fast response, which can help in certain high-intensity inspections. However, they use more energy and generate more heat than LEDs. Fluorescent lamps offer uniform light fields and can cover large areas. They work well for applications that need diffused lighting. Still, their shorter lifespan and lower stability make them less attractive compared to LEDs. Most industries now replace these older technologies with LEDs because a good light source must deliver stable, long-lasting, and energy-efficient performance.

Specialized Sources

Some machine vision tasks need specialized light sources. Near-infrared (NIR) light helps cameras see below the surface of materials like plastics. This allows for better defect detection and inspection of hidden features. UV light is important for fluorescence inspection. When UV light shines on certain materials, they emit visible light through fluorescence. This process reveals features such as special inks, gaskets, or tiny scratches that normal lighting cannot show. Using UV LEDs and filters, engineers can isolate fluorescence signals and improve defect detection. The table below shows how specialized sources enhance machine vision:

| Source Type | Key Benefit |

|---|---|

| NIR | Reveals subsurface features |

| UV | Enables fluorescence inspection |

| Multispectral LEDs | Allows precise wavelength selection for optimal illumination |

A good light source for specialized tasks must provide the right wavelength and intensity. This ensures high-quality images and reliable inspection results.

Light Source Control Machine Vision System

Controlling Machine Vision Lighting

Engineers use several methods for controlling machine vision lighting in 2025. The most common approach involves adjusting the intensity of the light source. Dimmers and pulse-width modulation (PWM) controllers allow precise changes in brightness. These tools help match the lighting to the camera’s exposure settings. This prevents overexposure or underexposure and ensures the camera captures clear images of the target object. In high-speed inspection, higher light intensity compensates for shorter exposure times. This reduces motion blur and keeps images sharp.

Flat dome lights have become popular for their ability to provide uniform, shadow-free illumination. These lights work well for flat and slightly curved surfaces. They outperform other types, such as ring lights or coaxial lights, by delivering even contrast and no shadows. This uniformity helps the sensor detect fine details and small codes. Engineers also use diffusers and filters to soften the light and improve image contrast. These accessories further enhance light source control machine vision system performance.

Constant current drives play a key role in controlling machine vision lighting. They keep the current steady, even if the voltage changes. This prevents sudden changes in brightness that can damage LEDs or cause instability. Constant current drivers also reduce heat buildup, which extends the life of the light source. Many machine vision systems now include built-in constant current circuits for this reason.

Note: Proper lighting control ensures consistent light levels and reliable inspection results.

Intensity and Stability

Stable lighting is essential for repeatable results in any light source control machine vision system. When the intensity stays the same, the system can detect small defects and subtle features. High-intensity lighting increases the contrast between defects and the background. This makes it easier to spot problems during inspection. Uniform lighting also reduces shadows and reflections that might hide defects.

- High-intensity lighting improves contrast for accurate detection.

- Uniform lighting ensures consistent inspection results across batches.

- Bright, well-distributed lighting enables high-speed image capture.

Illumination stability allows engineers to set threshold parameters closer to the background level. This helps the system find finer features and improves contrast. Stable lighting also means less measurement variance and higher reliability. For tasks that require color inspection or subtle feature detection, consistent light is critical. Regular calibration and high-quality hardware further improve repeatability. Telecentric lenses combined with stable lighting reduce distortion and boost feature contrast.

Constant current drives help maintain stable light output. Even small voltage or temperature changes can affect LED brightness. By using constant current, the system avoids these problems. This approach also extends the life of the LEDs and keeps performance steady over time.

Flickerless Solutions

Flickerless LED technology has become a standard in every advanced light source control machine vision system. Flicker happens when LEDs cycle on and off rapidly. Human eyes may not notice, but cameras can detect this flicker, which leads to poor image quality. Flickerless LED drivers solve this problem by keeping the light steady during image capture.

| Technology/Method | Description |

|---|---|

| Intelligent LED Lighting Control | Modules allow manual or digital adjustment of LED intensity. Feedback systems keep illumination consistent. |

| Vision System Integration | Cameras analyze image histograms and adjust lighting automatically for proper exposure. |

| Control Modules (e.g., ICMs) | Provide digital control and feedback loops for dynamic light intensity adjustment. |

| Camera and Lighting Synchronization | Cameras and LEDs work together to synchronize illumination with image capture. |

Dynamic control algorithms adjust the LED current in real time. These systems use sensor feedback to compensate for changes in temperature or LED aging. This ensures flickerless LED performance and reliable image capture. Some advanced sensors, like the Sony ISX031, use longer exposure times to avoid pixel saturation and capture stable images. Flickerless LED lighting prevents errors in applications such as automotive safety and high-speed inspection.

Tip: Always use flickerless LED drivers in any light source control machine vision system to avoid misinterpretation and ensure reliable results.

Technologies

Lighting Controllers

Lighting controllers have become smarter and more adaptable in 2025. Many systems now use AI and machine learning to adjust lighting in real time. These lighting controllers help optimize conditions for each inspection, which improves accuracy and efficiency. Energy-efficient LED lighting paired with intelligent controllers reduces power use and lowers costs. Some lighting controllers are designed for sensitive tasks, such as precision medicine, where adaptable lighting is needed for clear images. Industry 4.0 and smart factories rely on these controllers to support collaborative robots and deep learning. Lighting controllers also play a key role in multispectral imaging, where different wavelengths help reveal hidden features.

Accessories like modular lenses, diffusers, and polarizers allow engineers to tailor illumination for each application. Segmented lighting and multispectral LEDs with adjustable wavelengths give even more control.

Software Integration

Software integration brings flexibility and automation to modern machine vision systems. By linking motion control with vision, engineers can move cameras or parts to get the best lighting and image capture. This setup allows the system to adjust lighting and part position automatically, making it easier to inspect objects from different angles. Communication protocols like Ethernet/IP and I/O signals help synchronize cameras, lighting, and other devices. Programmable Logic Controllers (PLCs) often manage these tasks, ensuring that lighting stays consistent for every inspection. Automated lighting control supports reliable inspection and helps image processing algorithms work with clear, repeatable images.

Feedback Systems

Feedback systems keep lighting conditions stable in machine vision. Closed-loop feedback compensates for changes caused by LED aging, temperature shifts, or power supply issues. Three main types exist: temperature-based feedback, optical sensor feedback, and camera-based feedback. The camera-based method measures brightness in a specific area and adjusts lighting to keep it steady. This approach helps the system handle changes in ambient light and maintain consistent image quality. Reliable feedback ensures that inspections remain accurate, even as conditions change.

| Accessory/Hardware | Function |

|---|---|

| Modular lenses/diffusers | Adjust beam angle and reduce glare |

| Segmented/multispectral LEDs | Customize wavelength and intensity |

| Embedded controllers | Enable plug-and-play lighting control |

| Microstrobe controllers | Synchronize lighting with camera timing |

Machine Vision System Selection

Contrast and Brightness

Selecting the right light source for a machine vision system starts with understanding contrast and brightness. High brightness improves the signal-to-noise ratio and helps the sensor capture clear features. Maximum contrast allows the camera to distinguish object details, making feature extraction easier. Uniform illumination ensures the sensor sees consistent grayscale levels, which supports reliable extraction of important features.

- Key factors for light source selection:

- Choose a light source with enough brightness for the sensor and camera.

- Ensure uniform lighting to avoid shadows and uneven contrast.

- Match the spectral content of the light source to the sensor’s sensitivity.

- Position the light source to control reflections and highlight maximum contrast.

- Consider the surface of the object, as metal, glass, or plastic reflect light differently.

Tip: Use contrast enhancement techniques, such as colored lighting or polarizers, to boost maximum contrast on features of interest.

Robustness

A robust machine vision system needs lighting that can handle harsh environments. Engineers often use enclosures rated by IP or NEMA standards to protect the light source from dust and moisture. Washdown-rated lights with built-in heating or cooling help the sensor and camera work well during cleaning or chemical exposure. Secure mounting and automotive-grade components prevent vibration from affecting the image acquisition system. Potting compounds protect electronic parts from shock and corrosion. High-brightness or strobing modes help the sensor maintain image clarity, even when the environment is tough.

| Robustness Feature | Benefit for Machine Vision System |

|---|---|

| IP/NEMA Enclosures | Protects lighting from dust and water |

| Washdown-rated Lights | Withstands cleaning and chemicals |

| Secure Mounting | Prevents vibration and loosening |

| Potting Compounds | Shields electronics from moisture |

Defect Detection

Defect detection depends on the integration of the light source, sensor, and camera. Engineers start by understanding the application and collecting sample images. They design the image acquisition system to highlight defects with maximum contrast and clear features. Testing with real parts ensures the sensor and camera can capture defects for software extraction. Iteration and optimization improve the system until defect detection meets quality standards.

- Best practices for integrating light source control:

- Define the requirements for defect detection and part handling.

- Collect images of both defective and good parts for analysis.

- Design the lighting and camera setup to maximize contrast and resolution.

- Test and adjust the system to ensure the sensor captures defects clearly.

- Repeat the process until the machine vision system achieves reliable results.

Note: Poor lighting cannot be fixed by software. The sensor and camera need optimized lighting for accurate image acquisition and feature extraction.

Common mistakes in light source selection include waiting too long to plan lighting, choosing the wrong color, or ignoring environmental needs. The table below shows how to avoid these errors:

| Mistake | How to Avoid |

|---|---|

| Late lighting decisions | Plan lighting early in the design process |

| Wrong color choice | Match light color to object and sensor needs |

| Ignoring harsh environments | Use lights with proper IP/NEMA ratings |

| Fixed setups for changing needs | Choose adjustable lighting solutions |

| Hard-to-read barcodes | Use polarized or overdrive lighting |

Machine vision lighting shapes inspection quality, with lighting choices contributing up to 90% of system effectiveness. Engineers should:

- Assess inspection environments and sample surfaces.

- Invest in energy-efficient, modular lighting.

- Optimize angle, intensity, and color for each task.

- Integrate AI and real-time feedback for adaptability.

Regularly reviewing guides, tutorials, and expert advice helps teams stay ahead as LED and AI-driven lighting evolve. The market for machine vision lighting continues to grow, driven by automation and innovation. Smart lighting will define the next era of quality control.

FAQ

What is the main reason engineers choose LED lighting for machine vision?

LED lighting gives stable, bright, and energy-efficient light. Engineers like LEDs because they last long and offer many color options. LEDs also switch on and off quickly, which helps with fast inspections.

Tip: LEDs reduce maintenance and lower energy costs.

How does flickerless LED technology help machine vision systems?

Flickerless LED drivers keep the light steady. Cameras capture clear images without lines or bands. This helps the system find small defects and improves inspection accuracy.

Can machine vision lighting adjust for different products on the same line?

Yes. Smart lighting controllers and software can change brightness, color, or angle for each product. This flexibility supports fast changeovers and keeps inspection results reliable.

Why do engineers use feedback systems in lighting control?

Feedback systems monitor light output and make real-time adjustments. They keep lighting stable, even if temperature or power changes. This ensures the camera always gets the best image.

What mistakes should engineers avoid when selecting lighting?

| Mistake | Solution |

|---|---|

| Choosing wrong color | Match light to object and sensor |

| Ignoring environment | Use protected enclosures |

| Fixed setups | Pick adjustable lighting |

Engineers should plan lighting early and test with real samples.

See Also

What Lies Ahead For Component Counting Vision Tech

The Role Of Structured Light In Improving Vision Systems

Why Proper Lighting Is Essential For Vision System Success

Understanding Semiconductor Technology In Machine Vision Systems