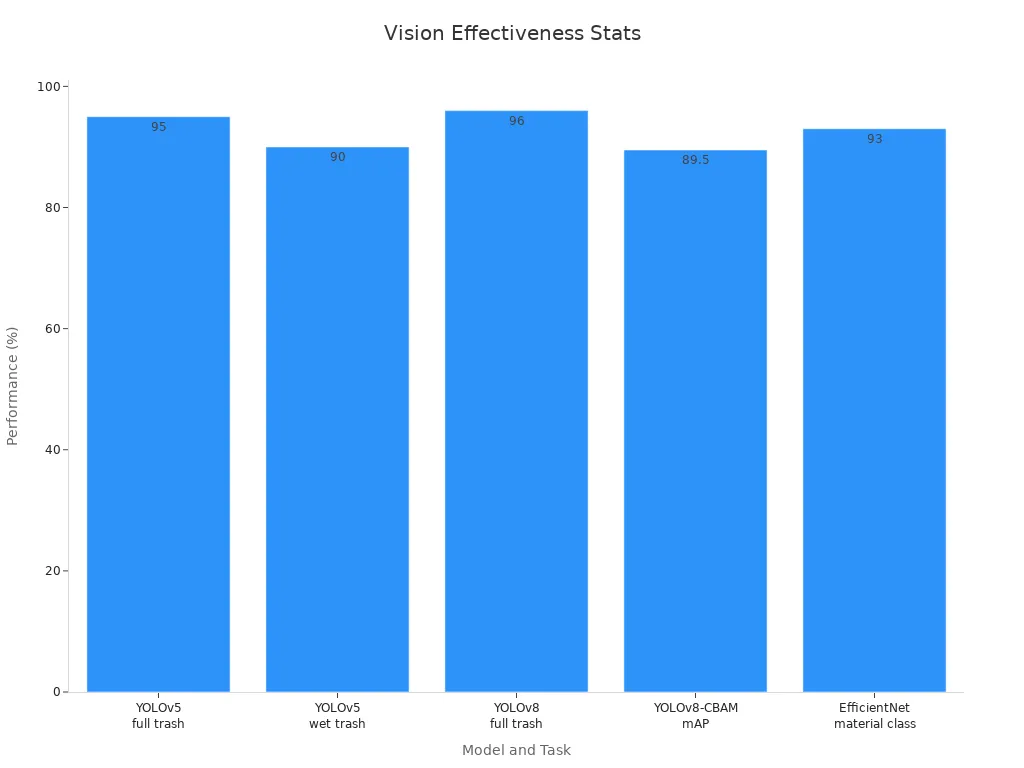

A garbage out machine vision system uses advanced cameras and artificial intelligence to identify and sort waste materials. The accuracy of these systems depends on the quality of input data, which follows the garbage in, garbage out rule. When trained with high-quality images and clear labels, these systems can reach up to 96% accuracy in classifying trash bins, as the chart below shows.

Machine vision supports automated waste sorting by recognizing different materials on a conveyor belt. Studies reveal that models like Mask R-CNN, trained on well-annotated datasets, achieve strong results but struggle if input images have overlapping objects or poor lighting.

Key Takeaways

- Garbage out machine vision systems use cameras and AI to sort waste, but their accuracy depends on the quality of input data.

- High-quality, well-labeled data helps these systems achieve up to 96% accuracy in identifying and sorting trash.

- Combining advanced sensors, smart software, and real-time monitoring improves sorting speed, reduces errors, and supports recycling efforts.

- Regular data cleaning, audits, and staff training prevent common data problems and keep the system reliable.

- These systems boost efficiency in industries and recycling centers, helping reduce waste, lower costs, and meet sustainability goals.

Garbage Out Machine Vision System

What It Is

A garbage out machine vision system refers to a technology that uses cameras and artificial intelligence to sort and identify waste materials. This system follows a simple rule: the quality of the output depends on the quality of the input. If the system receives poor data, it produces poor results. The concept comes from the early days of computer science and remains important today. Key points include:

- The system’s output quality matches the input data quality.

- Incorrect or low-quality input leads to errors, even if the system works perfectly.

- Machine learning models can make mistakes if trained with faulty data.

- The idea applies to many fields, including computer science, AI, and machine vision.

- The term "garbage in, garbage out" started in the 1950s and 1960s.

- Real-world failures, such as program crashes or wrong medical diagnoses, often result from bad input.

- During the COVID-19 pandemic, poor data led to forecasting errors, showing how important good input is for accurate results.

A garbage out machine vision system highlights the need for clean, accurate data at every stage.

Core Principles

The core principles of a garbage out machine vision system focus on combining advanced hardware and smart software to sort waste quickly and accurately. High-resolution cameras, hyperspectral imaging, and sensors work together to capture detailed images of waste materials. Artificial intelligence algorithms then analyze these images to identify and classify different types of waste. The system adapts to new materials and improves sorting efficiency over time.

Industry reports explain that these systems automate object identification, inspection, measurement, and sorting. They make decisions at high speed, helping factories reduce waste and improve efficiency. Machine vision systems also generate important data that supports better process control and product quality. Integration with industrial automation boosts productivity, traceability, and safety.

Note: The success of a garbage out machine vision system depends on the seamless integration of cameras, sensors, and AI. Each part must work together to deliver reliable results.

These principles ensure that waste management facilities can sort materials more effectively, reduce errors, and support recycling efforts.

How Automated Waste Sorting Works

System Components

Automated waste sorting systems rely on a combination of cameras, optics, and lighting to analyze materials moving along conveyor belts. High-resolution cameras capture detailed images of waste items. Specialized lighting ensures that the system can see objects clearly, even in challenging conditions. These images feed into advanced computer vision software, which identifies and classifies each item.

Many facilities use a mix of sensors, such as near-infrared, humidity, and temperature sensors, to improve contaminant detection. For example, a technical study compared systems using multiple sensors and deep learning models. The best results came from combining sensor data with camera images, which improved the purity of sorted waste. Robotic arms, often equipped with suction cups or grippers, pick and sort recyclables at high speeds. These robots work continuously, increasing efficiency and safety.

Material recovery facilities use conveyors, shredders, and mechanical sorting equipment adapted from other industries. These components help separate paper, metals, plastics, and glass. Real-time monitoring and data analytics optimize the process, reduce labor costs, and increase recovery rates. Automated waste sorting systems in manufacturing installations show how technology can improve recycling and reduce contamination.

Tip: Smart waste bins with sensors can optimize collection schedules and further reduce operational costs.

Deep Learning and AI

Deep learning and AI play a key role in computer vision in waste management. These technologies allow systems to learn from large datasets and improve over time. Empirical studies show that deep learning models, such as DenseNet121 and MobileNet, achieve high accuracy in waste classification tasks. For example, DenseNet121 reached a test accuracy of 99.6% when optimized with genetic algorithms.

AI-powered waste management systems use convolutional neural networks (CNNs) to extract features from images. These models can identify different types of waste, even when items overlap or appear in poor lighting. Transfer learning and data augmentation help improve model performance. Deep learning also supports contaminant detection, making sorting more reliable.

Computer vision in waste management benefits from AI’s adaptability and robustness. Automated waste sorting systems that use deep learning can classify materials quickly and accurately. This approach reduces contamination and increases recycling rates. Real-time monitoring ensures that the system maintains high performance, even as waste streams change.

Key Features and Limitations

Strengths

Automated waste sorting systems offer several strengths that make them valuable in modern waste management. These systems use advanced sensors, including infrared, near-infrared, metal detectors, and X-ray fluorescence sensors, to identify different materials quickly and accurately. Control systems coordinate these sensors with sorting mechanisms such as air jets, magnetic separators, and mechanical arms. This integration allows for fast and precise sorting, which boosts recycling rates and reduces contamination.

Industry data shows that these systems combine speed and accuracy effectively. For example, integrated measures like response time and error proportion demonstrate that automated sorting can detect and separate materials with high efficiency. In many cases, detection efficiency remains above 98%, even when only one factor—speed or accuracy—shows a strong effect. This high performance helps facilities process large volumes of waste without sacrificing quality.

Many systems also include safety features, such as emergency stops and protective barriers, to protect workers. The use of IoT and smart sensors enables real-time monitoring and dynamic adjustments, further improving operational efficiency. Modular and scalable designs allow facilities to customize systems for different needs, supporting both small and large operations.

Note: The combination of advanced technology and smart design makes automated waste sorting systems reliable and adaptable for various environments.

Weaknesses

Despite their strengths, garbage out machine vision systems face several limitations. Technical complexity requires specialized expertise for installation, operation, and maintenance. High initial investment and ongoing maintenance costs can challenge smaller organizations. Space constraints and integration with existing infrastructure often limit adoption, especially in older facilities.

Operational challenges also include the need for operator training and compliance with evolving regulations. Quality control issues, such as contamination risks, can arise if the system receives poor input data. Documented cases show that improper data labeling, missing data, and model bias can lead to unreliable results. For example, missing or incorrect data in public health models has caused faulty outputs, highlighting the importance of accurate input.

Statistical analyses reveal that problems like multicollinearity and outlier handling can degrade system reliability. Market demand for recycled materials can fluctuate, affecting the economic viability of these systems. Organizational and cultural changes may be necessary for successful adoption, as staff must adapt to new technologies and workflows.

Tip: Regular data audits and bias screening help maintain system accuracy and prevent garbage in, garbage out problems.

Garbage In, Garbage Out

Data Quality

The phrase garbage in, garbage out describes a simple truth in machine vision systems. When a system receives poor input, it produces poor results. Data quality shapes every step of the process. If training data quality is low, the system cannot learn to sort waste correctly. Research shows that imbalanced and noisy input data can lower the accuracy of machine vision models. For example, studies found that models using advanced data balancing methods performed better in hazardous waste prediction. Random Forest models, which handle noisy and irregular data well, achieved much higher accuracy than other algorithms. This result highlights the impact on model performance when data quality drops. Diverse and well-preprocessed input data can help models reach up to 85% accuracy. These findings prove that the necessity of data preprocessing and careful data integrity and cleaning cannot be ignored.

High data quality ensures that machine vision systems sort waste more accurately and efficiently.

Avoiding Common Pitfalls

Many organizations face challenges with garbage in, garbage out because of common data quality pitfalls. Problems like duplicate records, missing information, and inconsistent standards can lead to errors. To maintain strong data quality, experts recommend several best practices:

- Validate and clean data using rule-based and statistical checks.

- Standardize data formats and use clear metadata.

- Remove duplicate entries and resolve overlapping records.

- Conduct regular data audits and updates.

- Use automated monitoring tools for continuous quality checks.

- Assign clear data ownership and governance roles.

- Protect data with strong security and privacy measures.

- Invest in a unified data quality platform for a complete view of data health.

Organizations also benefit from training staff, setting clear data entry rules, and building a culture focused on quality. Strategic planning, robust testing, and regular updates help avoid integration and maintenance issues. These steps reduce the risk of garbage in, garbage out and keep machine vision systems running smoothly.

Applications

Industrial Use Cases

Industries worldwide have adopted smart waste solutions to improve efficiency and reduce costs. Manufacturing plants use computer vision in waste management to monitor production lines and sort defective products. Automotive and electronics factories rely on smart waste bins to separate materials like plastics, metals, and glass. These bins use sensors and cameras to identify and sort items automatically. The integration of smart waste bins with robotics has increased the speed and accuracy of sorting tasks.

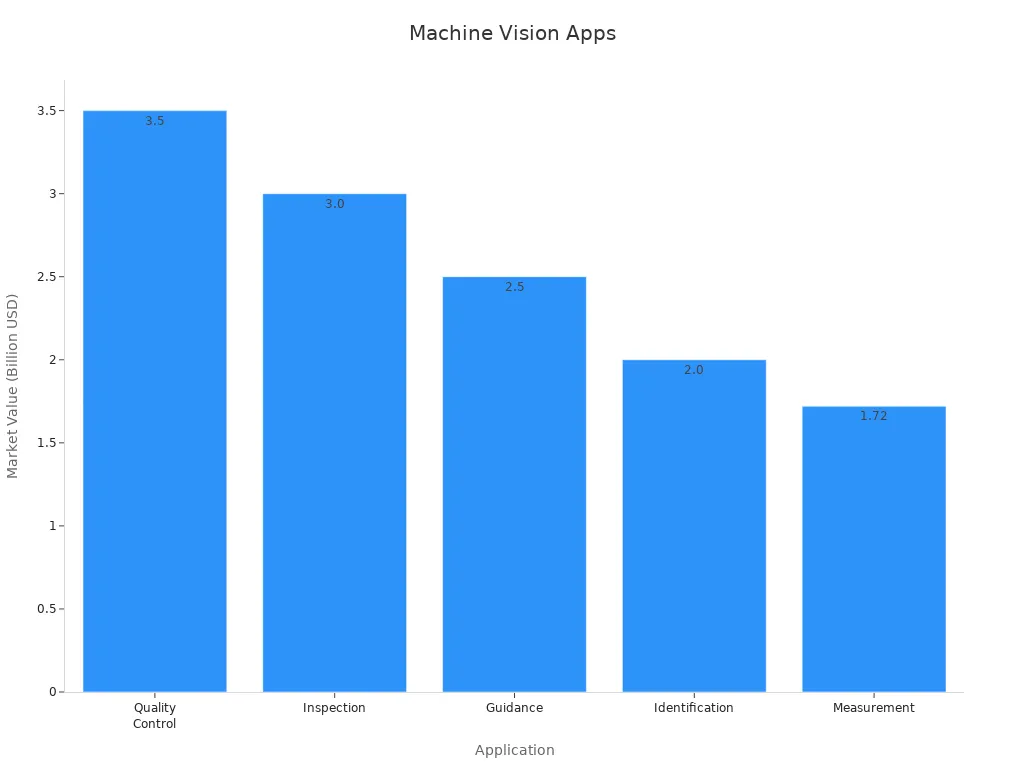

Market research shows strong growth in this sector. The global machine vision systems market is projected to reach $22.42 billion by 2029, with a compound annual growth rate of 10%. Automation, robotics, and Industry 4.0 initiatives drive this expansion. North America leads the market, while Asia-Pacific grows rapidly. The number of robots in factories reached 4.28 million in 2024, up 10% from the previous year. These trends highlight the growing role of computer vision in waste management and smart waste solutions across industries.

| Aspect | Data / Value |

|---|---|

| Global Market Size (2024) | USD 14.1 Billion |

| Forecast Market Size (2029) | USD 22.42 Billion |

| Forecast Market Size (2033) | USD 26.7 Billion |

| CAGR (2025-2033) | Approximately 7% to 10% |

| Key Application Values (2024) | Quality Control: USD 3.5 Billion |

| Inspection: USD 3.0 Billion | |

| Guidance: USD 2.5 Billion | |

| Identification: USD 2.0 Billion | |

| Measurement: USD 1.72 Billion | |

| Leading Regions (2024) | North America: USD 4.0 Billion |

| Europe: USD 3.5 Billion | |

| Asia-Pacific: USD 3.0 Billion | |

| Emerging Regions (2024) | South America: USD 1.0 Billion |

| Middle East & Africa: USD 1.22 Billion | |

| Market Drivers | Automation, AI, Industry 4.0, Robotics |

| End-Use Sectors | Manufacturing, Healthcare, Automotive, Aerospace, Food & Beverage, Agriculture, Retail, Entertainment |

| Technological Trends | AI, Deep Learning, 3D Vision, Edge Computing |

Recycling and Waste Management

Recycling centers and municipalities use computer vision in waste management to boost recycling rates and lower emissions. Smart waste bins play a key role in these facilities. They use sensors and cameras to detect and sort recyclables, reducing contamination and manual labor. Smart waste solutions help facilities process more waste in less time.

- EPA data shows recycling and composting prevented over 193 million metric tons of CO2 equivalent emissions in 2018.

- Vision AI systems increase sorting accuracy, leading to higher recycling rates.

- Smart waste bins automate sorting, cut operational costs, and handle larger waste volumes.

- Improved accuracy reduces landfill waste and supports sustainability goals.

- Machine learning enables smart waste solutions to adapt to new materials and challenges.

- Companies like ZenRobotics and Recycleye develop these technologies for real-world use.

Smart waste bins now appear in offices, schools, airports, and public spaces. They help cities meet sustainability targets and reduce environmental impact. Computer vision in waste management and smart waste solutions continue to transform recycling and waste management worldwide.

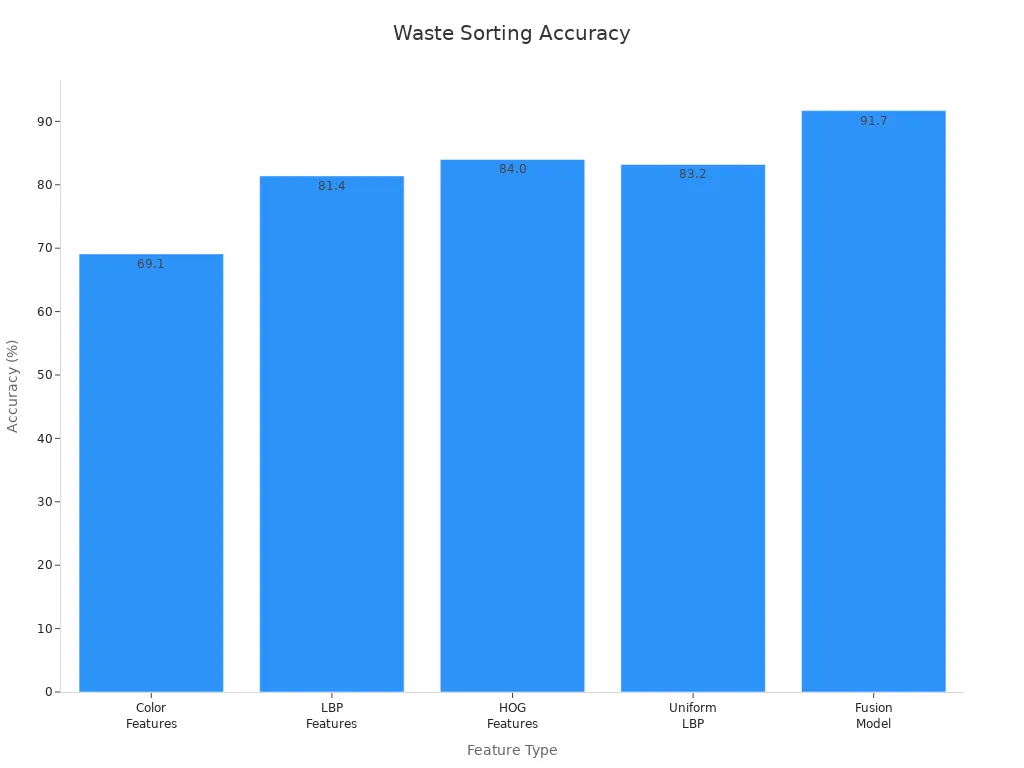

Understanding garbage out machine vision systems helps organizations achieve better waste sorting results. High-quality input data and a well-designed system setup lead to higher accuracy and efficiency. For example, combining multiple features with an artificial neural network increased sorting accuracy to 91.7%, as shown below.

| Feature Type | Accuracy (%) |

|---|---|

| Color Features | 69.1 |

| LBP Features | 81.4 |

| HOG Features | 84.0 |

| Uniform LBP | 83.2 |

| Fusion Model | 91.7 |

Facilities using real-time monitoring, like the Greyparrot Analyzer, react quickly to changes and improve resource recovery. Applying best practices ensures reliable, efficient automated waste sorting.

FAQ

What is the main cause of errors in garbage out machine vision systems?

Poor input data quality often causes errors. Blurry images, incorrect labels, or missing information confuse the system. High-quality, well-labeled data helps the system sort waste accurately.

How often should organizations update their training data?

Experts recommend updating training data regularly. New types of waste and changes in packaging appear often. Frequent updates help the system adapt and maintain high accuracy.

Can machine vision systems handle mixed or overlapping waste items?

Modern systems use advanced AI models to identify mixed or overlapping items. Performance drops if images lack clarity or if objects overlap too much. Good lighting and camera placement improve results.

What maintenance do these systems require?

Routine maintenance includes cleaning cameras, checking sensors, and updating software. Regular inspections prevent breakdowns and keep the system running smoothly.

Are garbage out machine vision systems cost-effective for small facilities?

Initial costs can be high for small facilities. Over time, savings from reduced labor and improved sorting may offset expenses. Some vendors offer scalable solutions for smaller operations.

See Also

Essential Insights Into Computer Vision And Machine Vision

Understanding The Fundamentals Of Sorting Machine Vision

A Clear Guide To Image Processing In Machine Vision