Optimization machine vision system and optimizer machine vision system both transform how companies approach industrial inspection. The optimization machine vision system adapts quickly to changing production needs. The optimizer machine vision system fits dynamic manufacturing lines where products and requirements shift often. Traditional vision approaches work best in stable environments with little variation. Matching the right system to business goals supports process optimization and better results.

Key Takeaways

- Optimization machine vision systems use AI to adapt quickly and improve accuracy in changing production environments.

- Traditional vision approaches work best in stable settings with simple, repetitive tasks and lower upfront costs.

- AI-driven systems reduce errors, save time, and boost productivity by automating inspections and adjusting to new conditions.

- Choosing the right vision system depends on business needs, production stability, and long-term goals.

- Combining both systems or selecting AI-based solutions can lead to better quality control, efficiency, and cost savings.

Definitions

Optimization Machine Vision System

An optimization machine vision system uses advanced technology to improve how machines see and understand objects. This system relies on smart algorithms and artificial intelligence. It can learn from data and adjust its settings to get better results over time. Many factories use an optimization machine vision system to handle tasks that change often. For example, when a new product enters the line, the system can adapt quickly.

The optimizer machine vision system works well in places where products or processes change a lot. It can handle different shapes, sizes, and colors without much manual adjustment. Engineers often choose an optimizer machine vision system for dynamic environments. They want a solution that keeps up with fast changes and helps reduce errors.

Tip: An optimization machine vision system can save time and money by reducing the need for manual checks and frequent reprogramming.

Traditional Vision Approaches

Traditional vision approaches use fixed rules and simple image processing techniques. These systems follow set instructions to inspect products. They do not learn or adapt on their own. A traditional vision system works best when the environment stays the same. For example, if a factory makes the same part every day, this approach can deliver reliable results.

Many companies use traditional vision approaches for basic inspections. These systems check for defects, measure parts, or read barcodes. They require manual setup and regular maintenance. When changes happen, engineers must update the system by hand.

- Traditional vision approaches offer:

- Consistent performance in stable settings

- Lower initial cost

- Simple operation

However, they may struggle with new or unexpected situations. They cannot match the flexibility of an optimization machine vision system or an optimizer machine vision system.

Differences

Performance & Accuracy

Optimization machine vision systems deliver high accuracy and precision in industrial environments. These systems use ai and advanced cameras to perform object detection and quality control tasks with minimal errors. Neural networks, especially deep learning models, learn from large datasets and adapt to complex scenarios. For example, the 2019 Facial Recognition Vendor Test evaluated 189 algorithms with over 18 million images, showing that neural network-based systems outperform traditional rule-based approaches in reliability and accuracy.

Traditional vision approaches rely on fixed rules and manual calibration. These systems often struggle with changes in lighting, object positioning, or unexpected defects. Human inspectors using traditional systems may miss subtle defects, leading to lower precision and inconsistent quality control. In contrast, optimization machine vision systems consistently achieve defect detection accuracy rates up to 95% in semiconductor production and reduce missed defects by 30% in electronics manufacturing.

Note: Progressive training methods and weight prediction techniques have further improved accuracy metrics, making ai-driven systems the preferred choice for high-speed quality checks.

Flexibility & Adaptability

Optimization machine vision systems excel in dynamic environments. Ai algorithms enable real-time adaptation to new products, changing lighting, and shifting object positions. These systems handle a wide range of object detection tasks without manual intervention. Policy-driven decision-making allows for seamless integration into evolving production lines, supporting continuous monitoring and quality control.

Traditional vision approaches lack this flexibility. Rule-based processing requires manual recalibration whenever conditions change. These systems cannot easily adapt to new product designs or unexpected defects. As a result, companies using traditional systems face downtime and reduced efficiency when production requirements shift.

- Key advantages of optimization machine vision systems:

- Real-time adaptation to dynamic environments

- Automated monitoring and quality control

- Consistent precision in object detection and defect identification

Implementation Complexity

Optimization machine vision systems involve complex integration of ai, advanced cameras, and software platforms. Engineers must configure neural networks, set up monitoring protocols, and fine-tune parameters for optimal performance. This complexity requires specialized knowledge and ongoing support. However, the investment in implementation leads to long-term gains in efficiency, accuracy, and productivity.

Traditional vision approaches offer simpler setup and operation. These systems use basic image processing techniques and require less technical expertise. However, their simplicity limits their ability to handle complex quality control tasks or adapt to new challenges. Manual adjustments become necessary as production lines evolve, increasing the risk of errors and reducing overall efficiency.

Tip: Companies should weigh the initial complexity of ai integration against the long-term benefits in precision, monitoring, and productivity.

Cost & Resources

The cost structure of optimization machine vision systems reflects their advanced capabilities. Initial investment in ai, advanced cameras, and integration can be significant. However, these systems reduce labor costs, minimize material waste, and lower operational expenses by automating inspections and improving efficiency. For example, automotive manufacturers report a 25% reduction in scrap rates and a 21% boost in productivity after deploying optimization machine vision systems.

Traditional vision approaches have lower upfront costs but incur higher long-term expenses. Manual labor, frequent recalibration, and increased scrap rates drive up operational costs. These systems also require more human monitoring, which can compromise safety and efficiency.

| Aspect | Optimization Machine Vision Systems | Traditional Vision Approaches |

|---|---|---|

| Accuracy | Up to 95% defect detection accuracy; 30% fewer missed defects; improved quality control | Relies on human inspectors; less precise defect detection |

| Flexibility | Real-time adaptation; handles dynamic environments and complex scenarios | Rigid rule-based processing; manual recalibration needed |

| Cost | Reduces labor and material waste; lowers operational costs | Higher operational costs; increased scrap rates |

| Productivity | 21% productivity boost; 40% shorter inspection cycles | Limited improvements; slower manual inspections |

| Compliance | Automated monitoring and statistical validation | Manual oversight; higher risk of errors |

| Safety | Reduces human intervention in hazardous tasks | Requires human presence in dangerous areas |

Companies seeking to maximize efficiency, precision, and quality control should consider the long-term resource savings offered by optimization machine vision systems.

Optimizing Machine Vision Systems

AI & Algorithm Integration

Optimizing machine vision systems relies on advanced ai and ai algorithms. Engineers use deep learning, genetic algorithms, and neural networks to improve real-time image processing and real-time data analysis. These ai techniques help systems adapt to new tasks and environments. The integration of ai allows for detailed data capture and accurate image analysis. Many projects show the power of ai algorithms in optimizing machine vision systems. The table below highlights several examples:

| Example/Project Name | AI Techniques Used | Application Context/Description |

|---|---|---|

| AForge.NET | Neural networks, Genetic algorithms | Framework for computer vision, image processing, and ai including optimizing machine vision systems |

| SketchingAI | Convolutional Neural Network + Genetic Algorithm | Combines CNN with genetic algorithms for model performance optimization |

| neural-network-genetic-algorithm | Genetic Algorithm | Evolving neural networks using genetic algorithms |

| deepneuroevolution | Genetic Algorithms + Deep Neural Networks | Evolving deep neural network agents |

| FeatureReductionGenetic | Genetic Algorithm | Feature reduction using genetic algorithms, relevant for feature selection in machine vision |

| GAKeras | Genetic Algorithm | Optimizing Keras Sequential models |

| ML-games | Genetic Algorithms + Neural Networks | Controlling in-game object behavior using combined ai techniques |

| ensemble-time-series | Deep Recurrent Neural Networks + Genetic Algorithms | Ensemble learning with deep RNNs and genetic algorithms for optimization |

Parameter Tuning

Engineers achieve real-time optimization by tuning parameters such as exposure, contrast, and focus. Optimizing machine vision systems with ai algorithms ensures real-time image processing and real-time data analysis. Fine-tuning improves accuracy and speed. For example:

- In robotics, fine-tuned manipulation policies maintained 96% accuracy over two months.

- Object detection models like YOLOv8, after tuning, deliver high precision and fast real-time image processing.

- Medical imaging systems, with parameter tuning, reach diagnostic precision near 99% and reduce reading time for radiologists.

These results show that optimizing machine vision systems with ai and parameter tuning leads to robust and reliable performance.

End-to-End Optimization

End-to-end optimization covers the entire workflow, from image capture to decision-making. Engineers use ai algorithms and deep learning for enhancing performance and model performance optimization. In scientific research, autonomous lab systems combine fine-tuning with Bayesian optimization to improve outcomes. Training time drops by up to 90%, and task performance increases by 10-20%. Optimizing machine vision systems with full integration of ai, real-time image processing, and real-time data analysis supports edge deployment and process automation. This approach ensures that optimizing machine vision systems deliver consistent results in manufacturing, defect detection, and other industries.

Application Scenarios

When to Use Optimization Machine Vision System

Companies choose optimizing machine vision systems for environments that demand high efficiency, precision, and adaptability. In PCB assembly, Samsung uses AI-powered inspection to analyze thousands of images. These systems detect defects with greater accuracy than human inspectors. In warehouse management, smart devices with object detection improve inventory sorting and reduce errors. Quality inspection in automotive and aerospace industries relies on deep learning for real-time quality control and predictive maintenance. These systems deliver fast, accurate results and support real-time data analysis. Optimizing machine vision systems enable real-time decisions, boost productivity, and ensure consistent quality control.

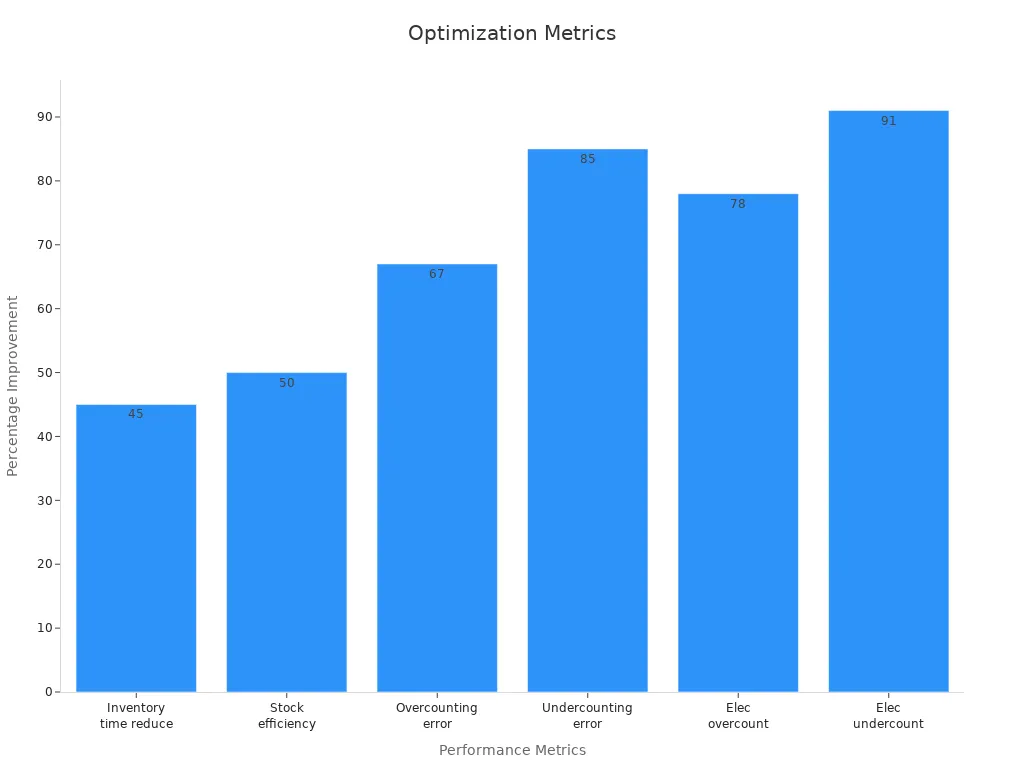

| Metric | Improvement/Result |

|---|---|

| Inventory time reduction | 45% |

| Stock efficiency improvement | 50% |

| Overcounting error reduction | 67% |

| Undercounting error reduction | 85% |

| Stock update time reduction | From 30–35 min to 10–12 min |

| Electronics overcounts reduction | 78% |

| Electronics undercounts reduction | 91% |

Tip: Optimizing machine vision systems increase efficiency and accuracy in sorting, monitoring, and predictive maintenance tasks.

When to Use Traditional Vision Approaches

Traditional vision approaches work best in stable environments with little change. Factories that produce the same part every day benefit from these systems. They provide reliable quality control for simple sorting and defect detection tasks. Companies use traditional vision for barcode reading, basic monitoring, and straightforward inspections. These systems require less technical skill and cost less to set up. However, they lack the flexibility and precision of optimizing machine vision systems. When production lines rarely change, traditional vision offers steady efficiency and accuracy.

Process Optimization in Industry

Process optimization depends on matching the right vision system to the task. Optimizing machine vision systems transform industries by automating sorting, monitoring, and predictive maintenance. In PCB assembly, AI-driven systems find defects quickly and with high precision. Warehouse management uses object detection to improve efficiency and reduce errors. Quality inspection in automotive and aerospace relies on deep learning for accurate monitoring and fast defect detection. These systems support real-time quality control and boost productivity. Traditional vision approaches maintain efficiency in simple, unchanging environments. Both methods help companies achieve better accuracy, precision, and efficiency in their operations.

Pros & Cons Table

Choosing between optimization machine vision systems and traditional vision approaches depends on the needs of each business. The table below shows the main strengths and weaknesses of both options. This summary helps decision-makers see which system fits their goals.

Tip: Review this table before making a final choice. The right system can improve quality, save time, and reduce costs.

| Feature | Optimization Machine Vision System | Traditional Vision Approach |

|---|---|---|

| Accuracy | Delivers high precision in complex tasks. | Provides reliable results in simple, stable settings. |

| Flexibility | Adapts quickly to new products and changes in the environment. | Handles only fixed tasks; needs manual updates for changes. |

| Implementation | Needs advanced setup and skilled engineers. | Offers easy installation and basic operation. |

| Cost | Higher initial investment but reduces long-term expenses. | Lower upfront cost but may increase labor and maintenance. |

| Speed | Processes images and data in real time. | Slower inspections; relies on manual checks. |

| Maintenance | Requires regular software updates and monitoring. | Needs manual recalibration and frequent human oversight. |

| Scalability | Supports growth and new applications with minimal changes. | Limited scalability; struggles with expanding requirements. |

| Error Handling | Detects subtle defects and rare errors with AI. | Misses small or unexpected defects more often. |

| Best Use Case | Dynamic manufacturing, fast-changing production lines, advanced quality control. | Stable environments, repetitive tasks, basic inspections. |

Decision-makers should weigh these pros and cons. Each approach offers unique benefits. The best choice aligns with the company’s production needs and long-term goals.

Decision Guide

Choosing the Right System

Selecting the best vision system depends on the environment, production needs, and available resources. Companies should match system strengths to their specific requirements. In stable environments with little change, traditional machine vision offers high accuracy and fast processing. These systems use hand-engineered rules for feature extraction and run on standard CPUs. They work well for repetitive tasks and require minimal data for setup.

In contrast, ai-based optimization machine vision systems excel in dynamic settings. These systems use deep learning to extract features and adapt to new products or lighting conditions. They require GPUs or ai accelerators and large labeled datasets for training. Although their speed may be lower than traditional systems, they handle complex tasks and changing environments with ease.

The table below summarizes key criteria for both approaches:

| Criteria/Benchmark | Traditional Machine Vision | AI-based Optimization Machine Vision |

|---|---|---|

| Feature Extraction | Hand-engineered rules | Deep learning automatically extracts features |

| Processing Speed | High speed (60+ FPS) in stable settings | Moderate speed (30+ FPS), depends on model and hardware |

| Accuracy | 98-99% in controlled conditions | 94%+ in variable conditions when trained |

| Adaptability | Best in stable environments | Adapts to changing conditions and variations |

| Hardware Requirements | CPUs, embedded processors | GPUs or ai accelerators |

| Implementation Complexity | Manual tuning required | Needs large labeled datasets and retraining |

| Data Needs | Minimal | Large datasets needed |

| Scalability | Limited to specific tasks | Can generalize to multiple tasks |

Tip: Hybrid systems that combine both methods can balance speed, adaptability, and cost.

Key Considerations

Decision-makers should evaluate several factors before choosing a vision system. Speed requirements play a major role. Some applications need processing in milliseconds, while others allow more time. Error rates also matter. Reducing false negatives and false positives improves reliability.

Hardware advances influence both cost and performance. Modern ai systems benefit from GPUs, FPGAs, and improved operating systems. Cost versus performance remains a key trade-off. Rapid hardware and software development help close the gap between budget and performance needs.

Software development tools now include GUIs and visual programming, making ai systems easier to deploy. Feature extraction, such as identifying size or texture, supports efficient decision-making. Robustness and reliability ensure the system adapts to changes in lighting or background.

The table below highlights important metrics:

| Key Consideration | Quantitative Evidence / Metrics |

|---|---|

| Speed Requirements | Processing speed ranges from milliseconds to minutes. Special hardware may be needed for high-speed tasks. |

| Error Rates | Lower escape rates and false alarms improve reliability. |

| Hardware Advances | Use of advanced processors and operating systems boosts performance and reduces costs. |

| Cost vs Performance | Trade-offs exist between performance and budget. Rapid development helps bridge this gap. |

| Software Development | GUIs and visual tools enable faster, cheaper application development. |

| Feature Extraction | Extracting relevant features supports efficient classification. |

| Robustness & Reliability | Systems must adapt to variations in illumination and positioning for high recognition rates. |

Note: Companies should align their choice with business goals, available data, and the need for adaptability. Ai-based systems offer flexibility and learning, while traditional systems provide speed and simplicity.

Optimization machine vision systems provide high accuracy, adaptability, and long-term savings. Traditional vision approaches offer simplicity and reliability in stable settings. Companies with dynamic production lines benefit from AI-driven systems. Factories with consistent products may choose traditional methods.

- Assess business needs and process goals before selecting a system.

For more insights, explore industry case studies or consult vision system experts.

FAQ

What is the main advantage of an optimization machine vision system?

Optimization machine vision systems adapt to changes quickly. They use AI to improve accuracy and reduce errors. These systems help companies save time and money by automating inspections and adjusting to new products or conditions.

Can traditional vision approaches handle complex inspection tasks?

Traditional vision approaches work best with simple, repetitive tasks. They struggle with complex inspections or changing environments. Engineers must update these systems manually when products or conditions change.

How does AI improve machine vision performance?

AI enables machine vision systems to learn from data. These systems recognize patterns, detect defects, and adjust settings automatically. AI helps increase accuracy and speed in quality control tasks.

Are optimization machine vision systems expensive to maintain?

Maintenance costs for optimization machine vision systems may seem high at first. Over time, these systems lower labor costs and reduce waste. Many companies find the long-term savings outweigh the initial investment.