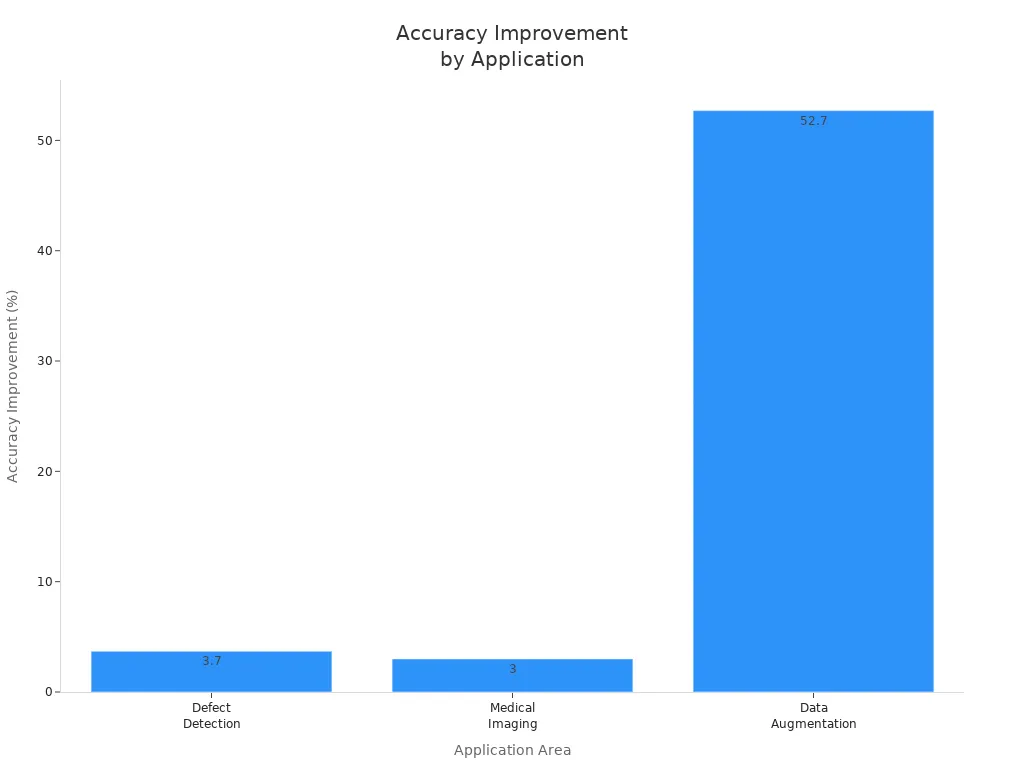

Image enhancement machine vision system technology transforms raw data into clear and actionable information. Enhancement techniques like adjusting contrast, filtering, and sharpening improve image quality for image processing machine vision system workflows. Enhanced images enable machine vision to extract features more accurately, supporting advanced algorithms and reducing errors. In manufacturing, quality control depends on enhancement to reveal defects and boost classification precision. Studies show that data augmentation and enhancement can raise accuracy from 44% to nearly 97%, with improvements often exceeding 50% in some scenarios.

- Enhanced image processing supports reliable machine vision, improves decision-making, and strengthens quality control in manufacturing and other industries.

- Image enhancement prepares data for advanced algorithms, increasing both information content and system performance.

Key Takeaways

- Image enhancement improves image quality, helping machine vision systems detect features and defects more accurately.

- Techniques like noise reduction, contrast adjustment, and super-resolution make images clearer and support better automated inspection.

- Enhanced images boost the accuracy and reliability of deep learning models used in quality control and defect detection.

- Industries such as manufacturing, food, pharma, and automotive rely on image enhancement to improve product quality and reduce errors.

- Following best practices in image enhancement workflows leads to faster, more efficient, and cost-effective machine vision systems.

Image Enhancement Basics

What Is Image Enhancement?

Image enhancement plays a central role in every image enhancement machine vision system. It refers to the set of techniques that improve the visual quality and information content of images before further analysis. In a typical image processing machine vision system, enhancement methods operate in two main domains: spatial and frequency.

Spatial domain methods work directly on the pixels of an image. These techniques include convolutional filters like Gaussian and Sobel filters, which help with edge detection, smoothing, and sharpening. Point processing methods, such as thresholding and negative images, also fall into this category. These approaches are efficient for handling local features and textures.

Frequency domain methods transform the image using mathematical tools like the Fourier transform. After this transformation, filters such as low-pass and high-pass masks can enhance or suppress specific frequency components. This process is especially useful for removing periodic noise or enhancing edges at certain scales. Advanced frequency domain techniques, such as Spatial Frequency Domain Imaging (SFDI), use sinusoidal patterns to extract detailed structural information from images.

Note: Spatial filtering is often faster for small areas, while frequency domain filtering becomes more efficient for larger regions due to the way convolution works in the frequency domain.

Core Objectives

The main goal of image enhancement in machine vision is to make images more suitable for automated analysis and decision-making. Enhancement improves image quality by adjusting contrast, brightness, and color balance, as well as by sharpening and filtering. These steps make important features stand out and reduce noise or irrelevant data.

- Enhancement helps machine vision algorithms extract features more accurately and reliably.

- In quality assurance, enhanced images allow for better defect detection and classification.

- For object detection and tracking, enhancement highlights details, making it easier to differentiate and follow objects.

The enhancement process usually involves several steps:

- Preprocessing, such as noise removal.

- Analysis to determine which properties need improvement.

- Applying enhancement adjustments.

- Post-processing to correct any artifacts.

Proper enhancement ensures consistent, high-quality images, which simplifies software development and increases the accuracy and efficiency of automated inspection. By overcoming challenges like lighting changes and noise, image enhancement supports robust and reliable machine vision systems.

Key Enhancement Techniques

Noise Reduction

Noise reduction stands as a fundamental step in image enhancement for machine vision. Industrial environments often introduce spatial noise from sensor imperfections or environmental factors. Techniques such as median filtering and Gaussian filtering remove unwanted noise while preserving important features. Median filters replace each pixel with the median value in its neighborhood, which helps maintain edges. Gaussian filters assign higher weights to central pixels, reducing high-frequency noise but keeping image details clear. These methods use convolution with specific kernels, and proper handling of image boundaries ensures effective noise reduction. By minimizing noise, image enhancement techniques improve image processing accuracy and reliability.

Contrast and Edge Enhancement

Contrast and edge enhancement play a vital role in making features stand out in images. Adjusting contrast helps distinguish objects from their backgrounds, which is essential for automated inspection tasks. Histogram equalization and adaptive methods address issues like low illumination and uneven lighting. Edge enhancement algorithms, such as Sobel or Canny, highlight boundaries by detecting rapid changes in pixel values. This process reveals defects, cracks, or gaps that might otherwise go unnoticed. Enhanced image quality through these methods leads to better segmentation and more reliable defect detection in machine vision applications.

Filtering Methods

Filtering methods support image enhancement by improving image clarity and supporting accurate analysis. Common filters include low-pass filters for noise reduction, high-pass filters for edge enhancement, and bandpass filters for isolating specific frequency ranges. The table below summarizes typical filtering methods and their applications:

| Filtering Method | Purpose/Application |

|---|---|

| Low-pass filter | Noise reduction and image smoothing |

| High-pass filter | Edge enhancement by highlighting high-frequency info |

| Binarization | Conversion to black-and-white images for analysis |

| Shrink filter | Increases dark pixels, decreases light pixels |

| Expand filter | Enhances bright pixels at the expense of dark pixels |

| Bandpass filter | Filters frequencies outside a specific range |

| Polarization filter | Improves imaging of reflective objects |

Filtering supports image processing in fields like industrial automation, food sorting, and quality control. Enhanced image quality from these filters enables machine vision systems to extract features more accurately.

Super-Resolution

Super-resolution technology transforms low-resolution images into high-resolution outputs, overcoming the limits of traditional imaging devices. Advanced algorithms, including deep learning models like convolutional neural networks, reconstruct fine details and sharpen edges. Super-resolution proves critical in applications such as medical imaging, surveillance, and industrial inspection, where detecting small features matters. These methods use interpolation and reconstruction to restore details, reducing blurring and noise. Enhanced image quality from super-resolution allows machine vision systems to analyze images with greater precision, supporting tasks that require high accuracy. Despite challenges like computational demands, ongoing advancements continue to expand the capabilities of image enhancement in machine vision.

Tip: Combining filtering and super-resolution in image enhancement workflows leads to clearer images and higher analysis accuracy, making automated inspection more reliable.

Performance Impact

Accuracy and Reliability

Image enhancement plays a critical role in improving the accuracy and reliability of machine vision systems. High-quality images allow advanced algorithms to extract features with greater precision, which leads to better inspection outcomes. When images suffer from poor lighting or noise, enhancement techniques adjust brightness, contrast, and sharpness, making important details more visible. This process supports reliable inspections and helps reduce errors in automated systems.

A study using the Q-index, a quantitative image quality metric, found that enhancement techniques can nearly double the Q-index values for low-quality images. This improvement directly correlates with better machine vision outputs. However, some methods may introduce artifacts, so careful selection of enhancement techniques remains important.

| Brightness Condition | CNN Accuracy (%) |

|---|---|

| Standard brightness | 98.3 |

| +20% increased brightness | 83.0 |

This table shows that even a 20% increase in image brightness can reduce the accuracy of a convolutional neural network from 98.3% to 83%. Proper image enhancement ensures that brightness and other factors remain optimal, supporting high accuracy in inspection tasks.

Automated inspection processes in manufacturing environments benefit greatly from image enhancement. Deep learning models, such as convolutional neural networks, rely on enhanced image data to detect subtle defects that human inspectors might miss. For example, a custom CNN model achieved an inspection accuracy of 99.86% on casting product images, far surpassing manual inspection rates of 70-85%. Enhanced images reveal defects more clearly, increasing the reliability and consistency of automated inspections. As a result, image enhancement helps reduce human error and supports quality control by providing consistent, high-quality data for analysis.

Improvements after implementing image enhancement in machine vision systems include:

- Identification accuracy improved up to 99%.

- Defect rates reduced from 5% to under 2%.

- Inspection speed increased by 40%.

- Per-unit inspection costs cut by at least 50%.

These results demonstrate that enhancement not only boosts accuracy but also increases efficiency and reduces costs in quality control processes.

| Method | Detection Accuracy (%) | Average Processing Time (sec/slice) |

|---|---|---|

| RetinexNet | 85 | 2.5 |

| Zero-DCE | 88 | 1.9 |

| Proposed Method | 98 | 1.1 |

The proposed image enhancement method in this table achieves 98% detection accuracy, outperforming other methods and reducing false detection rates. This improvement highlights the importance of enhancement for defect detection and inspection efficiency.

Deep Learning and Automation

Deep learning models depend on high-quality image data for training and deployment. Image enhancement ensures that input images contain clear, relevant features, which helps these models learn more effectively. Advanced image processing algorithms, such as feature localization and quality adjustment, form the backbone of automated visual inspection systems. These enhancements support the detection of defects and improve the overall performance of deep learning models.

An adaptive image enhancement framework using deep reinforcement learning can select the best augmentation method for each image. This approach increases the size and diversity of the training dataset, leading to higher accuracy and robustness in defect detection. As a result, automated inspection systems become more reliable and efficient.

Image enhancement also supports foundational processes in quality control and industrial automation. Enhanced images enable automated visual inspection systems to detect surface defects and assembly errors, improving product conformity and safety. These systems provide real-time feedback, allowing immediate adjustments in production and preventing costly rework. Integration with AI, IoT, and robotics further increases efficiency and accuracy in defect detection.

| Aspect | Role in Quality Control and Industrial Automation |

|---|---|

| Image Acquisition Quality | Ensures high-quality data capture, foundational for accurate image processing and defect detection. |

| AI Algorithm Dependency | Image enhancement improves AI accuracy in defect detection (95–98%) and OCR (over 99.5%). |

| Automated Visual Inspection | Reduces defect rates by up to 80%, lowers human error from 25% to under 2%, and shortens cycle times by up to 20%. |

| Real-time Feedback | Enables immediate adjustments in production, preventing delays and costly rework. |

| Camera and Sensor Technology | Advances in imaging hardware enhance image quality, supporting efficient processing and automation. |

Automated visual inspection systems, powered by enhanced images, deliver increased efficiency and safety in manufacturing. These systems reduce the time and effort required for manual inspection, lower costs, and improve product quality. Flexible, camera-agnostic platforms allow easy deployment and adaptation, accelerating the adoption of automation in various industries.

Note: Image enhancement forms the foundation for quality control, automation, and safety in modern manufacturing. By improving image quality, these systems achieve higher accuracy, efficiency, and reliability, supporting advanced algorithms and reducing errors across inspection tasks.

Quality Control Applications

Manufacturing

Manufacturing industries rely on image enhancement to achieve precise quality control. Enhanced quality control begins with high-magnification optical microscopes that inspect microscopic components in flat panel displays. These tools help with defect detection by revealing misaligned liquid crystal molecules or organic layers. Uniformity assessment of backlighting and color filters identifies issues like backlight bleeding and uneven illumination. Pixel-level inspection allows identification of dead or non-responsive pixels, which affect visual quality. Color and luminance evaluation ensures accurate color reproduction and consistent luminance. Contaminant detection in organic layers prevents defects caused by impurities. Inspection of plasma display cells for gas leaks maintains physical integrity and uniform image formation. High-resolution imaging documents defects, supporting analysis and correction. Image processing libraries automate defect detection, dimensional measurement, and assembly verification, reducing manual errors and improving efficiency. These applications ensure consistent product standards and safety.

Food and Pharma

Image enhancement plays a vital role in food and pharmaceutical quality control. Noise reduction filters remove unwanted artifacts, improving image clarity for inspection. Contrast enhancement makes defects more visible, supporting accurate defect detection. Edge detection precisely identifies boundaries, allowing for accurate localization of defects. High-resolution cameras and advanced algorithms enable rapid detection of surface defects like scratches, dents, and color inconsistencies. Automated dimensional measurement ensures products meet strict size specifications. Real-time monitoring and continuous inspection maintain uniformity and compliance with quality standards. Enhanced quality control supports targeted repairs, reduces material waste, and improves efficiency. AI visual systems capture sharp images, and machine learning algorithms extract features for object identification. These systems detect subtle surface defects, contaminants, and foreign objects, improving safety and reducing defective products reaching consumers.

Automotive

Automotive manufacturing uses image enhancement to improve process monitoring and quality control. AI-driven enhancement normalizes images from diverse sources, ensuring consistent size, orientation, and background. Automated cropping, background replacement, and color adjustments reduce manual editing costs. AI flags compliance issues such as blurry images, sun glares, or vehicle damage, improving defect detection and safety. The system supports ongoing learning, improving enhancement and normalization over time. Automated defect detection identifies flaws in car parts, reducing human error and improving accuracy. Assembly verification ensures correct component positioning, enhancing efficiency. Surface inspection detects paint defects, dents, and inconsistencies, meeting industry standards for quality. Predictive maintenance uses visual data to detect early signs of wear, enabling timely repairs and supporting safety. These applications improve production quality, reduce returns, and provide a competitive advantage through faster, more accurate inspection.

AI-powered image enhancement in automated quality control systems achieves 99% defect detection accuracy, reduces inspection time from 1 minute to 2.2 seconds, and lowers defect rates by 30%. These improvements enable earlier identification of defects, continuous inspection, and lower operating expenses, resulting in higher product quality and safety across manufacturing industries.

Enhancement Workflow

Steps in the Process

A well-structured image enhancement workflow increases efficiency and accuracy in machine vision systems. The process begins with image acquisition, where cameras capture raw data under controlled lighting. Next, preprocessing steps such as resizing, normalization, and noise reduction improve image quality and consistency. Color correction follows, ensuring that images maintain accurate color representation for reliable inspection.

Engineers then apply enhancement techniques tailored to the application. These may include contrast adjustment, edge sharpening, or advanced methods like super-resolution. Filtering methods remove unwanted artifacts and highlight important features. After enhancement, the system performs inspection tasks such as defect detection or measurement. Real-time processing ensures that the workflow supports automation and immediate feedback.

The final step involves post-processing, where the system corrects any artifacts and prepares images for storage or further analysis. This workflow supports high efficiency and reliable inspection outcomes.

Best Practices

Optimizing image enhancement solutions requires careful planning and ongoing evaluation. The following best practices help maximize efficiency and inspection accuracy:

- Perform fundamental preprocessing, including resizing, normalization, noise reduction, and color correction, to stabilize image quality.

- Standardize color and intensity during preprocessing to improve model convergence and generalization.

- Apply advanced augmentation techniques, such as CutMix and Mixup, to increase robustness against occlusions and overfitting.

- Use style transfer and domain adaptation to minimize domain shifts between training and deployment environments.

- Integrate self-supervised learning tasks to leverage unlabeled data and enhance feature representations.

- Tune camera parameters iteratively, focusing on lens, sensor, and ISP settings for optimal image enhancement.

- Preserve sharp edges and color accuracy based on the specific inspection application.

- Combine hardware and software optimization to achieve the best results for machine vision, even if images appear less appealing to humans.

- Consider outsourcing or automation for tuning when expertise is limited, especially for smaller companies.

- Leverage industry alliances and specialized tools to stay updated on the latest image enhancement solutions and best practices.

| Best Practice Aspect | Description |

|---|---|

| Iterative Camera Tuning | Adjust lens, sensor, and ISP settings for each application and hardware change. |

| Data Preservation | Maintain sharp edges and color accuracy for better feature extraction and classification. |

| Hardware-Software Co-Design | Optimize both camera hardware and software for machine vision, not human aesthetics. |

| Application-Specific Optimization | Tailor enhancement to the needs of each inspection task, such as segmentation or recognition. |

Tip: Regularly review and update the enhancement workflow to adapt to new inspection challenges and maintain high efficiency in automation environments.

Image enhancement remains vital for machine vision, driving accuracy, reliability, and automation across industries. Robust strategies—such as advanced lighting, optics, and calibration—maximize system performance. Machine vision engineers should regularly assess workflows for improvement opportunities.

| Calibration Technique | Impact on Image Quality |

|---|---|

| Detector Normalization | Enhances sensitivity and resolution |

| Scatter Correction | Reduces noise and artifacts |

| Motion Correction | Minimizes motion blur |

- Evaluate business needs

- Collect high-quality data

- Integrate and test solutions

These steps ensure machine vision systems deliver consistent, high-quality results.

FAQ

What is the main purpose of image enhancement in machine vision?

Image enhancement improves image quality so that machine vision systems can detect features and defects more accurately. Enhanced images help algorithms make better decisions and support reliable automated inspection.

Which industries benefit most from image enhancement?

Manufacturing, automotive, food, and pharmaceutical industries gain the most from image enhancement. These sectors use enhanced images for defect detection, measurement, and process monitoring.

Can image enhancement fix all poor-quality images?

Image enhancement can improve many images, but it cannot recover information lost due to extreme blur, low resolution, or severe noise. High-quality image capture remains essential for best results.

How does image enhancement support deep learning models?

Enhanced images provide clear features and consistent quality. Deep learning models learn faster and perform better when trained on enhanced data. This leads to higher accuracy in tasks like defect detection and classification.

See Also

The Impact Of Deep Learning On Machine Vision Technology

Image Recognition’s Importance In Machine Vision Quality Assurance

Does Filtering Improve The Accuracy Of Machine Vision Systems

The Role Of Feature Extraction In Machine Vision Performance