Imagine a factory where a camera captures every product for inspection. If the image quality drops, the system might miss tiny defects or misclassify objects. Image preprocessing prepares raw images by removing noise, adjusting contrast, and correcting color, which stabilizes image quality and boosts inspection accuracy. Post-processing comes after the initial analysis, fixing artifacts and ensuring reliable results in the image post-processing machine vision system.

- Studies show that improving image quality with preprocessing steps like resizing, normalization, and enhancement can raise detection accuracy up to 99%, speed up inspection by 40%, and reduce defect rates.

- High-quality image preprocessing and careful post-processing both play a vital role in achieving consistent inspection outcomes.

Key Takeaways

- Image preprocessing cleans and improves raw images to help machine vision systems detect objects and defects more accurately.

- Post-processing refines analysis results by removing artifacts and highlighting important features for reliable inspection.

- Good preprocessing and post-processing together boost detection accuracy, speed up inspections, and reduce errors in industrial applications.

- Choosing the right methods depends on factors like image quality, environment, system speed, and cost to achieve the best results.

- Following best practices, such as testing with real data and balancing speed and accuracy, leads to more effective and reliable machine vision systems.

Definitions

Image Preprocessing

Image preprocessing changes raw image data into a format that computer vision systems can use. This step removes unwanted distortions and improves qualities that matter for computer vision. Many computer vision systems use preprocessing as the first step in their workflow. Common techniques include resizing, grayscaling, noise reduction, normalization, binarization, and contrast enhancement. These methods help prepare the image for later steps like segmentation and feature extraction.

CMOS and CCD sensors both capture images, but they handle data differently. CCD sensors send out an analog signal, which needs digitizing and extra preprocessing steps. These steps might include gamma correction, median filtering to fix bad pixels, and lens correction to fix distortions. CMOS sensors digitize each pixel directly, which allows for flexible image capture and sometimes reduces the need for extra postprocess machine vision system steps. Both sensor types use color filter arrays, so they need complex algorithms to turn raw data into a usable image.

Preprocessing is important because it sets the stage for accurate analysis. If the image is not clear or has too much noise, computer vision systems may not work well. Good preprocessing helps computer vision systems find objects and defects more easily.

Image Post-Processing Machine Vision System

The image post-processing machine vision system works after the main analysis. This step fixes artifacts, sharpens details, and removes unwanted effects from earlier processing. Postprocess machine vision system steps often include edge enhancement, noise reduction, and color artifact removal. The amount of post-processing needed depends on the sensor type and the quality of the original image.

In a postprocess machine vision system, the goal is to make sure the final image supports reliable decisions. For example, after object detection, the system might use post-processing to highlight defects or clean up the image for reporting. Both CMOS and CCD sensors can create images that need post-processing, but CMOS sensors often need less because they handle some corrections during capture.

Distinguishing between preprocessing and post-processing matters for system performance and accuracy. Preprocessing prepares the image for computer vision, while post-processing ensures the results are clear and useful. When engineers understand both steps, they can design better computer vision systems and improve the results of the image post-processing machine vision system.

Workflow Differences

Preprocessing Steps

In a typical machine vision workflow, preprocessing happens right after the system captures an image. This step prepares the image for further analysis and detection. The workflow usually follows these stages:

- Image or video processing (preprocessing at this early stage)

- Labeling

- Model training

- Model predictions

- Model corrections (postprocess machine vision system)

- Model deployment

Preprocessing improves image quality and makes detection more reliable. Industrial computer vision systems use several common preprocessing techniques:

- Filtering and noise reduction: Filters like median or wavelet-based filters remove unwanted noise. This step helps the system see important features more clearly.

- Contrast and brightness adjustment: Methods such as histogram equalization make features stand out, which helps with detection.

- Morphological operations: Erosion, dilation, and other operations refine the image structure and remove small artifacts.

- Feature extraction: Edge detection and texture analysis prepare the image for classification and detection.

- Advanced hardware-based preprocessing: Some systems use real-time FPGA or in-sensor processing to filter and enhance images as they are captured.

Tip: Real-time preprocessing is important for applications that need fast detection, such as robotic guidance or automated inspection.

Noise reduction during preprocessing greatly improves the accuracy of detection. For example, studies show that wavelet-based denoising combined with deep learning models can raise segmentation accuracy from 93% to 99%. This means the system finds objects and defects more reliably, even in challenging conditions.

However, not every preprocessing step always helps. Contrast enhancement can increase the number of features detected, but it may also lower the precision of detection. The effect depends on the type of image and the detection task.

Preprocessing in 2D systems focuses on noise reduction and contrast enhancement. In 3D systems, preprocessing includes capturing and processing XYZ data, which allows for more stable detection of small dents or flaws.

Postprocess Machine Vision System

The postprocess machine vision system comes into play after the main detection and analysis steps. This stage focuses on refining results and ensuring the reliability of the final output. Post-processing often includes:

- Artifact removal: Algorithms detect and remove unwanted patterns, such as stripes or equipment errors, that can distort the image.

- Edge enhancement and sharpening: These steps make important features clearer for final inspection or reporting.

- Noise reduction: Sometimes, additional filtering is needed to clean up the image after detection.

- Highlighting defects: The system may mark or outline detected defects to make them easier to review.

The postprocess machine vision system is especially important when the original image quality cannot be improved during capture. Artifact removal at this stage restores image quality and reduces the risk of misinterpretation. For example, removing stripe artifacts improves the structural integrity of the image, making detection results more trustworthy.

Note: Combining manual and automated post-processing methods often gives the best results in real-time industrial applications.

The requirements for postprocess machine vision system steps differ between 2D and 3D systems. In 2D, post-processing usually measures defect sizes or verifies features. In 3D, it uses volumetric data for tasks like coplanarity checks, which are not possible with 2D alone.

The impact of preprocessing and postprocess machine vision system steps on detection and image quality is clear. Preprocessing sets the stage for accurate detection by improving image quality and reducing noise. Post-processing ensures that the final results are reliable and easy to interpret, even when real-time constraints or equipment limits affect the original image.

| Step | Main Techniques Used | Impact on Detection and Image Quality |

|---|---|---|

| Preprocessing | Noise reduction, contrast adjustment, morphological ops, feature extraction, real-time filtering | Improves image quality, boosts detection accuracy, prepares for analysis |

| Postprocess machine vision system | Artifact removal, edge enhancement, noise reduction, defect highlighting | Restores image quality, ensures reliable detection, supports final decisions |

Machine learning plays a key role in both preprocessing and postprocess machine vision system steps. Feature extraction during preprocessing helps computer vision models generalize better. Post-processing refines model outputs, making detection results more meaningful and reliable for computer vision systems.

Inspection and Object Detection

Object Detection Machine Vision System

An object detection machine vision system uses advanced image analysis to find, classify, and track objects in real-time. Preprocessing steps play a key role in making detection more accurate. For example, engineers use noise reduction, contrast enhancement, and edge detection to improve image quality before running object detection algorithms. The table below shows common preprocessing techniques and their uses in object detection machine vision systems:

| Technique Category | Specific Techniques / Methods | Purpose / Application Example |

|---|---|---|

| Image Acquisition | High-resolution cameras, proper lighting | Capture clear, detailed images; avoid shadows (e.g., manufacturing inspection) |

| Preprocessing | Noise reduction, contrast enhancement, edge detection | Improve image quality for better analysis |

| Filtering | Gaussian filter (noise smoothing), Sobel filter (edge detection), Histogram equalization (contrast enhancement) | Enhance image quality and highlight features |

| Morphological Operations | Erosion, Dilation, Opening, Closing | Shape manipulation for noise removal, object identification |

Post-processing also improves detection results. After object detection algorithms identify objects, post-processing steps like denoising, dehazing, and illumination enhancement make features clearer. These steps help the object detection machine vision system work well even in low-contrast or blurry images. Some systems use transformer-based models that simplify post-processing by improving classification and localization accuracy, especially for complex defects.

Inspection Applications

Inspection in industrial automation relies on both preprocessing and post-processing to ensure high-quality results. Automated inspection systems use preprocessing to remove noise and highlight important features, making it easier for object detection algorithms to find defects. Post-processing then analyzes the detected features and helps make pass/fail decisions. This process supports real-time defect detection and automated quality control.

Accurate image analysis allows manufacturers to automate inspection tasks, reduce labor costs, and improve product consistency. Real-time detection enables fast sorting and classification, which keeps production lines moving smoothly. Automated inspection systems can detect a wide range of defects, such as labeling errors, barcode problems, and print quality issues. These systems use deep learning models for defect detection, which learn from example images and improve over time.

Quality assurance benefits from reliable detection and classification. AI-powered inspection systems achieve over 99.5% accuracy in defect detection, outperforming traditional methods. Real-time monitoring also improves workplace safety and supports predictive maintenance. Industrial automation systems that use object detection machine vision systems and advanced image analysis help manufacturers future-proof their operations and maintain high standards for quality control.

Choosing the Right Approach

Factors to Consider

Selecting the right preprocessing and post-processing methods shapes the success of any machine vision system. Engineers must weigh several factors to ensure high-quality results and effective automation.

- Data quality stands as a top priority. The system must handle noise, lighting changes, and sensor errors. Noise reduction, such as Gaussian or wavelet denoising, improves edge clarity and supports real-time analytics.

- The choice of preprocessing filters depends on the type of noise and the need for stable detection. Projection processing can average image intensity, reducing false detections. Differential processing highlights edges, making object boundaries clearer.

- Environmental conditions, like lighting and background, affect preprocessing choices. Engineers often experiment with different algorithms to find the best fit for real-time quality control.

- System speed matters for real-time applications. Some preprocessing steps may slow down automation, so balancing speed and accuracy is essential.

- Cost also plays a role. Advanced preprocessing and post-processing improve accuracy but require more powerful hardware and skilled engineers, raising project costs. Efficient design can lower hardware needs and save money.

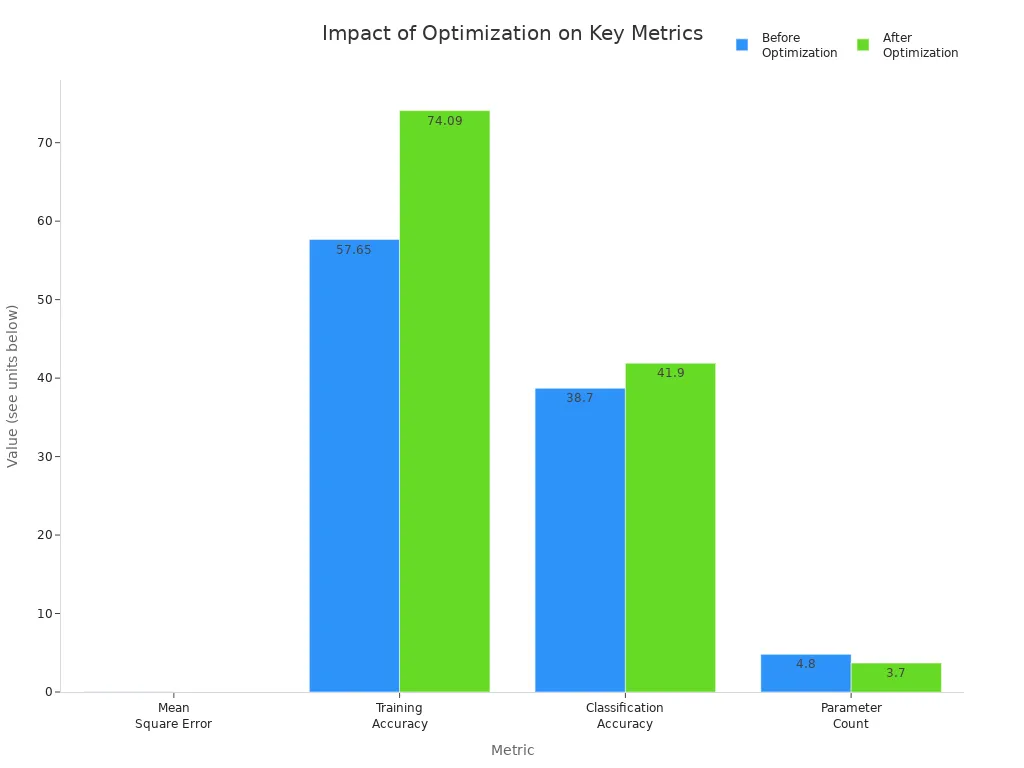

| Metric | Before Optimization | After Optimization | Impact on Scalability |

|---|---|---|---|

| Mean Square Error (MSE) | 0.02 | 0.005 | Better image quality and faster feature extraction |

| Training Accuracy | 57.65% | 74.09% | Faster, more effective training for larger datasets |

| Classification Accuracy | 38.7% | 41.9% | Improved accuracy supports robust automation |

| Parameter Count | 4.8 million | 3.7 million | Lower resource use and faster training |

| Training Time & Calculation | N/A | Faster | Reduced time, critical for real-time industrial systems |

Best Practices

Optimizing a machine vision system for automation and quality control requires careful planning.

- Engineers should always split data into training and test sets before preprocessing. This prevents data leakage and ensures reliable real-time results.

- Use pipelines to apply preprocessing only to training data. Handle missing values with imputation and scale numeric features for consistency.

- Choose preprocessing and post-processing steps based on the application. For edge devices, use quantization and pruning to speed up real-time predictions. For cloud systems, focus on reducing data transfer delays.

- Balance accuracy, speed, and resource use. In industrial automation, speed may matter more than perfect accuracy. In healthcare, accuracy takes priority.

- Test equipment and algorithms on real-world samples before full deployment. This ensures the system meets quality control standards.

- Minimize end-user adjustments. Automated systems should run with little manual intervention to maintain consistent real-time quality control.

- Refine the system online and test with large sample sets. This approach supports reliable automation and real-time analytics.

Tip: Most design time should focus on imaging, as it directly affects system accuracy and real-time performance.

Image preprocessing and post-processing serve different roles in machine vision. Preprocessing prepares images for better detection, feature extraction, and classification, while post-processing refines results by removing noise and filling gaps. Both steps support high-quality inspection by making defects easier to find and classify.

- Preprocessing uses denoising, contrast adjustment, and morphological operations to improve detection and classification.

- Post-processing sharpens detection results, highlights defects, and ensures reliable inspection outcomes.

Experts recommend adjusting lighting, reducing noise, and refining edges to boost inspection accuracy. New trends include real-time analysis, lightweight AI models, and advanced restoration for better detection and classification. Future developments will bring faster, more accurate inspection and detection, helping industries find defects and improve quality.

For anyone designing a machine vision workflow, balancing preprocessing and post-processing leads to better inspection, faster detection, and more reliable defect detection. How will your next inspection system use these steps to catch every defect?

FAQ

What is the main difference between image preprocessing and post-processing?

Image preprocessing prepares raw images for analysis. Image post-processing improves results after analysis. Preprocessing cleans and enhances images. Post-processing refines outputs and highlights important features.

Why does image preprocessing matter in machine vision?

Image preprocessing removes noise and corrects lighting. This step helps the system find objects and defects more easily. Good preprocessing leads to better detection and fewer errors.

Can post-processing fix all image problems?

Post-processing can improve results, but it cannot fix every problem. If the original image has poor quality, some defects may remain. Preprocessing and good image capture are both important.

Which industries use both preprocessing and post-processing?

| Industry | Application Example |

|---|---|

| Electronics | PCB defect detection |

| Food & Beverage | Packaging inspection |

| Automotive | Surface flaw detection |

| Pharmaceuticals | Pill counting and sorting |

See Also

Understanding How Machine Vision Systems Use Image Processing

Top Libraries For Image Processing In Machine Vision Systems

Essential Principles Behind Edge Detection In Machine Vision

Exploring Pixel-Based Machine Vision In Today’s Applications