A gray scale image machine vision system delivers three main benefits: improved detection accuracy, lower costs, and faster, simpler processing. Many factories and labs choose grayscale because it solves problems like lighting changes, noise, and difficult edge detection.

Common challenges addressed by grayscale systems include:

- Handling lighting and noise issues

- Improving edge and feature detection with subpixel accuracy

- Ensuring reliable measurements at production speeds

Studies show that deeper neural networks trained on grayscale images reach almost the same, or even better, accuracy as color systems:

| Model Depth | Color Accuracy (%) | Grayscale Accuracy (%) | Notes |

|---|---|---|---|

| ResNet-18 | ~99.6 | ~99.5 | Small gap, less with deeper models |

| ResNet-50 | Comparable | Comparable | Gap nearly gone |

| ResNet-101 | High | High | No significant difference |

Key Takeaways

- Grayscale vision systems improve detection by focusing on brightness differences, making object and defect recognition more accurate and reliable.

- Using grayscale cameras lowers costs by requiring simpler hardware, reducing power use, and speeding up image processing with less data.

- Processing grayscale images is faster because the system handles only one channel, enabling real-time analysis and higher productivity.

- Grayscale systems are easy to integrate and adapt, working well with tools like OpenCV and fitting many industries from manufacturing to healthcare.

- Choosing grayscale vision helps companies achieve efficient, flexible, and cost-effective machine vision solutions without sacrificing accuracy.

Detection Accuracy

Object Identification

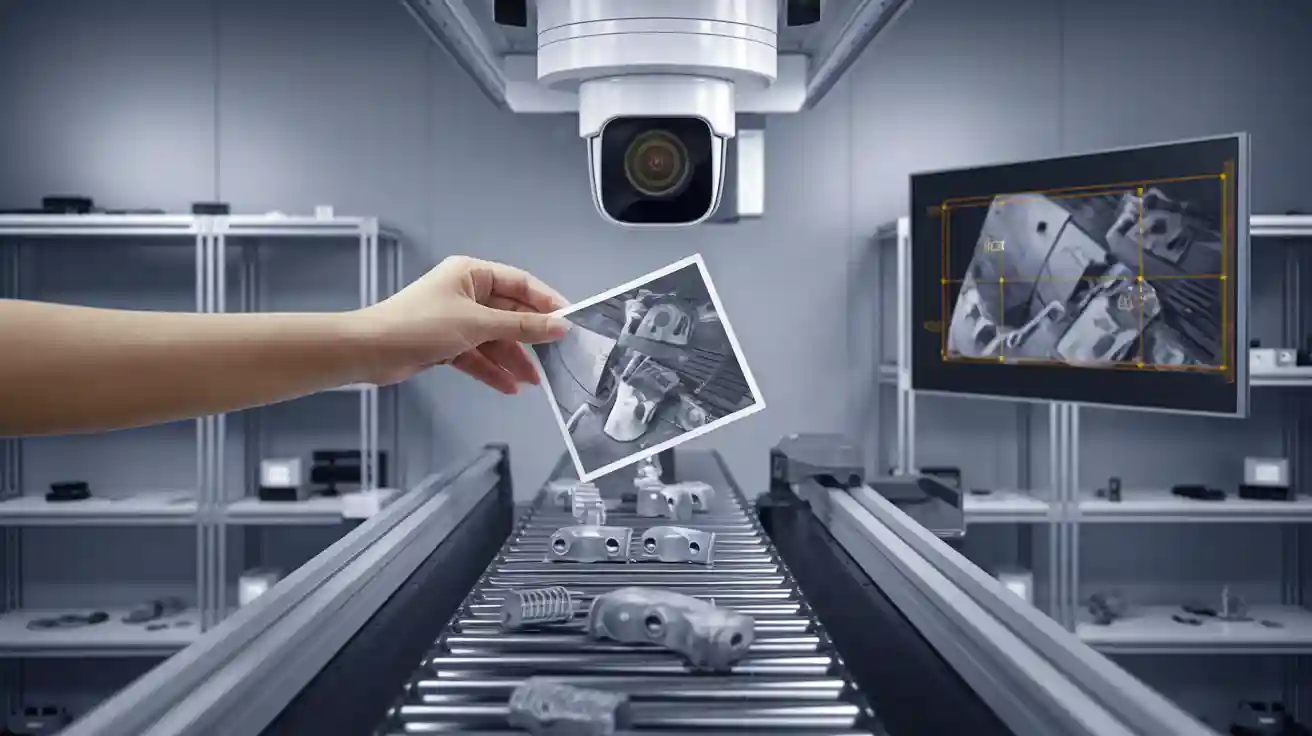

A gray scale image machine vision system improves object identification by focusing on intensity differences instead of color. This approach allows the camera to capture subtle changes in brightness, which helps the system recognize shapes and edges more clearly. In computer vision, researchers have developed models like YOLO-MIF that work specifically with grayscale images. These models use advanced image processing techniques to handle challenges such as limited object discrimination. By using only one channel, the camera reduces unnecessary data, making processing faster and more reliable.

Neuroscience studies show that the brain also relies on intensity and contrast to identify objects. Neurons in the visual cortex respond to changes in brightness, supporting the idea that grayscale images help with precise object recognition. The camera captures these intensity patterns, and computer vision algorithms use them for feature detection and image enhancement. Grayscale images simplify the processing pipeline, allowing the system to focus on important details without distractions from color.

The opencv library plays a key role in this process. It provides tools for image processing, image enhancement, and object detection. With opencv, the camera can quickly analyze grayscale images, improving detection accuracy in real time. This method works well in many fields, including industrial inspection and medical imaging.

Defect Detection

Defect detection becomes more efficient with grayscale images. The camera can spot flaws by analyzing contrast and intensity differences. In industrial settings, grayscale systems often outperform color systems when color is not essential. The table below compares color and grayscale systems for defect detection:

| Aspect | Color Vision Systems | Grayscale Vision Systems |

|---|---|---|

| Defect Detection Capability | Good for color-based defects; needed for color recognition tasks. | Effective for most inspections; excels at detecting shape, texture, and contrast-based flaws. |

| Data Channels | Three (RGB) | One (grayscale) |

| Lighting Challenges | Sensitive to lighting changes | Less affected by lighting variations |

| Application Suitability | Best for color-critical tasks | Best for shape, contrast, or texture-focused tasks |

Grayscale images allow the camera to use simple thresholding methods for image processing. Techniques like adaptive thresholding and Otsu’s method, available in the opencv library, help the system separate defects from the background. These methods improve reliability and speed, making grayscale a popular choice for computer vision applications. The camera processes fewer data points, which leads to faster image enhancement and more accurate detection. Grayscale systems also support real-time monitoring and noise reduction, further boosting defect detection rates.

Cost Efficiency

Hardware Savings

A gray scale image machine vision system helps companies save money on hardware. The camera in a grayscale system uses only one sensor channel, while a color camera needs three. This simple design means the camera costs less to make and buy. The camera also uses less power because it does not need to process color data. Lower energy use leads to smaller electricity bills. Maintenance becomes easier, too. The camera has fewer parts, so it breaks less often and needs fewer repairs. Many factories choose grayscale cameras for these reasons. They want reliable image processing without high costs.

Tip: Grayscale cameras often last longer because they have fewer moving parts and less complex electronics.

Processing Costs

Grayscale images require less data than color images. The camera captures only one channel, so the image file is smaller. This smaller size means the camera can send images faster to the computer. The computer uses less memory and less bandwidth for each image. Image processing becomes quicker and more efficient. The camera can handle more images every second, which helps in fast production lines. Grayscale image processing also uses less power from the computer. Preprocessing steps, such as grayscale conversion and compression, keep important features while making the image smaller. Neural modules can focus on key parts of the image, saving even more resources. Hardware like FPGA-based preprocessing can speed up image enhancement and filtering at the camera itself. This reduces the load on the rest of the system. Studies show that preprocessing can cut the time it takes for the camera to return an image by up to 84%. This big improvement helps companies save money and boost real-time performance.

A grayscale camera supports fast and reliable image processing. It makes image enhancement easier and cheaper. Many industries use grayscale systems to lower costs and improve efficiency.

System Simplicity

Fast Processing

Grayscale images help a system work faster. The system only needs to process one channel instead of three, which makes image processing much quicker. When a system uses grayscale images, it can analyze each image with less data. This means the system can handle more images every second. Many factories use this method to keep up with fast production lines. Grayscale images also make it easier for the system to use thresholding techniques. These methods turn complex images into simple binary formats. The system can then spot important features quickly. Adaptive thresholding helps the system adjust to changes in lighting, so image processing stays reliable in different environments. Otsu’s method lets the system set the best threshold automatically, which saves time and improves accuracy. Each of these steps makes the system more productive and efficient.

Easy Integration

A grayscale image machine vision system is easy to set up and connect with other tools. Grayscale images use less data, so the system can send and receive images faster. This helps the system work well with other machines and software. Many engineers use grayscale images as a preprocessing step. This step prepares the image for more advanced image processing tasks. Gray level quantisation helps the system create stable features for machine learning models. Binning methods make the system more adaptable to different types of images. Calibration techniques, such as detector normalization and scatter correction, improve image quality. These steps help the system handle changes in lighting and noise. The system becomes more reliable and efficient. Grayscale images also make it easier for the system to use automated workflows. The system can process images with less manual work, which saves time and reduces errors. Many industries choose grayscale systems because they are simple, flexible, and easy to integrate.

Gray Scale Image Machine Vision System Benefits

Computational Efficiency

A gray scale image machine vision system stands out for its computational efficiency. This system uses only one channel for image processing, which reduces the amount of data and speeds up every step. In computer vision, this means faster processing and less memory use. The system can handle more images per second, which is important for real-time tasks. Many engineers use opencv to build these systems because opencv supports fast image processing and easy integration with hardware.

The table below shows key metrics that measure computational efficiency and image quality in a gray scale image machine vision system:

| Metric Name | Description | Importance for System Performance |

|---|---|---|

| Root Mean Square Contrast Difference (RMS) | Measures global image contrast. Higher RMS means better contrast. | Ensures clear images for processing. |

| Normalized Root Mean Squared Contrast Difference (NRMS) | Shows how close grayscale output is to the original. Lower NRMS is better. | Keeps important details for computer vision. |

| Gradient Recall Ratio (GRR) | Measures how well the system keeps image details. Higher GRR is better. | Helps with feature detection in opencv. |

| Edge Recall Ratio (ERR) | Shows how well edges are kept. Higher ERR means better edge retention. | Important for shape recognition in computer vision. |

| Computational Efficiency | Linear time complexity, fast like traditional methods. | Makes real-time processing possible. |

A gray scale image machine vision system also benefits from reduced model complexity. By using fewer parameters, the system avoids overfitting and works better in real-world applications. Engineers often replace fully connected layers with 1×1 convolutions, which lowers computational load and speeds up processing. This makes the system ideal for tasks like automated sorting, quality inspection, and image optimization. With opencv, the system can use advanced algorithms for image processing and computer vision without slowing down.

Versatility

The gray scale image machine vision system shows great versatility across many industries. In manufacturing, companies use these systems for quality control, defect detection, and process optimization. Healthcare professionals rely on them for medical image analysis, such as tumor detection and treatment planning. Robotics engineers use the system for vision-guided robots, object location, and automation.

Here is a table showing where gray scale image machine vision systems are used:

| Industry | Examples / Applications |

|---|---|

| Manufacturing | Quality control, defect detection, assembly automation |

| Healthcare | Tumor detection, lesion identification, diagnosis |

| Robotics | Bin picking, object location, 3D imaging, automation |

A common misconception is that these systems only compare images to a single good part. In reality, the system uses advanced computer vision algorithms, such as edge extraction and pattern matching, often powered by opencv. The system can extract features, measure contrast, and analyze shapes with high accuracy. Recent advances in deep learning and opencv have made gray scale image machine vision systems even more powerful. For example, new neural networks inspired by the brain can classify complex features and handle difficult text recognition tasks. These improvements allow the system to achieve high accuracy and speed, even in challenging environments.

The gray scale image machine vision system supports flexible deployment, including cloud and edge setups. This flexibility, combined with strong image processing and computer vision capabilities, makes the system a top choice for many modern applications. Engineers can use opencv for image optimization, noise reduction, and feature extraction, making the system adaptable and efficient.

A gray scale image machine vision system offers three key advantages: detection accuracy, cost efficiency, and system simplicity. Industries such as manufacturing, pharmaceuticals, and coal processing use these systems for fast, reliable, and non-intrusive monitoring. Studies show that real-time texture analysis and in-line quality checks improve product control.

- Experts recommend testing cameras in real-world lighting, choosing sensors with high dynamic range, and using user-friendly interfaces for easy setup.

The global market for machine vision systems continues to grow as more companies seek efficient, adaptable solutions.

FAQ

What is a gray scale image machine vision system?

A gray scale image machine vision system uses only shades of gray to analyze images. The system detects shapes, edges, and patterns by measuring brightness. Many industries use this system for fast and accurate inspections.

Tip: Grayscale systems often work better in changing light conditions.

Why do companies choose grayscale over color systems?

Companies pick grayscale systems because they cost less and process images faster. The system uses less data, which means lower hardware and energy costs. Grayscale also makes it easier to spot defects that do not depend on color.

Can a grayscale system detect all types of defects?

A grayscale system finds most defects related to shape, texture, or contrast. It may not work well for color-based flaws. For example, it cannot tell if a red part turns blue, but it can spot cracks or scratches.

How does grayscale improve processing speed?

The system processes only one channel instead of three. This reduces the amount of data and speeds up analysis. Many factories use grayscale to keep up with fast production lines and real-time monitoring.

- Faster processing helps increase productivity.

- Lower data use saves memory and bandwidth.

Is it easy to upgrade to a grayscale machine vision system?

Most engineers find it easy to switch to grayscale systems. The system uses simple hardware and software. Many tools, like opencv, support grayscale image processing. This makes setup and integration quick and straightforward.

See Also

Understanding How Machine Vision Systems Process Images

The Role Of Cameras Within Machine Vision Systems

How To Properly Position Equipment For Machine Vision