A prompt machine vision system uses ai to interpret images and video based on specific prompts or instructions. This year, these systems gain momentum because ai models now process prompts with greater speed and precision. Synthetic data generation and efficient data labeling from generative ai have improved training for every machine vision system. Multi-angle cameras and LIDAR deliver better depth perception, while edge computing allows real-time analysis on low-power devices. Prompts guide ai to adapt quickly to tasks in healthcare, autonomous vehicles, and retail. Privacy-preserving techniques support responsible use of ai-powered prompts.

Key Takeaways

- Prompt machine vision systems use AI guided by clear instructions to analyze images quickly and accurately, adapting to new tasks without needing extensive retraining.

- These systems excel at learning from few examples, making them cost-effective and flexible for real-world uses like manufacturing, healthcare, and retail.

- Advanced hardware like multi-angle cameras and edge computing enable real-time image processing, improving defect detection and decision-making speed.

- Visual prompt engineering lets engineers guide AI models with text and visual cues, allowing fast adjustments and better performance across diverse tasks.

- Prompt machine vision systems reduce errors, lower costs, and enhance efficiency while addressing privacy and ethical concerns through responsible AI practices.

Prompt Machine Vision System Basics

What Is a Prompt Machine Vision System

A prompt machine vision system uses ai to analyze images and video by following specific instructions, or prompts, given by users or other systems. This approach relies on prompt engineering, which means designing clear and effective prompts to guide large ai models in solving computer vision tasks. These systems combine advanced hardware, such as smart cameras and multi-camera setups, with powerful software that uses ai and machine learning to process visual data.

Researchers describe prompt machine vision systems as a new direction in computer vision. They focus on visual prompt engineering, which helps ai vision systems adapt quickly to new tasks. By creating prompts tailored to each image or scenario, these systems improve performance and flexibility. The model can handle a wide range of computer vision tasks, such as object detection, classification, and segmentation, even with limited training data.

Note: System integration plays a key role in building a complete machine vision system. Companies often link products from different sources to create solutions for industries like recycling, defense, and manufacturing. Specialized applications continue to emerge as startups and established firms develop tailored ai vision systems.

Recent studies highlight several technical components that define prompt machine vision systems:

- Advanced hardware, including high-speed and high-resolution cameras, supports diverse application needs.

- Sophisticated software integrates ai and machine learning for real-time image analysis.

- System integration connects products from multiple vendors to form robust machine vision solutions.

- New technologies, such as high-speed infrared imaging, expand the range of possible applications.

- Market consolidation and partnerships help companies offer more comprehensive machine vision system portfolios.

Prompt engineering has become a central research focus. Scientists review and verify methods that enhance the adaptability and performance of large vision models. This systematic approach advances the capabilities of ai vision systems and supports their growing importance in industry.

How It Differs from Traditional Machine Vision

Prompt machine vision systems differ from traditional machine vision in several important ways. Traditional machine vision relies on manual feature extraction and works best in simple or controlled environments. These systems often struggle with complex images or tasks that require adaptability. In contrast, prompt machine vision systems use ai models that learn features automatically and respond to prompts, making them more flexible and efficient.

- 3D machine vision systems, a key part of modern ai vision systems, deliver sub-millimeter precision and superior defect detection compared to older 2D systems.

- They operate continuously, reducing downtime and operational costs in manufacturing.

- Industries such as automotive, aerospace, pharmaceuticals, and food processing benefit from precise flaw detection, fill-level validation, and improved product safety.

Experimental results show clear advantages for prompt machine vision systems:

- An automotive parts company reduced part variations by 40% after using hypothesis testing with ai vision systems.

- Pharmaceutical packaging systems improved defect detection accuracy from 98.5% (manual) to 99.9% with ai-based inspection.

- Semiconductor companies saw a 60% reduction in defect rates after implementing new cleaning steps, validated by hypothesis testing.

- A/B testing in soldering defect detection found ai-based vision systems achieved a 97.2% detection rate, compared to 93.5% for legacy systems.

| Dataset / Task | Setting | Performance Metric | Value / Improvement | Notes |

|---|---|---|---|---|

| MiniImageNet (Few-shot Classification) | 1-shot | Accuracy (%) | 66.57% | Effective learning from limited data |

| MiniImageNet | 5-shot | Accuracy (%) | 84.42% | Strong few-shot learning capabilities |

| FC100 | 1-shot | Accuracy (%) | 44.78% | Outperforms previous methods |

| FC100 | 5-shot | Accuracy (%) | 66.27% | Robust and transferable representations |

| Cross-domain (Medical Imaging) | 5-way 5-shot | Accuracy (%) | Matches baselines | Adapts to medical imaging datasets |

| Few-shot Object Detection | 3-shot | mAP Improvement Over Baseline | +8% | Large improvement in low-shot settings |

| Few-shot Object Detection | 5-shot | mAP Improvement Over Baseline | +6% | Superior detection with few samples |

| Few-shot Object Detection | 10-shot | mAP Improvement Over Baseline | +3% | Maintains advantage as samples grow |

| Few-shot Object Detection | Baseball Field (10-shot) | Average Precision (AP) | 82% | High accuracy on specific classes |

Traditional machine vision systems perform well in simple environments but require large labeled datasets and significant computational resources for deep learning models. Prompt machine vision systems, using prompt engineering, excel in few-shot learning. They achieve high accuracy and adaptability with less data, making them ideal for real-world computer vision tasks.

Prompt Engineering in AI Vision Systems

Visual Prompting Techniques

Prompt engineering shapes how ai vision systems understand and process images. Engineers design prompts as structured inputs, such as text, images, or instructions, to guide each model. These prompts help the model focus on specific tasks, like image segmentation or object detection. Visual prompting adapts ideas from text prompting in natural language processing. It uses spatial cues, bounding boxes, and visual hints to direct the model’s attention.

A typical workflow for prompt engineering in ai vision systems includes:

- Selecting the right model for the image task.

- Crafting clear prompts, using both text and visual elements.

- Adjusting hyperparameters, such as guidance scale and inference steps.

- Refining prompts through iteration to improve results.

Prompts allow rapid adaptation. Engineers can change prompts to shift the model’s focus without retraining. This flexibility supports real-time adjustments and rapid prototyping. Visual prompting enables ai vision systems to handle new image types or tasks with minimal delay. The iterative process lets teams optimize outputs quickly, even in resource-limited settings.

Note: Structured prompts, including spatial and visual cues, directly influence how the model performs image generation, segmentation, and object detection.

Few-Shot Learning and Adaptability

Few-shot learning stands at the core of modern ai vision systems. These systems use prompts to learn from only a few labeled images. Few-shot learning systems reduce the need for large datasets. The model adapts to new tasks or data distributions with minimal training. This approach supports zero-shot generalization, where the model handles unseen tasks using only prompts.

Few-shot classification and few-shot object detection both benefit from prompt engineering. Engineers use prompts to guide the model in recognizing new image classes or detecting objects with limited examples. Self-supervised learning further boosts adaptability. The model learns useful features from unlabeled images, then uses prompts for specific tasks.

In practice, ai vision systems combine few-shot learning, self-supervised learning, and prompt engineering to achieve high accuracy. For example, few-shot object detection models use prompts to identify rare objects in images. Few-shot classification models rely on prompts to sort images into new categories. These techniques make ai vision systems more flexible and cost-effective. They also enable real-world applications, such as medical image analysis and automated inspection, where labeled data is scarce.

Key Trends in Machine Vision System Development

Vision-Language Models

Vision-language models have become a driving force in the machine vision system landscape. These models combine image and text processing, enabling ai to understand both visual and written prompts. Engineers use prompts to guide the model in tasks like image segmentation, bounding box creation, and image captioning. The model can generate captions for images, identify objects, and draw bounding boxes around them. This approach supports tasks such as semantic segmentation and image captioning with high accuracy.

Large pre-trained vision-language models accelerate prompt engineering. They allow machine vision systems to adapt quickly to new tasks. The model can process images, interpret prompts, and deliver results in real time. This flexibility supports applications in manufacturing, healthcare, and e-commerce. The integration of ai tools into cameras and edge devices has made machine vision more accessible and powerful.

Note: Recent research highlights several trends shaping machine vision system development:

| Trend Category | Key Findings and Trends |

|---|---|

| Artificial Intelligence (AI) | AI is the dominant trend, embedded in cameras and edge devices; AI enables addressing complex tasks like flaw detection; AI tools are integrated in most machine vision software. |

| Cameras and Image Sensors | Higher resolution sensors (up to 250 MP) are becoming available; SWIR cameras are more accessible and less costly due to new sensors; pixel size reduction has slowed due to optical challenges. |

| Camera Interfaces | Major interfaces include Camera Link, GigE Vision, USB3 Vision, CoaxPress; speeds are increasing (e.g., GigE Vision up to 100 Gbps); new protocols like RDMA improve reliability. |

| Lenses | Advances include ruggedized lenses, lenses for smaller pixels and larger sensors, telecentric lenses for precision, wide-angle lenses with distortion correction, and growing interest in liquid lenses. |

| Lighting | Shift from halogen to LED illumination; LEDs becoming more efficient with higher output and better thermal management (e.g., Chip-on-board LEDs). |

| Software | Bifurcation between ease-of-use low-code/no-code solutions and flexible SDKs; AI tools are being refined for specific applications to reduce developer effort. |

| Computational Imaging | Emerging field combining multiple images algorithmically; techniques like photometric stereo and super-resolution enhance image quality and defect detection. |

Advances in Object Detection

Object detection has seen major breakthroughs through visual prompt engineering. Engineers use prompts to direct the model to locate objects, draw bounding boxes, and perform image segmentation. The model can process images with few-shot learning, using only a handful of examples to recognize new objects. This capability reduces the need for large labeled datasets.

Recent studies show that applying the Image-of-Thought prompting method to GPT-4o improves object localization accuracy by 16.34%. The model, when guided by prompts, draws more precise bounding boxes and delivers better object detection results. The IoT prompting method also increases the total score on the MMBench(dev) benchmark, confirming gains in image captioning and object-centric reasoning.

| Category | GPT-4o Accuracy | GPT-4o + IoT Accuracy | Improvement (%) |

|---|---|---|---|

| Object Localization | 0.667 | 0.762 | 16.34 |

Engineers now rely on prompts for image segmentation, bounding box creation, and image captioning. The model adapts to new tasks, processes images efficiently, and supports real-time machine vision system applications. These advances make object detection central to modern machine vision.

Applications of AI Vision Systems

Manufacturing and Inspection

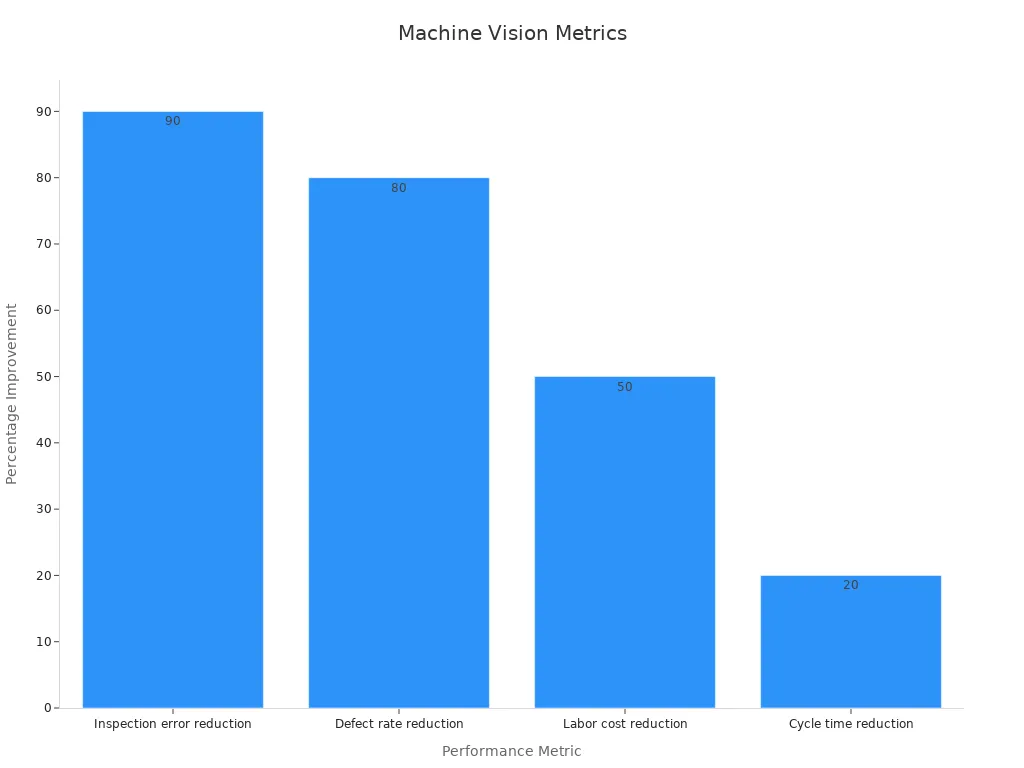

Manufacturers use prompt machine vision systems to improve quality control and efficiency. These systems rely on ai for object detection, defect detection, and real-time anomaly detection. Engineers deploy machine vision to inspect products, identify flaws, and ensure consistent standards. The integration of ai and image processing algorithms enables real-time processing and rapid recognition of defects.

| Performance Metric | Impact Description |

|---|---|

| Inspection error reduction | More than 90% decrease compared to manual inspection |

| Defect rate reduction | Up to 80% fewer defects |

| Labor cost reduction | Approximately 50% less spent on quality assurance labor |

| Cycle time reduction | Up to 20% faster production cycles |

Prompt machine vision systems use ai to automate defect detection, reducing human error and waste. Real-time anomaly detection supports faster production and lower costs. These systems analyze images, draw bounding boxes around defects, and deliver actionable insights.

Healthcare and Medical Imaging

Healthcare applications benefit from ai-powered machine vision systems. Hospitals and clinics use these systems for image recognition, object detection, and real-time analysis of medical scans. Machine vision supports early disease detection and improves diagnostic accuracy.

- CT and MRI imaging usage increased in major healthcare systems from 2000 to 2016.

- Over 30% of imaging procedures are unnecessary, costing the U.S. about $30 billion each year.

- Ai and machine vision improve workflow efficiency and resource allocation.

- Predictive ai models help forecast disease progression.

- Private sector investment in ai for medical imaging exceeded $6 billion in 2022.

Prompt machine vision systems enable real-time processing of medical images, supporting faster and more accurate recognition of abnormalities. These advances help reduce unnecessary procedures and improve patient outcomes.

E-commerce and Retail

E-commerce platforms use machine vision for product recognition, object detection, and real-time anomaly detection. Ai models identify products in images, match them to catalogs, and support automated inventory management. Edge ai devices enable real-time processing, which is critical for responsive recognition and customer experience.

Recent trends show that zero-shot and few-shot learning allow ai to recognize new products with minimal training data. Multimodal ai combines visual and text data for better recognition accuracy. Regulatory focus on ethical ai, such as the EU AI Act 2024, increases trust in machine vision systems. These developments drive adoption in real-world applications, making product recognition faster and more reliable.

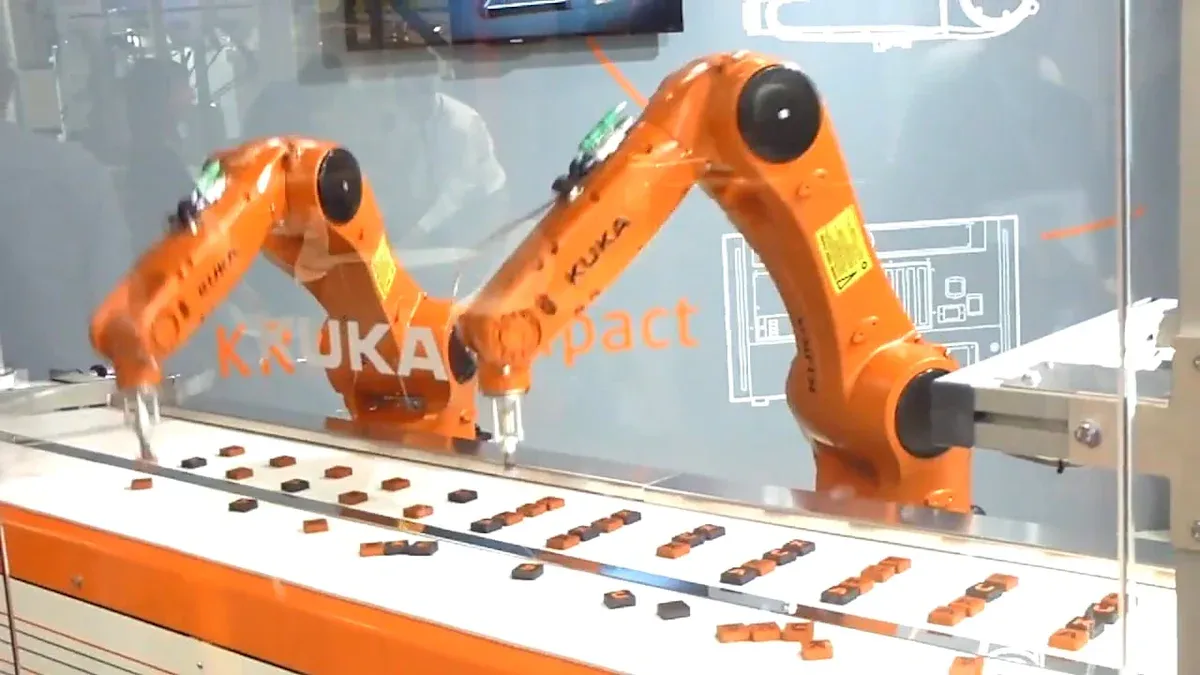

Robotics and Automation

Robotics relies on prompt machine vision systems for object detection, recognition, and real-time decision-making. Robots use ai to analyze images, detect objects, and plan actions. In complex environments, prompt-based systems adapt quickly to new tasks.

Quantitative evaluations in simulators show that prompt vision systems like DKPrompt achieve higher task completion rates than traditional methods. Robots use ai to generate visually grounded plans, recover from failures, and re-plan when needed. Real-time processing and recognition enable robots to perform tasks such as sorting, assembly, and navigation with high accuracy. These capabilities support real-world applications in manufacturing, logistics, and service industries.

Benefits and Challenges

Efficiency and Flexibility

A prompt machine vision system delivers high efficiency and flexibility in many industries. Engineers can use prompts to quickly adjust the focus of a machine vision system, allowing it to switch between tasks like object detection, classification, or segmentation. This adaptability supports real-time decision-making and reduces downtime. In manufacturing, ai-driven systems have cut paint defects by 30% and improved quality control. OpenCV-based solutions process images at up to 18 frames per second in standard settings and over 500 frames per second in high-speed modes. These speeds enable real-time analysis for critical applications.

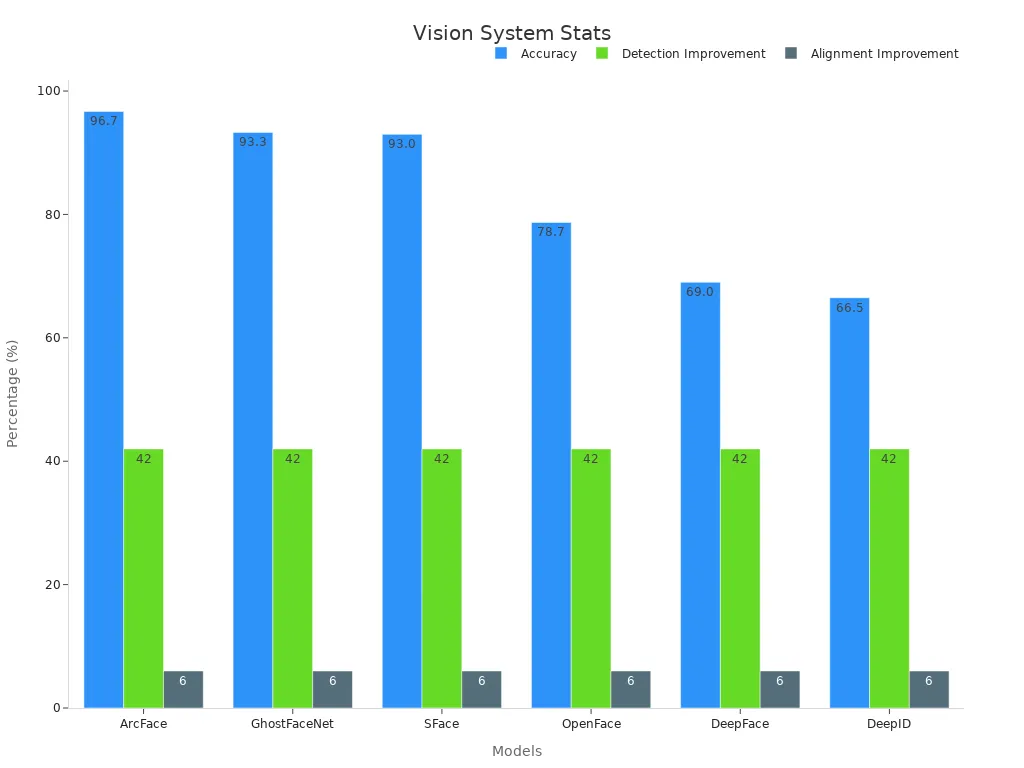

The following table compares the accuracy and improvement rates of several machine vision models:

| Model | Accuracy (%) | Improvement from Detection (%) | Improvement from Alignment (%) |

|---|---|---|---|

| ArcFace | 96.7 | 42 | 6 |

| GhostFaceNet | 93.3 | 42 | 6 |

| SFace | 93.0 | 42 | 6 |

| OpenFace | 78.7 | 42 | 6 |

| DeepFace | 69.0 | 42 | 6 |

| DeepID | 66.5 | 42 | 6 |

Few-shot learning plays a key role in this flexibility. With only a few labeled images, ai models can adapt to new tasks using prompts, making the system cost-effective and scalable.

Data Quality and Prompt Design

The success of a prompt machine vision system depends on the quality of both data and prompt design. Engineers must create clear prompts that guide ai to focus on the right features in each image. High-quality images and accurate labeling improve the results of few-shot learning. Poor data or unclear prompts can lead to errors in object detection or classification. Teams often use prompt engineering to refine prompts and test different approaches. This process helps the machine vision system learn from fewer examples and deliver reliable results.

Tip: Teams should regularly review and update prompts to match changing tasks or new types of images.

Ethical and Computational Considerations

Engineers must address ethical and computational challenges when deploying ai in machine vision. Real-time analysis of images can raise privacy concerns, especially in healthcare or public spaces. Teams should use privacy-preserving techniques and follow regulations to protect sensitive data. Computational demands also matter. Running ai models for real-time image analysis requires powerful hardware and efficient algorithms. Few-shot learning and prompt engineering help reduce the need for large datasets and lower the computational load. By balancing these factors, organizations can build responsible and effective machine vision systems.

Prompt machine vision systems have advanced rapidly this year. Improved AI models, better hardware, and efficient prompt engineering drive their adoption. A comprehensive review highlights their impact in fields like healthcare, manufacturing, and autonomous systems. Many industries now rely on a machine vision system for real-time analysis and decision-making. Organizations should explore these technologies to stay competitive. Staying informed about new developments will help leaders unlock future potential.

FAQ

What is the main advantage of a prompt machine vision system?

A prompt machine vision system adapts quickly to new tasks. It uses prompts to guide AI models, which helps teams solve different problems without retraining the system. This flexibility saves time and resources.

How does a machine vision system improve manufacturing quality?

A machine vision system detects defects and checks product quality in real time. It reduces human error and speeds up inspections. Many factories use these systems to lower defect rates and improve overall efficiency.

Can a prompt machine vision system work with limited data?

Yes, a prompt machine vision system uses few-shot learning. It learns from only a few labeled images. This feature makes it useful in fields where collecting large datasets is difficult or expensive.

Are there privacy concerns with machine vision systems?

Teams must protect sensitive data when using a machine vision system, especially in healthcare or public spaces. Privacy-preserving techniques and strict regulations help keep personal information safe.

What industries benefit most from prompt machine vision systems?

- Manufacturing

- Healthcare

- E-commerce

- Robotics

These industries use prompt machine vision systems for tasks like inspection, diagnosis, product recognition, and automation.

See Also

A Comprehensive Guide To Inspection Vision Systems In 2025

How AI-Driven Vision Technology Is Changing Industries Now

Comparing Firmware-Based Vision With Conventional Machine Systems

Essential Features And Advantages Of Vision Systems In Healthcare