Image pre-processing machine vision system plays a crucial role in modern machine vision systems. Pre-processing serves as the bridge between capturing digital images and extracting valuable information. This step removes noise, improves image quality, and prepares data for analysis. The process enhances accuracy and reliability in machine vision systems.

- Defect detection accuracy rises from 93.5% to 97.2% after preprocessing.

- Barcode verification accuracy in machine vision systems exceeds 99% with preprocessing.

Preprocessing optimizes images for feature extraction, segmentation, and interpretation, making it foundational for every image pre-processing machine vision system.

Key Takeaways

- Image pre-processing improves image quality by removing noise and adjusting brightness, which helps machine vision systems detect features more accurately.

- Techniques like noise reduction, normalization, resizing, and edge detection prepare images for better analysis and faster, more reliable results.

- Pre-processing boosts accuracy in defect detection and quality control, reducing errors and speeding up inspection processes.

- Real-world applications in industries like manufacturing and pharmaceuticals rely on pre-processing to automate inspections and ensure product quality.

- To build effective machine vision systems, use high-quality cameras, apply key pre-processing steps, optimize data flow, and monitor performance regularly.

Role in Machine Vision Systems

Enhancing Image Quality

Image pre-processing machine vision system stands as a vital link between image acquisition and image processing software in modern machine vision systems. After cameras capture images, pre-processing steps such as noise reduction, contrast enhancement, and normalization come into play. These operations address issues caused by lighting, humidity, and camera limitations. By correcting these defects, pre-processing ensures that the images sent to image processing software are clear and consistent. This step helps enhance the quality of the data, making it easier for computer vision algorithms to identify shapes, colors, and defects.

High-quality images lead to more reliable vision results. When image pre-processing improves clarity, image processing software can extract features with greater precision. This improvement supports real-time analysis, which is essential for applications that require immediate feedback, such as automated inspection or robotics.

Preparing Data for Analysis

Machine vision systems rely on accurate data for automated decision-making. Image pre-processing prepares raw images for further analysis by computer vision and image processing software. Techniques like resizing, normalization, and noise reduction ensure that images meet the input requirements of neural networks and other algorithms. For example, resizing images allows them to fit the expected dimensions of image processing software, while noise reduction removes unwanted artifacts that could confuse the system.

A technical report shows that optimized preprocessing increases correlation coefficients from 0.7 to 0.89 and reduces RMSE from 5.6 to 3.4 µg/m3. These improvements demonstrate how image pre-processing machine vision system boosts the accuracy and reliability of automated decisions.

- Machine vision systems use pre-processing to deliver consistent results in real-time analysis.

- Image processing software benefits from enhanced input, leading to better feature extraction and object recognition.

Image Pre-processing Techniques

Modern machine vision relies on a range of image pre-processing techniques to prepare data for analysis. These methods address challenges such as noise, artifacts, and inconsistent feature visibility. By applying targeted image processing steps, engineers can improve the quality and reliability of results from image processing software. The following sections describe the most important techniques used in image enhancement, image restoration, and image manipulation.

Noise Reduction

Noise often appears in raw images due to sensor limitations or environmental factors. Effective noise reduction improves image clarity and supports accurate image processing. Common noise reduction methods include:

- Median Filtering: Replaces each pixel with the median value of its neighbors, removing salt-and-pepper noise while preserving edges.

- Bilateral Filtering: Smooths the image while keeping edges sharp by considering both spatial and intensity differences.

- Gaussian Filtering: Applies a Gaussian kernel to blur the image, reducing random noise but sometimes softening edges.

- Wavelet Denoising: Transforms the image into the wavelet domain, filters out noise, and reconstructs the image, preserving fine details.

- Non-Local Means Denoising: Compares all pixels to find similar patches, averaging them to reduce noise while maintaining texture.

These image processing techniques help remove unwanted artifacts and prepare images for further analysis.

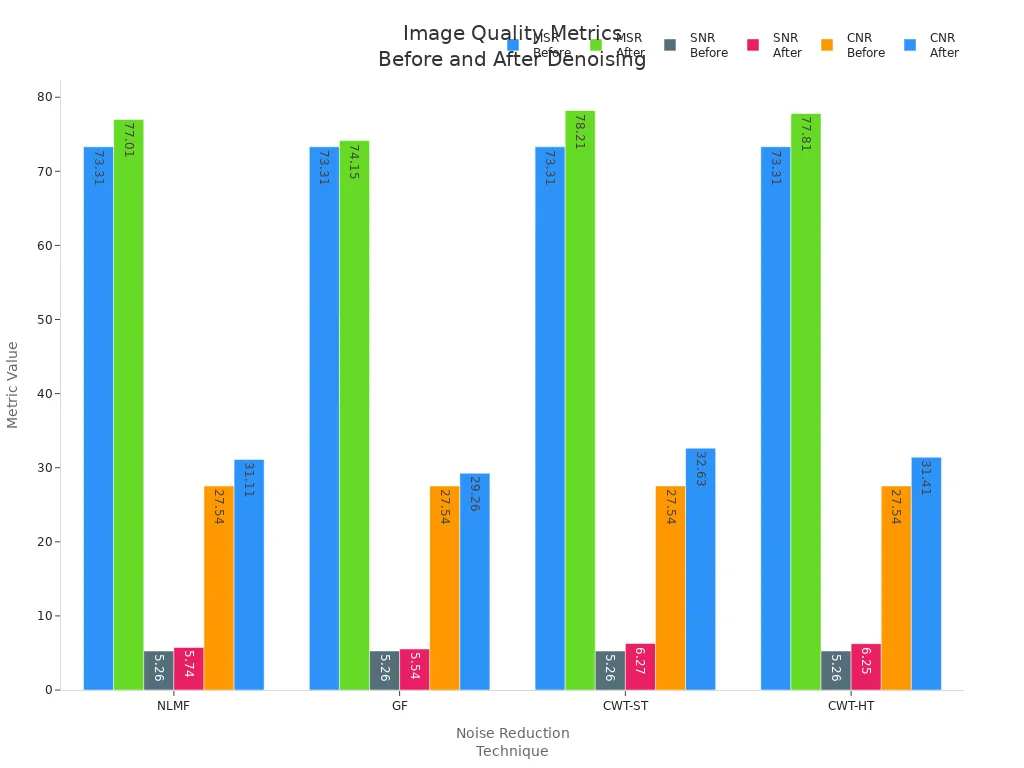

The effectiveness of noise reduction can be measured using quantitative metrics. The table below shows improvements in image quality after applying different noise reduction methods:

| Technique | Metric | Before Denoising | After Denoising |

|---|---|---|---|

| Non-Local Means Filter | MSR | 73.31 | 77.01 |

| SNR | 5.26 dB | 5.74 dB | |

| CNR | 27.54 dB | 31.11 dB | |

| Gaussian Filtering | MSR | 73.31 | 74.15 |

| SNR | 5.26 dB | 5.54 dB | |

| CNR | 27.54 dB | 29.26 dB | |

| Wavelet-based (CWT-ST) | MSR | 73.31 | 78.21 |

| SNR | 5.26 dB | 6.27 dB | |

| CNR | 27.54 dB | 32.63 dB | |

| Wavelet-based (CWT-HT) | MSR | 73.31 | 77.81 |

| SNR | 5.26 dB | 6.25 dB | |

| CNR | 27.54 dB | 31.41 dB |

Noise reduction not only improves image enhancement but also supports robust image restoration and image manipulation in machine vision.

Contrast and Brightness

Adjusting contrast and brightness is essential for image enhancement and image processing. These adjustments make features more visible and help image processing software detect important details. Key algorithms include:

- Histogram Equalization: Redistributes pixel intensities for a uniform histogram, improving visibility in dark or bright areas.

- Contrast Stretching: Expands the intensity range, making features stand out.

- Gamma Correction: Adjusts brightness non-linearly, fine-tuning mid-tones and preserving highlights and shadows.

- Contrast-Limited Adaptive Histogram Equalization (CLAHE): Enhances local contrast by computing histograms for small tiles, limiting noise amplification.

- Log Local Color Correction (LLCC): Uses logarithmic tone mapping to improve contrast in both dark and bright regions.

Enhanced contrast and brightness help image processing software detect defects, distinguish objects, and improve quality assurance.

Contrast and brightness adjustments play a critical role in image enhancement, supporting accurate feature extraction and reliable image manipulation.

Normalization and Resizing

Normalization and resizing standardize images for consistent input to image processing software. These steps are vital for machine learning models and image processing pipelines. Normalization transforms pixel values to a common scale, reducing bias and improving model focus on patterns. Resizing ensures images fit the expected dimensions, balancing accuracy and computational cost.

- Resizing images to 256×256 or 320×320 pixels achieves optimal recognition performance.

- Very low resolutions reduce diagnostic quality, while intermediate resolutions improve performance but remain suboptimal.

- Maintaining aspect ratio during resizing preserves important features and prevents recognition errors.

- AI-powered resizing methods adapt to image-specific features, further enhancing recognition accuracy.

Normalization techniques such as Min-Max Scaling and Standardization speed up model training and improve recognition accuracy. Binning reduces noise and standardizes intensity variations, supporting robust image processing and image restoration.

Normalization and resizing accelerate training, reduce computational resources, and improve the consistency of image processing software outputs.

Edge Detection and Binarization

Edge detection and binarization highlight important structures in images, supporting accurate measurement and object recognition. These image processing steps are crucial for industrial inspection and quality control.

- Edge detection algorithms identify boundaries between objects and backgrounds.

- Binarization converts grayscale images to black-and-white, simplifying analysis for image processing software.

The table below summarizes improvements in detection accuracy after applying these techniques:

| Metric | Before Improvement | After Improvement | Notes |

|---|---|---|---|

| Edge detection error | 0.0305 | 0.0108 | Error reduced by ~65%, improving accuracy |

| Measurement accuracy | Improved | Improved | Meets engineering practice requirements |

| Error trend with samples | N/A | Decreasing | Accuracy improves with more measurements |

Edge detection accuracy remains within ±2 pixels, and alignment accuracy within ±15 microns, even under varying lighting and angles. These results support high-quality production and real-time image processing.

Edge detection and binarization enable precise image manipulation, image enhancement, and image restoration, making them essential for advanced image processing software.

Impact on Image Processing

Improving Accuracy

Pre-processing plays a vital role in machine vision systems by improving the accuracy of downstream image processing and computer vision tasks. When engineers apply artifact removal, tissue segmentation, and color normalization, they reduce non-informative data and variability in images. These steps help eliminate artifacts that could cause diagnostic errors and address differences in staining or scanning. As a result, models receive higher-quality input, which leads to better classification and prediction outcomes in digital pathology and other fields.

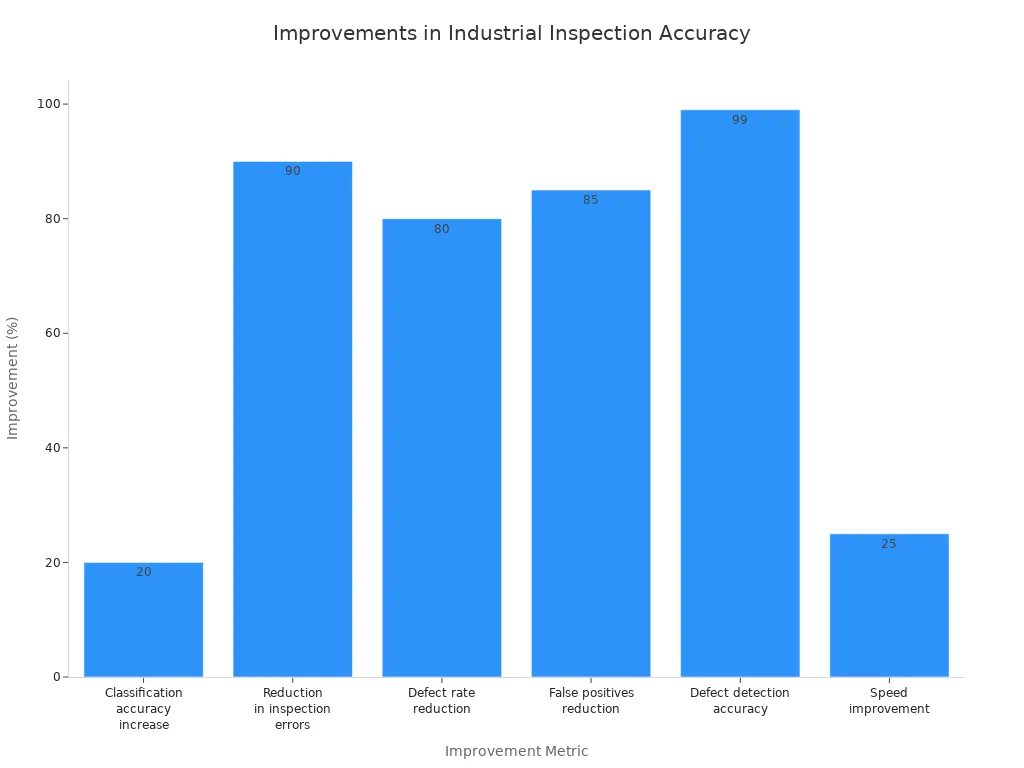

In industrial inspection, pre-processing techniques such as geometric transformations and photometric adjustments enhance image alignment and quality. These improvements allow machine vision systems to recognize defects more accurately and reduce errors. Data augmentation, including synthetic defect generation and standardization of imaging conditions, further boosts robustness and accuracy. AI-driven visual inspection systems that use these methods can achieve up to 99% defect detection accuracy and reduce inspection time by 25%.

| Improvement Metric | Measurable Improvement |

|---|---|

| Classification accuracy increase with deep learning | 20% increase over traditional algorithms |

| Reduction in inspection errors vs. manual inspection | Over 90% reduction |

| Defect rate reduction with automated inspection | Up to 80% reduction |

| False positives reduction in defect detection | 85% reduction |

| Defect detection accuracy of AI-driven systems | Up to 99% accuracy |

| Speed improvement in part inspection | 25% faster inspection |

Pre-processing also supports object detection and image recognition by filtering out poor-quality images. This filtering step enables models to extract better features and achieve state-of-the-art performance in tasks such as drug inhibition prediction and compound classification.

Reducing Errors

Machine vision systems depend on high-quality input to minimize errors in object detection, image recognition, and quality control. Pre-processing enhances image quality by removing noise, adjusting brightness, and sharpening edges. These steps make features clearer and easier for algorithms to analyze. For example, advanced filtering methods like Median-Mean Hybrid filtering and Unsharp Masking with Bilateral Filter improve efficiency by up to 87.5%. These improvements lead to faster and more reliable processing.

Object detection and classification tasks benefit from refined pre-processing algorithms. When engineers use techniques such as Canny edge detection and illumination correction, they maintain accuracy even in low-light or shadowed environments. In one case, refining pre-processing lowered mean square error from 0.02 to 0.005 and increased recognition accuracy from 58% to 74%.

Quality control systems also see fewer errors after pre-processing. Key improvements include:

- Enhanced image quality through contrast, brightness, and noise removal.

- Segmentation that isolates regions of interest, helping algorithms focus on products rather than backgrounds.

- Proper camera positioning and lighting to eliminate shadows and glare.

- Clean, high-quality images for AI models, enabling precise defect detection.

These steps ensure that machine vision systems deliver consistent, accurate results in real-time object detection, image recognition, and quality control.

Real-world Applications

Industrial Inspection

Machine vision systems have transformed industrial inspection by automating tasks that once required manual labor. In semiconductor manufacturing, image processing detects defects on die surfaces with high precision. Algorithms and machine learning models, such as convolutional neural networks, analyze images for scratches, cracks, and misalignments. These systems adapt to changing production conditions, learning from new data to maintain quality standards. Noise reduction, contrast enhancement, and image registration improve image quality, making defect detection more reliable.

Frame grabbers play a key role in these machine vision systems. They handle image pre-processing tasks like data formatting and initial checks, reducing the workload on the main processor. With features such as Direct Memory Access and synchronization, frame grabbers support real-time inspection across multiple cameras. This hardware integration ensures fast, accurate, and reliable vision analysis, even in high-speed environments.

Case studies show that combining image pre-processing with advanced analytics leads to better inspection results. For example, resizing and cropping images allow deep learning models to classify metallic surfaces and microstructures with high accuracy, even when using small datasets. These improvements help manufacturers achieve real-time analysis, reduce costs, and optimize resources.

Automated Quality Control

Automated quality control relies on machine vision systems to ensure products meet strict standards. Image pre-processing enhances the clarity of images, allowing vision algorithms to spot defects like incomplete packaging, incorrect labeling, or surface irregularities. In industries such as pharmaceuticals and food processing, these systems check for product completeness and safety.

Machine vision systems use real-time monitoring to catch errors as they happen. Automated visual inspection identifies missing parts, assembly mistakes, and texture issues. Dimensional measurement tools verify diameters, coating thickness, and alignment, supporting precision engineering. Sorting and classification tasks use vision to group items by size, shape, or color, improving efficiency.

Integrating image pre-processing with deep learning models boosts the performance of computer vision applications. Techniques like normalization, binarization, and contrast adjustment prepare data for neural networks, increasing accuracy and reducing computational load. These advances make real-time quality control possible, even in complex or fast-moving production lines.

Machine vision systems with robust image pre-processing deliver consistent, high-quality inspection and quality control, supporting safer products and more efficient manufacturing.

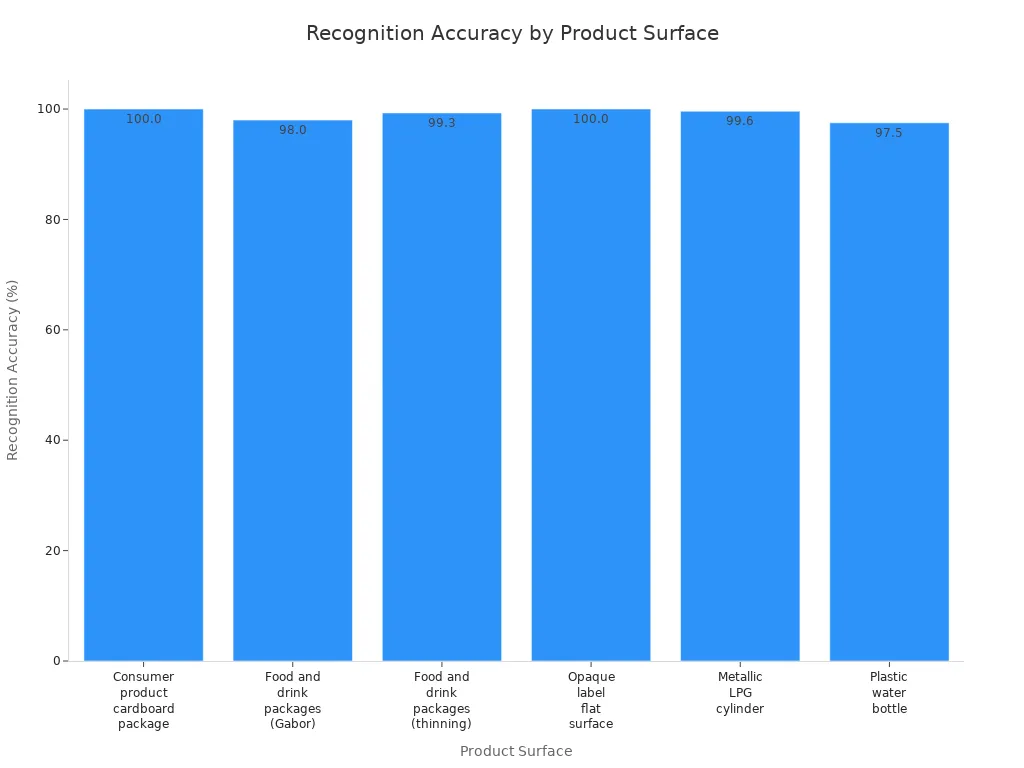

Image pre-processing stands as a foundation for successful machine vision systems. It improves image quality, supports real-time analysis, and ensures reliable results. Techniques such as noise reduction, normalization, and contrast enhancement increase recognition accuracy across diverse surfaces, as shown below:

| Preprocessing Techniques | Product Surface | Recognition Accuracy |

|---|---|---|

| Image binarization | Consumer product cardboard package | 100.0% |

| Morphological processing, binarization, contour extraction | Plastic water bottle | 97.5% |

Key steps for organizations to implement robust pre-processing in real-time vision pipelines include:

- Select high-speed, high-accuracy vision cameras for quality image capture.

- Apply processing techniques like normalization and noise reduction.

- Optimize real-time data flow and processing speed.

- Use multiprocessing to handle multiple frames efficiently.

- Monitor performance metrics to maintain reliability.

These steps help vision systems deliver high-quality, real-time results in demanding environments. Pre-processing remains essential for modern image processing pipelines, enabling accurate, efficient, and reliable vision applications.

FAQ

What is image pre-processing in machine vision?

Image pre-processing prepares raw images for analysis. It removes noise, adjusts brightness, and enhances features. This step helps machine vision systems achieve better accuracy and reliability.

Why do machine vision systems need noise reduction?

Noise reduction improves image clarity. It removes unwanted artifacts that can confuse algorithms. Engineers use filters like median or Gaussian to make features stand out for better detection.

How does normalization help machine vision models?

Normalization scales pixel values to a standard range. This process ensures that models receive consistent input. It speeds up training and improves recognition accuracy.

Can pre-processing speed up real-time inspection?

Yes. Pre-processing simplifies images and removes irrelevant data. This allows machine vision systems to analyze images faster and make quick decisions in real-time environments.

Which industries benefit most from image pre-processing?

Industries like manufacturing, pharmaceuticals, and food processing use image pre-processing. It helps them detect defects, ensure quality, and automate inspection tasks efficiently.

See Also

Understanding How Machine Vision Systems Process Images

Top Libraries Used In Advanced Image Processing Vision

The Importance Of Image Recognition In Vision Quality Control

Fundamental Principles Behind Edge Detection In Machine Vision