Policy machine vision systems play a vital role in automation, helping you achieve precision and control in industrial processes. These systems ensure tasks are performed with high accuracy while adhering to regulatory standards. By integrating policies into machine vision, they go beyond traditional automation methods, offering enhanced efficiency and safety monitoring.

For example, studies show that combining worker re-identification with PPE classification improves tracking accuracy by 4% and safety compliance monitoring by 13%. In manufacturing, computer vision technology detects PPE and human presence, ensuring compliance in dynamic environments. These advancements demonstrate how policy machine vision systems redefine industrial automation with smarter, safer operations.

Key Takeaways

- Policy machine vision systems help automation by making tasks accurate and safe. They also help industries follow rules and regulations.

- These systems use built-in rules to make quick decisions and adapt to changing situations.

- Using policy machine vision systems can make work faster, lower costs, and keep workers safer.

- Industries like factories and shipping gain a lot from these systems. They make work easier and improve product quality.

- The future of these systems depends on AI improvements, which will make them even better and more useful in many areas.

Understanding Policy Machine Vision Systems

Definition and Core Features

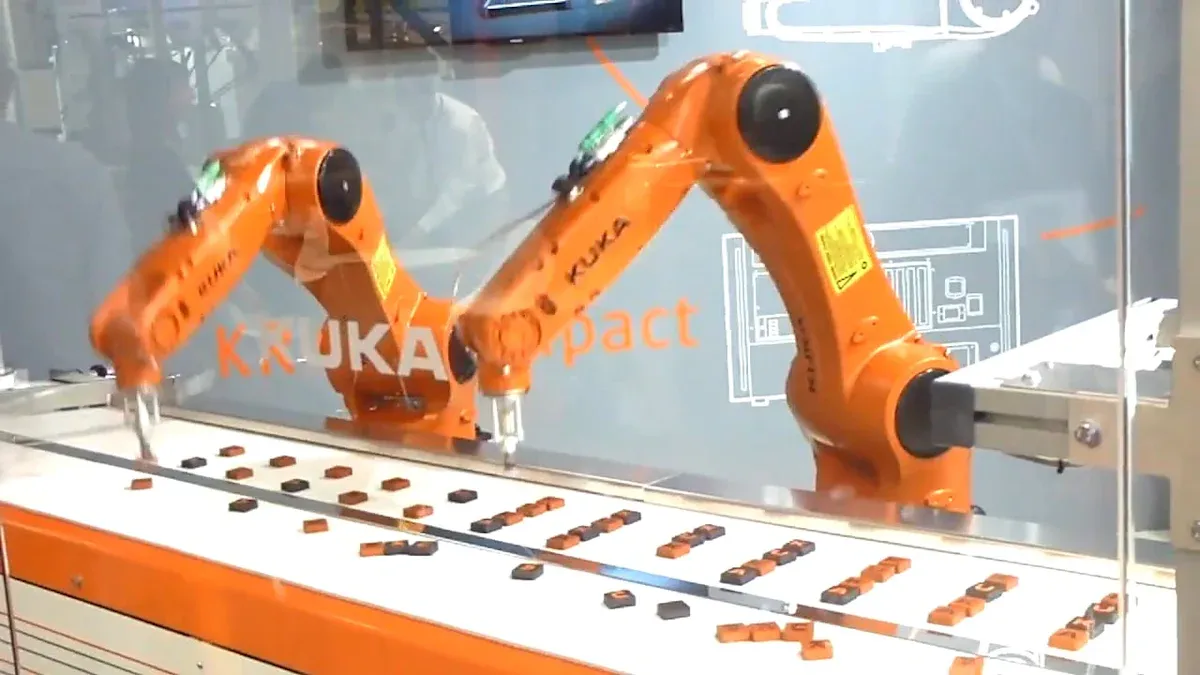

Policy machine vision systems combine advanced image analysis with policy-driven decision-making to automate complex processes. These systems use computer vision to interpret visual data and apply predefined policies to ensure compliance and efficiency. Unlike traditional machine vision systems, they focus on integrating rules and regulations directly into their operations.

Core features include precise measurements, complex object recognition, and real-time decision-making. For example, these systems excel at detecting defects in manufacturing or identifying objects in logistics with high accuracy. Research by Zayas et al. (1996) highlights their ability to acquire non-destructive information during inspections, while Lu et al. (2000) emphasizes their cost-effectiveness and consistency in quality control tasks.

Integration of Policies in Machine Vision

Integrating policies into machine vision transforms how automation systems operate. Policies act as a guiding framework, ensuring that every decision aligns with industry standards and organizational goals. This integration allows machine vision systems to adapt to dynamic environments, making them ideal for industries with strict compliance requirements.

For instance, policy machine vision systems can monitor worker safety by recognizing personal protective equipment (PPE) and detecting unsafe behaviors. Tao et al. (1995b) demonstrated how these systems assist humans in visually intensive tasks, reducing errors and improving workflow. By embedding policies, you can achieve both object recognition and adherence to regulations simultaneously.

Components of Policy Machine Vision Systems

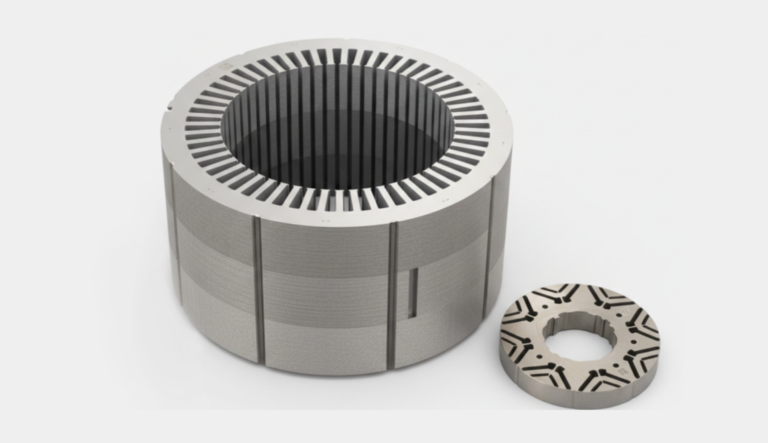

Policy machine vision systems consist of several key components that work together to deliver optimal performance:

- Image Acquisition: Captures high-quality images for analysis. Advanced cameras and sensors ensure precise measurements and detailed object recognition.

- Processing Unit: Analyzes visual data using algorithms and applies policies to make decisions. This component handles complex object recognition tasks efficiently.

- Policy Database: Stores predefined rules and regulations. It ensures the system adheres to compliance standards during operations.

- Output Interface: Communicates results to operators or other systems. It provides actionable insights for process optimization.

Case studies reveal that successful implementation of policy machine vision systems depends on seamless integration of these components. For example, Davidson et al. (2001) used image analysis to measure physical features of chocolate chip biscuits, showcasing the importance of precise measurements in quality control.

These components enable policy machine vision systems to deliver enhanced quality, improved safety, and better data collection compared to traditional automation methods. The table below illustrates their advantages:

| Advantage | Machine Vision Systems | Traditional Automation Methods |

|---|---|---|

| Improved Workflow | Eliminates bottlenecks, ensuring maximum efficiency | Often slower due to manual inspections |

| Enhanced Quality Control | Detects defects and inconsistencies with high precision | Relies on human inspectors, prone to errors |

| Cost Savings | Reduces labor costs and material waste | Higher operational costs due to manual labor |

| Improved Worker Safety | Reduces human intervention in hazardous tasks | Requires human presence in dangerous areas |

| Better Data Collection | Provides real-time insights for process optimization | Limited data collection capabilities |

Comparing Policy Machine Vision Systems to Traditional Systems

Policy-Driven Decision-Making vs. Rule-Based Processing

Policy-driven decision-making in machine vision systems offers flexibility and adaptability that traditional rule-based processing cannot match. Instead of relying solely on rigid rules, policy machine vision systems use data-driven approaches to make decisions in real time. This allows you to handle complex scenarios and dynamic environments more effectively.

For example, Gartner’s 2023 report predicts that by 2025, over 80% of enterprises will depend on AI and advanced analytics for decision-making. These systems excel in industries where adaptability is crucial, such as manufacturing and logistics. While rule-based systems ensure uniformity and compliance, they struggle in situations requiring nuanced judgment or rapid adjustments.

| Decision-Making Approach | Strengths | Weaknesses |

|---|---|---|

| Rule-Based | Regulatory compliance, uniformity | Rigidity in complex situations |

| Data-Driven | Flexibility, real-time adaptation | Requires large datasets and analytics |

Compliance and Regulation Adherence

Policy machine vision systems integrate compliance directly into their operations, ensuring adherence to industry standards without manual intervention. These systems monitor processes and enforce regulations automatically, reducing the risk of human error. For example, they can identify whether workers are wearing proper safety gear or detect deviations from quality standards in production lines.

The Big Data Institute at Oxford University describes data as "the fuel driving contemporary innovation." By leveraging this data, machine vision systems ensure compliance while optimizing workflows. Traditional systems often require manual oversight, which increases the likelihood of errors and inefficiencies.

Adaptability in Dynamic Environments

Adaptability is a defining feature of policy machine vision systems. These systems process real-time data, recognize patterns, and predict obstacles, making them ideal for dynamic industrial environments. For instance, they can adjust to changes in lighting, object positioning, or environmental conditions without compromising accuracy.

| Feature | Benefit |

|---|---|

| Real-time data processing | Immediate response to environmental changes |

| Pattern recognition | Accurate identification of objects in dynamic settings |

| Obstacle prediction | Safer and more efficient navigation |

Traditional systems lack this level of adaptability. They often require manual recalibration or intervention when conditions change. Policy machine vision systems eliminate these bottlenecks, ensuring seamless operations and improved safety.

Applications of Policy Machine Vision Systems

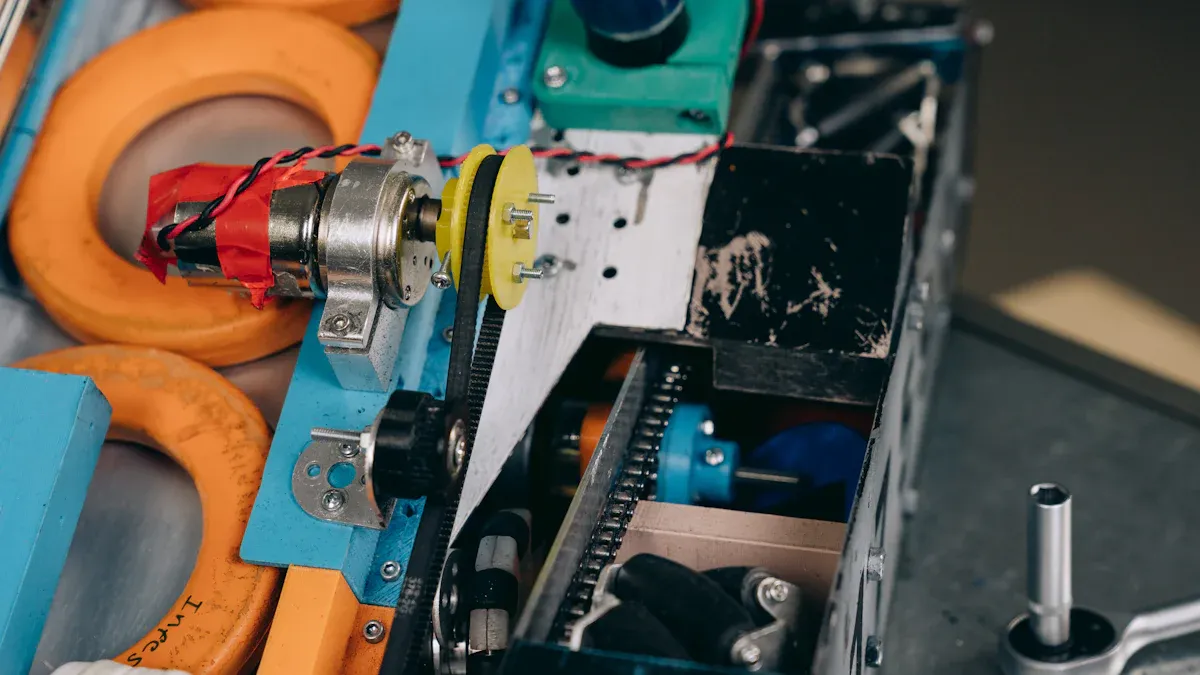

Manufacturing and Quality Control

Policy machine vision systems have revolutionized manufacturing by enhancing quality inspection processes. These systems use advanced image analysis to detect surface flaws, verify assembly accuracy, and ensure product consistency. For example, in the automotive industry, manufacturers have reported a 21% productivity boost and a 25% reduction in scrap rates. Defect detection accuracy has also improved, leading to fewer recalls and higher customer satisfaction.

Electronics manufacturers have seen similar benefits. By integrating machine vision systems, they reduced missed defects by 30% and shortened inspection cycle times by 40%. These systems excel at object recognition, identifying even microscopic flaws with 95% accuracy in semiconductor production. This level of precision ensures that products meet stringent quality standards while minimizing waste.

Tip: Implementing machine vision systems in your production line can significantly reduce costs and improve operational efficiency.

Logistics and Supply Chain Optimization

In logistics, machine vision technology automates tasks like package sorting, barcode scanning, and inventory management. These systems enhance operational efficiency by reducing errors and speeding up processes. For instance, Averroes.ai demonstrated how machine vision systems reduced false rejects, saving manufacturers substantial costs.

Machine vision systems also improve quality control in supply chains. They detect defects that manual inspections might miss, ensuring consistent product standards. By leveraging object recognition capabilities, these systems streamline operations and maintain high levels of accuracy, even in dynamic environments.

Note: Industry reports highlight the growing demand for machine vision systems in logistics, driven by their ability to optimize workflows and reduce operational bottlenecks.

Healthcare and Safety Monitoring

In healthcare, policy machine vision systems play a critical role in safety monitoring. These systems provide real-time alerts for safety issues, such as detecting when someone is too close to moving machinery. They also enforce compliance by verifying the use of personal protective equipment (PPE) and restricting access to authorized personnel.

Studies show that machine vision systems can track safety trends over time, helping organizations assess the effectiveness of their health and safety initiatives. By integrating these systems, you can enhance workplace safety and reduce the risk of accidents.

Callout: AI-powered machine vision systems are transforming healthcare by ensuring compliance and improving safety standards.

Benefits of Policy Machine Vision Systems

Enhanced Operational Efficiency

Policy machine vision systems significantly improve operational efficiency by streamlining processes and reducing manual intervention. These systems analyze visual data in real time, enabling faster decision-making and minimizing delays. For example, in manufacturing, they detect defects early, preventing costly rework and ensuring smooth workflows.

You can observe efficiency gains in various metrics. A study revealed that these systems reduce incident resolution time and decrease the number of problem tickets, even as customer numbers and system complexity grow. Additionally, they enhance the ability to implement operational changes without increasing workforce size. The table below highlights these improvements:

| Evidence Type | Description |

|---|---|

| Incident Resolution Time | Decrease in the time taken to resolve incidents. |

| Incident Tickets | Substantial decrease in the number of incident and problem tickets. |

| Change Implementation | Notable increase in the capability to implement operational changes. |

By automating repetitive tasks and optimizing workflows, policy machine vision systems ensure that your operations run efficiently, saving time and resources.

Improved Compliance with Standards

Compliance with industry standards is critical in sectors like healthcare, manufacturing, and logistics. Policy machine vision systems excel in this area by embedding regulations directly into their operations. These systems monitor processes, enforce rules, and provide real-time alerts for deviations, ensuring adherence to standards without manual oversight.

Statistical studies demonstrate the compliance improvements offered by these systems compared to standard procedures. For instance, the Bland-Altman test assesses agreement between measurement systems, highlighting the superior compliance of machine vision systems. The 2-sample T-test compares performance metrics, while the 2-sample equivalence test confirms that machine vision systems achieve statistically equivalent results to standard methods. The table below summarizes these findings:

| Statistical Method | Description |

|---|---|

| Bland-Altman test | Assesses agreement between two measurement systems, highlighting differences in compliance. |

| 2-sample T-test | Compares means of measurements from machine vision and standard systems to evaluate performance. |

| 2-sample equivalence test | Determines if the machine vision system’s measurements are statistically equivalent to standard methods. |

By leveraging these systems, you can ensure consistent compliance while reducing the risk of human error.

Increased Safety in Workplaces

Workplace safety is a top priority in industrial automation. Policy machine vision systems enhance safety by monitoring environments and identifying potential hazards. These systems detect unsafe behaviors, verify the use of personal protective equipment (PPE), and restrict access to unauthorized areas.

For example, in manufacturing, machine vision systems recognize when workers are too close to moving machinery, triggering alerts to prevent accidents. They also track safety trends over time, helping you evaluate and improve health and safety initiatives. By reducing human intervention in hazardous tasks, these systems create safer workplaces and minimize risks.

Tip: Integrating policy machine vision systems into your operations can significantly reduce workplace accidents and improve overall safety standards.

Future Trends in Policy Machine Vision Systems

Innovations in AI-Powered Systems

The future of policy machine vision systems lies in the integration of advanced technologies like AI and machine learning. These ai-powered systems enhance the ability to process visual data and make decisions with greater accuracy. Smart cameras, equipped with AI algorithms, are becoming more common. They provide precise measurements and adapt to changing environments in real time. This innovation improves the quality of inspections and ensures compliance with industry standards.

Experts predict that while the machine vision market may grow slowly in the short term, long-term advancements will drive significant expansion. Specialized applications, such as automated quality control and safety monitoring, will further enhance the functionality of these systems. By leveraging AI, you can achieve precise measurements and improve the overall efficiency of automation processes.

Addressing Challenges in Implementation

Despite their potential, implementing policy machine vision systems comes with challenges. Current AI metrics often fail to address critical aspects like fairness, transparency, and privacy. The lack of transparent algorithms can lead to mistrust in AI-powered systems. Privacy concerns also arise as these systems process large volumes of personal data.

To overcome these challenges, you need robust metrics that evaluate the ethical and social dimensions of AI. For example, developing standards to measure transparency and accountability can build trust in these systems. Additionally, metrics that align with global goals, such as the United Nations Sustainable Development Goals, can ensure these systems contribute positively to areas like health and climate action.

Long-Term Industry Impact

The long-term impact of policy machine vision systems will reshape industries. As automation becomes more widespread, these systems will play a crucial role in improving efficiency and ensuring compliance. Industries like manufacturing, logistics, and healthcare will benefit from their ability to deliver precise measurements and maintain high-quality standards.

Technological advancements will also create new opportunities. For instance, the integration of AI-powered systems will enable more specialized applications, such as predictive maintenance and advanced safety monitoring. These innovations will not only enhance productivity but also set new benchmarks for quality and safety across various sectors.

Policy machine vision systems have revolutionized automation by combining advanced technology with policy-driven frameworks. These systems enhance efficiency by streamlining processes and reducing errors. They ensure compliance with industry standards through continuous monitoring and real-time decision-making. Their ability to operate 24/7 without fatigue provides unmatched reliability. You can also scale these systems as your operations grow, making them a cost-effective solution for long-term use.

With their data-driven insights, these systems refine workflows and improve safety protocols. As industries evolve, policy machine vision systems will continue to shape the future, setting new benchmarks for efficiency, compliance, and workplace safety.

FAQ

What makes policy machine vision systems different from traditional systems?

Policy machine vision systems integrate rules and regulations directly into their operations. This allows them to adapt to dynamic environments and ensure compliance automatically. Traditional systems rely on fixed rules, which limits their flexibility in complex scenarios.

Can policy machine vision systems improve workplace safety?

Yes, these systems monitor environments in real time to detect hazards and unsafe behaviors. They verify the use of personal protective equipment (PPE) and restrict access to dangerous areas. This reduces accidents and enhances overall safety.

Are policy machine vision systems suitable for small businesses?

Absolutely! These systems scale easily to match your operational needs. Small businesses benefit from their cost-effectiveness, improved efficiency, and ability to ensure compliance without requiring large investments in manual oversight.

How do these systems handle changes in the environment?

Policy machine vision systems process real-time data and adjust to changes like lighting or object positioning. Their adaptability ensures accurate performance even in dynamic settings, eliminating the need for manual recalibration.

What industries benefit the most from policy machine vision systems?

Manufacturing, logistics, and healthcare see the greatest advantages. These systems enhance quality control, optimize supply chains, and improve workplace safety. Their ability to enforce compliance makes them ideal for industries with strict regulations.

See Also

Comparing Firmware Machine Vision With Conventional Systems

How Guidance Machine Vision Enhances Robotic Functionality

A Complete Guide to Machine Vision in Automation

Understanding Automotive Machine Vision Systems and Their Function