A machine learning (ML) machine vision system uses artificial intelligence to help machines interpret visual information, automate inspections, and make decisions based on images. Machine learning improves machine vision technology by allowing systems to learn patterns from labeled data, adapt to new classes, and detect defects faster than traditional rule-based approaches. This leads to higher accuracy and efficiency in real-world tasks. The global market for machine vision technology demonstrates rapid growth, with projections showing a rise from $20.4 billion in 2024 to $69.49 billion by 2034, as shown below:

| Year | Market Size (USD Billion) | CAGR (%) | Regional Highlights |

|---|---|---|---|

| 2024 | 20.4 | N/A | Asia Pacific 44% market share |

| 2025 | 23.06 | N/A | North America fastest CAGR |

| 2034 | 69.49 | 13.04 | Hardware dominant, software fastest growing |

Understanding how machine vision systems work helps industries benefit from automation, real-time quality control, and improved adaptability.

Key Takeaways

- Machine learning machine vision systems use AI to help machines see, learn, and make decisions from images, improving accuracy and speed.

- These systems combine cameras, sensors, and software to automate tasks like inspection, sorting, and quality control in many industries.

- Deep learning and advanced techniques allow machine vision to handle complex tasks and adapt to new conditions without manual rules.

- Machine vision boosts productivity, reduces errors, and saves costs by detecting defects early and automating real-time decisions.

- Challenges include collecting quality data, labeling images, and managing computing needs, but ongoing improvements make these systems more efficient.

What Is a Machine Learning (ML) Machine Vision System?

Definition

A machine learning (ML) machine vision system combines computer vision with artificial intelligence to help machines understand and process images or videos. In this system, machine learning allows computers to learn from examples instead of following only fixed rules. The system uses large sets of labeled images to train models that can recognize patterns, objects, or defects. This approach makes machine vision technology more flexible and powerful than traditional rule-based systems.

Machine vision technology uses cameras and sensors to capture visual data. The computer vision part processes this data, while machine learning helps the system improve its accuracy over time. Deep learning, a special type of machine learning, plays a big role in modern machine vision systems. It can handle complex inspection tasks, such as finding small defects on products or working in places with poor lighting. These systems can solve problems that are too hard for simple rules.

Note: Deep learning models in machine vision technology can inspect subtle differences and work in challenging environments. They learn from labeled images, making them useful for tasks where manual rules do not work well.

Key Features

Machine learning (ML) machine vision systems have several important features that set them apart from older technologies:

- Automation of Visual Tasks: These systems can perform tasks like sorting, counting, or checking products without human help. This automation saves time and reduces errors.

- Continuous Improvement: The system learns from new data. As it processes more images, it gets better at recognizing patterns and making decisions.

- Adaptability: Machine vision technology can adjust to new types of products or changes in the environment. For example, it can still work well if lighting conditions change or if new defects appear.

- Integration of Advanced Techniques:

- Active learning helps the system choose the most useful images for training, which saves time and reduces the need for manual labeling.

- Deep learning models can handle difficult inspection tasks that traditional methods cannot manage.

- Hybrid approaches, such as combining active learning with semi-supervised learning or transfer learning, make the system more efficient and accurate.

- Human-in-the-loop systems allow experts to review and label data, ensuring high-quality results.

Machine vision technology supports many applications in industries like manufacturing, agriculture, and healthcare. These systems help automate inspections, control processes, and improve safety. AI machine vision and computer vision work together to make these tasks faster and more reliable.

Computer vision and machine vision are closely related. Computer vision focuses on teaching computers to understand images, while machine vision technology uses this understanding to solve real-world problems. AI machine vision systems use computer vision and machine learning to deliver smart solutions for many applications.

Core Components

Hardware

Machine vision systems rely on several key hardware components to capture and process visual information. Each part plays a unique role in ensuring accurate image analysis and reliable results. The table below outlines the main hardware elements found in most machine vision setups:

| Hardware Component | Description |

|---|---|

| Lighting | Provides illumination for clear image capture; uses techniques like front, back, diffused, and spectrum lighting (RGB, UV, NIR, SWIR). |

| Lens | Focuses light to create sharp images; defined by focal length, aperture, and field of view. |

| Camera | Captures images; may include embedded processors or FPGAs for initial image processing. |

| Cabling | Connects cameras to processing units; includes Ethernet, USB, CoaXPress, and Camera Link interfaces. |

| Interface Peripherals | Enables communication between cameras, computers, and other devices. |

| Computing Platforms | Processes image data; includes PCs and vision controllers with CPUs, GPUs, and I/O interfaces. |

| Calibration Tools | Aligns and adjusts system components for accuracy. |

Proper lighting ensures that machine vision can capture high-quality images. Lenses and cameras work together to focus and record the scene. Cabling and interface peripherals connect all parts, while computing platforms handle complex image processing tasks. Calibration tools keep the system accurate over time.

Software

Software forms the brain of machine vision systems. It uses advanced algorithms and models to perform image analysis and make decisions. Common types of software include:

- Image classification models that assign labels to entire images.

- Object detection models that find and locate objects within images.

- Image segmentation models that divide images into smaller parts for detailed study.

- Generative models that create new images based on learned patterns.

Most machine vision software uses deep learning, especially convolutional neural networks (CNNs), to improve image processing and defect detection. Performance metrics such as precision, recall, and F1 score help measure how well these models work. Generative AI can also automate manufacturing and create new data for training. By combining these tools, machine vision systems can process images, detect defects, and recognize objects with high accuracy.

Data Flow

The data flow in machine vision systems follows a clear path from image capture to decision-making. The process starts when cameras or imaging devices collect high-resolution images. The system then uses image processing techniques to enhance these images by removing noise and adjusting brightness. This step improves the quality of image analysis.

Next, the system extracts important features such as edges, textures, and shapes. Machine learning models compare these features to known patterns to identify objects or defects. The system then classifies the detected items and interprets the results. Finally, machine vision systems make automated decisions, such as rejecting faulty products or sending alerts. This workflow allows for real-time quality control and boosts productivity in many industries.

Tip: Effective image pre-processing increases the accuracy and reliability of automated decisions in machine vision applications.

Key Concepts in Machine Learning

Pattern Recognition

Pattern recognition forms the backbone of machine learning in machine vision systems. These systems use cameras and sensors to capture images, then apply neural algorithms to extract features like edges, shapes, and colors. Feature extraction reduces data complexity and helps the system focus on important details. With this approach, image recognition and object detection become more accurate. Statistical and probabilistic models allow the system to classify images, even in noisy or complex environments. For example, defect detection accuracy can exceed 99%, and object recognition mean Average Precision improves by over 15%. Pattern recognition enables real-time decisions and supports tasks such as quality inspection and facial recognition. Neural networks adapt to new data, making these systems robust and flexible.

Model Training

Model training allows machine learning systems to improve over time. During training, neural networks learn from labeled datasets, adjusting their parameters to boost accuracy in image classification and object detection. Self-supervised learning methods, such as those used in advanced neural models, help systems learn from unlabeled data. This approach increases adaptability in fields like cellular imaging and biodiversity monitoring. As models process more data, they handle changes in lighting, object orientation, and background clutter. Reinforcement learning lets systems learn from rewards and mistakes, optimizing their performance. Integrating machine learning into image processing pipelines ensures continuous improvement and scalability. Active learning and human-in-the-loop corrections further enhance model accuracy by focusing on uncertain or difficult data points.

Tip: High-quality labeled data, provided by domain experts or professional annotation teams, directly improves the performance of neural networks in machine vision tasks.

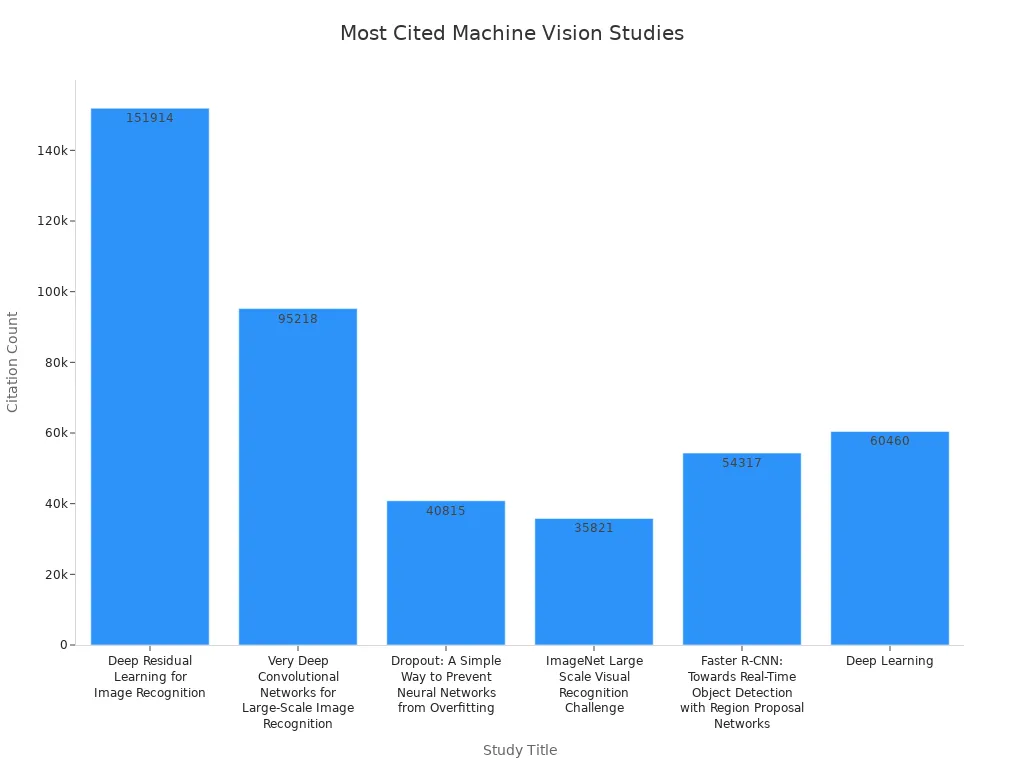

Deep Learning

Deep learning has transformed machine vision by using convolutional neural networks (CNNs) to learn directly from raw images. These deep learning algorithms outperform traditional methods in both binary and multi-class classification tasks. The table below shows how deep learning boosts accuracy and efficiency:

| Task Type | Deep Learning Accuracy (%) | Traditional Methods Accuracy (%) |

|---|---|---|

| Binary Classification | 94.05 – 98.13 | 85.65 – 89.32 |

| Eight-Class Classification | 76.77 – 88.95 | 63.55 – 69.69 |

Deep learning increases defect detection rates by 25% and reduces inspection errors by over 90%. Manufacturing cycle times drop by up to 20%, and labor costs fall by about 50%. CNNs and other neural networks adapt to new data using data augmentation and active learning, which further improve accuracy. These advances make deep learning essential for image recognition, image classification, and image processing in industries like healthcare, manufacturing, and autonomous vehicles.

Applications of Machine Vision Technology

Industrial Automation

Machine vision plays a key role in industrial automation. Factories use inspection systems to check products for defects, measure parts, and verify packaging. These systems help with quality control by finding surface flaws, checking fill levels, and reading barcodes. Many manufacturing applications use ai machine vision for assembly tasks. Robots with cameras guide parts into place, pick and sort items, and check if components are present and facing the right way. Computer vision applications also track products through the supply chain, making sure each item is in the right place. Real-time process control uses machine vision to monitor machines and trigger maintenance before problems happen. These applications improve safety by keeping workers away from dangerous equipment and by tracking movement to prevent accidents.

Tip: Machine vision inspection systems can stop production lines or remove faulty products automatically, reducing waste and saving money.

Quality Inspection

Quality control depends on advanced inspection systems powered by ai machine vision. These systems spot tiny cracks, color changes, or surface defects that people might miss. Deep learning models help inspection systems learn from new data, so they adapt to changes in products or lighting. Computer vision applications in quality control include 3D vision for checking shapes and hyperspectral imaging for analyzing food freshness. Factories use robotic arms with cameras to inspect car wheels or circuit boards in real time. Edge AI allows inspection systems to process images quickly on the factory floor, so companies can fix problems right away. These inspection systems also keep records for traceability and help meet industry standards.

- Inspection systems in food processing use hyperspectral imaging to sort and package produce.

- Automotive factories use ai machine vision to inspect vehicles during assembly.

- Electronics makers rely on computer vision applications to detect cold solder joints.

Other Industries

Machine vision applications reach far beyond factories. In agriculture, drones with cameras monitor crops, spot pests, and check soil moisture. Automated sorting machines use ai machine vision to grade fruits and vegetables by size and color. Computer vision applications guide drones to spray pesticides only where needed, saving chemicals and protecting the environment. Livestock farms use inspection systems to watch animal health and behavior. In aquaculture, machine vision tracks fish or shrimp to improve feeding. Self-driving cars and autonomous vehicles rely on machine vision for object tracking, lane detection, and obstacle avoidance. These applications show how machine vision and ai machine vision support safety, efficiency, and quality control in many fields.

Note: John Deere uses machine vision and ai machine vision in tractors to identify weeds and help farmers make better decisions.

Benefits, Challenges, and Comparison

Main Benefits

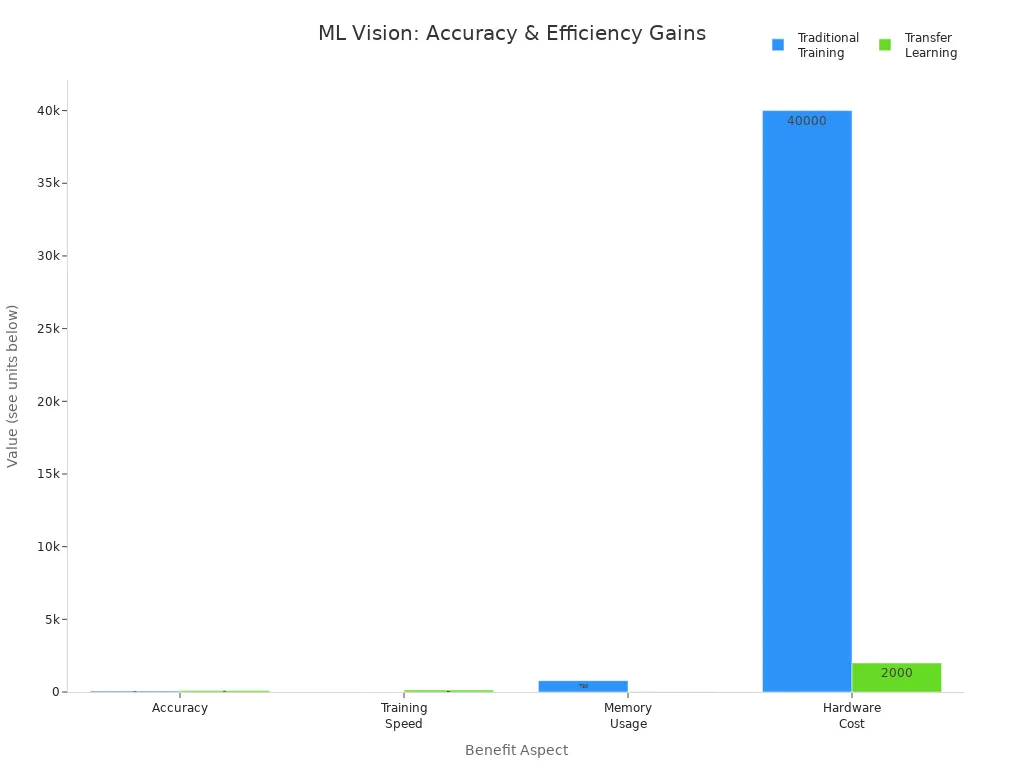

Machine vision systems bring major improvements to industries that need fast and reliable visual inspection. These systems use machine learning to boost accuracy and efficiency far beyond traditional methods. For example, transfer learning and fine-tuning can raise classification accuracy from about 70% to nearly 99.9%. Training speeds increase up to 140 times, and memory usage drops by 97%. Companies can now use standard office hardware instead of expensive data center GPUs. The table below shows these benefits:

| Benefit Aspect | Traditional Training | Transfer Learning / Fine-Tuning |

|---|---|---|

| Accuracy | ~70.87% classification accuracy | Up to 99.9% accuracy |

| Training Speed | Baseline | Up to 140 times faster convergence |

| Training Data Required | Millions of examples | Smaller, high-quality datasets (e.g., 50,000) |

| Memory Usage | Up to 780GB | Reduced to 24GB (97% reduction) |

| Hardware Cost | $40,000+ data center GPUs | $2,000 consumer-grade GPUs |

| Training Infrastructure | Specialized data centers | Standard office hardware |

| Model Size Supported | Limited by hardware | Up to 65B parameters on a single GPU |

Machine vision also improves productivity. In retail, inventory turnover increased by 25%. In industrial inspection, companies like GE reduced inspection time by 75%. Machine vision systems can inspect one part every two seconds, and error rates drop below 1%, much better than manual inspection.

Common Challenges

Deploying machine vision systems comes with several challenges:

- Data collection is hard because data sources are often scattered and in different formats.

- Labeling images takes time and money, especially when experts must do it for tasks like medical imaging.

- Real-world data may not cover all possible cases, so models might not work well in new situations.

- Deep learning models need a lot of computing power, which can be a problem for devices with limited resources.

- Some industries need models that are easy to understand, but deep learning models can be complex and hard to explain.

- Integrating machine vision into existing systems and keeping models updated requires ongoing work and good monitoring tools.

Data quality and volume also matter. High-quality, large datasets help machine vision systems make more accurate decisions and process many objects quickly. Poor data can lead to errors and lower reliability.

Machine Vision vs. Computer Vision

Machine vision and computer vision share some technology, but they serve different purposes. Machine vision focuses on industrial tasks like quality control, defect detection, and robotic guidance. It uses cameras, sensors, and rule-based algorithms for fast, real-time decisions. Computer vision covers a wider range of applications, such as medical imaging, security, and autonomous vehicles. It uses advanced algorithms, including deep learning, to interpret complex visual data.

| Aspect | Machine Vision | Computer Vision |

|---|---|---|

| Technology Focus | Rule-based, predefined algorithms; image processing with cameras, sensors, and lighting | Advanced algorithms including deep learning (CNNs), reinforcement learning, and GANs; image analysis and interpretation |

| Data Processing | Uses simple, rule-based processing for specific tasks; fast, real-time decision-making | Uses complex, flexible models to analyze and interpret complex visual data; can learn and adapt over time |

| Application Environment | Primarily industrial and manufacturing settings; integrated into automation systems | Broad applications including healthcare, security, big data analytics; can operate standalone or integrated |

| Processing Capability | Optimized for speed and precision in controlled environments; limited flexibility | Handles complex, dynamic environments; capable of pattern recognition, facial recognition, medical imaging |

| Integration | Typically integrated into existing industrial hardware and software systems | Can function standalone or be integrated; more flexible in deployment |

| Real-time vs Historical | Focus on real-time image processing for immediate action | Supports both real-time and historical data analysis for deeper insights |

| Computational Requirements | Lower computational overhead, suitable for high-speed manufacturing | Higher computational needs due to complex algorithms and large datasets |

| Typical Applications | Quality control, defect detection, robotic guidance, assembly line inspection | Medical imaging, surveillance, autonomous vehicles, retail analytics, pattern recognition |

Note: Machine vision is a specialized branch of computer vision, designed for speed and reliability in industrial settings, while computer vision can solve a broader set of problems in many fields.

Machine vision systems use cameras and sensors to capture images, process data, and automate decisions in real time. These systems excel at quantitative analysis, supporting inspection, safety, and productivity across industries. Key components include image acquisition, data delivery, feature extraction, and automated decision making. Machine vision improves product quality, increases efficiency, and reduces waste by detecting defects early. Challenges include the need for high-quality data and skilled professionals.

Understanding machine vision helps professionals optimize processes and adapt to future trends in automation and artificial intelligence.

FAQ

What is the main difference between machine vision and computer vision?

Machine vision focuses on industrial tasks like inspection and automation. Computer vision covers a wider range of applications, including healthcare and security. Machine vision often works in factories, while computer vision can work in many fields.

How does machine learning improve machine vision systems?

Machine learning helps systems learn from data. These systems get better at finding patterns and defects over time. They can adapt to new products or changes in the environment without needing new rules.

What industries use machine vision technology?

Many industries use machine vision. Manufacturing, agriculture, healthcare, and automotive companies rely on it for inspection, sorting, and safety. Retailers use it for inventory checks. Farmers use it to monitor crops and livestock.

Do machine vision systems need a lot of data?

Yes, machine vision systems work best with large, high-quality datasets. More data helps the system learn better and make accurate decisions. Small or poor-quality datasets can lead to mistakes.

See Also

Understanding Models Behind Computer And Machine Vision Systems

Essential Insights Into Computer And Machine Vision Technology

A Clear Guide To Image Processing In Machine Vision