Image pattern classification stands at the core of every modern machine vision system. This technology lets machines see and understand each image, helping them sort, check, and decide faster than ever. In factories, these systems spot defects early in the process, which keeps products high quality and reduces waste. The image pattern classification machine vision system uses AI to learn from many images, matching or even beating human performance. Machine vision systems run all day, catching mistakes in real time and keeping production lines moving. Advances in sensors and image processing help these systems capture more detail, making every image count for safety and smart manufacturing.

Key Takeaways

- Image pattern classification helps machines see and understand images, enabling faster and more accurate decisions in many industries.

- Machine vision systems improve quality control by detecting defects better than humans, reducing errors and saving money.

- Advanced AI models like convolutional neural networks allow machines to learn from images and adapt to new tasks quickly.

- Real-time image processing supports automation, making factories safer, faster, and more efficient.

- Implementing machine vision requires good data, proper setup, and expert knowledge but offers great benefits in productivity and product quality.

Why Image Pattern Classification Matters

Core Role in Machine Vision

Image pattern classification machine vision system forms the backbone of how machines see and understand the world. Today, the amount of visual data from IoT devices and AI systems grows rapidly. Machines need to sort and make sense of this data to work well in real-time applications. Machine vision uses classification to turn unstructured images into useful information. This process helps machines recognize objects, spot defects, and make decisions quickly.

- Machine vision systems use advanced models like convolutional neural networks (CNNs) and Vision Transformers (ViTs) to learn patterns in images.

- These models break down images into smaller parts, find important features, and focus on key areas. This helps machines handle complex images, even when lighting or angles change.

- Object detection models, such as YOLO, allow machines to find and classify objects in real time. This is important for tasks like traffic monitoring and security.

- Machine vision systems can adapt to new tasks using transfer learning. This means they learn from one set of images and apply that knowledge to new problems.

Note: Proper imaging setup, including the right camera, lens, and lighting, accounts for over 85% of success in machine vision. Clear images lead to high accuracy in classification and quality control.

Machine vision plays a key role in many industries. In healthcare, image classification helps doctors find diseases in X-rays and MRIs. In agriculture, it helps farmers check crop health and spot pests. Security systems use machine vision to recognize faces and detect threats. These examples show how image pattern classification machine vision system supports critical work across different fields.

Impact on Automation

Machine vision drives industrial automation by making processes faster, safer, and more reliable. The image pattern classification machine vision system allows factories to inspect products and parts with high accuracy. Machines can spot defects that humans might miss, even differences as small as one pixel. This leads to better quality control and fewer mistakes.

- Automated inspection systems increase defect detection accuracy from about 63% (human level) to 97%. This reduces errors and saves money.

- AI and machine learning improve pattern recognition accuracy by up to 15%. Machines can adapt to new data and changing conditions.

- Real-time image processing lets robots and machines guide themselves, check quality, and respond quickly to problems.

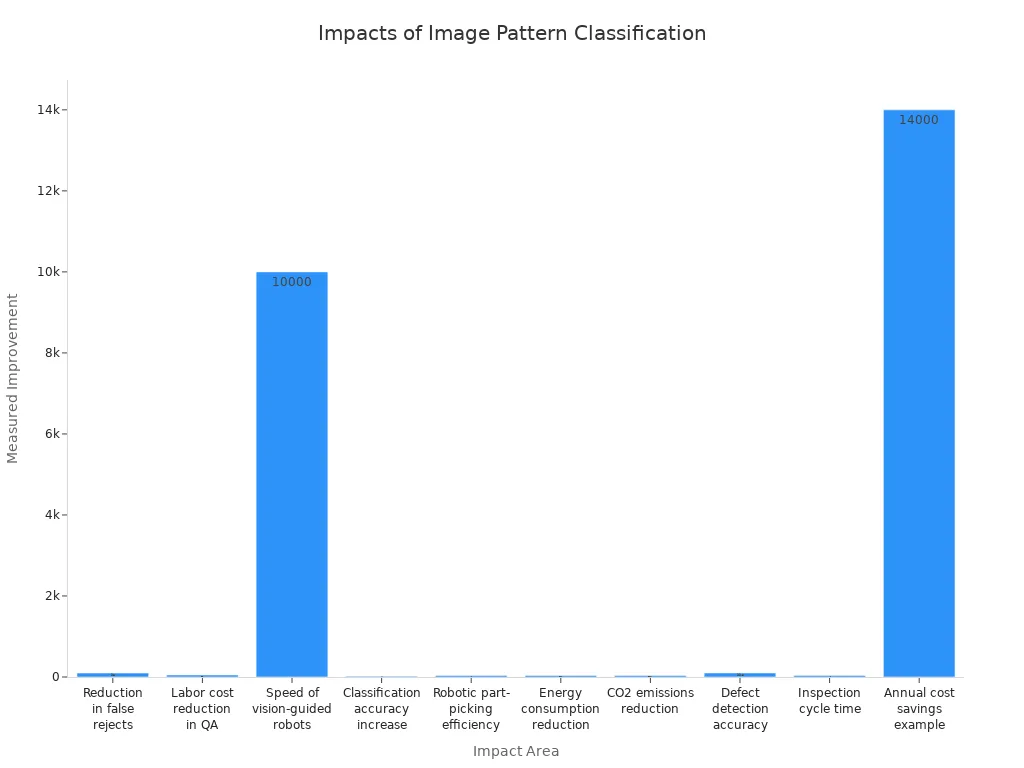

| Impact Area | Measurable Improvement |

|---|---|

| Reduction in false rejects | From 12,000 to 246 units weekly, saving $18M annually per line |

| Labor cost reduction in QA | Approximately 50% reduction |

| Speed of vision-guided robots | Up to 10,000 parts per hour |

| Classification accuracy increase | 20% improvement over traditional algorithms |

| Robotic part-picking efficiency | Over 40% improvement |

| Energy consumption reduction | 38.24% decrease |

| CO2 emissions reduction | 38.17% decrease |

| Defect detection accuracy | Over 99.5% accuracy, 30% reduction in missed defects |

| Inspection cycle time | 40% faster inspections |

| Annual cost savings example | $14,000 saved annually in bakery quality control |

Machine vision supports real-time decision-making in automated systems. For example, in driverless cars, image classification helps the vehicle recognize pedestrians, signs, and other cars. The system can then make quick choices to keep everyone safe. In factories, real-time monitoring allows machines to detect wear or changes in parts, preventing accidents and costly failures.

Industrial automation benefits from machine vision in several ways:

- It reduces downtime by up to 50% through predictive maintenance.

- It cuts operational costs by 20-30% and boosts productivity by up to 40%.

- It enables robots to work faster and more accurately, handling up to 10,000 parts per hour.

Machine vision systems also help companies scale up without raising costs. They provide reliable, repeatable results, which is essential for quality control and efficiency. As a result, image pattern classification machine vision system stands as a key driver of modern industrial automation.

How Image Pattern Classification Machine Vision System Works

Pattern Recognition Process

A pattern recognition machine vision system follows a clear set of steps to turn raw images into useful information. The process starts with image acquisition. Cameras or sensors capture images of objects or scenes. The system then uses preprocessing to improve image quality. This step removes noise, adjusts brightness, and sharpens edges, making the images easier for the system to analyze.

The next step is feature extraction. The system highlights important details in the image, such as shapes, edges, colors, or textures. This step helps the pattern recognition machine vision system focus on what matters most for image recognition. After feature extraction, the system uses classification to sort images into categories. AI and machine learning algorithms, especially convolutional neural networks (CNNs), play a big role here. These algorithms learn from large sets of labeled images, allowing the system to recognize patterns that humans might miss.

The pattern recognition machine vision system also uses evaluation metrics like accuracy, precision, and recall to check how well it works. Sometimes, a two-step classification process helps the system double-check uncertain results, improving reliability.

Tip: AI-powered systems can adapt to new data and changing environments, making real-time image recognition more accurate and efficient.

Feature Extraction and Classification

Feature extraction is a key part of any pattern recognition machine vision system. The system transforms raw image data into meaningful features. These features can include edges, textures, shapes, or keypoints. Algorithms like Histogram of Oriented Gradients (HOG), Speeded-Up Robust Features (SURF), and Local Binary Patterns (LBP) help the system find these features. Deep learning models, such as CNNs, automate feature extraction by learning directly from the image data.

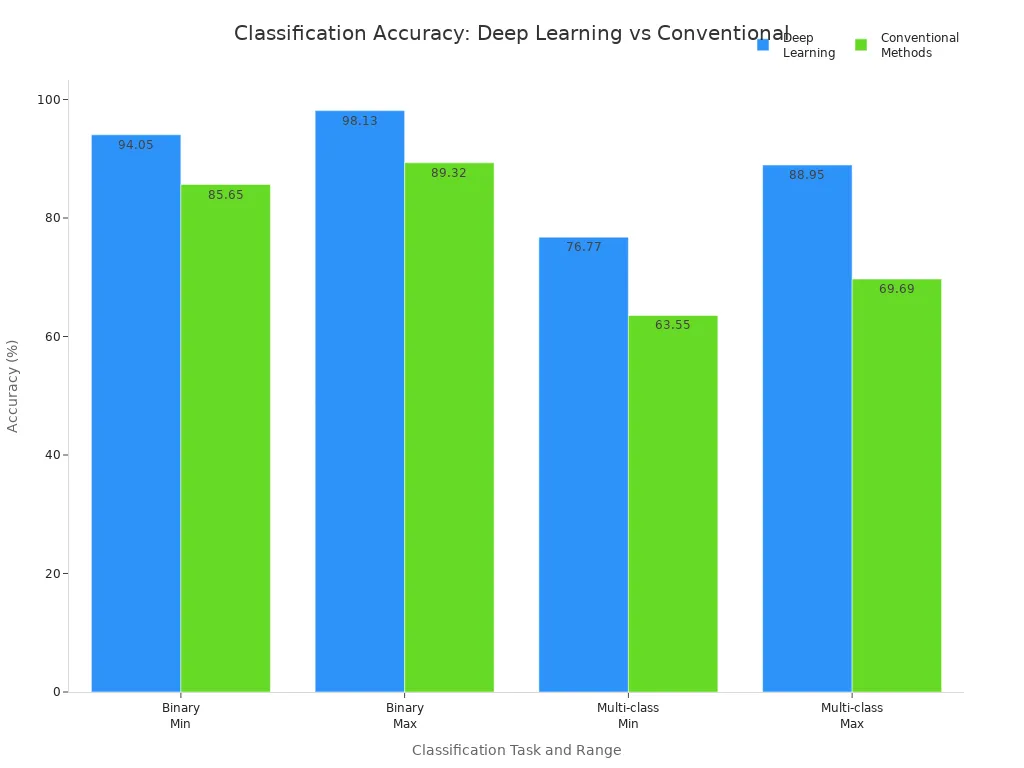

The classification stage uses these features to sort images into groups. Deep learning models outperform traditional machine learning algorithms in this step. They handle both binary and multi-class classification, even in complex or cluttered scenes. The system uses real-time processing to make quick decisions, which is important for applications like robotics and quality control.

AI, machine learning, and neural network pattern recognition help the image pattern classification machine vision system achieve high accuracy in image analysis and data processing. These systems support real-time data analysis, making them essential for modern industries.

Key Technologies in Pattern Recognition Machine Vision System

Sensors and Image Capture

A pattern recognition machine vision system starts with sensors that capture images. Most machine vision cameras use CCD (Charge-Coupled Device) or CMOS (Complementary Metal-Oxide-Semiconductor) sensors. These sensors contain many small photo sensors that collect light and turn it into electrical signals. Monochrome sensors create grayscale images, while color sensors use Bayer filters to capture color data. The right sensor choice affects image recognition accuracy and speed.

There are four main types of machine vision systems based on sensor design:

| Sensor Type | How It Works | Best Use Cases |

|---|---|---|

| 1D Vision System | Scans one line at a time | Fast checks on moving materials |

| 2D Area Scan | Takes a full image snapshot | Defect detection, label checks |

| 2D Line Scan | Builds images line by line as objects move | High-speed inspection, cylindrical items |

| 3D Vision System | Captures depth and volume using special methods | Robotic guidance, shape measurement |

A 2D system captures flat images, which works well for simple inspections. A 3D system adds depth, helping with complex shapes and precise measurements. This improves pattern recognition machine vision system performance in industries like automotive and aerospace.

Algorithms and Deep Learning

Algorithms drive the pattern recognition machine vision system. These systems use both classic and modern approaches. K-means and ISODATA are unsupervised algorithms that group similar image data. Support Vector Machines and Random Forests are supervised machine learning algorithms that handle larger datasets and offer high accuracy. Deep learning models, especially Convolutional Neural Networks (CNNs), have changed image recognition. CNNs like LeNet, ResNet, Inception-v3, VGG16, and MobileNet lead in accuracy and scalability.

Deep learning uses layers to learn features from images. This helps the system spot patterns that humans might miss. Transfer learning and ensemble methods boost accuracy and allow the system to adapt to new tasks. AI and deep learning models now set the standard for image recognition in many fields.

Tip: AI-powered systems use data augmentation and hyperparameter tuning to improve learning and handle class imbalance.

Template Matching Methods

Template matching is a simple method in pattern recognition machine vision systems. The system compares new images to stored templates. This works well when patterns stay the same, such as in fingerprint or facial recognition. Template matching is fast and reliable for clear, repeatable patterns. However, it struggles with complex or changing data.

Machine learning and deep learning algorithms handle more complex image recognition tasks. They learn from large datasets and adapt to new patterns. While template matching is quick for simple jobs, AI and learning methods offer higher accuracy for difficult tasks. When annotated data is limited, template matching remains useful, but machine learning becomes more powerful as data grows.

Applications of Machine Vision

Manufacturing and Quality Control

Manufacturers use machine vision to automate inspection and improve quality control. Image pattern classification replaces manual checks with fast, accurate image recognition. On assembly lines, cameras capture images of products. The system uses object detection to spot defects and sort items. This process increases speed and reduces human error. Deep learning models help with defect detection by finding small flaws that people might miss. High-resolution cameras and advanced lighting make even tiny defects visible. Automated inspection systems provide consistent quality and help companies reduce waste. Real-time monitoring allows early detection of problems, so defective products do not reach customers. Machine vision also sorts large image datasets, making quality assurance more efficient.

Automated quality control leads to higher precision, better yield, and scalable production.

Healthcare and Medical Imaging

Machine vision supports doctors and specialists in healthcare. Image recognition helps detect diseases in X-rays, MRIs, and CT scans. Deep learning models, such as convolutional neural networks, classify diseases like pneumonia or brain tumors. These systems often outperform human experts in some tasks. Machine vision reduces the workload for radiologists and speeds up diagnosis. It also helps track disease progression and plan surgeries by identifying important structures in medical images. AI models organize biomedical image databases, making it easier to find and analyze patient data. This technology improves diagnostic accuracy and supports early detection of health problems.

- Disease detection and diagnosis

- Monitoring treatment response

- Organizing medical image data

Automotive and Security

In the automotive industry, machine vision powers object detection for autonomous vehicles. Cars use image recognition to identify road signs, lane markings, and other vehicles. This technology keeps passengers safe and helps cars follow traffic rules. Machine vision also checks for manufacturing defects in car parts, ensuring high quality and safety. Security systems use facial recognition systems to monitor public spaces and prevent threats. These systems tag and track people or objects in real time. Law enforcement agencies use facial recognition systems to identify suspects from surveillance footage. Machine vision improves accuracy and reduces errors in security monitoring.

| Application Area | Machine Vision Role |

|---|---|

| Autonomous Vehicles | Object detection, lane and sign recognition |

| Security Surveillance | Real-time monitoring, facial recognition systems |

| Automotive Manufacturing | Quality control, defect detection |

Facial recognition systems and advanced object detection make security and transportation safer and more reliable.

Benefits and Challenges

Advantages for Industry

Image pattern classification brings many advantages to industry. Companies use these systems to improve inspection accuracy and ensure only high-quality products reach customers. Automation of inspection processes increases efficiency and productivity. Real-time data analysis helps manufacturers optimize operations and adapt quickly to new requirements. These systems also reduce human error and minimize waste, which leads to better product consistency.

- Advanced sensors and cameras capture high-speed, high-resolution images, supporting accurate detection even in challenging environments.

- Integration with AI, neural networks, and deep learning allows precise defect detection and lower reject rates.

- Optimized algorithms speed up data processing, making the entire system more efficient.

| Aspect | Traditional Methods | Image Classification Benefits |

|---|---|---|

| Accuracy | Moderate | High – automated quality control and defect detection reduce errors significantly |

| Processing Speed | Slow | Fast – automation accelerates inspection and production processes |

| Cost Savings | Low | High – automation reduces labor costs and defect-related expenses |

| Safety | Manual Inspections | Automated Systems – reduce human error and improve workplace safety |

In manufacturing, image classification systems have reduced error rates by up to 90% through automated defect detection. This improvement not only raises product quality but also boosts operational efficiency. The adoption of image recognition technology is expected to save the manufacturing sector $27 billion annually by 2025. Convolutional Neural Networks and Support Vector Machines enable precise detection and classification, while transfer learning speeds up deployment and adaptation. These advances in learning and automation drive productivity and lower error rates.

Implementation Obstacles

Despite the benefits, companies face several challenges when implementing image pattern classification in machine vision systems.

- High-quality, well-labeled datasets are essential. Poor data or too many errors during training can confuse learning algorithms and reduce detection performance.

- Unsupervised learning methods may lack control over the number of classes, which can affect accuracy and precision.

- Configuring Convolutional Neural Networks requires careful setup of multiple layers, adding complexity to system design.

- Data augmentation is necessary to prevent overfitting and improve model generalization by exposing the model to varied image transformations.

| Challenge Category | Description |

|---|---|

| High Implementation Costs | Significant upfront investment in hardware, software, and integration; ongoing maintenance costs. |

| Complexity and Expertise | Requires specialized skills for installation, operation, and maintenance, increasing expenses. |

| Technical Limitations | Hardware failures, software bugs, and need for regular calibration affect system reliability. |

| Data Privacy and Ethics | Processing personal data raises privacy, predictive harm, and algorithmic discrimination concerns. |

Empirical research shows that poor data quality, such as noisy labels or distorted training data, lowers the fairness and performance of image classification models. Companies must define data quality metrics, monitor for anomalies, and adapt data as deployment scenarios change. Data cleaning, transformation, and enrichment support robust model performance. High computational requirements for real-time data processing and data analysis also present obstacles, especially when scaling up learning systems.

Image pattern classification drives machine vision forward by improving efficiency, accuracy, and innovation across industries. Companies use ai to automate inspections, boost productivity, and reduce errors. The rapid growth of ai in machine vision brings smarter models, real-time edge computing, and new sensors.

Experts expect ai to shape future trends with Vision Transformers, 3D vision, and generative ai for better data.

- Ai-powered systems now support healthcare, manufacturing, and smart cities.

- Edge ai and multimodal ai make machine vision faster and more secure.

- Responsible ai use will address privacy and fairness as adoption grows.

FAQ

What is image pattern classification in machine vision?

Image pattern classification helps machines recognize and sort objects in pictures. The system uses AI to find patterns, shapes, or colors. This process allows machines to make decisions based on what they see.

How does machine vision improve quality control?

Machine vision checks products for defects by analyzing images. The system finds mistakes faster than people. Companies use this technology to keep products safe and reduce waste.

Can machine vision systems work in real time?

Yes, many machine vision systems process images instantly. They help robots and machines react quickly. Real-time analysis supports tasks like sorting, guiding robots, and checking product quality.

What industries use image pattern classification?

Manufacturers, healthcare providers, and car makers use image pattern classification. Security systems and agriculture also rely on this technology for tasks like defect detection, disease diagnosis, and crop monitoring.

Are machine vision systems hard to set up?

Some systems need expert setup and training. Companies must choose the right cameras, lighting, and software. Good data and regular updates help the system work well.

See Also

How Image Recognition Enhances Quality Control In Machine Vision

Understanding Pattern Recognition Systems In Machine Vision Technology

Why Triggering Is Crucial For Effective Machine Vision Operations

A Comprehensive Guide To Image Processing In Machine Vision

Key Insights Into Computer Vision And Machine Vision Technologies