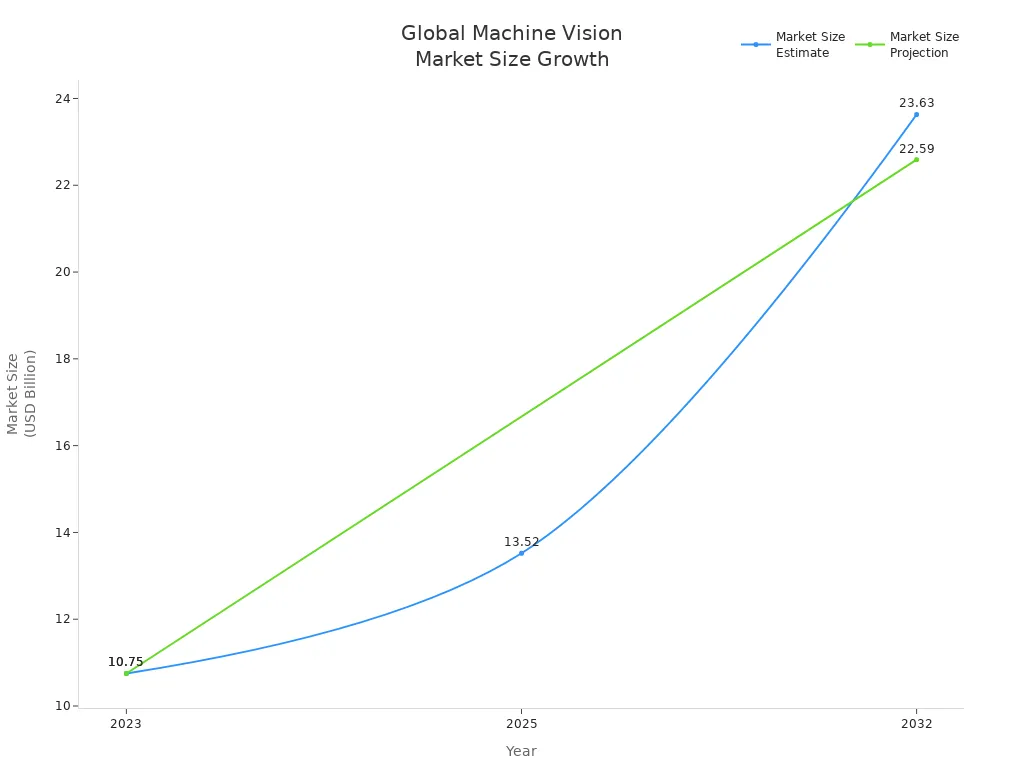

A luminance machine vision system uses advanced cameras and sensors to measure and analyze light in industrial environments. These machine vision systems rely on precise lighting, which determines how well they detect product defects or measure dimensions. The importance of lighting grows as industries demand higher accuracy. Common types include back lighting for edge detection, diffuse light for surface inspection, and dark field light for flaw detection. The market for these systems continues to expand, as shown below:

| Metric | Value (USD Billion) | Year/Period | CAGR (%) |

|---|---|---|---|

| Global Machine Vision Market | 10.75 | 2023 | N/A |

| Projected Market Size | 22.59 | 2032 | 8.7 (2024-2032) |

Lighting remains the core element for reliable detection in all types of machine vision systems.

Key Takeaways

- Luminance machine vision systems use controlled lighting and advanced cameras to capture clear images for accurate defect detection and measurement.

- Proper and consistent lighting is crucial to improve contrast, reduce shadows, and ensure reliable inspection results across different industrial tasks.

- Different system types—area scan, line-scan, and 3D/event-based—serve specific needs like inspecting slow objects, fast-moving materials, or capturing depth information.

- Choosing the right light source, camera, and lens based on the application and environment boosts system accuracy and reduces errors.

- Regular calibration and testing under real conditions keep the system performing well and help maintain high-quality inspections over time.

Luminance Machine Vision System Basics

What Is Luminance?

Luminance describes the amount of visible light that a surface emits or reflects in a specific direction. In a luminance machine vision system, luminance plays a central role in how well cameras capture details. Proper illumination ensures that cameras can see features clearly, which is vital for accurate image processing. When lighting is consistent and controlled, the system avoids shadows, glare, and reflections that can reduce detection accuracy. Machine vision lighting setups, such as dome lights or ring lights, help create even illumination. These setups prevent hotspots and make it easier for cameras to detect flaws or measure objects.

Tip: Consistent illumination is the foundation for reliable image processing and high accuracy in industrial inspection.

Key Components

A luminance machine vision system relies on several core components to function effectively:

- Lighting: Delivers the right amount and type of illumination for the scene. The position, angle, and color spectrum of the light source affect how well cameras capture details.

- Cameras: Act as the eyes of the system, capturing images based on the reflected or emitted light from objects.

- Lenses: Focus light onto the camera sensor, ensuring sharp and clear images for image processing.

- Sensors: Detect the position or state of objects and trigger image capture at the right moment.

- Frame Grabber: Transfers image data from cameras to the computing platform.

- Computing Platform: Processes image data and runs image processing algorithms.

- Processing Software: Analyzes images, extracts features, and makes decisions.

- Control Units: Coordinate the operation of all components.

Each part works together to ensure the system captures high-quality images for precise analysis.

Image Quality Factors

Several factors influence image quality in a luminance machine vision system. The most important include:

| Factor | Impact on Image Quality |

|---|---|

| Contrast | Maximizes differences between object features and background, making features easier to distinguish. |

| Uniformity | Ensures even grayscale values across the image, reducing errors in image processing. |

| Color Reproduction | Maintains true colors, which is important for sorting and inspection tasks. |

Stable illumination is essential. If lighting changes, cameras may capture inconsistent images, leading to errors in image processing. Regular calibration and adaptive lighting systems help maintain consistent illumination. The direction and intensity of light also affect how well cameras detect features. High-quality lenses and proper exposure settings further improve image clarity. When all these factors align, the system achieves reliable detection and high accuracy.

Machine Vision Lighting

Lighting plays a critical role in every machine vision lighting system. The importance of lighting cannot be overstated. Proper illumination determines how well cameras capture details and how accurately the system detects defects. In manufacturing, optimized machine vision lighting has led to a 94% reduction in defect escape rates and a detection accuracy of 99.7%. These improvements result from high-intensity illumination with precise color temperature, which enhances the camera’s ability to capture detailed images. Consistent illumination also reduces customer complaints and ensures repeatable results across production lines.

LED Illumination

LED illumination forms the backbone of modern machine vision lighting. LEDs offer stable, efficient, and long-lasting light sources. The table below shows common types of LED illumination and their features:

| LED Illumination Type | Description | Efficiency Rating / Notes |

|---|---|---|

| Monochromatic LEDs (e.g., Red 660nm) | Stable and efficient; ideal for narrow wavelength applications. | High source lumen efficacy; can be overdriven in strobe mode. |

| White LEDs (Phosphor converted) | Used for broadband illumination; created by blue LEDs exciting yellow phosphors. | Efficiency depends on blue LED performance and color temperature. |

| Narrow wavelength monochromatic LEDs | Tailored for specific tasks; matched to camera sensor sensitivity. | Efficiency varies; spectral matching maximizes illumination. |

Thermal management and matching the LED wavelength to the camera sensor are essential for effective illumination.

Lighting Techniques

Machine vision lighting uses several techniques to maximize contrast and highlight features. The table below summarizes key lighting methods and their applications:

| Lighting Technique | Effect on Contrast and Application in Inspection |

|---|---|

| Backlighting | Creates strong silhouettes for edge detection and presence verification. |

| Bright Field | Illuminates from above to enhance contrast on flat surfaces. |

| Dark Field | Uses low-angle light to reveal surface flaws and textures. |

| Diffuse Lighting | Provides even illumination, reducing glare on shiny or curved surfaces. |

| Multispectral Lighting | Uses infrared or ultraviolet light to reveal hidden defects and material differences. |

Filters and polarizers can further improve contrast by reducing glare and isolating specific wavelengths.

Contrast and Consistency

High-quality machine vision lighting ensures strong contrast and consistent illumination. Proper illumination reduces shadows, glare, and reflections, making features more visible. Consistent light allows the system to deliver reliable detection and repeatable results. Environmental factors such as ambient light, dust, and temperature can affect illumination. Regular calibration and adaptive lighting systems help maintain stable illumination. When machine vision lighting is optimized, AI models detect defects more effectively, leading to fewer errors and higher inspection accuracy.

Tip: Always match the lighting technique and illumination type to the object’s surface and inspection goal for best results.

System Types in Machine Vision Systems

Modern machine vision systems come in several main types. Each type uses different technology to solve specific industrial challenges. Understanding the strengths and weaknesses of these systems helps engineers choose the right solution for their needs. The most common types of machine vision systems include area scan systems, line-scan cameras, and advanced 3D and event-based systems.

Area-Scan Systems

Area scan systems use 2D cameras to capture full images in a single frame. These systems work best for stationary or slow-moving objects. They provide a simple setup and flexible integration. Area scan systems excel at tasks like defect detection, label verification, and barcode reading. They offer a cost-effective solution for many general inspections.

| Feature | Area Scan Systems |

|---|---|

| Image Capture | Full 2D image in one frame |

| Best For | Stationary or slow-moving objects |

| Setup | Simple, flexible |

| Typical Applications | Defect detection, label checks, sorting |

| Advantages | Easy integration, good for various shapes |

| Limitations | Limited resolution for large surfaces, possible motion blur at high speeds |

Area scan systems do not provide depth information. They may struggle with very large or continuous surfaces. For these reasons, engineers often use them for discrete items and slower processes.

Note: Area scan systems remain the most common choice for basic 2D inspection tasks in manufacturing.

Line-Scan Systems

Line-scan cameras capture images one line of pixels at a time. The system builds a complete image as the object or camera moves. This method allows for very high detection speed and resolution, especially for fast-moving or continuous materials. Line-scan cameras produce seamless images without motion blur, making them ideal for inspecting webs, sheets, or conveyor belts.

| Feature | Line-Scan Cameras | Area Scan Systems |

|---|---|---|

| Image Acquisition | One line at a time; needs movement | Full 2D image in one frame |

| Detection Speed | Very high; suited for fast-moving materials | Limited by frame rate |

| Resolution | High over large areas; seamless images | Fixed by sensor size |

| Synchronization | Requires precise movement sync | No sync needed |

| Use Cases | High-speed inspection of continuous objects | Inspection of discrete, slower items |

| Advantages | High speed, high resolution, no motion blur | Simpler setup, flexible |

| Limitations | Complex integration, higher cost, not for stationary scenes | Motion blur at high speeds, limited for large surfaces |

Line-scan cameras offer high dynamic range and maximum sensitivity. They work well for applications that need 100% inspection at high throughput. However, these systems require precise synchronization and more complex integration. Engineers often select line-scan cameras for industries like paper, textile, and electronics, where materials move quickly and require detailed inspection.

3D and Event-Based Systems

3D vision systems add depth and volume measurement to traditional 2D imaging. These systems use technologies such as laser triangulation, stereo vision, or structured light. 3D vision systems help robots guide parts, measure object dimensions, and inspect complex surfaces. They play a key role in tasks that require precise spatial information, such as robotic pick-and-place or quality control of molded parts.

Event-based systems represent a newer type of machine vision technology. These sensors detect changes in light intensity at each pixel, similar to how the human eye works. Event-based systems operate at very high speeds, with low latency and power use. They excel in environments with dynamic lighting or where fast detection is critical.

- Typical applications for 3D and event-based machine vision systems include:

- Predictive maintenance through vibration monitoring

- High-speed counting of objects on conveyor belts

- Real-time particle or object size monitoring for quality control

- Defect detection such as paint flaws or scratches

- Safety monitoring with real-time object tracking

3D vision systems provide detailed depth data, which is essential for precision tasks. They often cost more and require more maintenance than 2D systems. Event-based systems offer high temporal precision and work well in challenging lighting. They reduce data processing needs and support industrial automation and IoT applications.

Tip: Choose 3D or event-based systems for advanced detection tasks that require depth, speed, or operation in difficult lighting conditions.

| Vision System Type | Advantages | Limitations |

|---|---|---|

| Area-Scan (2D) | Captures full 2D images; good for defect detection and label verification | No depth information; limited light sensitivity |

| Line-Scan (2D) | High resolution; high dynamic range; ideal for high-speed inspection | Needs object motion and encoder feedback; complex integration |

| 3D Vision | Provides depth and volume data; critical for robotic guidance | Higher cost; increased complexity; more maintenance |

| Event-Based | High speed; low latency; power efficient; works in dynamic lighting | Less detailed explicit limitations available |

These types of machine vision systems give manufacturers the flexibility to match the right technology to each inspection challenge. By understanding the differences, engineers can improve detection accuracy and production efficiency.

Detection and Applications

Luminance machine vision systems play a vital role in modern industries. They support a wide range of detection tasks, from defect detection to barcode reading and object detection and counting. These systems use advanced cameras, precise light sources, and robust image processing to deliver reliable results. Below, the main application areas highlight how these systems improve efficiency and accuracy.

Industrial Inspection

Manufacturers rely on luminance machine vision systems for automated inspection and process monitoring. These systems perform defect detection by capturing high-resolution images under controlled light. They identify surface flaws, missing components, and assembly errors. Object detection and counting ensure that each product meets strict standards. The systems also verify the presence or absence of parts, monitor worker safety, and sort items based on color, shape, or size.

- Common detection tasks in industrial settings include:

- Defect detection and error proofing

- Barcode reading and OCR for traceability

- Counting and sorting components

- Assembly verification

- Process monitoring

Proper light selection and placement maximize contrast, making defects stand out during image processing. Manufacturers use these systems to reduce human error, increase throughput, and maintain consistent quality control. Object detection and counting help track production output and prevent costly mistakes.

Note: 2D luminance-based systems remain the most popular for surface inspection, barcode reading, and defect detection on discrete parts.

Display and Lighting Testing

Display and lighting industries demand precise measuring and testing. Luminance machine vision systems excel in these environments by using specialized light sources and advanced image processing. Engineers use smart LED lighting with integrated feedback and temperature control to achieve a high signal-to-noise ratio. Thermoelectric cooled lasers provide stable wavelengths, allowing selective filtering for accurate measuring. White light fiber optic sources, calibrated to NIST standards, enable automated lighting control and precise measurements.

- Real-world examples include:

- LED spotlights replacing halogen lights for display testing, offering long life, low heat, selectable colors, and high intensity

- High dynamic range luminance display systems, such as those based on JVC DLA-RS600U projectors, deliver over 100,000-to-1 luminance dynamic range and pseudo 11-bit grayscale precision. These systems synchronize with EEG and infrared eye-tracking for advanced visual perception studies.

Engineers select the right light source to maximize contrast and ensure accurate detection. These systems measure brightness, uniformity, and color consistency in displays and lighting products. Automated inspection routines use image processing to detect defects, such as dead pixels or uneven illumination.

Tip: Matching the light source to the display or lighting product ensures reliable measuring and robust detection.

OCR and Quality Control

Optical character recognition (OCR) and quality control represent critical applications for luminance machine vision systems. These systems use optimized light and advanced image processing to capture clear images of printed text, labels, and barcodes. Proper lighting conditions account for up to 90% of overall system performance. Optimized lighting can improve defect detection rates by up to 30%.

| Evidence Aspect | Impact on Machine Vision Performance |

|---|---|

| Proper lighting conditions | Account for up to 90% of overall system performance |

| Optimized lighting | Can improve defect detection rates by up to 30% |

OCR systems read serial numbers, expiration dates, and product codes with high accuracy. Barcode reading ensures traceability and inventory management. Object detection and counting support quality control by verifying that each product matches specifications. Automated inspection routines reduce human error and fatigue, ensuring uniform standards.

Machine vision systems deliver real-time image processing and consistent defect detection. By automating inspections, they help companies maintain high levels of quality control. Proper luminance ensures that images remain clear and detailed, supporting precise OCR and reliable barcode reading.

Callout: For best results in OCR and quality control, always optimize light and image processing settings to match the inspection task.

Choosing a Luminance Machine Vision System

Selection Criteria

Selecting the right luminance machine vision system requires careful attention to several factors. Engineers must focus on how the system’s light source and illumination highlight object features. The right lighting creates clear contrast between important and unimportant parts, which is essential for accurate ocv and inspection. The choice of optical lens also matters. Focal length, aperture, and magnification all affect how the system captures light and delivers sharp images for ocv and image analysis software.

The camera type, whether CMOS or CCD, impacts resolution and reliability. Each camera responds differently to light and illumination, so matching the camera to the application ensures better ocv results. The table below summarizes key selection criteria:

| Selection Criterion | Key Considerations |

|---|---|

| Light Source & Lighting | Must highlight object features and create clear contrast between important and unimportant parts. |

| Optical Lens | Important parameters include focal length, aperture, magnification, and interface type. |

| Camera | Choice between CMOS and CCD cameras based on resolution, reliability, and image quality. |

Tip: Always test the system with real samples under production conditions to verify that the lighting and illumination deliver consistent ocv performance.

Common mistakes can lead to poor results. Many users select lighting based only on brightness, ignoring how light interacts with the object’s surface. Others try to use one system for too many tasks, causing complexity. Testing with too few samples or copying old solutions without adaptation often leads to failure. Early involvement of all stakeholders and regular calibration help avoid these issues.

Matching System to Application

Matching a luminance machine vision system to its application starts with understanding the inspection environment. Object size and camera field of view determine the intensity and distribution of light and illumination needed. Larger objects require more intense, evenly distributed illumination. The distance between the camera, lighting, and object also affects the choice of light source. For longer distances, engineers may select high-intensity light sources.

Camera spectral sensitivity plays a role. For example, CMOS cameras respond well to IR light, so matching the light source spectrum to the camera sensor improves ocv and image analysis software performance. Environmental factors such as space, part placement, and motion speed influence the geometry and type of lighting. High-speed inspections may need strobe lighting to freeze motion.

Ambient light can interfere with the system. Using physical enclosures, high-power strobing, or filters helps maintain consistent illumination. Different types of light sources, such as LED, quartz halogen, or xenon, offer unique benefits. No single light source fits every application, so practical testing is essential.

A successful integration considers sensor selection, lens choice, lighting design, and mechanical setup. Regular calibration and maintenance keep the system performing well. Prototyping and testing under real production conditions ensure that the chosen lighting and illumination deliver reliable ocv and quality control.

Note: The best results come from combining theoretical analysis with hands-on testing, always adapting the lighting and illumination to the specific needs of the application.

A luminance machine vision system supports modern manufacturing by using advanced cameras and sensors to analyze light. Main types include area scan, line-scan, and 3D machine vision systems, each excelling at tasks like defect detection, object counting, and precise measurement. Effective lighting remains essential for accurate detection. Engineers should tailor light sources, lens selection, and software to the application. Regular calibration and matching the light spectrum to the camera sensor improve results. For ongoing success, research new lighting technologies and AI-driven algorithms to boost detection rates and system flexibility.

Tip: Prioritize consistent light and robust lighting design to maximize inspection accuracy and long-term value.

FAQ

What is the main advantage of using luminance machine vision systems?

Luminance machine vision systems provide accurate detection of defects and features. They use controlled lighting and advanced cameras. This combination ensures high-quality images and reliable inspection results in industrial environments.

How does lighting affect machine vision accuracy?

Lighting determines how well the system captures object details. Proper lighting increases contrast and reduces shadows. This leads to more accurate detection and fewer inspection errors.

Can luminance machine vision systems inspect moving objects?

Yes. Line-scan and event-based systems can inspect fast-moving objects. These systems capture images quickly and reduce motion blur. Manufacturers use them for conveyor belts and continuous production lines.

What industries benefit most from these systems?

Industries such as electronics, automotive, packaging, and display manufacturing benefit most. These sectors require precise inspection, defect detection, and quality control.

How often should engineers calibrate machine vision systems?

Engineers should calibrate systems regularly. Frequent calibration maintains consistent lighting and image quality. This practice helps prevent errors and ensures reliable inspection performance.

See Also

Why Proper Lighting Is Essential For Machine Vision

Understanding Lenses And Their Role In Machine Vision

Comprehensive Overview Of Semiconductor-Based Machine Vision