An object detection machine vision system uses computer vision to find, identify, and track objects in images or video. This system automates tasks like quality control, safety checks, and object tracking. Machine vision systems help manufacturing, healthcare, and automotive industries improve accuracy and speed. The market for computer vision and object detection continues to grow, reaching over $20 billion in 2024. Companies use object detection for tasks such as defect detection, worker safety, and automated inspection. Computer vision and object detection systems now support real-time analytics and smarter decision-making.

Key Takeaways

- Object detection machine vision systems use cameras and software to find and identify objects in images or videos, helping industries improve accuracy and speed.

- These systems include key parts like high-resolution cameras, lenses, lighting, and software that work together to capture and analyze images effectively.

- Deep learning models like YOLO and SSD enable fast, real-time object detection, making them ideal for applications in manufacturing, healthcare, and automotive safety.

- Machine vision systems improve quality control by detecting defects quickly, reducing errors, and lowering inspection costs across various industries.

- Successful deployment requires quality labeled data, choosing the right algorithm for the task, handling environmental challenges, and regularly updating models for best results.

Object Detection Machine Vision System Basics

What Is Object Detection?

Object detection helps computer vision systems recognize, locate, and classify objects in images or videos. The main goal is to find where objects are and what they are. An object detection machine vision system uses bounding boxes to show the position of each object. These systems support many tasks, such as quality inspection, safety monitoring, and counting items. Object detection works in steps: image preprocessing, feature extraction, region proposal, classification, localization, and post-processing. This process allows computer vision to automate tasks in retail, healthcare, transportation, and agriculture. Object detection systems help industries improve accuracy and speed by using images for real-time decisions.

Object detection does not replace human decision-making. It helps people by highlighting important details and reducing errors.

Key Components of Machine Vision Systems

A typical object detection machine vision system includes several key parts. Cameras capture images with high resolution. Image sensors, such as CCD or CMOS, turn light into electrical signals. Lenses focus light to create sharp images. Lighting provides the right brightness and contrast for detection. Advanced lighting techniques, like LED pulsing and multispectral lighting, help reveal hidden features and reduce motion blur. Software and image analysis software process images, run detection algorithms, and display results. The table below shows the main components:

| Component Category | Description |

|---|---|

| Image Sensors | Capture images by converting light into signals. |

| Machine Vision Lenses | Focus light for clear images. |

| Machine Vision Lighting | Provide steady, bright light for accurate detection. |

| Cameras | Take images for inspection and measuring. |

| Software Components | Analyze images and control the system. |

Types of Machine Vision Systems

There are three main types of machine vision systems: 1D, 2D, and 3D. Each type uses different technology and serves unique purposes.

| Vision System Type | Technology | Applications | Notes |

|---|---|---|---|

| 1D (Line-scan) | Captures images line-by-line | Linear measuring and inspection | Simple and low cost |

| 2D (Area scan) | Captures 2D images (length and width) | Barcode reading, defect detection, object counting, surface inspection | Easy to use, fits many tasks |

| 3D | Adds depth using lasers or special sensors | Robot guidance, complex measuring, high-precision inspection | More complex, higher cost |

These types of machine vision systems allow computer vision to handle many inspection and measuring tasks. The right system depends on the objects, images, and level of detail needed.

How Object Detection Algorithms Work

Image Acquisition and Processing

Object detection begins with capturing images. High-resolution cameras and proper lighting help create clear images for computer vision tasks. Good lighting removes shadows and highlights important features. After capturing, the system uses preprocessing to improve image quality. Noise reduction, contrast enhancement, and edge detection make it easier to find objects. These steps help computer vision systems spot small defects or changes in manufacturing and other industries.

| Technique Category | Specific Techniques / Methods | Purpose / Application Example |

|---|---|---|

| Image Acquisition | High-resolution cameras, proper lighting | Capture clear, detailed images; avoid shadows (e.g., manufacturing inspection) |

| Preprocessing | Noise reduction, contrast enhancement, edge detection | Improve image quality for better analysis |

| Filtering | Gaussian filter (noise smoothing), Sobel filter (edge detection), Histogram equalization (contrast enhancement) | Enhance image quality and highlight features |

| Morphological Operations | Erosion, Dilation, Opening, Closing | Shape manipulation for noise removal, object identification |

| Feature Extraction | Shape-based (area, perimeter), Texture analysis, Color-based, Histogram-based features | Extract object characteristics for recognition |

| Advanced Machine Learning | Convolutional Neural Networks (CNNs), Faster R-CNN, YOLO | Real-time object detection and classification in various applications |

Computer vision systems use these techniques to prepare images for object detection. The system then moves to the next step: extracting features and finding objects.

Object Detection Algorithms Overview

Object detection algorithms follow a step-by-step workflow. Each step helps computer vision systems find and identify objects in images or video. The process works as follows:

- Image Acquisition: The system captures an image using a camera or loads it from a dataset.

- Pre-processing: The system improves image quality to make detection easier.

- Feature Extraction: The system finds important features in the image, such as edges or shapes.

- Classification and Localization: Convolutional Neural Networks (CNNs) classify objects and find their locations.

- Post-processing: The system uses methods like Non-Maximum Suppression to remove duplicate bounding boxes.

- Visualization and Output: The system draws a bounding box around each detected object and adds labels.

In real-world applications, such as wood detection or gesture recognition, computer vision models process images, draw a bounding box for each object, and count or label the results.

Traditional object detection algorithms, such as Viola-Jones and HOG-SVM, use hand-crafted features and sliding windows. These methods work well in simple scenes but struggle with complex backgrounds or lighting. They also run slower and miss objects in cluttered images. Deep learning-based object detection models, like those using CNNs, learn features from large datasets. These models adapt to new images and handle complex scenes better. They also process images faster, making them ideal for real-time object detection.

Computer vision systems rely on bounding box placement for object localization. The bounding box shows where each object is in the image. Accurate localization helps with object classification and tracking. The system uses multiple bounding boxes when it finds more than one object. Post-processing ensures that only the best bounding box for each object remains.

Deep Learning Models (YOLO, SSD)

Deep learning models have changed how computer vision handles object detection. YOLO (You Only Look Once) and SSD (Single Shot MultiBox Detector) are popular object detection models. Both models use a single pass through a neural network to detect objects and draw a bounding box for each one. This approach allows real-time object detection, even on low-powered devices.

| Model | Real-Time Capability | Speed (fps) | Accuracy (mAP) | Hardware/Deployment Notes |

|---|---|---|---|---|

| SSD | Yes | 46 | >70% | Works on many hardware platforms, good for industrial use |

| YOLO | Yes | N/A | N/A | Fast on low-powered devices, uses efficient convolutional networks |

YOLO processes the whole image at once. This method speeds up detection and helps the model understand the context of each object. SSD also detects objects in a single step, balancing speed and accuracy. Both models use bounding box predictions for object localization and object classification. They work well for real-time object detection in video surveillance, self-driving cars, and robotics.

Computer vision systems use these object detection models to find and track objects in real time. The models draw a bounding box around each object and update the results quickly. Real-time object detection helps industries monitor safety, count items, and guide robots. The use of deep learning models like YOLO and SSD has set new standards for speed and accuracy in computer vision.

Tip: Real-time object detection models need powerful GPUs for training but can run on less powerful devices after training. This makes them flexible for many applications.

Applications of Machine Vision Systems

Quality Control and Defect Detection

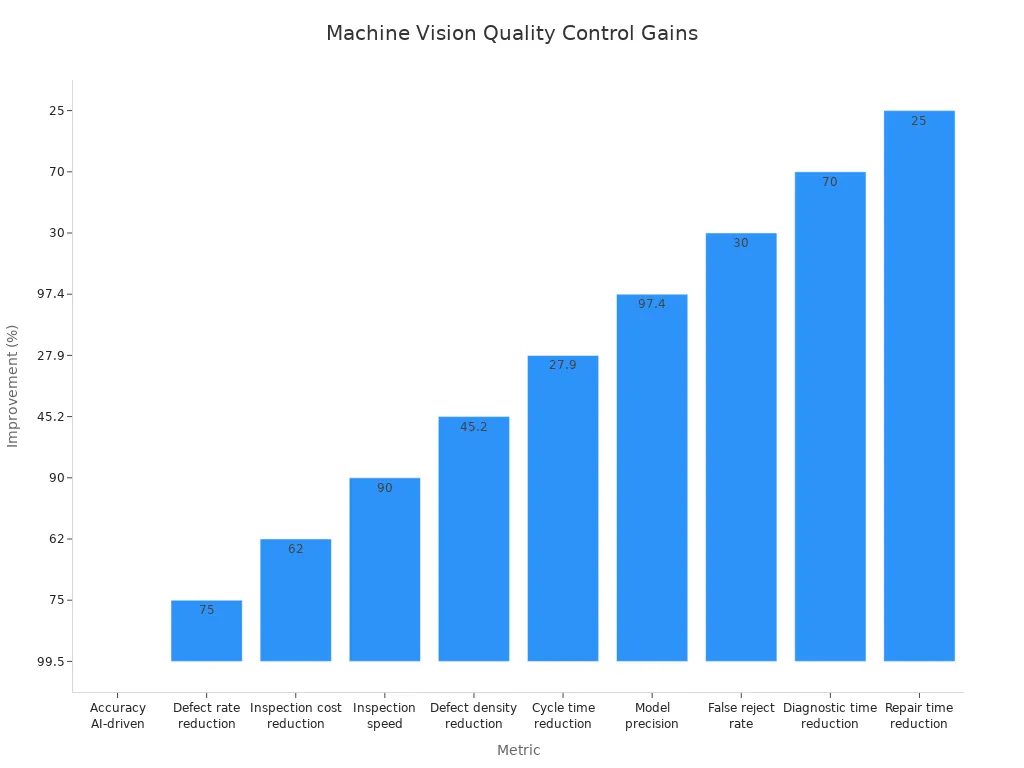

Object detection machine vision systems play a key role in quality control and defect detection. In manufacturing, these systems inspect products for defects, check labels, and monitor alignment. They use high-resolution cameras and advanced detection algorithms to spot even small flaws. Companies like Tesla use machine vision for inspection during car assembly. Healthcare facilities use object detection to count pills and check for contamination on tools. These systems help reduce errors and improve safety.

| Metric | Improvement Achieved |

|---|---|

| Accuracy with AI-driven systems | Up to 99.5%+ (vs. 85-90% traditional) |

| Defect rate reduction in consumer electronics | 75% decrease |

| Inspection cost reduction in automotive | 62% savings |

| Inspection speed | Reduced from 2-3 seconds/unit to 0.2 seconds/unit |

| Defect density reduction | 45.2% decrease |

Machine vision systems increase accuracy, reduce costs, and speed up inspection. They help companies find defects quickly and keep products safe.

Object Detection and Counting in Industry

Industries use object detection and counting to track products on conveyor belts and in storage. High-resolution cameras and adaptive lighting focus on each box or item. Deep learning models recognize objects, even when they overlap or move fast. The system draws a box around each object and counts them in real time. This reduces human error and saves labor costs.

- Real-time detection and counting work at high speeds.

- The system adapts to different object sizes and shapes.

- Anomaly detection flags miscounts or foreign objects.

- Live dashboards show counting results for quick checks.

Object detection and counting help factories keep accurate records and avoid inventory mistakes.

Automation in Healthcare and Vehicles

Object detection supports automation in healthcare and vehicles. In hospitals, these systems analyze medical images to detect tumors or count cells. They help doctors make faster and more accurate diagnoses. In vehicles, object detection identifies pedestrians, other cars, and obstacles. Tesla uses machine vision for lane detection and parking. Self-driving cars use detection to improve safety and reduce accidents.

- Object detection in healthcare improves treatment planning.

- Vehicle automation reduces human error and traffic accidents.

- Detection systems in cars help drivers stay safe and avoid collisions.

| Industry | Real-World Object Detection Applications |

|---|---|

| Manufacturing | Automated sorting, quality control, predictive maintenance, workplace safety monitoring, color sensing for consistency |

| Healthcare | Pill counting, sterile tool processing, PPE monitoring, AI-assisted cancer screening |

| Automotive | Tesla’s inspection systems, parking and lane detection in vehicles |

Getting Started with Object Detection

Data and Training Requirements

Building a strong object detection system starts with quality data. Teams need thousands of labeled images to train deep learning models. Most projects require tens of thousands of annotated images because object detection models must learn from many examples. The more complex the task, the more data is needed. Data augmentation, such as rotating or cropping images, helps increase dataset size. Transfer learning, where a model starts with knowledge from another dataset, can also reduce the need for new data.

- Large datasets improve detection accuracy.

- High-quality annotations, like bounding boxes, are essential.

- Consistent labeling helps the model learn better.

- Data engines and AI-assisted tools speed up annotation.

Tip: Training annotators and using clear guidelines ensures reliable object detection results.

Choosing Object Detection Algorithms

Selecting the right object detection algorithm depends on the application. Some tasks need real-time detection, while others focus on accuracy. Hardware limits, available data, and speed requirements all play a role. Popular algorithms include YOLO, SSD, and region-based CNNs. Each offers different strengths for detection tasks.

| Criteria | Considerations |

|---|---|

| Application Needs | Real-time vs. high accuracy |

| Hardware Constraints | GPU, CPU, or edge device |

| Data Availability | Amount and quality of labeled images |

| Performance Metrics | Precision, recall, mean average precision (mAP) |

Teams should test several algorithms to find the best fit for their object detection needs.

Deployment Tips

Deploying object detection systems brings new challenges. Lighting changes, object occlusion, and scale differences can affect detection. Teams can use image processing techniques, like histogram equalization, to handle lighting issues. Adding infrared sensors or depth cameras improves detection in tough environments. Regularly updating models with new data keeps detection performance high.

- Integrate detection systems with existing workflows for smooth operation.

- Use real-time monitoring to catch problems early.

- Scale across production lines by using flexible tools and robust models.

Note: Address privacy and bias concerns by following ethical guidelines and monitoring system performance.

Object detection machine vision systems transform industries by improving accuracy, speed, and safety. Companies in manufacturing, healthcare, and food processing report fewer errors, faster inspections, and better product quality. Many organizations use tools like OpenCV, TensorFlow, and PyTorch to build these systems.

Machine vision helps teams automate inspections, reduce waste, and protect brand reputation.

| Tool | Benefit |

|---|---|

| OpenCV | Real-time image analysis |

| TensorFlow | Deep learning for detection |

| PyTorch | Fast prototyping and research |

Exploring these resources can help organizations unlock new efficiencies and improve operations.

FAQ

What is the main benefit of using object detection machine vision systems?

Object detection machine vision systems help companies find problems quickly. They improve accuracy and speed. These systems also reduce human error and save money.

Can small businesses use machine vision systems?

Yes. Many small businesses use machine vision for tasks like counting products or checking quality. Affordable cameras and open-source software make it easier for small teams to start.

How much data does a machine vision system need?

A machine vision system needs thousands of labeled images for training. More data helps the system learn better. Teams often use data augmentation to increase the dataset size.

Do machine vision systems work in low light?

Some systems work in low light by using special lighting or infrared sensors. Good lighting helps the system see objects clearly. Teams often adjust lighting to match the environment.

What skills do teams need to set up object detection systems?

Teams need skills in computer vision, programming, and data labeling. Knowledge of tools like OpenCV or TensorFlow helps. Some companies offer user-friendly platforms for beginners.

See Also

A Comprehensive Guide To Object Recognition In Machine Vision

Essential Insights Into Computer And Machine Vision Technologies

Breaking Down Image Processing In Machine Vision Systems

How Machine Vision Enhances Defect Identification Capabilities

Fundamental Principles Behind Edge Detection In Machine Vision