An image machine vision system lets you give machines the power to see and understand images. You use these systems to capture, process, and analyze visual data in real time. The main parts include a camera for image capture, lighting to enhance visibility, and image processing software that interprets the data.

- You will find that machine vision systems often:

- Capture images with specialized cameras.

- Process data with powerful algorithms.

- Extract details for automated decisions.

Machine vision helps you improve quality, speed, and accuracy in industrial automation.

Key Takeaways

- Image machine vision systems let machines see and analyze images to improve quality and speed in automation.

- Key parts include cameras, lighting, lenses, sensors, processing units, and software that work together to capture and interpret images.

- These systems follow steps like capturing images, cleaning them, finding objects, and making decisions to automate tasks.

- You can choose from 1D, 2D, or 3D vision systems and smart cameras or PC-based setups depending on your needs and complexity.

- Machine vision boosts accuracy, productivity, and safety in industries like manufacturing, healthcare, automotive, and agriculture while facing challenges like cost and maintenance.

Image Machine Vision System Basics

Key Components

You can break down an image machine vision system into several essential parts. Each part works together to help you capture and analyze visual information with speed and accuracy. Here are the main components you will find in most machine vision systems:

- Lighting: You use lighting to illuminate the object. Good lighting makes details stand out and reduces shadows or glare.

- Lens: The lens focuses light onto the image sensor. You can choose manual, autofocus, or liquid lenses depending on your needs.

- Image Sensor: This part converts light into digital signals. The two main types are CCD and CMOS sensors. CMOS sensors are popular because they are fast and cost-effective.

- Camera: The camera captures the image. You might use line scan cameras for continuous materials or area scan cameras for stationary objects. 3D cameras help you measure depth and shape.

- Vision Processing Unit (VPU): This unit runs the algorithms that analyze images. It often uses CPUs or GPUs for fast processing.

- Image Processing Software: The software interprets the images. It finds patterns, measures objects, and detects defects.

- Communication Interfaces: These let your system send data to other machines or networks.

- Covers/Enclosures: These protect your cameras from dust, water, and other hazards. You can look for IP ratings like IP67 for tough environments.

- Sensors and Control Units: Sensors trigger image capture at the right time. Control units use the results to guide machines or processes.

Tip: The choice between custom-built and commercial off-the-shelf solutions affects how quickly you can deploy your system and how much flexibility you have.

Here is a table that summarizes the main categories and their functions:

| Component Category | Description & Examples |

|---|---|

| Image Sensors | Convert light to electrical signals; main types are CCD and CMOS sensors. |

| Lenses | Capture and focus light; types include manual, autofocus, and liquid lenses for different use cases. |

| Lighting | Primarily LEDs used for consistent, energy-efficient illumination essential for image clarity. |

| Cameras | Include line scan (for continuous surfaces) and area cameras (for stationary or smaller objects). |

| Vision Processing Units | Embedded CPUs or VPUs process images and run algorithms for inspection and decision-making. |

| Software Components | Advanced algorithms including AI and deep learning for image analysis, inspection, and decision-making. |

| Communication Interfaces | Enable data transmission between vision system and other devices or networks. |

Lighting plays a critical role in your image processing machine vision system. The type of lighting you choose—such as backlighting, ring lighting, or dome lighting—can affect how well you see edges, defects, or surface details. For example, backlighting helps you spot the outline of transparent objects, while ring lighting reduces shadows on small parts. You need to match the lighting to your application for the best results.

How It Works

You can think of an image machine vision system as a step-by-step process that turns raw images into useful decisions. Here is how a typical image processing machine vision system works:

- Image Acquisition: The system captures an image using a camera and proper lighting. You set parameters like exposure time and lighting angle to get a clear picture.

- Preprocessing: The software cleans up the image. It reduces noise, adjusts brightness, and prepares the image for analysis.

- Segmentation: The system separates objects from the background. This step helps you focus on the parts that matter.

- Feature Extraction: The software finds important details, such as edges, shapes, or colors. It uses filters and algorithms to highlight these features.

- Object Detection and Classification: The system locates and identifies objects in the image. It can sort items, check for defects, or read codes.

- Decision and Output: The system makes a decision based on the analysis. It might trigger a robot to pick up an item, reject a faulty product, or send data to another machine.

Note: Proper sequencing and timing are important. Sensors make sure the camera captures the image at the right moment, and the control unit acts on the results without delay.

Here is a simple list of the main steps in the process:

- Capture the image (acquisition)

- Clean and prepare the image (preprocessing)

- Find and separate objects (segmentation)

- Extract key features (feature extraction)

- Detect and classify objects (object detection and classification)

- Make decisions and send outputs (decision and output)

The image processing machine vision system uses advanced software to interpret visual information. It enhances image quality, extracts features, and applies algorithms like deep learning or edge detection. This lets you automate tasks such as defect detection, measurement, and pattern recognition. The system can even support real-time quality control and help you make fast, accurate decisions.

You may face some challenges, such as poor lighting or environmental changes. Shadows, glare, or low light can cause errors. You can solve these problems by using diffused lighting, polarizers, or adaptive lighting that changes with the environment. Regular updates and monitoring help keep your machine vision systems accurate and reliable.

Machine Vision Camera and Technology

Camera Types

When you choose a machine vision camera, you need to look at the sensor type, resolution, and how the camera connects to your system. Most machine vision cameras use either CCD or CMOS sensors. CMOS sensors are popular because they work fast and use less power. They also have better sensitivity to infrared light, which helps you capture high-resolution images in different lighting conditions. Monochrome cameras give you higher resolution and better sensitivity than color cameras. If you need color, you can pick single-chip cameras with Bayer filters or three-chip cameras that use prisms for better color accuracy. Three-chip cameras cost more and need more light, but they give you the best color detail.

You will find that machine vision camera vendors offer different options for your needs. Some focus on high performance, like Basler and Sony, giving you advanced sensors and flexible software. Others, such as The Imaging Source, provide a wide range of cameras for standard industrial image processing tasks. Specialized manufacturers like FLIR make cameras for thermal imaging, 3D, or rugged environments. For example, FLIR’s Blackfly S family gives you many sensor choices and interfaces, while Oryx cameras deliver high-resolution images at fast speeds for real-time processing.

| Camera Category | Characteristics and Specifications | Example Vendors |

|---|---|---|

| Performance Specialists | Advanced sensors, flexible software, high frame rates, and resolution. | Basler, Allied Vision, Sony |

| Broad Portfolio | Many camera types for standard industrial image processing, good support, and pricing. | The Imaging Source, IDS, JAI |

| Specialized Manufacturers | Thermal, 3D, high-speed, rugged cameras for unique industrial image processing needs. | FLIR, XIMEA, LUCID |

Larger sensors in a machine vision camera help you get high-resolution images by collecting more light. This improves your results in industrial image processing, especially when you need to spot tiny defects or measure small parts.

Image Processing

You use image processing to turn raw data from a machine vision camera into useful information. Modern industrial image processing relies on powerful algorithms to handle high-resolution images quickly. You can use classical feature extraction methods like SIFT, SURF, and ORB to find patterns or edges. For object recognition, deep learning models such as CNNs, YOLO, and U-Net help you classify and detect objects in high-resolution images. These tools make your machine vision system smarter and more accurate.

Noise and artifacts can affect your high-resolution images. Image processing software uses filters like Gaussian or median to clean up the images. Some advanced tools, like Topaz DeNoise AI, use deep learning to remove grain and color noise while keeping details sharp. You need to balance noise reduction so your industrial image processing does not lose important features.

You can use open-source libraries like OpenCV or commercial packages such as Cognex Vision Pro for your image processing and analysis. These tools help you with tasks like segmentation, feature extraction, and real-time processing. As sensor technology improves, you will see machine vision cameras that support multi-spectral and 3D imaging, making industrial image processing even more powerful.

Tip: Always match your machine vision camera and image processing software to your application. This ensures you get the best results for object recognition and quality control.

Types of Machine Vision Systems

1D, 2D, and 3D Systems

You can choose from three main types of machine vision systems: 1D, 2D, and 3D. Each type works best for different tasks. A 1D system scans one line at a time. You often use it for inspecting items on fast-moving conveyor belts or reading barcodes. This type forms a full image by stitching many lines together. It works well when you need to check long, continuous materials.

A 2D system captures flat images. You use a machine vision camera to get pictures that show length and width. This setup helps you find surface defects, read labels, or check if parts are in the right place. It is simple to set up and costs less than 3D systems.

A 3D system gives you depth information. It uses special cameras or lasers to build a 3D model of an object. You can measure height, volume, or shape. This helps you inspect complex parts, guide robots, or sort items by size. Many industries, like automotive, electronics, and packaging, use 3D machine vision to check for tiny flaws or measure parts with high accuracy.

Here is a table to help you compare these systems:

| Vision System Type | Data Captured | Typical Applications | Advantages | Limitations |

|---|---|---|---|---|

| 1D | One line at a time | Conveyor inspection, barcode scanning | No blur, fast for moving items | Less detail than 2D/3D |

| 2D | Flat images (length, width) | Surface checks, label reading, defect detection | Easy setup, affordable | No depth info |

| 3D | Depth and shape | Complex part measurement, robotic guidance | High accuracy, 3D models | Higher cost, complex setup |

Note: 3D machine vision systems are common in industries like electronics, automotive, and food processing. They help you find defects, measure parts, and guide robots with great precision.

Smart Cameras vs. PC-Based

When you set up machine vision systems, you can pick between smart cameras and PC-based solutions. A smart camera combines image capture and processing in one unit. You get a compact device that is easy to install and use. Smart cameras work well for simple, repeatable tasks like checking labels or counting items. They cost less and need less training to operate.

A PC-based system uses a separate machine vision camera connected to a powerful computer. This setup gives you more processing power and flexibility. You can handle complex inspections, use advanced software, and connect several cameras at once. PC-based systems fit large factories or tasks that need high-speed or detailed analysis.

Here is a table to show the main differences:

| Aspect | Smart Cameras | PC-Based Systems |

|---|---|---|

| Processing Power | Lower, for simple tasks | Higher, for complex tasks |

| Flexibility | Limited | Very flexible |

| Setup | Easy, all-in-one | More complex, needs PC |

| Cost | Lower | Higher |

| Scalability | Add more units easily | Supports many cameras and tasks |

Tip: If you need a quick, low-cost solution for a simple job, choose a smart camera. For advanced machine vision tasks or large-scale production, a PC-based system gives you more options and power.

Machine Vision Applications

Manufacturing

You use machine vision in industrial manufacturing to boost quality control and speed up production. Automated inspection systems check products for defects like scratches, cracks, or misalignments. These systems guide robotic arms for precise assembly and welding. You can also verify seals and closures in food and pharmaceutical packaging, which reduces product loss. AI-powered machine vision learns from examples, so it finds new types of defects and reduces false positives. Hybrid systems with edge and cloud computing let you make real-time decisions and analyze trends over time.

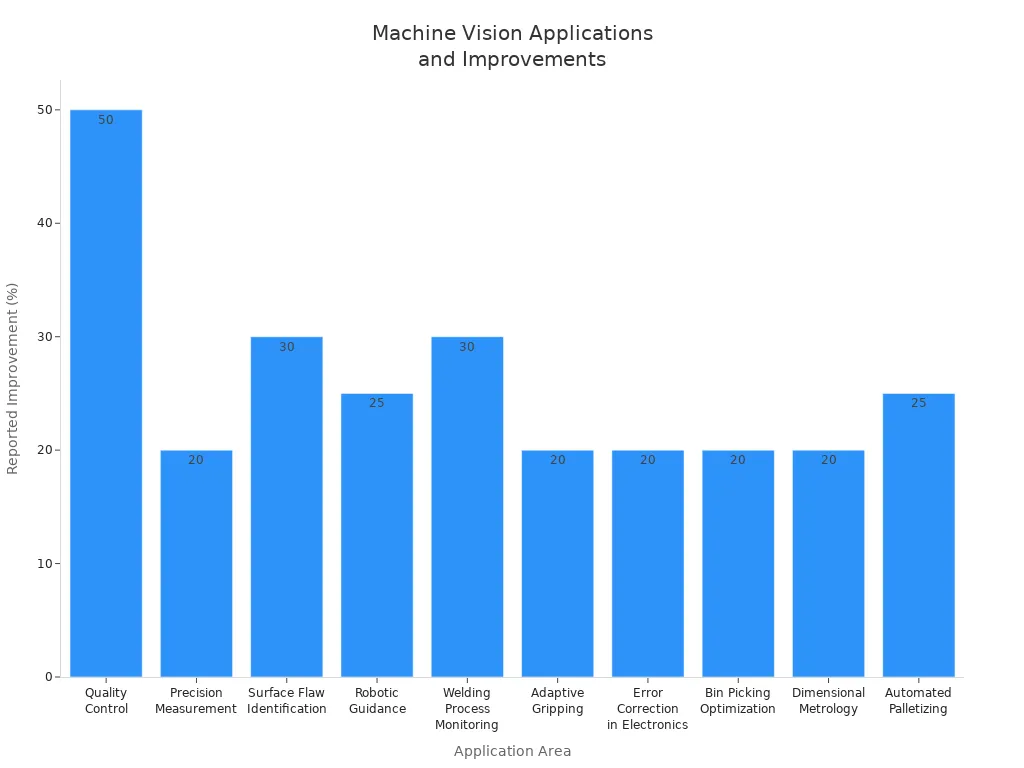

Here are some measurable improvements:

| Application Area | Description / Example | Measurable Improvements Reported |

|---|---|---|

| Quality Control | Real-time defect detection on production lines | Defect detection rates up to 99.9%, improved by 40-50% |

| Robotic Guidance | Guiding robotic arms for pick-and-place, welding, and assembly | Increased throughput, improved welding quality |

| Surface Flaw Identification | Detecting scratches, dents in metal fabrication | Less rework and scrap |

| Automated Palletizing | Spatial recognition for stacking and organizing goods | 25% increase in palletizing speed |

You gain increased efficiency, reduced labor needs, and enhanced quality control. Automated inspection finds defects faster and more accurately than manual checks. This leads to fewer errors, less waste, and better compliance with industry standards.

Healthcare

In healthcare, you rely on machine vision for accurate diagnostics and patient care. Automated inspection of medical images like X-rays and MRIs helps you detect diseases such as cancer early. Deep learning algorithms segment images, highlight tumors, and classify tissue types. This reduces human error and speeds up diagnosis. Machine vision also supports real-time patient monitoring and guides surgeons during complex procedures. You get improved safety and accuracy, which leads to better outcomes and fewer unnecessary treatments. Enhanced quality control in labs ensures test results stay reliable.

Automotive

You use machine vision in automotive manufacturing for high-precision inspection of parts. Automated inspection systems check for defects like micro-cracks, misalignments, and surface flaws in components such as airbags and brakes. These systems also verify assembly steps, making sure every part meets strict standards. In autonomous vehicles, machine vision detects lane markings, traffic signs, and obstacles. It helps control braking and steering, which improves safety and accuracy on the road. Enhanced quality control in automotive plants means fewer recalls and safer vehicles.

Agriculture

Machine vision transforms agriculture by automating inspection tasks from planting to harvest. You use cameras and sensors to detect plant health, count fruit, and predict yields. Automated inspection systems grade produce, spot diseases, and guide robots for harvesting. Drones with machine vision monitor large fields, helping you plan irrigation and fertilizer use. These systems reduce waste by catching problems early and ensure only the best crops reach the market. You achieve increased efficiency, lower costs, and enhanced quality control in every step of farming.

Machine Vision vs. Computer Vision

Key Differences

You may wonder how machine vision and computer vision differ. Machine vision focuses on using cameras and software to automate tasks like inspection and sorting in factories. You often see it in real-time systems that check products for defects or guide robots. Computer vision is a broader field that creates computer vision algorithms to help computers understand images at a high level. These algorithms can recognize faces, read barcodes, or even help self-driving cars see the road.

Here is a table to help you compare the two:

| Aspect | Machine Vision | Computer Vision |

|---|---|---|

| Definition | Systems engineering discipline focused on image-based automatic inspection and real-time decisions | Broader AI field enabling high-level understanding of images and signals |

| Processing | Simpler, real-time automated decisions | Complex decision-making, visual reasoning, predictive tasks |

| Inputs | Visual data from hardware like cameras, real-time image capture | Real or synthetic images, videos, stills, not always real-time |

| Outputs | Task-specific results (pass/fail, go/no-go), robotic actions | Information on size, color, visual reasoning, augmented images/videos |

| Applications | Industrial inspection, assembly, palletizing, machine tending | Face recognition, medical diagnostics, autonomous driving, behavior analysis |

| Relationship | Subset or application-oriented branch of computer vision | Provides foundational computer vision algorithms and models |

| Deployment Context | Industrial, manufacturing, distribution, fulfillment | Broader AI applications including autonomous systems and complex image understanding |

You use machine vision when you need fast, reliable decisions in industrial settings. Computer vision algorithms help you solve more complex problems, such as understanding scenes or predicting actions.

Note: Machine vision applies computer vision algorithms for real-time tasks, while computer vision develops these algorithms for many different uses.

Integration

You often integrate machine vision with other automation technologies to boost efficiency. For example, you can connect cameras and sensors to robots. This setup lets robots see their environment, plan movements, and avoid obstacles. Machine vision helps robots pick up objects, sort items, and inspect products with high accuracy.

Here are the main steps you follow to integrate machine vision into your automation system:

- Analyze your application needs and requirements.

- Define project specifications, including functions and performance metrics.

- Prioritize machine vision components as key elements in your design.

- Develop a detailed integration plan with organized tasks.

- Install and refine the system, testing before final deployment.

- Use a written validation plan to make sure the system meets your goals.

You need skilled engineers to combine all the parts—cameras, software, and robots—into one working system. Careful planning and testing help you get the best results from your machine vision setup.

Tip: When you integrate machine vision, you improve speed, accuracy, and flexibility in your production line.

Benefits and Challenges

Advantages

When you use machine vision systems, you gain many important benefits in your production process. These systems help you achieve high accuracy and reliable inspections, which means you can spot even the smallest defects that people might miss. Here are some of the top advantages you will notice:

- Increased Accuracy and Precision: You detect tiny defects and ensure every product meets your standards.

- Enhanced Productivity and Speed: Machine vision works faster than humans and never gets tired, so you keep your lines moving.

- Cost Efficiency: You save money over time by reducing labor costs and catching problems early.

- Improved Quality Control: Automated systems check every item, giving you consistent results and better traceability.

- Worker Safety: You can automate dangerous tasks, keeping your team safe.

- Real-Time Decision-Making: You get instant feedback, so you stop defective products before they move forward.

You can see these advantages in the table below:

| Advantage | Explanation |

|---|---|

| Automated Inline Inspection | You inspect every product, remove human error, and keep quality consistent. |

| Speed and Accuracy | You inspect quickly and with high accuracy, so you avoid bottlenecks. |

| Cost Reduction and ROI | You lower costs for labor and scrap, often seeing payback in under a year. |

| Process Optimization | You find defects in real time, which helps you improve your process. |

Tip: Machine vision gives you improved accuracy and better quality control and inspection, making your production more efficient and reliable.

Limitations

While machine vision brings many benefits, you also face some challenges when you set up these systems. High initial costs can make you hesitate, especially when you need special hardware and skilled engineers. You may find it hard to connect new systems with your old equipment, which can slow down your project. Changes in lighting or temperature can affect how well your system works, so you need to plan for these issues.

You might also need to spend time training your team and making sure everyone accepts the new technology. Calibration can be tricky, especially if your products change often. Maintenance and downtime can interrupt your work, so you need a good plan to keep everything running smoothly.

- High initial costs and uncertain return on investment

- Need for skilled personnel to build and maintain systems

- Integration issues with existing equipment

- Environmental changes that affect performance

- Maintenance and downtime concerns

- Calibration complexity for different products

- Training and acceptance among employees

Note: You can overcome many of these challenges with careful planning, regular maintenance, and ongoing training. This helps you keep your machine vision system running at its best.

You have seen how image machine vision systems help machines see and make decisions. These systems improve quality, speed, and safety in fields like manufacturing, healthcare, automotive, and agriculture.

- You gain faster inspections

- You reduce errors

- You keep workers safe

Machine vision keeps growing with new AI tools and better cameras. You can explore how these systems might change your work or industry in the future.

FAQ

What is the main difference between machine vision and computer vision?

You use machine vision for automated inspection and control in factories. Computer vision helps computers understand images in many fields. Machine vision focuses on real-time tasks. Computer vision covers broader applications, like face recognition or self-driving cars.

Can you use machine vision systems outside of factories?

Yes, you can use machine vision in healthcare, farming, and even traffic control. These systems help you detect diseases, sort crops, and monitor roads. You find them in many places, not just in manufacturing.

How do you choose the right camera for your machine vision system?

You look at your task first. Check the size of objects, speed, and lighting. Pick a camera with the right resolution and sensor type. Ask vendors for advice if you feel unsure.

Do machine vision systems need special lighting?

Yes, you need good lighting for clear images. The right lighting reduces shadows and glare. You can use backlighting, ring lights, or dome lights. Your choice depends on your inspection needs.

Is it hard to maintain a machine vision system?

You need to clean cameras and check lighting often. Update software when needed. Train your team to spot problems early. With regular care, your system stays accurate and reliable.

See Also

Understanding How Machine Vision Systems Use Image Processing

A Guide To Machine Vision Systems And Computer Vision Models

Essential Insights Into Computer Vision And Machine Vision Technology

Top Libraries For Image Processing In Machine Vision Systems