A contributor machine vision system uses input from many sources to analyze images and make decisions. Unlike a standard machine vision system, this approach gathers data from multiple cameras, sensors, and even human operators. The main goal is to improve product inspection, sorting, and process control in real time. Machine vision plays a key role in industries that need high accuracy. For example, machine vision systems can find almost every defect in a product, while humans might miss 20% of them. Machine vision also helps companies lower costs and boost efficiency. The global market for machine vision systems reached nearly $13 billion in 2024 and is set to grow to over $20 billion by 2033. Some products, like Blue River Technology’s See & Spray, use machine vision to cut herbicide use by 90%. Companies rely on a contributor machine vision system to ensure better product quality, faster production, and smarter operations.

- The machine vision systems market was valued at $12.92 billion in 2024.

- The market is projected to reach $20.53 billion by 2033.

- Machine vision systems can detect nearly 100% of defects in manufactured parts, while humans detect about 80%.

- Blue River Technology’s See & Spray system reduces herbicide costs by 90%.

Key Takeaways

- Contributor machine vision systems combine data from many sources like cameras, sensors, and humans to improve accuracy and decision-making.

- These systems use advanced cameras, lighting, and software to detect defects almost perfectly and work well in real time.

- They help industries like manufacturing, healthcare, and logistics by speeding up inspection, reducing errors, and lowering costs.

- Good integration and maintenance keep the system reliable and flexible for different tasks and environments.

- Using contributor machine vision systems gives companies a strong edge by boosting quality, efficiency, and product safety.

Components

Cameras and Sensors

Cameras and sensors form the core of every machine vision system. Modern cameras capture images in high detail, using RGB for color, event cameras for fast motion, and depth cameras for 3D shapes. Sensors measure depth and motion, adding more information to the images. These devices help the system see and understand objects with great accuracy. Hardware improvements, such as high-speed polygon mirrors, allow for rapid scanning and precise measurements. The table below shows how each component contributes to the system:

| Component Type | Description / Contribution |

|---|---|

| Polygon Mirrors | High-speed scanning for precise measurement in optical micrometers |

| Cameras | RGB, Event, Depth cameras improve imaging quality and accuracy |

| Sensors | Measure depth and motion, complementing visual data |

| Software Algorithms | Machine learning models for object detection and classification |

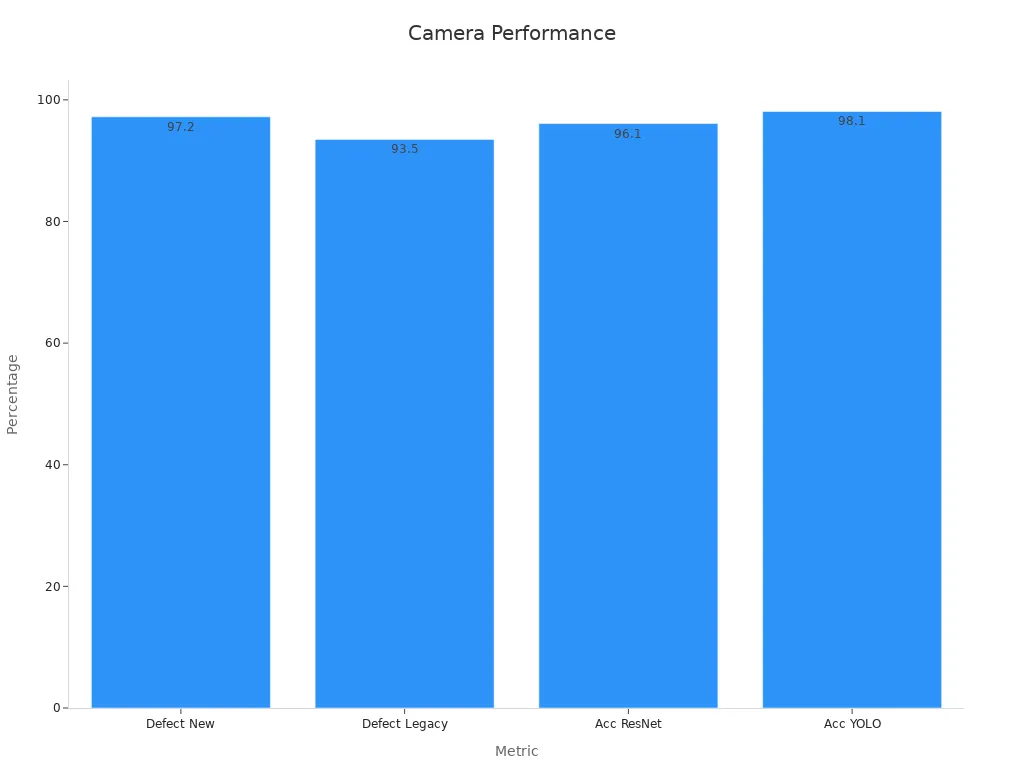

Recent studies show that new cameras and sensors can detect defects at a rate of 97.2%, compared to 93.5% for older systems.

Lighting

Lighting is a key part of machine vision. Good lighting helps the system capture clear images and spot small defects. Researchers at the University of Cordoba created a system that uses neural networks to find markers even in poor lighting. This makes machine vision more reliable in factories, warehouses, and on robots. Experts stress that no software can fix bad lighting. Designers must plan lighting early to get the best results. Proper lighting boosts image quality and helps machine vision systems work well in many settings.

Software and Algorithms

Software and algorithms process the images and data collected by cameras and sensors. Machine learning models, such as YOLOv5 and ResNet-50, help the system find and classify objects quickly. Recent advances have made these models more accurate and efficient. For example, new algorithms can reach over 98% accuracy in inspection tasks. Improvements like connected component labeling and high dynamic range reconstruction also help the system handle complex images. These tools allow machine vision to adapt and learn from new data, keeping accuracy high.

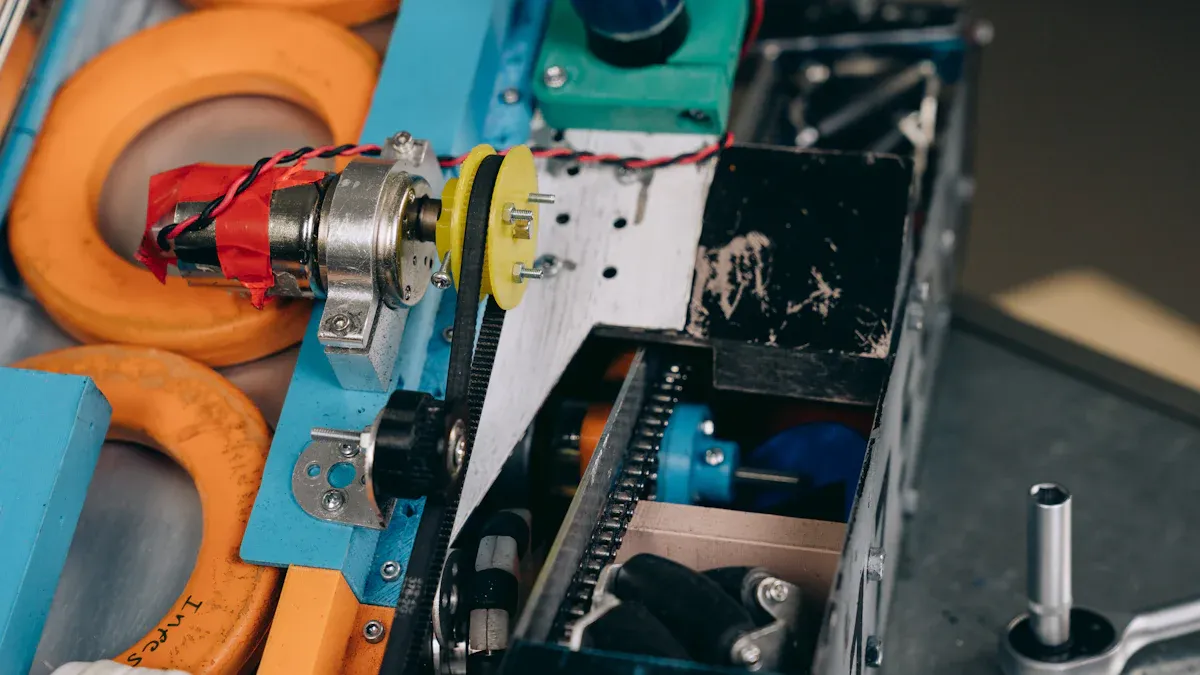

Integration

Integration brings all the parts of a machine vision system together. This step ensures that cameras, sensors, lighting, and software work as one unit. System integration testing checks that every part communicates and performs as expected. In real-world cases, such as CNC drilling machines, integration allows for modular design, sensor fusion, and robotic integration. This makes the system flexible and easy to upgrade. Robotic integration also lets machines make decisions and act on them without human help. Good integration leads to better performance, reliability, and easier maintenance.

How Contributor Machine Vision System Works

A contributor machine vision system follows a clear workflow. The process starts with collecting data from many sources. It then processes images using advanced algorithms. Finally, it makes decisions based on the results. Each step uses input from cameras, sensors, and sometimes human operators. This approach helps the system work better in real-world settings.

Data Collection

The first step in a contributor machine vision system is data collection. The system gathers images and information from different cameras and sensors. Sometimes, operators add extra data or labels. Using many sources helps the system see more details and reduces errors. For example, in medical imaging, researchers found that using data from several hospitals made the system more reliable. They also fixed problems like mislabeled images and bias by checking and relabeling data. This process improves the quality of the data and helps the system learn better.

- Multiple case studies show that using datasets from different sources makes the system more robust.

- Experts found that relabeling and checking data helps fix errors and bias.

- Studies in medical imaging highlight the need for diverse data to avoid mistakes and improve results.

Tip: Collecting data from many sources helps the machine vision system handle different situations and find more defects.

The table below shows how experts study and improve the data collection workflow:

| Step in Workflow | Description / Example | Method / Result |

|---|---|---|

| Data Collection & Preparation | Experts label thousands of data samples from different sources. | Creates high-quality datasets for training and testing. |

| Workflow Steps Identified | Steps include collecting, preparing, and checking data. | Ensures each part of the process is clear and repeatable. |

| Workflow Analysis | Researchers use models to study how steps connect and repeat. | Finds patterns and improves the workflow for better results. |

| Automated Step Identification | Systems learn to spot workflow steps automatically. | Makes it easier to manage large projects and keep data organized. |

| Context & Environment | Focus on real-world settings, like factories or labs, where data comes from many places. | Helps the system work well in different environments. |

Image Processing

After collecting data, the contributor machine vision system processes the images. It uses software and algorithms to find objects, measure features, and spot defects. The system often uses machine learning models, which learn from past examples to get better over time. In factories, image processing helps find tiny flaws that humans might miss. Industry reports show that machine vision systems lead the market in quality control, especially in electronics and semiconductor plants. These systems use metrics like Intersection over Union (IoU), precision, recall, and F1-score to measure how well they find and classify objects. For example, some models reach high accuracy scores, showing they can detect small and medium-sized objects very well.

- Flaw detection is the top use for image processing in machine vision.

- Metrics like IoU, precision, and recall help measure how well the system works.

- Advanced models can reach accuracy scores above 0.7, showing strong performance.

Note: Using strong image processing algorithms helps the machine vision system find more defects and improve product quality.

Decision-Making

The last step is decision-making. The contributor machine vision system uses the processed data to decide what action to take. It might sort products, flag defects, or send alerts to operators. The system uses several metrics to check its decisions, such as accuracy, precision, recall, and F1 score. These metrics help balance the need to find all defects with the need to avoid false alarms. For example, in a factory, the system might only flag a defect if it is very sure, based on a confidence score. This helps reduce the number of mistakes and keeps the process running smoothly.

- Precision is important when the system must avoid false alarms.

- Recall matters when missing a defect could be costly.

- F1 score helps balance finding all defects and avoiding mistakes.

- Confidence scores and decision thresholds guide when the system acts.

Tip: Using several metrics helps the machine vision system make better decisions and improve accuracy.

A contributor machine vision system uses input from many sources at every step. This teamwork makes the system more flexible and reliable. It can adapt to new tasks and handle changes in the environment. By following this workflow, the system helps companies improve quality, speed, and safety in their operations.

Key Features

Multi-Source Input

Contributor machine vision systems stand out because they gather data from many sources. These sources include cameras, sensors, and even user input. By combining information from different places, the system can see more details and make better decisions. Data-centric approaches, such as data augmentation and multi-task learning, help the system handle large and noisy datasets. This makes the machine vision system more robust and accurate. For example, using data from several channels can reveal almost three times more useful insights than using just one. This approach improves detection and inspection tasks in automation solutions.

Real-Time Analysis

Modern machine vision systems process information quickly. They use powerful hardware like GPUs and TPUs to analyze images and data in real time. Benchmarks such as MLPerf Inference show that these systems can handle low-latency tasks and keep up with fast-moving production lines. Key metrics like inference time, memory usage, and throughput help engineers measure and improve system speed. Real-time monitoring allows for instant feedback and quick action, which is important for real-time process control and inspection in automation.

Note: Real-time analysis helps companies spot problems as soon as they happen, making machine vision a strong vision-based solution for quality control.

Flexibility

Flexibility is a major advantage of contributor machine vision systems. These systems can adapt to new tasks and changing environments. In healthcare, for example, machine vision navigation reduces both radiation exposure and operative time compared to older methods. Studies show that these systems can model complex visual reasoning tasks, not just simple image classification. This flexibility means the system can handle different types of inspection and automation, making it useful in many industries.

| Feature | Contributor Machine Vision | Traditional Systems |

|---|---|---|

| Task Adaptability | High | Low |

| Environment Handling | Flexible | Rigid |

| Inspection Coverage | Broad | Narrow |

User Interaction

User interaction plays a key role in the design of machine vision systems. Good systems let users complete tasks easily and quickly. Research shows that users value effectiveness, efficiency, and clear feedback. Systems that use real-world language and simple options help users learn faster and make fewer mistakes. Usability testing ensures that the system meets user needs and supports easy recovery from errors. These features make machine vision systems more approachable and reliable for inspection and automation tasks.

Applications of Machine Vision Systems

Quality Control

Machine vision systems play a vital role in quality control across many industries. These systems use advanced inspection to find defects in products before they reach customers. Companies like Tesla use machine vision systems to spot production line defects and ensure only high-quality products leave the factory. Inspection systems can detect even the smallest defects, such as cracks or misalignments, that humans might miss. In electronics manufacturing, machine vision systems achieve 98% defect detection accuracy, compared to 85% for manual inspection. They also speed up inspection by 60% and reduce costs by 20%. Automated inspection systems help lower the number of defective products and reduce rejection rates. By using machine vision systems, companies can track every product, improve product identification, and prevent defective products from reaching the market.

Manufacturing

Manufacturing relies on machine vision systems for many applications. These systems inspect products on fast-moving production lines and help with automation. Automated optical inspection systems provide reliable and efficient quality control, reducing human error and fatigue. Machine vision systems increase inspection speed, allowing factories to process up to 10,000 parts per hour. They also help with product tracking and rejection of defective products. In the oil and gas industry, machine vision systems automate leak detection, improving safety and reducing water loss. Manufacturing plants use inspection systems to adapt to different products and changing requirements. These applications lead to fewer defects, lower rejection rates, and higher efficiency.

Logistics

Logistics companies use machine vision systems for product tracking, inspection, and rejection of damaged goods. Amazon’s Just Walk Out system uses machine vision systems to enable cashier-less shopping, showing how inspection systems can improve customer experience. In warehouses, machine vision systems help with product identification and tracking, making sure the right products reach the right place. Inspection systems also monitor product quality during shipping and storage, reducing the risk of defective products reaching customers. These applications help companies manage inventory, lower rejection rates, and improve overall efficiency.

Healthcare

Healthcare benefits from machine vision systems in many ways. These systems support inspection of medical images, such as X-rays, MRIs, and CT scans, to detect defects like tumors or fractures. Machine vision systems reach accuracy levels similar to expert radiologists, improving disease detection and treatment planning. Inspection systems also help track patient movements, prevent falls, and manage medical supplies. In hospitals, machine vision systems reduce medication errors by scanning labels and improve communication among staff. These applications lead to better patient safety, fewer defective products, and lower rejection rates in medical processes.

Note: Machine vision systems have many applications, from quality control and manufacturing to logistics and healthcare. They improve inspection, reduce defects, and help companies deliver better products.

Benefits

Accuracy

Contributor machine vision systems deliver high accuracy in inspection and quality control. These systems use advanced calibration to keep accuracy within 1% deviation over 10,000 cycles. Machine vision reduces human error rates from 25% to under 2%, which means fewer defective products reach customers. In one test, a machine vision system classified 994 out of 1,000 parts correctly, achieving 99.4% accuracy. Precision, recall, and F1-score help measure how well the system finds defects and ensures quality assurance. 3D stereo vision also improves depth estimation by over 90%, making inspection more reliable for every product.

- Vision system calibration maintains accuracy within 1% over thousands of cycles.

- Machine vision reduces human error rates from 25% to under 2%.

- 3D stereo vision boosts object depth estimation accuracy by over 90%.

Efficiency

Machine vision systems increase efficiency in inspection and production throughput. Real-time monitoring saves over 900 hours of production time for manufacturers. Automated inspection and data collection help companies spot bottlenecks and improve throughput. AI-driven tools in CNC operations cut programming time by up to 80%. Lean manufacturing with machine vision leads to a 90% reduction in cycle time and a 50% increase in productivity. These improvements allow factories to inspect more products, find defects faster, and keep production lines moving.

| Metric Name | Description | Productivity Impact |

|---|---|---|

| Process Cycle Time | Time to complete a process from start to finish | Identifies bottlenecks and delays |

| Throughput Rate | Units processed per hour or shift | Shows productivity levels |

| First-Time Completion | Tasks done right the first time | Reflects quality and efficiency |

Cost Savings

Companies save money by using machine vision for inspection and quality control. Total Cost of Ownership (TCO) analysis looks at all costs, including purchase, maintenance, and downtime. By finding defects early and reducing errors, machine vision lowers the cost per product. TCO also helps companies spot hidden costs and improve return on investment. Predictive analytics and cost modeling tools help businesses find new ways to save money and negotiate better supplier terms. These savings make machine vision a smart choice for quality assurance and inspection.

- TCO includes direct and indirect costs, such as maintenance and downtime.

- Companies use TCO to align investments with business goals and find cost-saving opportunities.

Competitive Edge

Contributor machine vision systems give companies a strong competitive edge. The global market for machine vision is growing fast, driven by automation and Industry 4.0. Companies use machine vision for inspection, quality control, and product traceability. Smart cameras and AI help businesses analyze consumer behavior and market trends quickly. Real-time inspection lets companies adjust product launches and marketing strategies on the fly. Machine vision also helps detect subtle patterns in products that humans might miss. This technology supports higher efficiency, faster response, and better decision-making, helping companies stay ahead in their industries.

- The machine vision market is projected to grow from $13.52 billion in 2025 to $23.63 billion by 2032.

- Automation, AI, and robotics integration create new opportunities for quality control and inspection.

- Real-time analysis and product traceability improve product development and marketing.

Challenges

Integration Complexity

Contributor machine vision systems often face challenges when integrating multiple cameras, sensors, and software into one working unit. The process involves more than just connecting hardware. Teams must collect data from different sources without losing important details. They also need to improve the quality of the information and use standard methods to handle different types of data.

- Teams must weigh and judge the quality of each data source, which can be difficult when sources vary.

- Mixing numbers and written information adds another layer of complexity, as each type has its own value.

- Building trust in the system requires clear steps and open records of decisions and assumptions.

- Experts recommend a step-by-step approach that uses both expert opinions and transparent methods.

- The needs of each project can change, making it harder to create a single solution for all cases.

Note: Combining many vision components into one system takes careful planning and clear communication.

Data Security

Data security stands as a major concern for machine vision systems. These systems collect and process large amounts of sensitive data, such as product images or patient records. If someone gains unauthorized access, they could steal or misuse this information. Companies must use strong encryption, regular security checks, and strict access controls to protect data. Training staff to spot risks and follow safety rules also helps keep information safe. As machine vision systems grow more complex, the need for better security grows as well.

Maintenance

Keeping a contributor machine vision system running smoothly requires ongoing maintenance. The costs and effort can be high, especially in large factories. Maintenance can take up a significant part of a company’s budget, as shown in the table below:

| Maintenance Cost Metric | Estimated Range |

|---|---|

| Percentage of Cost of Goods Produced | 15% to 70% |

| Percentage of Sales | 0.5% to 25% |

| Percentage of Total Cost of Ownership | Around 37.5% |

| Planned Production Downtime Percentage | Around 13.3% |

- Reactive maintenance often leads to higher costs and more unexpected downtime.

- Preventive maintenance helps reduce both downtime and the number of defects.

- Predictive maintenance lowers unplanned downtime by about 18.5% and defects by nearly 87.3% compared to preventive methods.

A strong maintenance plan extends the life of the system and keeps it reliable. Companies that invest in preventive and predictive maintenance see fewer breakdowns and better performance over time.

Contributor machine vision systems transform how industries manage inspection and quality control. These systems use advanced technology to automate tasks, improve accuracy, and support many applications. Companies see higher productivity and efficiency as machine vision systems handle inspection, orientation, and rejection. Real-time monitoring and AI integration help reduce human error and labor costs. Machine vision systems achieve a recall of 100% and an F1 score of 92.02%, showing strong reliability. They support early defect detection, waste reduction, and better data analysis. Machine vision systems adapt to new applications, making them valuable in manufacturing, logistics, and healthcare. Companies should explore how machine vision systems can improve their operations and consider new applications for future growth.

- Increased productivity and efficiency through automation of inspection and rejection tasks.

- Enhanced quality control and consistency with precise defect detection and measurement.

- Reduced labor costs and minimized human error by automating quality control.

- Improved data collection and analysis for real-time monitoring and predictive maintenance.

- Integration of AI and machine learning boosts adaptability and long-term success.

Machine vision systems offer real-world improvements, such as a 25% increase in defect detection and a 34% rise in operational reliability. Their wide range of applications and proven results make them essential for modern industries.

FAQ

What makes a contributor machine vision system different from a regular machine vision system?

A contributor machine vision system uses data from many sources, such as cameras, sensors, and people. This approach helps the system see more details and make better decisions than a regular system that uses only one source.

Can a contributor machine vision system work in different industries?

Yes. Companies use these systems in manufacturing, healthcare, logistics, and more. The system adapts to many tasks, such as inspecting products, tracking items, or analyzing medical images.

How does the system handle poor lighting or unclear images?

The system uses advanced lighting setups and smart software. These tools help capture clear images, even in dark or changing environments. Good lighting and strong algorithms improve accuracy.

Is it hard to maintain a contributor machine vision system?

Maintenance can take time and planning. Teams must check cameras, update software, and clean sensors. Regular care keeps the system running well and helps avoid breakdowns.

What are the main benefits for companies using these systems?

- Higher accuracy in finding defects

- Faster inspection and production

- Lower costs from fewer mistakes

- Better product quality

Companies gain a strong advantage by using these systems.

See Also

Understanding The Basics Of Automotive Machine Vision Systems

Comparing Firmware-Based And Traditional Machine Vision Technologies

A Detailed Look At Cameras Used In Machine Vision

Exploring Electronic Components In Machine Vision Systems

Defining Quality Assurance Through Machine Vision Technology