An illuminance machine vision system uses controlled lighting and advanced cameras to capture clear images for automated analysis. Why does a factory robot sometimes misjudge a product’s size or shape? The answer often lies in the importance of lighting. Good lighting ensures sharp focus and high contrast, which are critical for precise measurements. Industrial studies reveal that poor illumination or focus can cause errors by reducing image clarity. The importance of lighting comes from its direct effect on exposure, detail, and calibration in every automated process.

Key Takeaways

- Good lighting is essential for machine vision systems, as it improves image clarity and accuracy, making up to 90% of system performance.

- Illuminance machine vision systems use adjustable lighting, advanced cameras, and AI to capture clear images and detect defects in real time.

- Different lighting types and techniques, like LED lighting and bright or dark field lighting, help reveal details and reduce errors for various inspection tasks.

- Proper calibration and lighting setup ensure consistent, high-quality images that speed up inspections and reduce mistakes in automated processes.

- These systems boost automation across industries by improving defect detection, increasing speed, lowering costs, and supporting smarter decision-making.

Illuminance Machine Vision System

What It Is

An illuminance machine vision system is a specialized technology that uses controlled lighting and advanced cameras to help machines "see" and understand objects. This system stands out from traditional vision systems because it focuses on creating the best possible lighting conditions for image capture. The main goal is to make every detail of an object visible, even in challenging environments.

Good lighting makes a big difference in how well a machine can detect shapes, colors, and defects. Up to 90% of a vision system’s performance depends on optimized illumination.

The system uses several key components:

- Specialized light sources, such as LEDs or halogen lamps, provide steady and adjustable illumination.

- Optics, including lenses and filters, shape and direct the light for clear images.

- Sensors, like cameras or photodetectors, capture the images with high accuracy.

- Diffusors scatter the light to reduce glare and shadows.

- Housings protect the lighting and optical parts, making the system durable in tough industrial settings.

These features allow the system to highlight important object features, reduce shadows, and improve detection accuracy. Unlike older systems, an illuminance machine vision system can adapt its lighting to match the needs of different inspection tasks. This flexibility supports many types of machine vision, such as defect detection, sorting, and robot guidance.

How It Works

The illuminance machine vision system works by combining smart lighting control with advanced image processing. The process starts when the system’s cameras capture images of objects under carefully managed illumination. The lighting can be adjusted in brightness, color, and direction to match the object’s surface, size, and material.

Here is how the system operates step by step:

- The system selects the right lighting type and direction for the task. For example, diffuse lighting helps inspect shiny surfaces, while backlighting creates clear outlines for measuring shapes.

- Cameras take high-resolution images under these lighting conditions.

- The images go through pre-processing steps, such as noise reduction and contrast enhancement, to make features stand out.

- Advanced algorithms, including deep learning and pattern recognition, analyze the images. These tools can spot defects, measure sizes, and identify colors or shapes in real time.

- AI and machine learning adjust the lighting and camera settings automatically. This keeps image quality high, even if the environment changes.

- The system makes instant decisions, such as sorting products or guiding robots, without stopping production.

| Component/Aspect | Role in Real-Time Processing and Analysis |

|---|---|

| High-resolution cameras | Capture clear, detailed images essential for accurate analysis. |

| Proper lighting | Critical for image clarity; up to 90% of system performance depends on optimized illumination. |

| Image pre-processing | Includes noise reduction, contrast enhancement, and edge detection to prepare images for feature extraction. |

| Advanced algorithms | Use deep learning, blob analysis, and pattern recognition to identify shapes, colors, sizes, and defects in real time. |

| AI and machine learning | Optimize camera settings and lighting dynamically, improve processing accuracy, and enable nuanced decision-making. |

| Real-time decision-making | Enables immediate actions like rejecting defective products or guiding robots without stopping production. |

| Adaptive lighting systems | Use AI to adjust illumination parameters in response to object and environmental changes, maintaining image quality. |

| Communication interfaces | Ensure smooth, real-time data transfer between system components and external devices. |

Different types of machine vision require different lighting techniques. For example, bright field lighting works well for flat surfaces, while dark field lighting highlights scratches or dents. The system can switch between these methods to suit each inspection task. Smart controllers and tunable LEDs allow quick changes to illumination, making the system flexible and reliable.

A well-designed vision system design uses all these elements to improve imaging quality, increase speed, and ensure precision. The combination of advanced lighting, optics, and real-time processing helps industries achieve better accuracy and efficiency in automation.

Machine Vision Lighting

Lighting Types

Lighting plays a central role in every machine vision lighting system. The choice of lighting type affects how well a camera can capture details and detect defects. Several lighting types are common in vision system design. Each type offers unique benefits and drawbacks.

| Lighting Type | Common Usage in Machine Vision | Key Characteristics and Lifespan Notes |

|---|---|---|

| Fluorescent Lighting | Small- to medium-scale inspection stations | Efficient, affordable, provides diffuse light; lifespan not specified explicitly |

| Quartz Halogen | High-precision applications requiring bright light | High intensity, produces heat; lifespan not specified explicitly |

| LED Lighting | Increasingly popular for various scales | Long life expectancy, energy efficient, versatile colors; lifespan noted as long but no exact data |

| Metal Halide | Specialized microscopy and high-intensity needs | Discrete wavelength peaks, used in fluorescence studies; lifespan not specified explicitly |

| Xenon Lighting | High-speed inspections requiring strobe lighting | Intense bursts of light, not ideal for continuous use; lifespan not specified explicitly |

LED lighting has become the most popular choice in machine vision lighting. LEDs last much longer than other types and use less energy. They can stay on all the time and come in many shapes, sizes, and colors. Fluorescent lighting works well for large areas and costs less, but it does not last as long as LEDs. Quartz-halogen lights give off bright, full-spectrum light, which helps with color imaging, but they get hot and need more maintenance. Metal halide and xenon lights provide very bright light for special tasks, such as high-speed inspections or microscopy, but they require warm-up time and use more energy.

| Lighting Type | Advantages | Disadvantages |

|---|---|---|

| LED | Long lifespan; energy efficient; directional light; low maintenance; flexible spectral output | Less cost-effective for large areas; may need other sources for some uses |

| Fluorescent | Cost-effective for large areas; stable output | Lower intensity; less flexible color; shorter lifespan |

| Quartz-Halogen | High intensity; full spectrum; good for color imaging | Shorter lifespan; generates heat; needs warm-up |

| Metal Halide | Very bright; good for microscopy; useful for fluorescence | Shorter lifespan; omnidirectional; needs warm-up; higher maintenance |

| Xenon | Very bright strobe; good for high-speed inspections | Needs warm-up; high energy use; mostly for special tasks |

Tip: Matching the lighting type to the camera’s sensitivity and the inspection task improves both efficiency and accuracy.

Lighting Techniques

Lighting techniques determine how illumination interacts with the object. The right lighting setup can reveal hidden defects, highlight edges, or reduce glare. Machine vision lighting uses several main techniques:

- Bright Field Lighting: This technique shines light directly onto the object from above or at a high angle. It works best for flat or matte surfaces. Bright field lighting highlights large flaws like scratches or dents but may cause glare on shiny surfaces.

- Dark Field Lighting: Here, light comes in at a low angle. Only raised or rough areas reflect light into the camera, making defects stand out against a dark background. Dark field lighting is ideal for finding tiny cracks or particles on reflective surfaces.

- Backlighting: The light source sits behind the object. This setup creates a silhouette, making it easy to measure shapes or find defects in transparent materials.

- Ring Lighting: A ring of LEDs surrounds the camera lens. This provides even illumination and reduces shadows, which helps with edge detection on shiny or curved objects.

- Bar Lighting: Long, narrow lights shine across the object. Bar lights can work in both bright field and dark field modes. They help inspect large or long items, such as metal sheets or bottles.

- Dome Lighting: A dome covers the object and fills it with soft, even light. Dome lighting removes shadows and glare, making it perfect for curved or glossy items.

- Spotlights: Focused beams highlight small areas or features. Spotlights help when only a specific part of the object needs inspection.

Note: Diffused lighting, often achieved with domes or diffusers, reduces glare and shadows. This technique is essential for inspecting reflective or complex-shaped objects, such as electronics or medical devices.

Proper lighting setup and calibration are critical. For example, using high-intensity lighting helps cameras see tiny defects, while diffused lighting makes subtle flaws on shiny surfaces easier to spot. Combining different lighting techniques often gives the best results.

| Aspect | Bright Field Lighting | Dark Field Lighting |

|---|---|---|

| Illumination Angle | 45-90 degrees, direct reflection | 10-15 degrees, low angle, scattered light |

| Image Characteristics | Bright images, strong contrast, may cause glare | Dark background, bright highlights on defects |

| Surface Suitability | Flat, matte, or slightly reflective surfaces | Reflective or mirrored surfaces |

| Setup Considerations | Broader coverage, higher angles | Close proximity, low-angle lighting |

Role in Image Quality

Lighting directly affects image quality in machine vision lighting systems. Good lighting increases contrast, reduces shadows, and makes features stand out. When lighting is consistent and well-distributed, cameras capture clear images every time. This consistency leads to repeatable, reliable inspections.

- High-intensity lighting improves contrast between defects and the background. This makes it easier for the system to find flaws.

- Uniform illumination ensures that every part of the object appears the same in each image. This reduces errors and false positives.

- Proper lighting setup allows for high-speed image capture with less motion blur, which is important for fast-moving production lines.

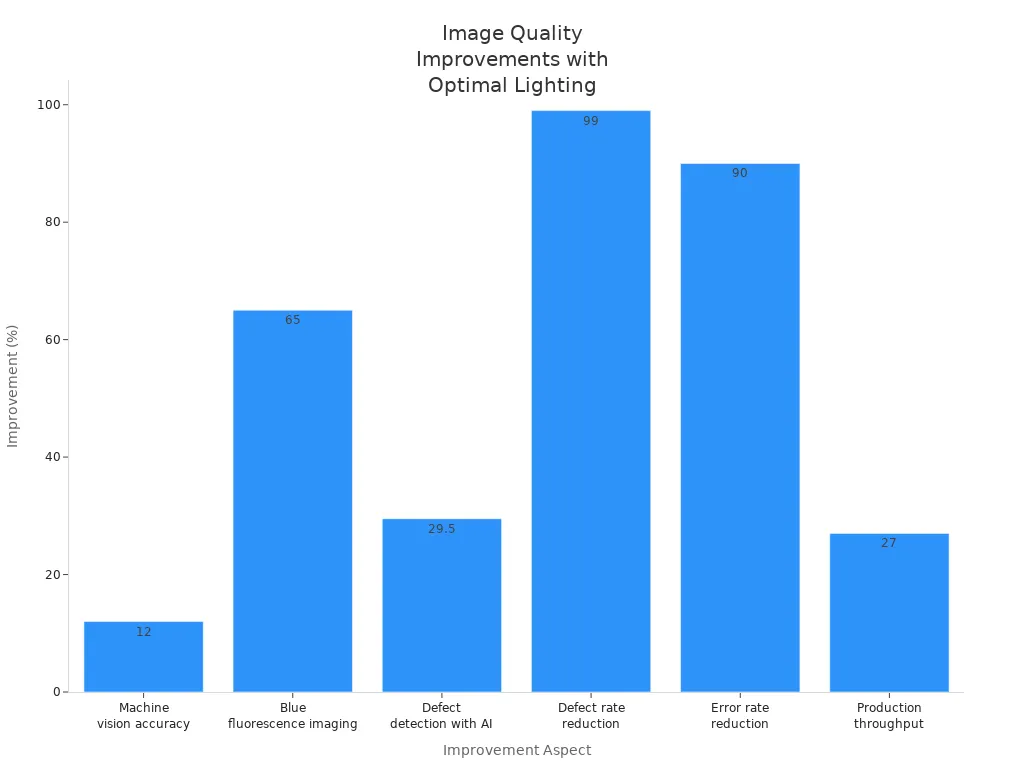

Optimal lighting and calibration can improve machine vision accuracy by over 12%, with some systems reaching up to 95% accuracy. Defect detection rates can increase by 25% to 34%, and defect rates can drop by up to 99%. These improvements show how lighting optimization boosts both quality and efficiency.

| Calibration Technique | Impact on Image Quality |

|---|---|

| Detector Normalization | Improves detector sensitivity and resolution |

| Energy Calibration | Enhances contrast and sharpness |

| Timing Calibration | Improves timing resolution |

| Scatter Correction | Reduces noise and artifacts |

| Attenuation Correction | Improves quantitative accuracy |

| Motion Correction | Reduces motion blur and artifacts |

A well-designed lighting setup supports the vision system design by maximizing contrast and minimizing errors. Consistent illumination across batches ensures that inspections remain accurate and repeatable. Good lighting is the foundation of reliable machine vision lighting, helping industries achieve better results and higher productivity.

Components and Performance

Key Components

A modern illuminance machine vision system uses several important parts. Each part helps the system work better and reduces mistakes.

- Lighting: This part provides the right amount of light for the camera. Good lighting removes shadows and glare, making it easier to see small details. Different types of lighting, like ring lights or backlighting, help with different inspection tasks.

- Lenses and Optics: Lenses focus the light onto the camera sensor. They control how sharp and clear the image looks. Optics also filter out unwanted light, which helps the system see only what matters.

- Image Sensors and Cameras: These parts turn the illuminated scene into digital images. Sensors like CMOS or CCD capture details quickly and accurately.

- Processing Units and Interfaces: These units analyze the images. They use powerful chips to find patterns, measure sizes, and spot defects in real time. Interfaces connect cameras and processors so data moves fast.

- Calibration Tools: These tools help align the camera, lens, and lighting. Proper calibration keeps the system accurate and reliable.

- Diffusors and Housings: Diffusors spread the light evenly, reducing harsh spots. Housings protect the system from dust and damage.

Note: Careful integration and system design make sure all these parts work together for the best results.

Impact on Automation

Each component plays a key role in improving automation. Lighting gives clear, high-contrast images, which helps the system find defects quickly. Lenses and optics keep images sharp and reduce errors from blurry pictures. Sensors capture real-world details, which helps the system make better decisions. Processing units speed up inspections, so factories can check more products in less time.

Advanced lighting, such as LED arrays and strobe lights, increases inspection speed by removing shadows and glare. This allows cameras to capture clear images even on fast-moving lines. Proper illumination also supports accurate color detection and high-quality image capture, which are important for sorting and quality checks.

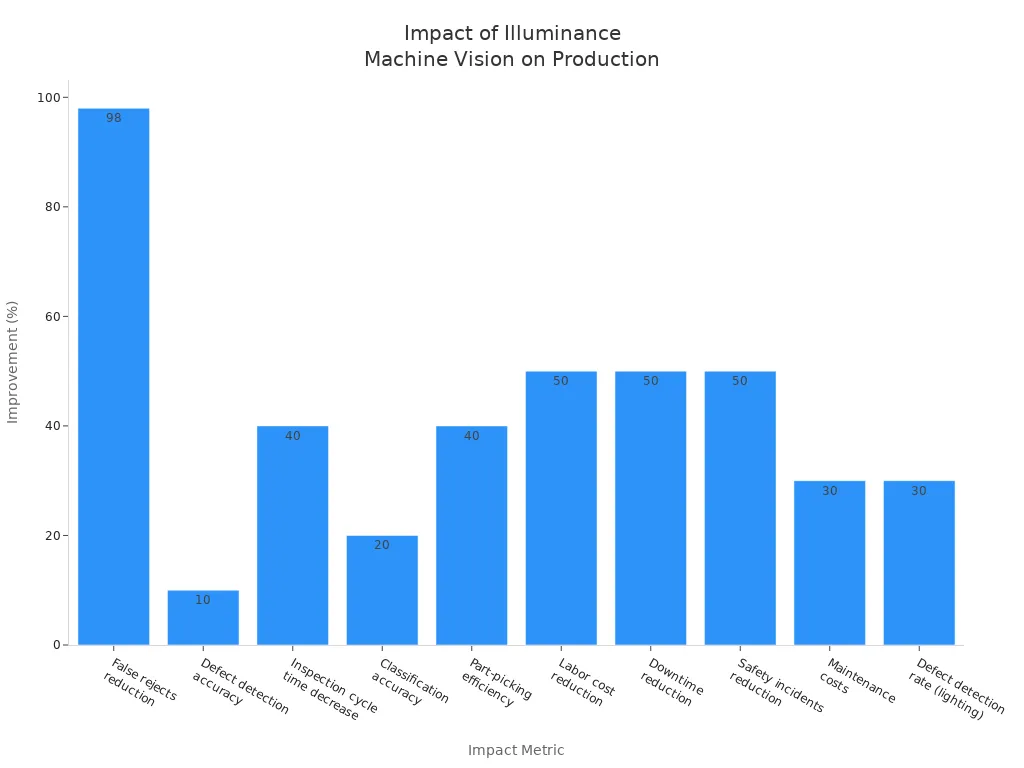

The table below shows how these systems improve production:

| Impact Metric | Measurable Improvement |

|---|---|

| Weekly false rejects reduced | ~98% reduction, saving millions per line |

| Defect detection accuracy | Over 99.5% with AI-driven systems |

| Inspection cycle time | 40% faster |

| Classification accuracy | 20% increase |

| Robotic picking efficiency | Over 40% improvement |

| Labor costs | 50% reduction |

| Downtime | Up to 50% less |

| Safety incidents | 40-60% fewer |

| Maintenance costs | 20-40% lower |

| Optimized lighting effect | Up to 90% of system performance |

When all components work together, the system reduces errors, speeds up inspections, and saves money. Factories see fewer mistakes, better product quality, and safer workplaces.

Machine Vision Applications

Manufacturing

Manufacturing uses machine vision applications to improve speed, accuracy, and quality. Factories rely on these systems for many tasks:

- Counting parts and pieces to reduce errors and save time.

- Detecting objects with software and machine learning for better sorting.

- Monitoring machines for predictive maintenance, which helps prevent breakdowns.

- Identifying defects, such as surface flaws or faulty packaging, to enhance quality control.

- Reading barcodes faster than manual scanning.

- Checking product assembly with AI-driven inspection for higher efficiency.

Automotive plants use machine vision applications to inspect thousands of parts, like engine blocks, for cracks or misalignment. Controlled lighting ensures cameras capture clear images, making it easier to spot small defects. These systems help factories meet strict safety standards, lower labor costs, and reduce waste.

Healthcare

Healthcare professionals use machine vision applications to improve diagnosis and patient care. These systems help in several ways:

- Detecting subtle abnormalities in X-ray images for more accurate diagnosis.

- Providing real-time illuminated imaging during surgery for better visualization.

- Sharpening ultrasound scans to improve diagnostic accuracy.

- Finding lesions in MRI scans with the right lighting.

- Reducing eye strain for doctors by giving consistent, uniform lighting.

Machine vision applications also automate laboratory work. Enhanced image quality allows algorithms to find and classify samples quickly. This reduces human error and increases the speed of testing, helping doctors make better decisions.

Logistics

Logistics companies depend on machine vision applications to move packages quickly and accurately. These systems use optimal lighting to capture clear images, even when packages move fast on conveyors. Key uses include:

- Improving barcode reading and package sorting.

- Automating picking, labeling, and inventory tracking.

- Reducing errors and manual labor, which increases safety and throughput.

- Supporting real-time decision-making for shipment verification.

Warehouses use machine vision applications to measure package size and weight, sort items, and track shipments. Companies like Amazon and UPS use these systems to handle large volumes and reduce bottlenecks. Proper lighting helps the system work well with different package sizes and shapes.

Food and Beverage

Food and beverage factories use machine vision applications to keep products safe and high quality. The right lighting is critical for these systems. The table below shows key benefits:

| Benefit Aspect | Impact |

|---|---|

| Lighting Importance | Up to 90% of system performance depends on proper lighting. |

| Defect Detection | Detection rates improve by about 30% with optimized lighting. |

| Consistent Inspection | Automated systems reduce human error and ensure steady quality. |

| Real-time Monitoring | Lighting enables quick checks and fast problem-solving. |

| Regulatory Compliance | Systems catch contaminants and labeling errors, meeting safety standards. |

| Waste Reduction | Accurate sorting lowers waste and supports sustainability. |

| Speed Adaptation | Fast cameras and lighting keep up with high production speeds. |

Machine vision applications in this industry spot defects, check packaging seals, and ensure correct labeling. Real-time inspections help factories fix problems quickly and avoid recalls, saving money and protecting brand reputation.

Illuminance machine vision systems transform automation by enabling 100% inline inspection and consistent quality. Key improvements include optimized lighting for defect detection, real-time process adjustments, and high-speed inspection. Selecting reliable lighting and components ensures long-term performance and easy integration with smart technologies. Businesses gain better yield, lower costs, and improved product quality. Future trends point to smarter lighting, AI-driven inspection, and advanced imaging. Companies should explore these systems to boost efficiency and prepare for new automation advances.

FAQ

What is the main benefit of using controlled lighting in machine vision systems?

Controlled lighting helps cameras capture clear and detailed images. This improves the accuracy of inspections and reduces errors. Factories can spot defects faster and make better decisions.

How does lighting affect defect detection in automation?

Lighting increases contrast between defects and the background. Good lighting makes flaws easier to see. This leads to higher detection rates and fewer missed problems during inspections.

Can machine vision systems work in different environments?

Yes. These systems adapt to many environments by adjusting lighting and camera settings. They work well in factories, hospitals, warehouses, and food plants.

What is the role of calibration in machine vision lighting?

Calibration aligns the camera, lens, and lighting. This process ensures accurate and repeatable inspections. Proper calibration keeps the system reliable over time.

Are there advanced lighting options for special tasks?

Some systems use multispectral lighting to capture images at different wavelengths. This helps detect features that normal lighting cannot reveal. Multispectral setups improve inspections for complex materials.

See Also

Understanding The Role Of Illumination In Machine Vision

Why Proper Lighting Equipment Is Essential For Machine Vision

A Comprehensive Guide To Electronics In Machine Vision Systems

How Cameras Function Within Machine Vision Systems Explained

Exploring Image Processing Techniques In Machine Vision Systems