A prediction machine vision system uses computer vision and advanced algorithms to anticipate outcomes, while traditional machine vision follows fixed rules. Many businesses see higher quality and improved user satisfaction with prediction-based systems. Metrics such as user retention, customer lifetime value, and monthly recurring revenue support this value. The table below shows how these metrics reflect the quality and impact of prediction machine vision in the market.

| Metric | Description | Relevance to Value Proposition |

|---|---|---|

| User Retention | Users who keep using the product | Shows satisfaction and quality |

| Customer Lifetime Value (CLV) | Total revenue from a customer | Higher CLV shows strong value and quality |

| Monthly Recurring Revenue (MRR) | Regular monthly income | Stable MRR means lasting quality |

Computer vision powers both systems, but prediction machine vision system stands out for its ability to deliver reliable and high-quality results even as conditions change.

Key Takeaways

- Prediction machine vision systems use AI to learn from data and adapt to new situations, while traditional systems follow fixed rules and work best in stable environments.

- Prediction systems offer higher accuracy, better adaptability, and faster processing, making them ideal for complex and changing tasks.

- Industries like manufacturing, healthcare, agriculture, and robotics benefit most from prediction machine vision due to improved quality, speed, and defect detection.

- Traditional machine vision systems are easier and cheaper to set up but lack flexibility, while prediction systems require more data and computing power but deliver greater long-term value.

- Choosing the right system depends on task complexity, data availability, cost, and the need for real-time adaptability to ensure the best results.

How They Work

Traditional Machine Vision

Traditional machine vision uses a clear and structured approach to analyze images. The system depends on a combination of hardware and software to complete its tasks.

- Cameras and lenses capture images under controlled lighting.

- Image sensors, such as CCD or CMOS, convert these images into digital signals.

- The vision processing unit runs image processing algorithms to extract features like size, shape, and color.

- The software compares these features to preset standards.

- If the product meets the standards, the system allows it to pass. If not, it triggers actions like sorting or rejection.

This process relies on rule-based logic. The system follows strict "if-then" rules to make decisions. For example, if a part is too large, the system rejects it. Communication systems connect the vision system to automation equipment, allowing real-time control.

Traditional machine vision improves efficiency and quality in industries by automating inspection, measurement, and classification. The system uses external computers for processing, which adds flexibility but can slow down response times.

Prediction Machine Vision System

A prediction machine vision system uses computer vision and advanced AI to anticipate outcomes. Instead of following fixed rules, the system learns from data. It uses deep learning, convolutional neural networks (CNNs), and dynamic vision models to recognize patterns and predict future events.

- The system collects large amounts of data from cameras and sensors.

- AI models analyze this data to find complex patterns.

- The system uses predictive algorithms to forecast what will happen next.

- It adapts to new data and changing environments, improving accuracy over time.

| Algorithm / Model / Technique | Description | Application |

|---|---|---|

| Deep Learning | AI method that analyzes complex image patterns for prediction tasks | Motion prediction, anomaly detection, forecasting events |

| CNNs | Specialized deep learning networks for image feature extraction | Object detection, image classification |

| DNNs | Multi-layer neural networks for pattern recognition | Healthcare video analysis, forecasting |

| Event-based Vision | Captures changes in scenes for real-time analysis | Motion detection, reducing processing load |

| Dynamic Vision Reservoir | Advanced computing for motion recognition | Real-time motion prediction, manufacturing |

The prediction machine vision system uses computer vision to process data in real time. It can handle large datasets, such as SUN, LSUN, Open Images, Cityscapes, and KITTI. These datasets help train AI models to generalize across many applications.

Recent advances in AI, such as vision transformers and self-supervised learning, allow the system to learn from unlabeled data. Real-time adaptive processing and edge computing help the system work faster and more efficiently.

The prediction machine vision system does not just react to what it sees. It uses computer vision and AI to predict what will happen next, making it more flexible and powerful than traditional systems.

The evolution from rule-based logic to AI-driven prediction marks a major change in machine vision. Early systems used strict rules, but modern systems use data and AI to adapt and improve. This shift allows prediction machine vision systems to solve complex problems in manufacturing, healthcare, and autonomous vehicles.

Performance

Accuracy and Metrics

Prediction machine vision systems and traditional machine vision systems both rely on computer vision to inspect products and detect defects. However, their performance differs when measured by accuracy, precision, recall, and F1 score. These metrics help companies understand the quality of their inspection process and the reliability of their classification model.

A direct comparison of different models in a controlled trial for breast lesion classification shows how prediction systems, powered by AI and deep learning, perform against traditional machine learning approaches:

| Model | Accuracy | Sensitivity | Specificity | F1 Score | Average Precision (AUCPR) |

|---|---|---|---|---|---|

| Random Forest (RF) | 90% | 71% | 100% | 0.83 | 0.90 |

| Convolutional Neural Network (CNN) | 91% | 82% | 96% | 0.87 | 0.88 |

| AutoML Vision | 86% | 84% | 88% | 0.83 | 0.95 |

Statistical tests show no significant difference between these models in this specific trial, but the results highlight the high classification accuracy and balanced performance of prediction systems using AI.

In a separate experiment, a machine vision system inspected 1,000 parts for defects. The confusion matrix revealed 986 true positives, 8 true negatives, 2 false positives, and 4 false negatives. The system achieved an accuracy of 99.4%. Precision for the GOOD class reached 0.998, while recall for the BAD class was 0.8. The F1 score, which combines precision and recall, provided a balanced view of the system’s quality. These metrics show that prediction systems can deliver high-quality results, especially when trained on large amounts of data.

Accuracy in machine vision means the measurement matches the true value. Repeatability ensures the system gives the same result under the same conditions. Calibration is necessary for repeatable systems to achieve true accuracy. Without repeatability, accuracy cannot be trusted. These principles apply to both traditional and prediction-based systems, but prediction systems often improve both accuracy and repeatability by learning from more data.

Adaptability

Traditional machine vision systems use fixed rules to detect defects and classify products. These rules work well in stable environments but struggle when conditions change. For example, changes in lighting, background, or product appearance can reduce quality and lead to missed defects.

Prediction machine vision systems use computer vision and AI to adapt to new data and changing environments. They learn from patterns in the data and adjust their models over time. This adaptability allows them to maintain high quality even when the environment changes. In real-world tests, prediction systems using deep learning, such as MobileNetV2, show strong robustness. They use techniques like image augmentation and normalization to handle variations in lighting and background. These systems excel at anomaly detection, quickly identifying new types of defects that traditional systems might miss.

A comparison of system robustness under different conditions highlights these differences:

| Class | Accuracy (%) | Precision (%) | Recall (%) | F1-Score (%) |

|---|---|---|---|---|

| Admin | 90.20 | 89.50 | 91.00 | 90.24 |

| Intruder | 98.60 | 98.40 | 98.80 | 98.60 |

| No Human | 75.80 | 74.00 | 77.50 | 75.70 |

The prediction system classified intruders with near-perfect accuracy, showing strong adaptability and quality in complex environments. Some misclassifications occurred between Admin and No Human classes, but the system still outperformed traditional models. The use of advanced AI and computer vision techniques allows prediction systems to adapt quickly and maintain high performance in dynamic settings.

Speed and Scalability

Speed and scalability are critical for industries that process large volumes of data and require real-time quality control. Traditional machine vision systems process images using external computers and fixed algorithms. This approach can slow down response times, especially when the system faces new types of defects or needs to analyze more data.

Prediction machine vision systems use AI and computer vision to process data in real time. They handle large datasets and scale easily as production grows. These systems use edge computing and adaptive algorithms to deliver fast, reliable results. For example, in manufacturing, a prediction system can inspect thousands of products per hour, detect defects, and provide instant feedback to operators. The system’s ability to learn from new data ensures that it keeps up with changing production lines and new defect types.

Tip: Companies that need to scale their operations and maintain high quality should consider prediction machine vision systems. These systems offer faster processing, better adaptability, and improved defect detection compared to traditional approaches.

Prediction systems also support advanced tasks like anomaly detection and predictive maintenance. They use data from sensors and cameras to forecast equipment failures and prevent costly downtime. This proactive approach improves overall quality and reduces waste.

Real-World Applications

Manufacturing and Quality Control

Manufacturers use prediction machine vision systems to improve manufacturing quality and reduce defects. These systems analyze data from cameras and sensors to spot problems early. They support automatic inspection and automated sorting, which helps factories keep products consistent. Machine vision systems increase production speed and accuracy. They also lower the number of defective items. By using computer vision and prediction, companies can adjust processes quickly when data shows a change in product quality. Studies show that these systems make fewer errors than human inspectors. They also provide quick feedback, which helps maintain high quality. In one case, AI-powered computer vision algorithms reached over 95% accuracy in detecting defects in brake parts. This high level of prediction helps companies save money and improve customer satisfaction.

Robotics and Automation

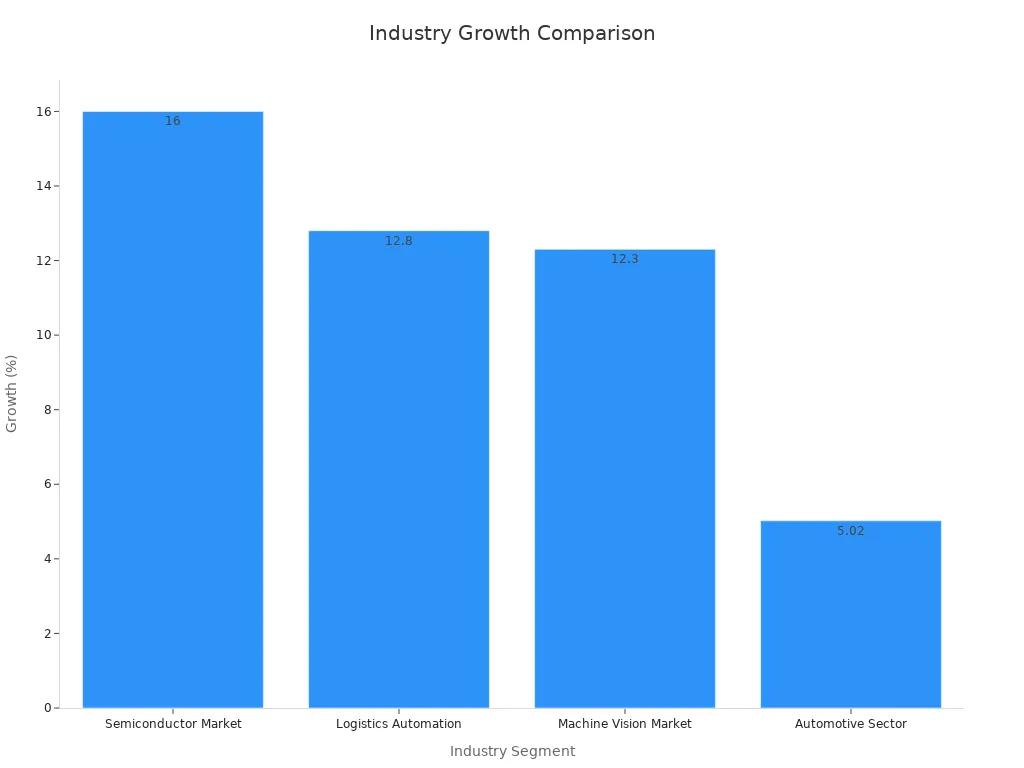

Robots use prediction and computer vision to perform complex tasks. They rely on data from advanced lenses and sensors to recognize objects and move safely. These systems help robots with sorting, navigation, and assembly. The use of prediction allows robots to adapt to new situations and avoid mistakes. In the semiconductor and automotive industries, machine vision supports growth by improving inspection and quality control. The machine vision market is growing fast, with 2D and 3D systems helping robots work more efficiently. The chart below shows how different industries benefit from machine vision and prediction.

Agriculture and Pharmaceuticals

Prediction and hyperspectral machine vision play a big role in agriculture and pharmaceuticals. In agriculture, sensors collect data to predict crop weight and monitor plant health. Over half of farmers use sensors for plant protection and nutrition. In pharmaceuticals, hyperspectral imaging systems check products at the molecular level. This helps with detecting defects and ensures high quality. The technology reduces inspection time by 61% and lowers false positives by 48%. It also cuts production expenses by 15%. These improvements show how prediction and data analysis lead to better quality and safer products.

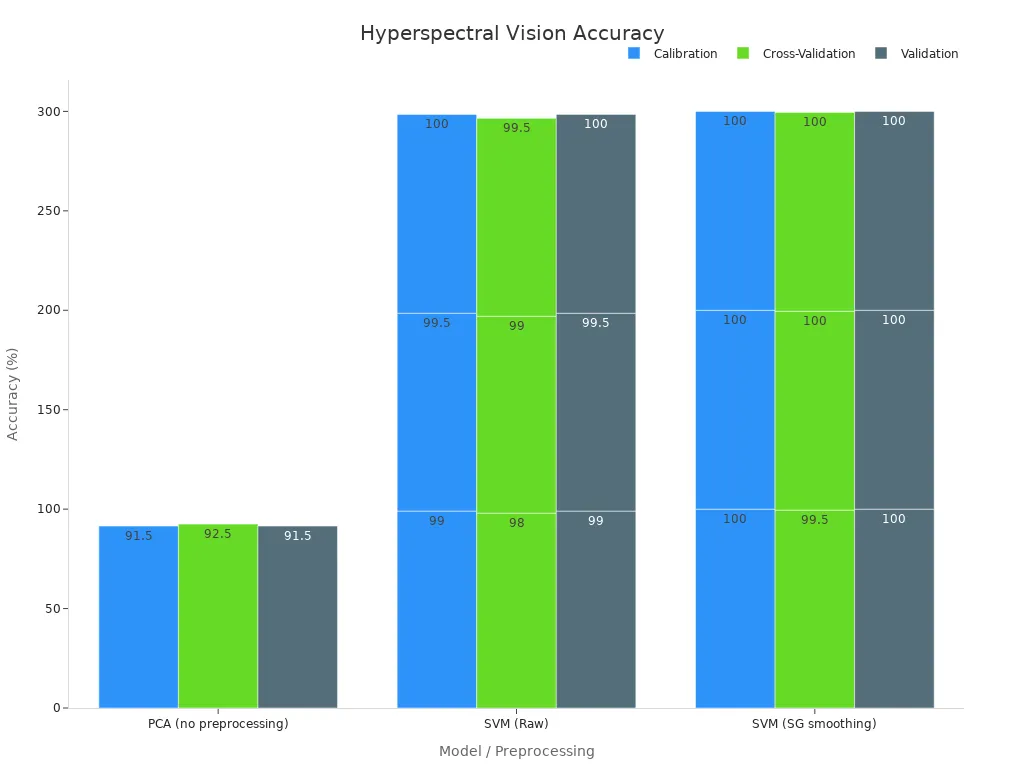

Hyperspectral Machine Vision

Hyperspectral machine vision uses data from many wavelengths to improve prediction and quality control. These systems can detect defects that normal cameras miss. They use machine learning models like SVM and CNN to analyze data and make accurate predictions. For example, SVM models with proper preprocessing can reach 100% accuracy in calibration and validation. Hyperspectral imaging systems help with advanced tasks such as wood species identification and pharmaceutical analysis. The chart below shows the high accuracy of these systems in prediction tasks.

Note: Hyperspectral machine vision and prediction systems use large amounts of data to improve quality, reduce defects, and support industries from manufacturing to healthcare.

Pros and Cons

Strengths

Prediction machine vision systems and traditional machine vision each offer unique strengths. The table below highlights key differences:

| Aspect | Traditional Machine Vision | Prediction Machine Vision System |

|---|---|---|

| Accuracy | High in simple, well-defined tasks | Often surpasses human-level accuracy in complex tasks |

| Adaptability | Limited to fixed environments | Robust to changes and new scenarios |

| Data Requirements | Works with small datasets | Learns from large amounts of data |

| Explainability | Transparent and easy to trace | Less interpretable, often a ‘black box’ |

| Productivity | Consistent and fast in stable settings | Excels at enhancing productivity in dynamic environments |

Prediction systems use advanced algorithms to analyze data and adapt quickly. They handle complex tasks, such as object recognition and medical imaging, with high accuracy. These systems improve quality control and support automation. They also help companies respond to new challenges by learning from fresh data.

Limitations

Both systems face certain limitations. Traditional machine vision struggles with unexpected changes. It cannot handle new types of defects without manual updates. Prediction systems require large, labeled datasets and powerful computers. They may act as a ‘black box,’ making decisions hard to explain. Sometimes, prediction models can make mistakes if the data changes too much or if the system faces adversarial attacks.

Note: Rule-based systems work best in controlled environments. Prediction systems perform better in complex, changing settings but need more resources.

Cost and Integration

- Traditional systems use simple models and need less data, which makes them easier to set up and integrate.

- Prediction systems handle large, complex datasets and offer better accuracy, but they need more computational power and data storage.

- Integration of prediction systems can be challenging. These systems require training, retraining, and careful monitoring to avoid errors.

- In healthcare and manufacturing, prediction systems can reduce long-term costs by improving diagnostic accuracy and treatment selection.

- Some companies combine both systems to balance flexibility, scalability, and cost efficiency.

Tip: Companies should consider their data availability, need for adaptability, and long-term goals before choosing a system.

Choosing the Right System

Decision Factors

Selecting the best machine vision system depends on several important factors. Each factor helps companies decide if a traditional or prediction-based approach fits their needs.

- Task Complexity: Deep learning and prediction systems work well for complex or changing tasks. Traditional systems handle simple, well-defined jobs.

- Data Availability: Prediction systems need large datasets for training. Traditional systems can work with fewer samples.

- Real-Time Requirements: Traditional systems process images quickly with less computing power. Prediction systems can also work in real time but may need special hardware.

- Cost and Resources: Traditional systems cost less to set up but require experts to create rules. Prediction systems need more investment in hardware but less manual tuning.

- Computational Resources: Prediction systems use more computing power. Traditional systems are less demanding.

Decision tree models use branching logic and numerical criteria like accuracy, precision, and recall. These models offer fast processing and clear results, especially when data is limited. Deep learning models, used in prediction systems, learn features from raw images and handle complex tasks. Companies must weigh accuracy, speed, data needs, and costs before choosing.

Matching Needs

Companies should match their needs to the right system. For stable environments with simple tasks, traditional machine vision works well. It offers fast results and lower costs. In dynamic settings, prediction systems shine. They adapt to new data and changing conditions. These systems support advanced uses like predictive maintenance and anomaly detection. For example, factories use prediction systems to spot equipment problems early and plan repairs. This approach reduces downtime and saves money.

Prediction systems also help in industries where quality and safety matter most. They improve inspection, support predictive maintenance, and boost productivity. Companies with large datasets and changing environments benefit most from prediction-based solutions. The right choice depends on the company’s goals, resources, and the complexity of the tasks.

Choosing between traditional and prediction machine vision systems depends on the task, data, and environment. Prediction systems adapt to new situations, use AI for better accuracy, and support real-time decisions. Current trends show industries like food, automotive, and robotics benefit from smarter, flexible vision solutions.

- AI and 3D imaging improve quality and safety in manufacturing.

- Real-time processing and pattern recognition help robots work in changing environments.

- Companies must match system features to their needs for the best results.

The future of machine vision will bring even more intelligent, adaptive, and secure solutions for many industries.

FAQ

What is the main difference between prediction machine vision and traditional machine vision?

Prediction machine vision uses AI to learn from data and predict outcomes. Traditional machine vision follows fixed rules to inspect and sort items. Prediction systems adapt to changes, while traditional systems work best in stable environments.

Can prediction machine vision systems work without large datasets?

Prediction machine vision systems need large datasets for training. Without enough data, their accuracy drops. Traditional systems do not need as much data because they use simple rules.

Are prediction machine vision systems more expensive to set up?

Yes, prediction machine vision systems often cost more at first. They need powerful computers and lots of data. Over time, they can save money by reducing errors and improving quality.

Which industries benefit most from prediction machine vision?

Industries like manufacturing, healthcare, agriculture, and robotics gain the most. These fields need high accuracy, fast decisions, and the ability to adapt to new challenges.

See Also

Comparing Firmware-Based Vision With Conventional Systems

Understanding Predictive Maintenance Using Machine Vision Technology

A Clear Guide To Image Processing In Vision Systems

Exploring Computer Vision Models And Their Machine Vision Uses