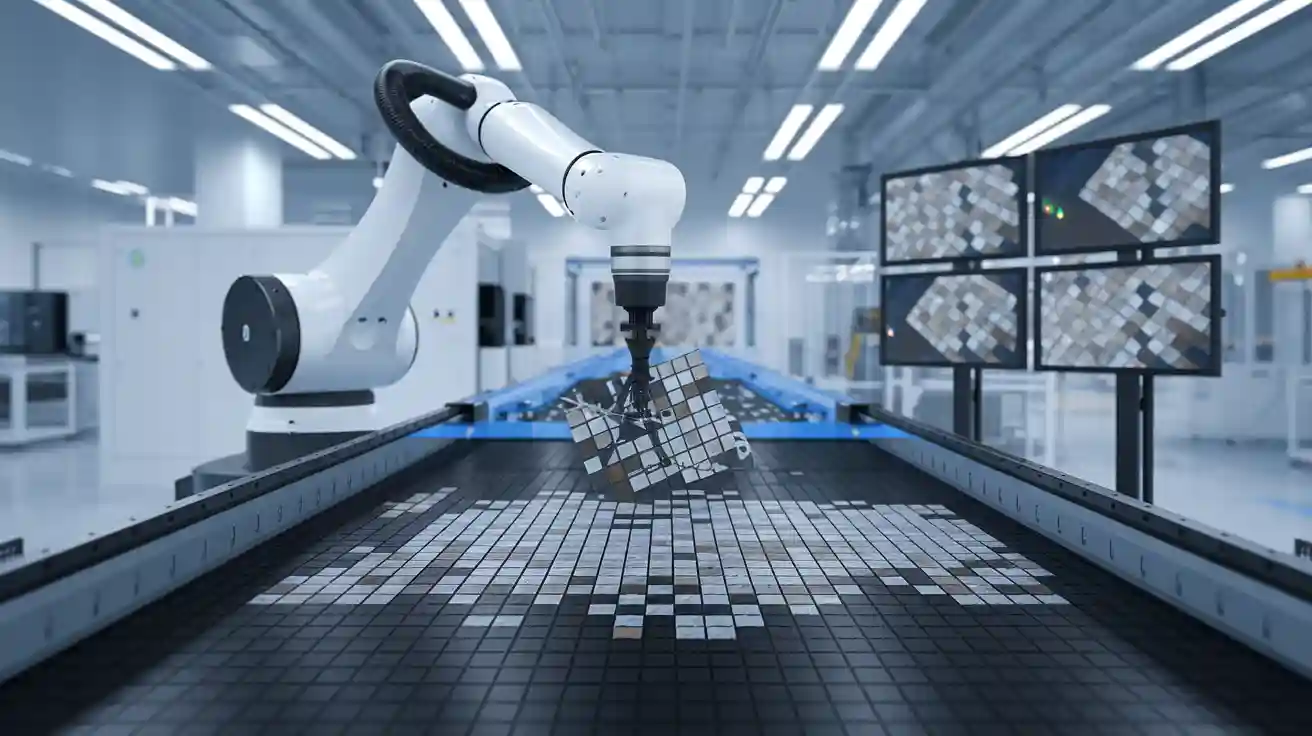

An image mosaic machine vision system combines data from multiple cameras and sensors to create a unified, detailed view of manufacturing components. This system uses adaptive AI algorithms to detect subtle defects and analyze complex patterns, which improves inspection accuracy beyond traditional single-source vision systems. Manufacturers rely on the image mosaic machine vision system for large or intricate parts, as it reduces errors, eliminates the need for manual adjustments, and ensures consistent quality in high-precision environments.

Key Takeaways

- Image mosaic machine vision systems combine images from multiple cameras to create one detailed, seamless view of large or complex parts.

- These systems use advanced algorithms to align, stitch, and blend images, helping detect tiny defects that single cameras might miss.

- Manufacturers benefit from faster, more accurate inspections that cover wide surfaces in a single pass, reducing errors and manual work.

- The systems support various industries by improving quality control, lowering costs, and speeding up production with real-time image processing.

- Adjustable lighting, precise camera setups, and user-friendly software make these systems reliable and easy to use in modern manufacturing.

Overview

Definition

An image mosaic machine vision system creates a single, seamless image from multiple camera inputs. This system captures overlapping images of a target object or area. It then aligns and merges these images to form a comprehensive view. Engineers use this technology to inspect large or complex parts that do not fit within a single camera’s field of view. The system provides a high-resolution, unified image that reveals fine details and subtle defects.

Note: This approach allows manufacturers to inspect surfaces or assemblies that would otherwise require manual repositioning or multiple inspections.

Key Features

The image mosaic machine vision system offers several important features that support modern manufacturing:

- Multi-Camera Integration: The system combines data from several cameras to cover wide or irregular surfaces.

- Automated Image Stitching: Advanced algorithms align and blend images in real time, ensuring smooth transitions and accurate representation.

- High Precision: The system detects small flaws and inconsistencies that single-camera setups might miss.

- Scalability: Manufacturers can expand the system to inspect larger objects by adding more cameras or sensors.

- User-Friendly Interface: Operators interact with intuitive software that displays the mosaic image and highlights areas of concern.

| Feature | Benefit |

|---|---|

| Multi-Camera Support | Full coverage of large parts |

| Real-Time Processing | Immediate inspection results |

| High Resolution | Detection of tiny defects |

| Flexible Configuration | Adaptation to various tasks |

These features help manufacturers achieve consistent quality and reduce inspection time. The image mosaic machine vision system supports both automated and manual workflows, making it a versatile tool for many production environments.

Image Mosaic Machine Vision System

Core Components

An image mosaic machine vision system relies on several essential components to deliver precise inspection results. Each part plays a unique role in capturing, processing, and presenting detailed visual information.

- CMOS Image Sensors: These sensors capture raw image data from multiple viewpoints. Manufacturers prefer cmos image sensor technology because it offers high sensitivity, fast readout speeds, and low power consumption. The sensors can capture both visible and infrared light, which supports a wide range of inspection tasks.

- Multi-Camera Arrays: The system uses several cameras arranged to cover large or irregular surfaces. Each camera collects overlapping images, which are later combined into a single view.

- Mechanical Stages and Mounts: Cameras and mirrors are mounted on adjustable stages. Operators or automated systems can move these stages vertically to accommodate different product sizes and maintain precise alignment.

- Lighting Systems: Uniform illumination is critical. Flat panel white LED lights with independently controlled sections ensure even lighting from various angles. This setup helps reduce shadows and highlights fine details.

- Processing Unit: A powerful computer or embedded processor runs the software that handles image capture, alignment, and analysis.

- Software Interface: Operators interact with user-friendly software that displays the mosaic image, highlights defects, and allows for easy configuration.

Manufacturers often combine mechanical adjustments, controlled lighting, and advanced software to address calibration and alignment challenges. For example, they use software algorithms to identify key features and compensate for minor misalignments, which improves the robustness of the system.

Algorithms and Techniques

The effectiveness of an image mosaic machine vision system depends on advanced algorithms that process and combine images from multiple sources. These techniques ensure the final output is accurate, seamless, and reliable.

- Geometric Corrections: The system corrects for lens distortion and perspective differences between cameras. This step ensures that each image aligns properly with its neighbors.

- Image Registration: Image registration aligns images from different cameras or sensors. This process addresses challenges such as differences in sensor field-of-view and misalignment. Advanced methods, like multi-scale template matching and self-supervised auto-encoders, help align data from sensors with different fields of view. These techniques enable precise fusion of images, which is critical for accurate defect detection and infrastructure inspection.

- Automatic Image Stitching: The system uses automatic image stitching to merge overlapping images into a single, unified view. Algorithms detect and match key features across images, then blend them together. Real-time mosaicing algorithms allow the system to process and display results immediately, supporting fast-paced manufacturing environments.

- Image Compositing and Blending: After alignment, the system blends the images to create a seamless mosaic. Blending algorithms smooth transitions between images, remove visible seams, and preserve important details.

- Feature Detection with SIFT: The Scale-Invariant Feature Transform (SIFT) algorithm identifies unique features in each image. SIFT helps match points between images, which improves the accuracy of stitching and registration.

- Color Accuracy with Bayer Mosaic Technology: Many systems use cmos image sensor arrays with a Bayer pattern to capture color information. Advanced demosaicing algorithms, such as color-adaptive local polynomial approximation, estimate gradients and guide interpolation of color channels. This approach preserves edge locations and reduces color artifacts, resulting in more accurate color reconstruction. The Bayer pattern also mimics human visual sensitivity by using more green filters, which enhances color fidelity in the final mosaic.

- Calibration and Alignment: Manufacturers address calibration by precisely positioning cameras and using mechanical stages for adjustment. They optimize lighting and employ software like Cognex’s PatMax to identify features and correct minor misalignments.

| Technique | Purpose | Benefit |

|---|---|---|

| Geometric Corrections | Adjusts for lens and perspective differences | Accurate image alignment |

| Image Registration | Aligns images from multiple sensors | Reliable defect detection |

| Automatic Image Stitching | Merges overlapping images | Seamless, high-resolution images |

| SIFT Feature Detection | Finds unique points for matching | Improved stitching accuracy |

| Bayer Mosaic Technology | Captures and reconstructs color | Enhanced color fidelity |

The combination of these components and techniques allows the image mosaic machine vision system to deliver high-resolution images with accurate color and seamless coverage. This capability supports automatic image stitching and enables manufacturers to inspect large or complex parts efficiently.

Applications

Manufacturing Use Cases

Image mosaic machine vision systems support a wide range of manufacturing applications. Engineers use these systems to inspect large workpieces, perform microscopic assembly, and detect surface flaws in complex structures.

| Feature/Parameter | Description/Capability |

|---|---|

| Image Mosaic Technology | Combines fast image stitching with traditional image measurement for large workpiece coverage |

| Optical System | Large field-of-view telecentric lenses and automatic zoom lenses for rapid and high-precision measurement |

| Workpiece Placement | Supports arbitrary placement of multiple workpieces, improving measurement efficiency |

| Coordinate System | Unified coordinate system for optical measurement, enhancing accuracy and efficiency |

| Industries Applied | Consumer electronics, semiconductors, automotive, aerospace |

| Software | FlashPro ultra-high speed detection vision software enabling rapid image processing and full inspection |

| Measurement Accuracy | Image mosaic measurement accuracy better than 8 micrometers |

| Measuring Range (XYZ mm) | Models available with ranges up to 600500200 mm |

| Lighting | LED ring lights and parallel LED contour lights for consistent illumination |

| System Benefits | Enables fast, precise, automated inspection and measurement of large workpieces on manufacturing lines |

Manufacturers rely on image mosaic machine vision systems for non-contact, high-accuracy measurement and defect detection. These systems use high-definition cameras and controlled lighting to capture detailed images. Advanced image processing algorithms, such as noise reduction and edge detection, help identify flaws quickly. This approach improves quality control and increases efficiency, especially for large or complex parts.

For microscopic assembly, image mosaic machine vision systems like ASHLAR provide several advantages:

- They create seamless mosaics by accurately stitching and registering microscopic image tiles.

- The systems correct for mechanical tolerances and illumination differences, which is important for single-cell analysis.

- They handle gigapixel-scale images, supporting detailed visualization and pixel-level machine learning.

- Compatibility with standard file formats and microscope platforms streamlines workflows.

- Subpixel registration allows for precise analysis of specific regions.

Engineers also use these systems for surface flaw detection in large structures, such as bridge cables:

- A climbing robot with four cameras moves along the cable, capturing continuous images.

- The system uses a scale-invariant feature transform algorithm to match features across overlapping images.

- Image mosaicking creates a composite image, showing the full defect morphology.

- The system detects and locates surface defects larger than 1 cm², increasing inspection speed and accuracy.

- The hardware processes only defect-containing images, optimizing performance.

These applications demonstrate how image mosaic machine vision systems improve quality control, efficiency, and coverage for large or complex areas.

High-Accuracy Automated Volume Measurement

Image mosaic machine vision systems enable high-accuracy automated volume measurement in manufacturing. These systems combine 3d acquisition with precise image stitching to measure the volume of objects quickly and reliably. Manufacturers use this capability to inspect parts with complex shapes or large dimensions. The system provides accurate data for process control and quality assurance, reducing manual measurement errors and supporting automated workflows.

Benefits

Accuracy and Coverage

Image mosaic machine vision systems deliver unmatched accuracy in manufacturing inspections. These systems combine images from multiple cameras to create a seamless, high-resolution panorama. Engineers can detect even the smallest defects, such as micro-cracks or surface irregularities, that single-camera setups might overlook. The unified image covers large or complex parts, ensuring no area goes unchecked. Operators use the auto-mosaic tool to automate the stitching process, which reduces manual errors and increases consistency.

Note: A single inspection pass now covers wide surfaces, eliminating the need for repeated repositioning or multiple scans.

Manufacturers benefit from improved quality control. The system’s advanced algorithms maintain precise alignment and color accuracy, even when inspecting irregular shapes or reflective materials. This comprehensive coverage supports strict industry standards and helps prevent costly recalls.

Cost and Efficiency

Image mosaic machine vision systems help manufacturers save time and money. By stitching together high-resolution images, the system creates a detailed surface model. This model improves simulation accuracy by over 30% and keeps measurement error within 1 μm. Engineers can predict and control surface wear and roughness more effectively. As a result, they reduce the need for physical machining trials and lower production costs.

The system also minimizes waste. Real-time monitoring allows operators to optimize machining processes as they happen. The image mosaic method compensates for lens limitations, so manufacturers do not need to invest in expensive custom optics. Automated inspection speeds up production lines and reduces labor costs.

| Benefit | Impact on Manufacturing |

|---|---|

| Enhanced Accuracy | Fewer defects and higher product quality |

| Wide Coverage | Complete inspection in less time |

| Lower Costs | Reduced waste and fewer trials |

| Improved Efficiency | Faster, automated workflows |

Tip: Real-time process control leads to fewer errors and more consistent results.

Image mosaic machine vision systems give manufacturers a clear, unified view of complex parts. These systems improve inspection accuracy and speed. Many companies now use a fully automated high-accuracy volume measurement tool to check product quality. Manufacturers can explore new solutions, talk with industry experts, or read more about system setup.

These steps help teams choose the best technology for their needs.

FAQ

What is the main advantage of using an image mosaic machine vision system?

Image mosaic machine vision systems provide a complete, high-resolution view of large or complex parts. This approach helps engineers find small defects and ensures every area receives inspection in a single pass.

How does the system handle different lighting conditions?

The system uses advanced LED lighting with adjustable sections. This setup creates even illumination and reduces shadows. Operators can fine-tune the lighting for each inspection task.

Can image mosaic machine vision systems work with moving production lines?

Yes. These systems process images in real time. They capture and stitch images quickly, so manufacturers can inspect products as they move along the line.

What industries benefit most from this technology?

Industries such as automotive, electronics, aerospace, and semiconductors use image mosaic machine vision systems. These sectors require precise inspection of large or detailed components.

See Also

Exploring Pixel-Based Machine Vision In Contemporary Uses

A Comprehensive Guide To Image Processing Vision Systems

The Impact Of Machine Vision On Aerospace Production