An information retrieval machine vision system combines machine vision and information retrieval to help machines see and understand their environment. These systems use computer vision and machine vision to process images and extract important details for automated decisions. In 2025, industries handle about 120 zettabytes of data, using computer vision and machine vision to power artificial intelligence across sectors worth $88 trillion each year. Multimodal models connect images, text, and video, making machine vision smarter and more useful in real-world tasks.

Key Takeaways

- Information retrieval machine vision systems combine advanced cameras, AI, and data processing to help machines see and understand their environment.

- These systems improve product quality and efficiency by detecting defects automatically and supporting real-time decision-making in industries like manufacturing, healthcare, and retail.

- Core technologies include high-resolution imaging, AI-powered algorithms, cloud platforms, and 5G connectivity, enabling fast and accurate image analysis.

- Challenges such as data quality, system scalability, and explainability require careful management to ensure reliable and fair machine vision applications.

- Future trends like multimodal AI, generative models, and edge computing will make machine vision smarter, faster, and more widely used across many sectors.

How Information Retrieval Machine Vision Systems Work

Core Technologies

Machine vision and computer vision systems rely on a blend of advanced hardware and software to capture and analyze images. These systems use high-resolution cameras, hyperspectral imaging, and 3D machine vision to collect detailed images from real-world environments. Embedded vision systems and cloud-based machine vision platforms allow for flexible deployment in various industries. The integration of 5G technology enables real-time data transfer, supporting fast and reliable communication between devices.

| Technical Advancement | Description and Impact | Industrial Application Examples |

|---|---|---|

| AI and Deep Learning | Autonomous learning from data improves accuracy and speed in image analysis and defect detection. | Cognex defect detection tools in manufacturing |

| Hyperspectral Imaging | Multi-wavelength imaging detects impurities and irregularities invisible to human eye. | Food safety and quality control (Headwall Photonics solution) |

| 3D Machine Vision | Captures 3D images for detailed inspection and validation of parts. | Automotive, electronics, aerospace component inspection |

| Cloud-based Machine Vision | Centralized data processing and storage with global access, reducing hardware costs. | Cognex ViDi platform for manufacturing automation |

| Embedded Vision Systems | Compact, integrated vision devices for easy integration and customization. | Basler AG AI-enabled retail checkout terminals |

| Fusion with 5G Technology | High-speed, low-latency wireless communication enables real-time data transfer and decision-making. | Ericsson and ABB 5G-enabled automotive machine vision system |

These core technologies form the backbone of every information retrieval machine vision system. They enable automated systems to capture images, process them efficiently, and extract valuable information for decision-making.

Computer Vision and AI

Computer vision and machine vision use artificial intelligence to interpret images and recognize patterns. Deep learning models, such as convolutional neural networks (CNNs), recurrent neural networks (RNNs), long short-term memory networks (LSTMs), and generative adversarial networks (GANs), play a key role in image recognition and object detection. CNNs extract features from images, while RNNs and LSTMs handle sequences and time-based data. GANs generate new images to improve training datasets.

Hybrid models combine CNNs with RNNs to analyze both spatial and temporal information. These models power content-based image retrieval, allowing systems to find similar images based on visual content. In medical imaging, deep learning models have matched or exceeded expert performance in tasks like skin cancer detection, diabetic retinopathy screening, tumor segmentation, tuberculosis detection, and bone fracture identification. These results show how computer vision and machine vision systems integrate image capture, processing, and retrieval algorithms to achieve high accuracy and efficiency.

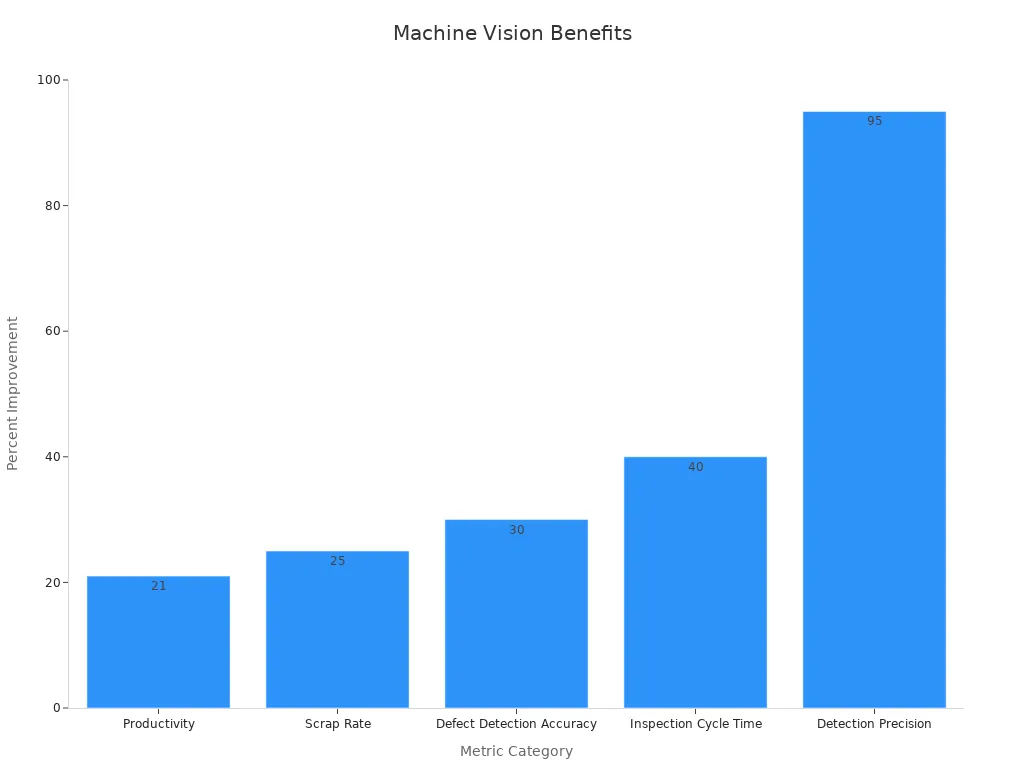

A recent study in industrial manufacturing found that computer vision algorithms powered by AI achieved over 95% accuracy in detecting tiny defects in brake parts. This level of performance demonstrates the reliability of modern machine vision systems in quality control.

Data Processing Flow

The data processing flow in an information retrieval machine vision system transforms raw images into actionable insights. The process starts with image capture using advanced cameras and sensors. Next, image processing techniques such as preprocessing, feature extraction, segmentation, and object recognition convert images into structured data.

- Automation of manual tasks in retail and agriculture increases speed and reduces errors.

- Real-time analysis enables quick decisions and operational responsiveness.

- Automated filtering removes irrelevant data, optimizing resource use and speeding up processing.

- Leading cloud providers offer high-accuracy models for extracting insights from images.

- Stepwise processing ensures each image moves from raw data to structured, analyzable information.

- Industries like healthcare, agriculture, social media, retail, and security benefit from these efficient workflows.

Feature engineering helps systems focus on the most important parts of images, improving recognition and retrieval. Automated systems use these structured data outputs to make decisions, monitor quality, and trigger alerts. The combination of computer vision, machine vision, and information retrieval ensures that every image contributes to smarter, faster, and more reliable operations.

Information Retrieval Machine Vision System Components

Hardware Overview

Machine vision systems rely on precise hardware to capture and process images. Cameras serve as the primary sensors, using synchronization and hardware triggers to ensure accurate image capture. High-resolution cameras, ultrasonic sensors, RADAR, and LIDAR work together to provide a complete view of the environment. Each sensor type offers unique strengths. Cameras deliver sharpness and dynamic range for detailed image analysis. Ultrasonic sensors excel in short-range detection, while RADAR and LIDAR provide robust performance in poor visibility and create 3D maps. Processors, including CPUs, GPUs, and TPUs, handle large volumes of images and support complex computer vision tasks. Memory and storage capacity affect how quickly the system processes data. Environmental factors like lighting, dust, and humidity can impact sensor performance, so proper lighting and protective covers are essential for reliable operation.

| Hardware Component | Description | Key Performance Metrics |

|---|---|---|

| Cameras | Capture high-resolution images for object detection | Sharpness, Dynamic Range, Sensitivity, Uniformity |

| Ultrasonic Sensors | Short-range detection | Robustness, Low Cost, Short Range |

| RADAR Sensors | Detect objects in poor visibility | Speed, Robustness, Medium Resolution |

| LIDAR Sensors | 3D mapping | High Resolution, Long Range |

Software and Algorithms

Image analysis software forms the core of machine vision and computer vision systems. These platforms use advanced algorithms for image processing, feature extraction, and retrieval. Convolutional Neural Networks (CNNs) and other deep learning models enable fast and accurate analysis of images. CNNs require less memory and power than other models, making them ideal for real-time applications. Image analysis software achieves high detection efficiency, with some systems reaching over 97% accuracy in medical diagnostics. Algorithms also optimize latency, throughput, and energy consumption, ensuring reliable performance across different types of machine vision systems.

Data and Feature Engineering

Structured data and feature engineering play a vital role in system accuracy. Engineers use techniques like feature selection, dimensionality reduction, and clustering to transform raw images into meaningful data. Methods such as Recursive Feature Elimination and Principal Component Analysis help select the most important features, improving model stability and accuracy. Collaboration with domain experts ensures that features reflect real-world needs. Studies show that high-quality structured data and careful feature engineering boost predictive performance more than complex models alone. For computer vision and machine vision, these steps turn images into actionable insights, supporting better decisions in industrial environments.

Tip: Effective feature engineering and structured data preparation often lead to higher accuracy than simply using more advanced models.

Machine Vision Applications

Industrial Automation

Machine vision applications drive industrial automation across manufacturing, logistics, and warehousing. Companies deploy machine vision robots for assembly, defect detection, and advanced driver assistance systems in automotive manufacturing. These robots help trace parts and products, track and identify packages, and optimize assembly lines. In food manufacturing, mobile robots inspect and package items, ensuring safety and reducing contamination. Warehouses use drones with machine vision to track and identify packages, count inventory, and integrate with enterprise resource planning systems. Automated inspection systems in logistics sort packages, scan barcodes, and manage conveyor operations. These applications increase productivity, reduce waste, and improve processes by providing real-time data and consistent performance.

| Industry Sector | Application | Impact |

|---|---|---|

| Automotive | Assembly, defect detection, ADAS | Higher quality, faster production |

| Food Industry | Inspection, packaging | Enhanced safety, reduced contamination |

| Retail | Inventory tracking, shelf monitoring | Improved stock accuracy |

| Logistics | Drone-based inventory, package sorting | Faster counting, cost savings |

Machine vision systems enable predictive maintenance by monitoring equipment health, reducing downtime, and extending equipment lifespan.

Improve Product Quality

Manufacturing relies on machine vision to improve product quality through precise and automated inspection. High-resolution cameras and computer vision algorithms detect even the smallest defects, surpassing human capabilities. Automated inspection ensures every product meets strict quality standards, reducing waste and minimizing recalls. Real-time analysis allows immediate corrective actions, supporting continuous improvement. In pharmaceutical manufacturing, machine vision applications monitor powder flow, granulation, and coating, providing comprehensive quality control. These systems collect data for predictive maintenance and long-term quality strategies. By eliminating human error and standardizing inspections, machine vision helps manufacturers improve product quality and reduce waste.

- Machine vision increases inspection accuracy and consistency.

- Automated inspection reduces inspection time and labor costs.

- Real-time monitoring enables quick responses to quality issues.

Other Applications

Machine vision applications extend beyond manufacturing and industrial automation. In healthcare, computer vision supports patient monitoring, posture recognition, and AI-assisted surgical guidance. Hospitals use machine vision to track patient movement, analyze chronic conditions, and improve service efficiency. Retailers apply machine vision for people counting, customer recognition, and basket size estimation. These applications help optimize staffing, reduce wait times, and enhance customer experiences. Machine vision also supports security, agriculture, and smart city projects by enabling object recognition, tracking, and automated decision-making. The flexibility of machine vision applications allows organizations to adapt quickly and address diverse challenges.

| Application / Metric | Use Case |

|---|---|

| Timed Up and Go (TUG) test | Fall risk assessment in healthcare |

| People counting | Real-time occupancy in hospitals and stores |

| Queue detection | Reducing wait times in retail |

| AI-assisted surgical guidance | 3D models for surgery planning |

Note: Machine vision applications continue to expand, helping industries improve efficiency, quality, and decision-making.

Challenges and Trends 2025

Current Challenges

Information retrieval machine vision systems face several challenges in 2025. Data quality remains a major concern. Poor data quality can reduce model accuracy, reliability, and fairness. Studies show that label errors and missing data can cause biased results and lower performance. Improving label quality can boost model efficiency by up to 88%. Data cascades, where one error leads to more problems, highlight the need for strong data management.

Scalability also presents issues. As data volumes grow, systems must process more images and information quickly. Metrics such as error ratio, empty values, and duplicate records show how often data problems occur. Gartner estimates that poor data quality can cost companies $15 million each year. Many data analysts spend over 40% of their time checking data, which slows down operations.

Interpretability is another challenge. Machine vision systems must explain their decisions, especially in critical applications. Research shows that clear explanations can double human productivity in annotation tasks. Trust metrics help identify when people rely too much on machine predictions. Real-world case studies reveal issues with color detection, high dynamic range, and reflective materials. Large system sizes and harsh environments can also affect stability and accuracy.

Note: Addressing these challenges is vital for reliable and safe machine vision applications across industries.

Innovations and Future Outlook

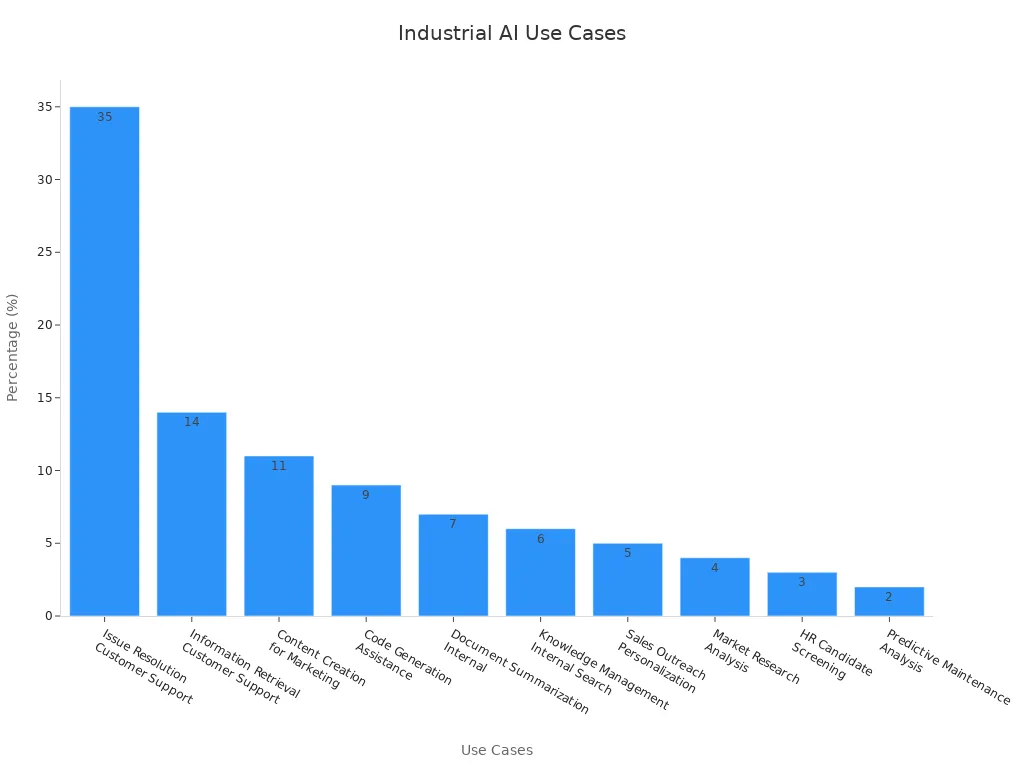

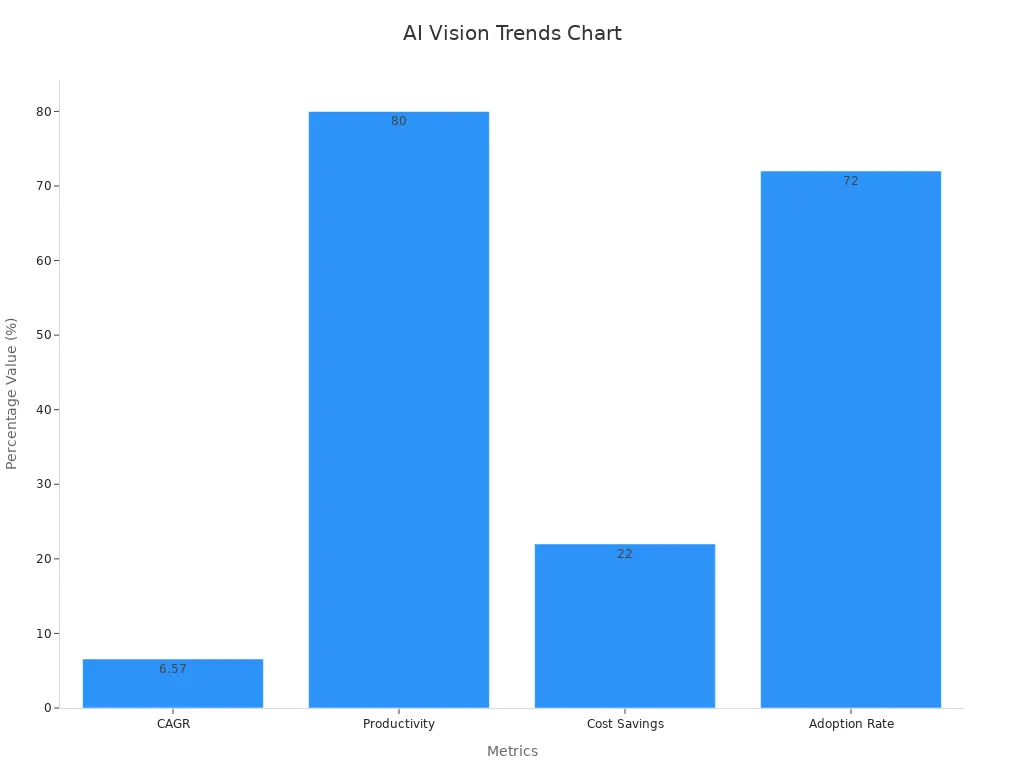

In 2025, machine vision systems will see rapid innovation. Companies invest billions in generative AI and advanced algorithms. The global AI market reached $208 billion in 2023 and could grow to $1.8 trillion by 2030. About 72% of organizations already use AI, and this number will rise. Machine vision market size is expected to double by 2035, with a steady growth rate of 6.57% per year.

Key trends include multimodal AI, which combines text, images, and audio for smarter decisions. Generative AI creates synthetic data to improve training. Vision transformers and 3D vision boost accuracy in medical and industrial applications. Edge AI devices process data locally, reducing delays and improving privacy. Automated guided vehicles use vision to optimize logistics. Explainable AI and new regulations ensure transparency and compliance, especially in sensitive sectors.

By 2025, about 75% of firms will use AI-powered vision systems. These innovations will expand applications in healthcare, manufacturing, and smart cities. As machine vision systems become more advanced, they will support safer, faster, and more reliable operations.

Information retrieval machine vision systems deliver measurable value across industries. They improve efficiency, safety, and product quality while supporting Industry 4.0 goals. The table below highlights key aspects:

| Aspect | Evidence Summary |

|---|---|

| Market Size Estimation | Validated by research and data triangulation |

| AI Impact | Enhances accuracy, speed, and decision-making |

| Industry Impact | Drives operational efficiency and quality |

Businesses benefit from faster inspections and better traceability. Ongoing innovation promises even broader applications and smarter automation in the years ahead.

FAQ

What is an information retrieval machine vision system?

An information retrieval machine vision system uses computer vision and artificial intelligence to process images. These automated systems extract important details for decision-making. They support industrial automation, improve processes, and increase productivity in manufacturing and other applications.

How does automated inspection improve product quality?

Automated inspection uses image analysis software and object detection to find defects. These systems check every product with high accuracy. They help reduce waste, improve product quality, and ensure compliance with industry standards.

What are common applications of machine vision?

Machine vision supports many applications. It helps track and identify packages in logistics, trace parts and products in manufacturing, and monitor quality in food production. Healthcare uses image recognition for diagnostics. Retailers use tracking for inventory and customer analysis.

Why is lighting important in machine vision systems?

Lighting affects image processing and recognition. Good lighting ensures clear images for accurate inspection and object detection. Poor lighting can lower efficiency and quality. Proper lighting setup helps automated systems work reliably in different environments.

What types of machine vision systems exist?

Types of machine vision systems include 2D and 3D imaging, content-based image retrieval, and systems for real-time tracking. Each type uses different sensors and image processing methods. They support various industrial automation needs and help improve productivity.

See Also

A Comprehensive Guide To Machine Vision Inspection Systems 2025

Exploring The Fundamentals Of Image Processing In Machine Vision

An Overview Of Computer Vision Models And Machine Vision Systems

Defining Illumination Techniques In Machine Vision Systems

Essential Insights Into Computer Vision And Machine Vision Technologies