The emergence machine vision system delivers unparalleled speed and precision in industrial imaging. This advanced machine vision solution captures thousands of frames per second, detecting micrometer-level defects and analyzing rapid events that drive quality improvements. Industries benefit from a significant reduction in screen breakage and internal parts looseness, as shown below:

| Year | Screen Breakage Rate | Internal Parts Looseness Rate |

|---|---|---|

| 2014 | 70% | 50% |

| 2024 | Within 10% | Within 10% |

With a projected 6.4% CAGR for the global machine vision market, the emergence machine vision system stands out as an essential tool for high-speed, high-resolution applications.

Key Takeaways

- The emergence machine vision system captures thousands of high-resolution images per second, detecting tiny defects and speeding up quality control.

- Advanced GigE cameras and GPUDirect technology enable fast, real-time processing and support many cameras working together for large-scale applications.

- The system integrates easily with existing automation platforms and uses deep learning to improve accuracy and adapt to changing inspection needs.

- Industries like manufacturing, sports, and virtual reality benefit from improved efficiency, better product quality, and enhanced performance analysis.

- Compared to traditional systems, this solution offers higher speed, resolution, and flexible integration, making it a leader in modern machine vision technology.

How It Works

Core Technology

The emergence machine vision system relies on high-speed GigE Vision cameras that support 10, 25, 50, and 100GigE interfaces. These cameras use advanced sensors from Sony and Gpixel, which deliver both high resolution and rapid frame rates. The system captures images at the fastest speeds without losing any data, even when handling thousands of frames per second. This capability ensures that every detail, from tiny defects to fast-moving objects, is recorded with precision.

- The cameras can operate in multi-camera configurations, supporting over 50 cameras on a single computer and more than 200 cameras across several computers.

- The system supports both area scan and line scan imaging, making it suitable for a wide range of machine vision tasks.

- Specific models, such as the PACE 10GigE line scan cameras, achieve line rates from 70 to 172kHz and resolutions up to 16Kx16, providing both color and monochrome imaging options.

Researchers have shown that machine vision technology improves production management and automation in industries like furniture manufacturing. Applications include workshop monitoring, quality inspection, and automatic sorting. Studies highlight that combining traditional machine vision with deep learning increases speed and accuracy, making the emergence machine vision system a powerful tool for advanced industrial applications.

Note: The integration of 3D machine vision technologies, such as structured light and binocular vision, helps overcome the limitations of 2D systems. This advancement allows the system to detect more complex and ambiguous defects.

System Components

The emergence machine vision system consists of several key components that work together to deliver high-speed, high-resolution imaging:

- GigE Vision Cameras: These include 10GigE, 25GigE, and 100GigE models. Each camera type offers different resolutions, frame rates, and special features to match specific application needs.

- Acquisition Software: eCapture Pro software manages image acquisition, processing, and system control. It includes FlexProc and FlexTrans technologies, which provide full control over capture and processing tasks.

- GPUDirect Technology: This feature enables direct data transfer from cameras to GPU memory, reducing latency and boosting processing speed. The eSDK supports zero-copy architecture, which accelerates high-performance developments.

- Multi-Camera Support: The system can connect dozens of cameras to a single server or hundreds across multiple servers, allowing for large-scale machine vision deployments.

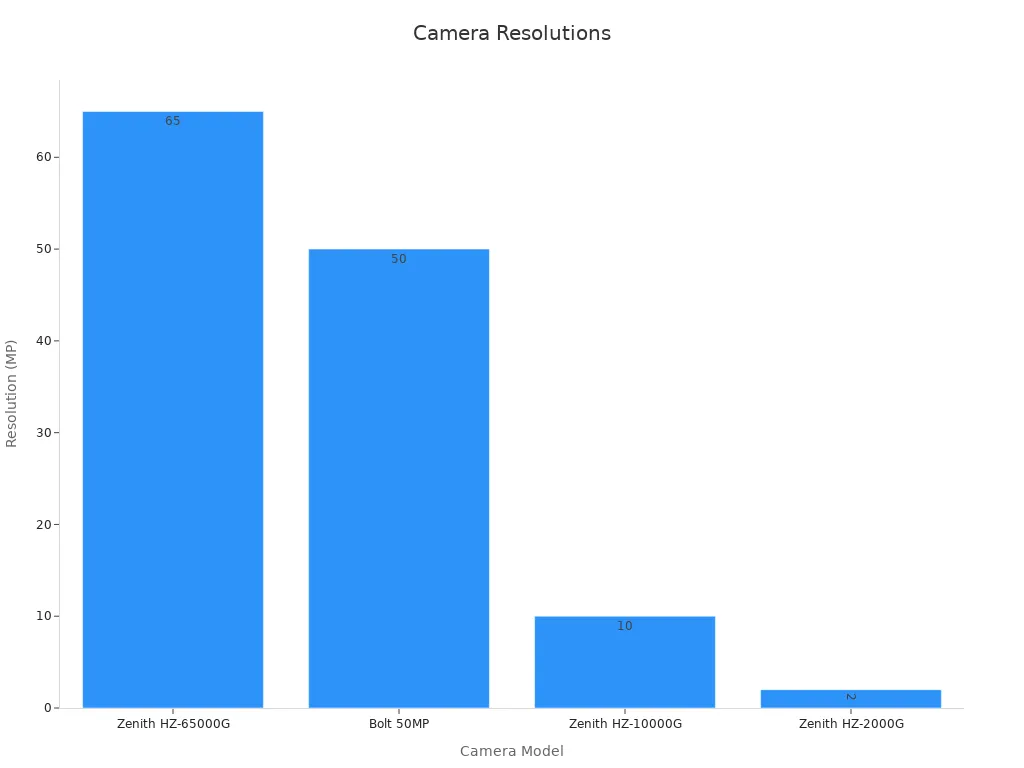

The following table summarizes the technical performance metrics for the main camera types used in the system:

| Camera Type | Model / Application | Resolution | Frame Rate | Line Scan Rate | Power Consumption | Special Features |

|---|---|---|---|---|---|---|

| 100GigE Area Scan | Zenith HZ-65000G (AOI Inspection) | 65MP | 71 fps | N/A | N/A | Zero-copy, GPU Direct, real-time processing |

| 100GigE Line Scan | Pinnacle LZ-16KG5 | N/A | N/A | 400 KHz | N/A | High-speed line scan for battery foil inspection |

| 100GigE Line Scan | Pinnacle LZT-9KG5 TDI | N/A | N/A | 600 KHz | N/A | Suitable for light-starved or high-rate applications |

| 25GigE Area Scan | Bolt 50MP (Volumetric Capture) | 50MP | N/A | N/A | N/A | Large multi-camera systems, distributed processing, redundancy |

| 10GigE Area Scan | Eros (upcoming) | Various | 10G, 5G, 2.5G, 1G | N/A | Lowest among 10GigE/5GigE | Zero-copy, GPU Direct, compact 29x29mm form factor |

| 100GigE Area Scan | Zenith HZ-10000G (Sports Analytics) | 10MP | Up to 1000 fps | N/A | N/A | Baseball seam tracking, real-time analytics |

| 100GigE Area Scan | Zenith HZ-2000G (Nanotechnology) | 2MP | N/A | N/A | N/A | Low latency, GPU Direct, reliable transfer for interferometric measurements |

| 100GigE Area Scan | Zenith HZ-21000G (Wind Tunnel) | N/A | N/A | N/A | N/A | Multi-server setup, 100GigE switch, GPU processing |

| 10/25/100GigE | Various demos | N/A | Multiple per server (up to 36 10GigE cameras) | N/A | N/A | Zero-copy, GPU Direct, multi-server distributed processing |

Laboratory testing confirms the operational efficiency of the system:

| Performance Metric | Result/Impact |

|---|---|

| Turnaround Time Reduction | Up to 25% reduction via intelligent route scheduler |

| Pre-analytical Error Identification | Up to 80% of common errors detected through specimen checks |

| Workflow Control | 100% control of workflow from accession to archive via middleware integration |

The system’s architecture ensures that acquisition, processing, and data transfer happen seamlessly. This design supports demanding machine vision applications, from industrial inspection to sports analytics. The emergence machine vision system delivers reliable, high-speed acquisition and real-time analysis, making it a leader in the field.

Features

High-Speed Imaging

The emergence machine vision system delivers exceptional high-speed imaging capabilities. Advanced GigE cameras capture thousands of frames per second, supporting both area scan and line scan modes. High resolution and rapid frame rates allow the system to detect minute defects and track fast-moving objects with precision. Near Infrared imaging expands the system’s ability to identify features invisible to standard cameras, making it suitable for specialized industrial tasks.

Performance metrics validate the system’s effectiveness in real-world environments:

| Metric | Description |

|---|---|

| Accuracy | Measures the overall success rate in correctly identifying objects. |

| Precision | Indicates how often positive identifications are correct, reducing false positives. |

| Recall | Reflects the ability to detect all relevant instances, ensuring no misses. |

| Execution Time | Represents how quickly the system processes images and identifies workpieces. |

High-speed cameras and advanced sensors enable real-time inspections on production lines. GPUs and TPUs accelerate image processing, while deep learning and AI in machine vision improve feature extraction and recognition. These technologies help the system maintain high accuracy, sensitivity, and specificity, even at rapid speeds.

Integration Options

The emergence machine vision system offers flexible integration for diverse industrial needs. Users can connect dozens of cameras to a single server or hundreds across multiple servers. The system supports plug-ins and software like eCapture Pro, which streamlines image acquisition and processing. Feature extraction and deep learning algorithms adapt to changing inspection requirements, ensuring reliable performance.

The system’s modular design allows seamless integration with existing automation platforms. Users benefit from software support for advanced machine vision applications, including real-time analytics and adaptive quality control.

Plug-ins extend the system’s capabilities, supporting tasks such as 3D mapping, volumetric capture, and automated defect detection. This flexibility ensures the system meets the evolving demands of modern manufacturing and research environments.

Benefits

Efficiency

The emergence machine vision system brings a new level of efficiency to industrial environments. Companies use these systems to reduce cycle times by balancing and optimizing production lines. Vision-guided robotic systems help automated guided vehicles and robots move with precision. Automated quality inspection detects defects, verifies packaging, and ensures products meet strict standards. Real-time monitoring and feedback allow teams to correct issues immediately, keeping operations smooth.

- Production lines run faster and with fewer errors.

- Automated inspection tasks lower labor costs and increase accuracy.

- High-resolution cameras and image processing reduce waste and improve product quality.

- Data analysis supports process optimization and predictive maintenance, which reduces downtime and extends equipment life.

- In the oil and gas sector, automated leak detection has improved operational efficiency and allowed for scalable solutions.

Machine vision systems provide continuous quality improvement. Immediate feedback and adjustments help maintain consistent product standards. These features make the system a valuable tool for any industry seeking reliable automation.

Industry Impact

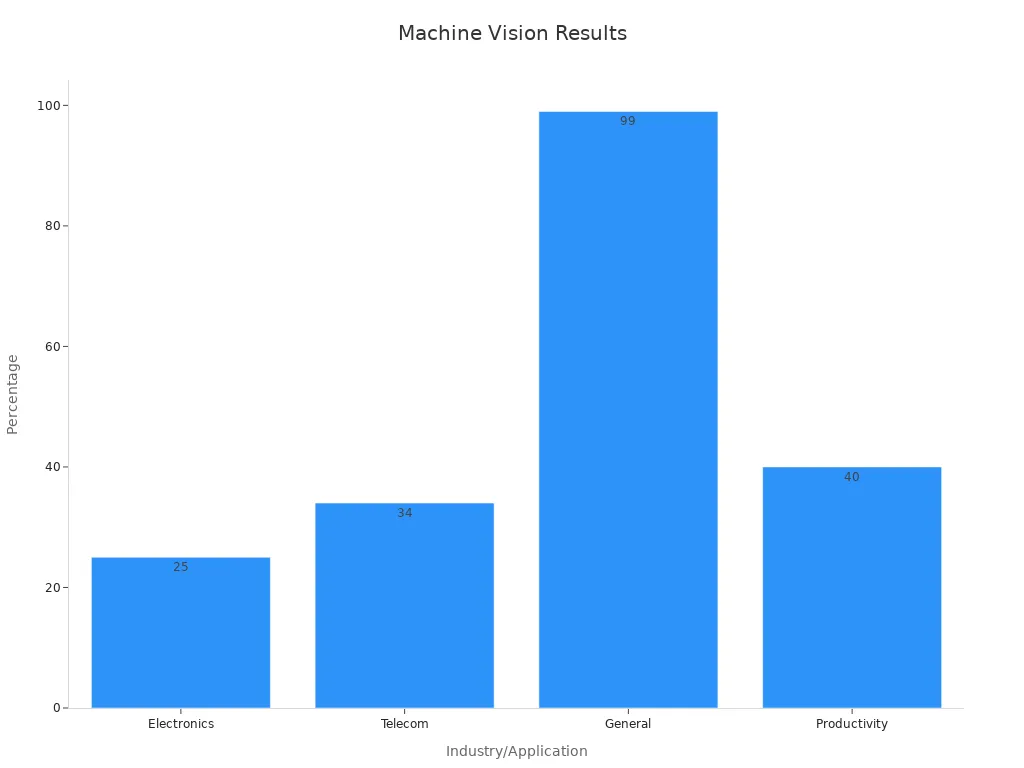

Industries across the globe experience significant benefits from machine vision technology. Manufacturing plants see higher productivity and better quality control. Sports technology companies use high-speed imaging for real-time analytics and performance tracking. Virtual reality developers rely on precise imaging for 3D mapping and immersive experiences. Traffic monitoring systems use advanced detection to manage flow and improve safety.

- Firms using AI, including machine vision, report higher product and process innovation.

- In Germany, AI adoption contributed 18% of total world-first sales, showing strong links to innovation.

- Companies with more experience in AI achieve better results over time.

Machine vision and automation drive progress in many sectors. These technologies support world-first innovations and help businesses exceed expectations.

Applications

Industrial Automation

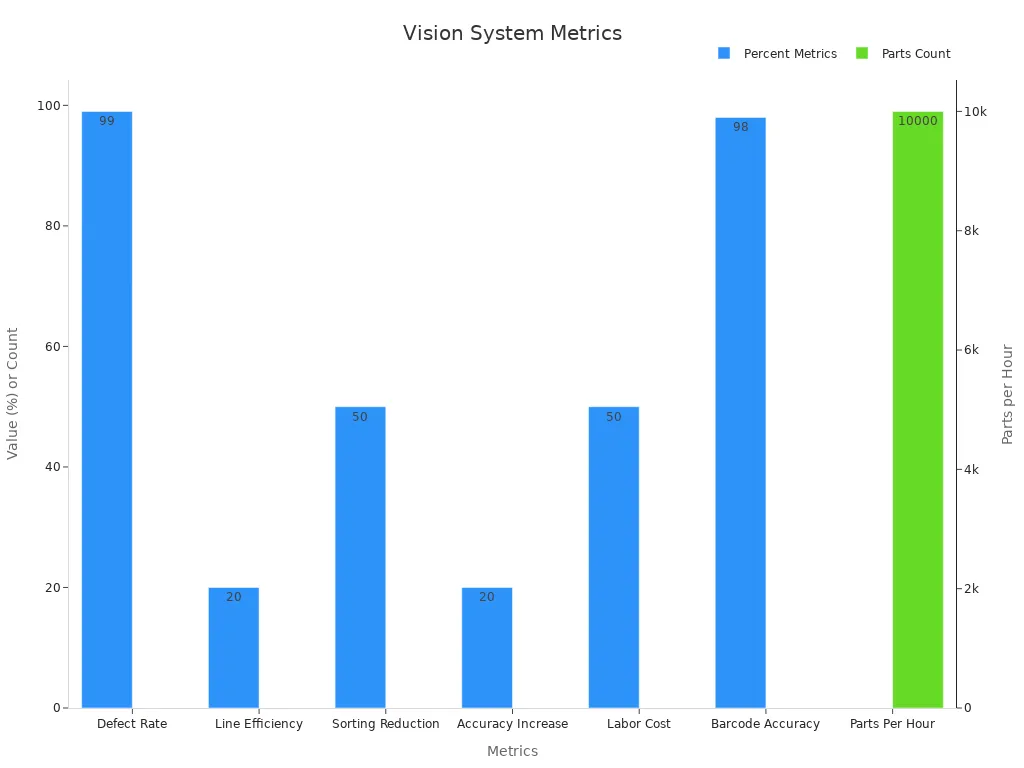

Industrial automation relies on fast, accurate systems to keep production lines moving. The emergence machine vision system supports 3d imaging, object recognition, and real-time inspection. Companies use these systems to detect defects, sort products, and guide robots. The technology improves quality and reduces waste. For example, AI-driven vision systems now recognize over 99% of product defects. Production line efficiency has increased by up to 20%. Sorting time has dropped by half, and classification accuracy has improved by 20%. Vision-guided robots handle up to 10,000 parts per hour, while labor costs in quality assurance have dropped by about 50%.

| Metric / Case Study | Statistic / Impact | Description / Effect |

|---|---|---|

| Defect Recognition Rate | > 99% | AI-driven vision systems detect nearly all product defects, ensuring high quality. |

| Production Line Efficiency | Up to 20% improvement | Robotics and vision integration increase speed and output on production lines. |

| Sorting Time Reduction | 50% reduction | Vision systems accelerate sorting processes, saving time and costs. |

| Classification Accuracy Increase | 20% improvement | Enhanced algorithms improve classification over traditional methods. |

| Parts Handled per Hour by Vision-Guided Robots | Up to 10,000 parts | High throughput enabled by vision-guided automation. |

| Labor Cost Reduction in Quality Assurance | Approximately 50% | Significant savings due to automation of inspection tasks. |

Real-world companies such as Siemens, Toyota, and Amazon have reported faster production, fewer errors, and better traceability after adopting these advanced applications.

Sports Technology

Sports technology uses 3d imaging and high-speed cameras to analyze movement and performance. Teams and coaches track sprinting, jumping, and reaction time. The system measures balance and stability, helping athletes improve their skills. Studies show that virtual reality and machine vision tools boost performance in most cases. Five out of six clinical trials found positive effects on balance and technical skills. These tools help both healthy athletes and those recovering from injuries. Most research focuses on sub-elite athletes, but the benefits are clear for training and rehabilitation.

- 3d imaging captures fast movements for detailed analysis.

- Machine vision systems provide accurate feedback on technique and form.

- Coaches use real-time data to adjust training plans.

Virtual Reality

Virtual reality depends on precise 3d imaging and object recognition for immersive experiences. The emergence machine vision system supports volumetric capture and 3d mapping, creating realistic environments. In sports and training, VR platforms measure neurocognitive function and reaction time. Most studies report improvements in balance and cognitive skills. The system adapts to different sports and user needs, making it valuable for both training and entertainment.

Industries such as healthcare, automotive, and telecommunications also benefit from these advanced applications. Machine vision systems deliver faster inspection, higher accuracy, and better recognition than manual methods. Deep learning models and automation continue to drive progress in diverse sectors.

Comparison with Other Machine Vision Systems

Key Differences

The emergence machine vision system stands out from traditional systems in several important ways. Most older machine vision solutions use slower data interfaces and lower resolution sensors. These systems often struggle with high-speed production lines or detailed inspections. The emergence system uses advanced GigE Vision cameras. These cameras support speeds up to 100GigE. They capture thousands of frames per second with high resolution.

| Feature | Traditional Systems | Emergence Machine Vision System |

|---|---|---|

| Data Interface | USB, Camera Link | 10/25/100GigE |

| Max Frame Rate | 100-200 fps | 1,000+ fps |

| Max Resolution | 5-20 MP | Up to 65 MP |

| Integration Options | Limited | Modular, multi-server |

| Deep Learning Support | Basic | Advanced, GPU-accelerated |

Traditional systems often require manual data transfer and slower processing. The emergence system uses GPUDirect technology. This feature sends image data straight to GPU memory. It enables real-time analysis and supports deep learning applications. Users can connect many cameras to one server or scale across multiple servers. This flexibility helps industries adapt to changing needs.

Unique Value

Emergent Vision Technologies leads the field in high-speed Ethernet cameras. The company introduced the first 10GigE and 100GigE machine vision cameras. Their products support both area scan and line scan imaging. This versatility allows use in many industries, from manufacturing to sports analytics.

The emergence machine vision system offers plug-ins and software tools for advanced tasks. These include 3D mapping, volumetric capture, and automated inspection. Deep learning integration improves accuracy and speeds up defect detection.

Emergent Vision Technologies invests in research and development. They focus on real-time performance and easy integration. Their systems help companies achieve higher productivity and better quality control. This commitment to innovation sets them apart from other machine vision providers.

The emergence machine vision system delivers unmatched speed, accuracy, and flexibility for modern industries. Companies gain real-time inspection, high-resolution imaging, and seamless integration. Market trends show strong growth and innovation:

| Aspect | Evidence Summary |

|---|---|

| Product Segment | Vision sensors & image-based barcode readers dominated in 2023 due to cost-effectiveness and reliability, indicating sustained demand. |

| Application Segment | Inspection leads the market, highlighting machine vision’s critical role in quality control and waste reduction. |

| End-User Segment | Manufacturing dominates, driven by Industry 4.0 and smart manufacturing growth, supporting long-term adoption. |

| Regional Outlook | Asia-Pacific holds the highest market share in 2023, fueled by rapid industrialization, government support, and investments in automation. |

| Strategic Acquisitions | Emerson’s acquisition of NI and Cognex’s acquisition of Moritex expand capabilities and market reach, indicating industry growth and innovation. |

| Forecast Period | Quantitative analysis from 2024 to 2032 provides a solid numerical foundation projecting market growth and benefits of adoption. |

For those seeking to enhance operations, exploring system integration guides or consulting with machine vision experts can provide a strong starting point.

FAQ

What industries benefit most from the emergence machine vision system?

Manufacturing, sports technology, virtual reality, and traffic monitoring see the greatest benefits. These sectors require high-speed, high-resolution imaging for quality control, analytics, and automation.

How does the system handle large amounts of image data?

The system uses GPUDirect technology. This feature sends image data directly to GPU memory. Processing happens quickly, even with thousands of frames per second.

Can users integrate the system with existing automation platforms?

Yes. The modular design and software support allow easy integration with most automation platforms. Plug-ins and APIs help users connect the system to their current workflows.

What makes the emergence machine vision system different from traditional systems?

The system uses advanced GigE cameras and supports high frame rates and resolutions. It offers real-time processing, deep learning support, and flexible integration options.

Is the system suitable for 3D imaging and volumetric capture?

Absolutely! The system supports 3D imaging, volumetric capture, and advanced mapping. These features help industries create detailed models and immersive environments.