An imaging system machine vision system uses cameras and computers to help you inspect and analyze objects automatically. You can find a machine vision system working in factories, checking products for errors or guiding robots. These systems capture images, process them, and make decisions much faster than people can. When you use an imaging system machine vision system, you improve accuracy and reduce mistakes.

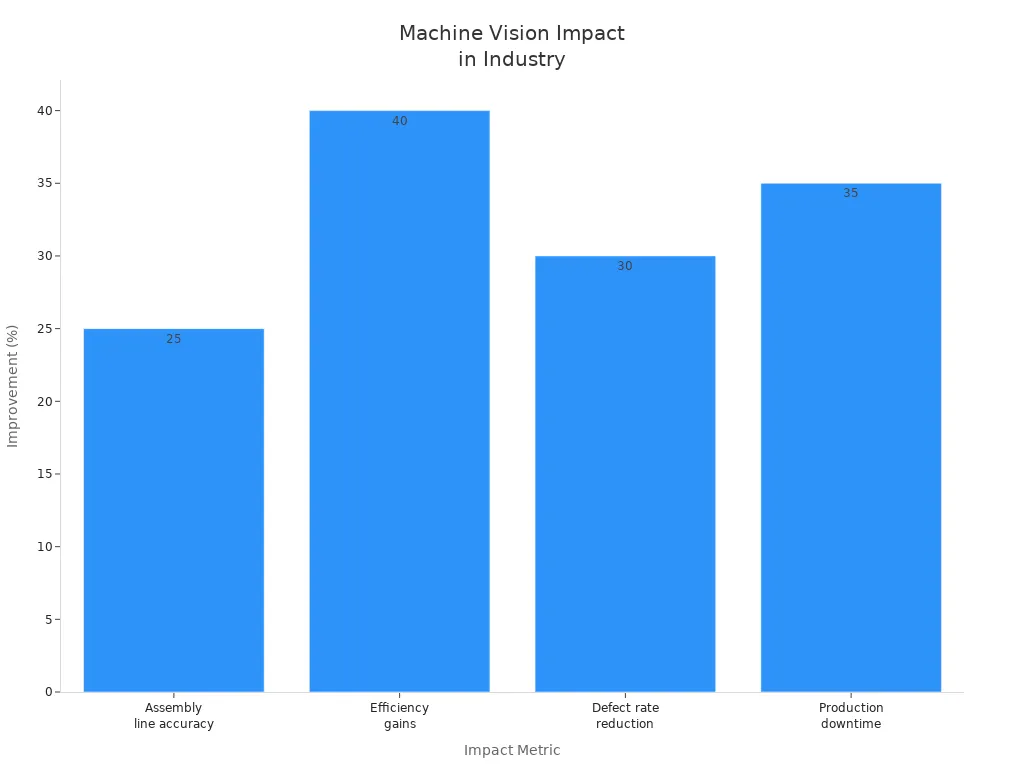

| Impact Metric | Improvement/Reduction |

|---|---|

| Assembly line accuracy | 25% |

| Efficiency gains | Up to 40% |

| Defect rate reduction | Up to 30% |

| Production downtime reduction | 35% |

Key Takeaways

- Machine vision systems use cameras, lighting, and computers to inspect objects automatically, improving accuracy and speed over manual checks.

- Good lighting and the right camera setup are essential to capture clear images and detect defects reliably.

- There are three main types of machine vision systems—1D, 2D, and 3D—each suited for different inspection tasks and industries.

- These systems help detect defects, control quality, and boost automation, leading to fewer errors, lower costs, and higher productivity.

- Machine vision is widely used in manufacturing, healthcare, automotive, and agriculture to improve quality, safety, and efficiency.

Imaging System Machine Vision System

What It Is

You can think of an imaging system machine vision system as a smart set of eyes for machines. This system uses a camera, special lighting, and a computer to inspect and analyze objects automatically. Unlike traditional inspection, where people look for defects by eye, a machine vision system works much faster and with greater accuracy.

Here are some key principles that define an imaging system machine vision system:

- The system uses cameras and sensors to capture clear images of objects.

- Lighting plays a huge role, often making up 90% of the system’s performance. Proper lighting helps the camera see details and spot defects.

- The system uses image processing and analysis algorithms to find important information, such as defects or measurements.

- It makes decisions based on set rules, like rejecting a faulty product or guiding a robot.

- The system connects with other machines using communication interfaces like Ethernet or USB.

- High accuracy, real-time processing, and easy integration with automation make these systems valuable in many industries.

When you compare a machine vision system to manual inspection, you see big differences:

- Manual inspection depends on people, which can lead to mistakes, slow work, and different results from different inspectors.

- Machine vision systems use high-resolution cameras and controlled lighting to spot defects automatically.

- These systems work faster, reduce labor costs, and keep quality consistent.

- You get real-time inspection, fewer errors, and better product quality.

Tip: Good lighting and camera setup are critical. If the image is blurry or too dark, the system may miss defects.

How It Works

An imaging system machine vision system follows a series of steps to inspect and analyze objects. You can break down the process like this:

- The system detects when an object enters the camera’s view and triggers the camera and lighting.

- The camera captures an image with the right exposure and lighting.

- The system converts the image into digital data and stores it for processing.

- Image processing begins. The system adjusts brightness, removes noise, and highlights important areas.

- The system analyzes the image, looking for features, defects, or measurements.

- Based on the analysis, the system makes a decision—such as passing, rejecting, or sorting the object.

- The results control other machines or alert workers if something needs attention.

You will find several important technologies working together in an image processing machine vision system. The table below shows some of the main tools and methods:

| Technology Category | Examples and Details |

|---|---|

| Image Processing Algorithms | Blob analysis, edge detection, pattern recognition, noise reduction, feature extraction |

| Cameras | 3D cameras, color cameras, monochrome cameras, line scan cameras |

| Lighting Systems | LED arrays, multi-spectrum lighting, diffuse and directional lighting |

| Processors and Controllers | Industrial PCs, embedded controllers, ARM+FPGA, CPU+VPU |

| Communication Interfaces | Ethernet, USB 3.0, Camera Link, CoaXPress |

You can see that each part of the system plays a role in making sure the images are clear and the analysis is accurate. The camera and lighting must work together to capture high-quality images. The computer uses advanced algorithms to process and analyze the images. The system then makes decisions in real time, helping you improve efficiency and quality in your work.

Machine Vision Systems Types

1D, 2D, and 3D Systems

You will find three main types of machine vision systems: 1D, 2D, and 3D. Each type uses different technology and serves unique visual inspection tasks in manufacturing and other industries.

| System Type | Technology & Hardware | Software Requirements | Typical Applications |

|---|---|---|---|

| 1D | Linear sensors or line-by-line data analysis; simple cameras | Basic image processing software | Continuous process inspection, defect detection on materials like paper, metals, plastics; barcode reading |

| 2D | Area array or line scan cameras capturing flat images; standard cameras and lenses | Intermediate image processing software | Surface inspection, barcode reading, defect detection on discrete parts, quality control |

| 3D | Stereo vision, laser displacement sensors, fringe pattern projection, time-of-flight sensors | Advanced software, often with AI; calibration tools | Precise measurements, shape digitization, robotic guidance, 3D inspection, volume measurement |

1D machine vision systems work best for items moving on conveyor belts. You can use them for barcode reading or inspecting materials like paper and metal as they move. These systems analyze data one line at a time, making them fast and efficient for continuous inspection.

2D systems capture flat images. You will use them for tasks like label checking, surface inspection, and defect detection. These systems are cost-effective and easy to set up. They work well for checking the quality of stationary objects or guiding pick-and-place robots.

3D machine vision systems add depth to the inspection process. They use advanced sensors and software to measure height, volume, and shape. You will see these systems in industries that need precise measurements, such as automotive and aerospace. Although 3D systems are more complex and expensive, they provide the accuracy needed for high-quality manufacturing.

Note: 2D systems are great for surface-level inspections, while 3D systems help you measure and guide robots with high precision.

Inspection Systems

Inspection systems play a key role in automated quality control. You can use them to check products, materials, or processes against set standards. These systems use cameras and sensors to capture images, then software analyzes the data for defect detection, measurement, and sorting.

- Inspection systems fit into all types of machine vision systems:

- 1D inspection systems check continuous materials for defects or read barcodes.

- 2D inspection systems look for surface flaws, verify labels, and ensure product quality.

- 3D inspection systems measure thickness, height, and shape, guiding robots and checking assembly accuracy.

You will see inspection systems working with automation to improve quality and efficiency. They provide real-time feedback, allowing you to catch problems early and reduce waste. Automated inspection systems also lower manual labor costs and keep your production line running smoothly.

Inspection systems help you maintain high quality by detecting defects, tracking process stability, and supporting continuous improvement. They operate with minimal human intervention, making your manufacturing process more reliable and productive.

Core Components

Cameras and Sensors

You will find that the camera acts as the eyes of any image processing machine vision system. The camera captures images of objects, which the system then analyzes. You can choose from several types of cameras, each with its own strengths. Area scan cameras take 2D pictures and work well for objects that do not move quickly. Line scan cameras capture one line at a time, making them perfect for items moving on conveyor belts. If you need to measure depth or shape, 3D vision cameras give you a full view of the object’s surface.

Some cameras use special sensors. For example, infrared and thermal cameras detect heat, which helps you spot problems that are invisible to the human eye. Multispectral and hyperspectral cameras can see details across many wavelengths, revealing hidden defects or material differences. Smart cameras combine image capture and processing in one device, making them easy to install in tight spaces.

The sensor inside the camera plays a big role in how much image detail you can see. Larger sensors collect more light, which improves image quality and dynamic range. This helps you get better results in low-light conditions. The resolution of the camera, or the number of pixels, determines how much detail you can capture. Higher resolution lets you spot smaller defects, but it may slow down processing if you do not have enough computing power. You need to balance sensor size, pixel size, and resolution to get the best accuracy for your application.

Tip: Choose a camera with the right sensor and resolution for your inspection task. For tiny defects, use a high-resolution camera. For fast-moving items, pick a camera with a high frame rate.

You also need to consider the type of sensor. CMOS sensors work well for high-speed tasks and use less power. CCD sensors offer higher sensitivity and image quality, which is useful for detailed inspections. The right camera and sensor setup ensures your image processing machine vision system delivers accurate, reliable results.

Lighting

Lighting is just as important as the camera in any image processing machine vision system. Good lighting helps you capture clear images by reducing shadows and glare. You can use different lighting techniques based on what you need to inspect.

- Backlighting puts the light behind the object. This creates a strong silhouette, making it easy to see edges, holes, or gaps.

- Diffuse lighting spreads light evenly, which helps you inspect shiny or uneven surfaces without harsh reflections.

- Dark field lighting shines light at a low angle. This highlights scratches or dents by making them stand out against a dark background.

- Ring, bar, and dome lights give you more control. Ring lights reduce shadows on small parts. Bar lights highlight edges. Dome lights surround the object, removing shadows and reflections.

You must match the lighting to the object’s surface and the inspection goal. For example, shiny parts need diffuse or dome lighting to avoid glare. Transparent items work best with backlighting. You can also use advanced techniques like LED pulsing and strobing. These methods sync the light with the camera, which helps you capture sharp images of moving objects and saves energy.

Lighting challenges can include getting the right intensity, avoiding motion blur, and adapting to different object shapes. You can solve these problems by using high-intensity LEDs, modular lenses, and smart controls that adjust brightness and timing. Early testing with real samples helps you find the best lighting setup.

Note: Never overlook lighting when designing your system. The right lighting makes defect detection easier and improves the accuracy of your inspections.

Processing and Software

After the camera captures an image, the processing and software take over. The processing unit, which can be a CPU, GPU, or even a smart camera, runs image processing algorithms. These algorithms clean up the image, find patterns, and measure features. You can use commercial software like Cognex Vision Pro or open-source libraries such as OpenCV. Some systems offer no-code solutions, letting you set up inspections with drag-and-drop tools.

| Software Type | Examples | Key Features and Capabilities |

|---|---|---|

| Commercial Software | Cognex Vision Pro, MVTec Halcon, Matrox Imaging Library (MIL) | Pattern matching, deep learning, GPU acceleration, easy integration with factory automation |

| Open-Source Libraries | OpenCV, Scikit-image, TensorFlow | Fast image processing, segmentation, feature extraction, deep learning support |

| No-Code Solutions | MVTec MERLIC, Zebra Aurora | Drag-and-drop setup, real-time feedback, accessible for non-programmers |

You need real-time processing to keep up with fast production lines. High-speed processors and optimized software let you inspect up to hundreds of parts per second. Real-time feedback means you can catch defects right away and make quick decisions. Advanced systems use AI and machine learning to improve accuracy and adapt to new inspection tasks.

Communication interfaces connect your image processing machine vision system to other equipment. Modern systems use Ethernet, which lets you link directly to robots, PLCs, and factory networks. This setup reduces hardware costs and makes it easier to scale up. You can also use serial ports or discrete I/O for older machines. Supporting multiple protocols ensures your system works with different types of automation equipment.

Tip: Real-time data and analytics help you track performance, reduce waste, and improve efficiency. Make sure your system can handle large data volumes and integrate with your factory’s network.

When you select the right cameras, lighting, and processing software, you build a machine vision system that delivers high-speed, high-accuracy inspections. Each component must work together to give you reliable results and easy integration with your automation setup.

Applications and Benefits

Defect Detection

You can rely on machine vision systems for fast and accurate defect detection in many industries. These systems inspect surfaces for scratches, dents, discoloration, and other flaws. You will see them used in metal, plastic, textile, food, and pharmaceutical production. Machine vision checks metal parts for dimensional accuracy, weld quality, and internal defects. Automotive, aerospace, and heavy machinery companies depend on these systems to ensure safety and reliability. AI and machine learning help improve detection accuracy over time. Real-time feedback allows you to catch defective products early and reduce waste.

- Surface inspection finds scratches, dents, and contaminants.

- Metal parts inspection checks welds and dimensions.

- Automated visual inspection achieves detection rates above 99%.

- AI-driven systems reach up to 99.5% accuracy.

- Companies report up to 75% fewer defects and a 78% drop in returns.

You can also use machine vision for object detection and counting. This helps track items on the line and ensures only high-quality products move forward.

Quality Control

Machine vision systems transform quality control by automating inspection tasks. You can detect even the smallest defects that humans might miss. These systems keep inspection speed high and maintain consistent quality across long production runs. Real-time data analysis lets you spot trends and fix problems quickly. You can use machine vision for cap inspection, label checks, marking verification, and packaging inspection. Integration with Manufacturing Execution Systems (MES) gives you better data for decision-making.

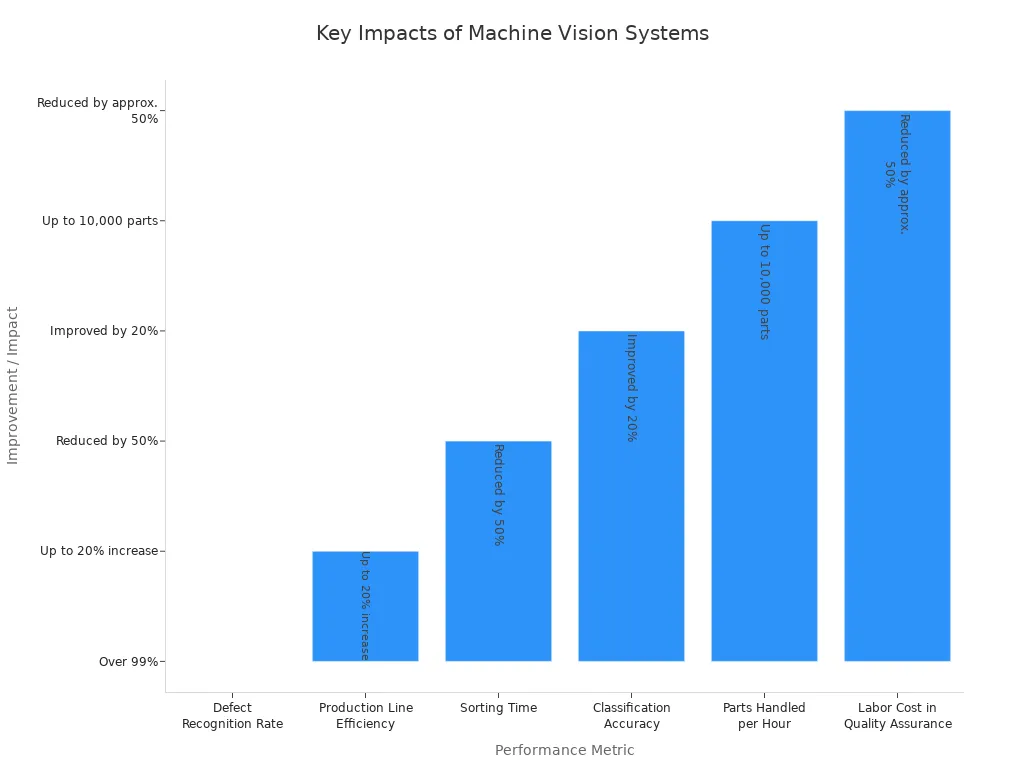

| Improvement Aspect | Result |

|---|---|

| Defect Escape Rate Reduction | Up to 94% fewer missed defects |

| Detection Accuracy | 99.7% for critical defects |

| Labor Cost Reduction | 68% lower quality control labor costs |

| Rework Reduction | 41% decrease in rework |

| Inspection Speed and Consistency | Continuous, reliable operation |

You gain improved product quality, fewer defective products, and higher customer satisfaction. Machine vision also supports object detection and counting, which helps you keep track of every item.

Automation and Efficiency

You boost automation and efficiency when you use machine vision systems. Automated inspection, orientation, and rejection tasks speed up production and reduce bottlenecks. You lower labor costs and cut human error by letting machines handle repetitive inspection work. Machine vision enables real-time monitoring, trend analysis, and predictive maintenance. This helps you optimize processes and prevent downtime.

- Automation of inspection and sorting tasks increases productivity.

- Enhanced quality control ensures product consistency.

- Real-time data collection supports process improvements.

- Safer work environments protect workers from hazards.

- High-speed, unsupervised inspection keeps production moving.

Companies report significant cost savings, better inventory control, and improved workplace safety. You can adapt quickly to changes in production without adding more staff. Machine vision systems help you deliver high-quality products, reduce defective products, and keep your operations running smoothly.

Industries Using Machine Vision

Manufacturing

You see machine vision systems everywhere in the manufacturing industry. These systems help you with tasks like barcode reading, counting, and quality checks. In North America, automotive manufacturing leads the way, holding almost half the market share by 2025. Globally, electronics and semiconductor companies use machine vision the most, with about 29% of the market. Automotive follows with 25%. You use machine vision for predictive maintenance, inventory management, and logistics. Barcode scanning and OCR help you track parts and products. You can spot defects, guide robots, and make sure every item meets your standards. A 360-degree bottle inspection system boosts production and cuts recalls. Defect detection systems improve productivity by up to 50%. When you connect machine vision with robotics and PLCs, you get real-time decisions and faster production.

- Common uses:

- Barcode reading and OCR for tracking

- Counting and sorting parts

- Quality control and defect detection

- Monitoring equipment for maintenance

Healthcare

You find machine vision systems in many healthcare settings. AI-driven tools help you read X-rays, CT scans, and MRIs. These systems use OCR to spot patterns and help doctors find diseases early. Deep learning models analyze huge sets of images, improving accuracy and saving time. In dental care, AI tools like Pearl and Overjet read dental X-rays, detect cavities, and measure bone loss. These tools use OCR to mark images and automate measurements. You get faster, more reliable results and fewer errors. AI also helps with tasks like insurance checks and billing, making clinics run smoother.

- Key benefits:

- Early disease detection

- Real-time clinical support

- Consistent, accurate diagnoses

- Reduced workload for staff

Automotive

You rely on machine vision in automotive manufacturing for many reasons. These systems check for defects in metal, glass, and seals. OCR and barcode reading track every part through production. You use machine vision for error proofing, making sure workers use the right tools and parts. Automated inspection and counting keep your line moving fast. You catch defects early, reduce waste, and improve product quality. Machine vision helps you meet safety rules and overcome labor shortages by automating repetitive tasks.

- Main uses:

- Defect detection and error proofing

- OCR and barcode reading for traceability

- Counting and sorting components

- Monitoring worker safety

Agriculture

You see machine vision changing how you grow and harvest crops. These systems help with crop monitoring, yield estimation, and pest detection. Automated robots use machine vision for harvesting, checking fruit size, color, and firmness. Hyperspectral imaging sorts fruit by sweetness and nutrients. AI-powered systems spot diseases early, helping you save crops. Livestock management uses machine vision for counting and health checks. You use OCR and barcode tags to track animals and equipment. Machine vision helps you use resources better, reduce labor costs, and increase profits.

- Applications:

- Crop and livestock monitoring

- Automated harvesting and sorting

- Disease and pest detection

- Counting and tracking with barcode and OCR

Tip: Machine vision systems help you improve efficiency, accuracy, and quality in every industry. You can use them for barcode reading, OCR, counting, and monitoring to get better results and stay ahead in your field.

You see imaging system machine vision systems changing how you achieve quality in many industries. These systems use cameras, lighting, and smart software to inspect products and improve quality control. You get real-time feedback, which helps you spot defects and keep quality high. Companies report faster production, better sorting, and fewer errors. You can use these systems for quality control in manufacturing, healthcare, and more. The market keeps growing as more businesses want better quality and automation.

If you want to boost quality and efficiency, explore how machine vision can help your work. Look for new trends in AI and IoT to make your quality control even stronger.

FAQ

What is the main purpose of a machine vision system?

You use a machine vision system to inspect and analyze objects automatically. This helps you find defects, measure parts, and guide machines. You improve quality and speed in your work.

Can you use machine vision systems outside factories?

Yes! You find machine vision in healthcare, farming, and even traffic control. These systems help doctors read X-rays, farmers check crops, and cities monitor roads.

How do you choose the right camera for your system?

You pick a camera based on what you need to inspect. For tiny defects, use a high-resolution camera. For fast-moving items, choose a camera with a high frame rate.

Tip: Test different cameras with your real products before making a final choice.

Do machine vision systems need special lighting?

Yes, good lighting is very important. You use special lights to reduce shadows and glare. The right lighting helps your camera see details and spot defects more easily.

See Also

Understanding Machine Vision Systems For Semiconductor Applications

An Overview Of Image Processing In Vision Systems

How To Properly Position Equipment In Vision Systems