A computer vision machine vision system uses cameras and advanced software to help machines see and understand images, much like how people use their eyes and brains. These systems play a key role in modern factories, where they inspect thousands of parts every hour and reduce labor costs by up to 50%. In agriculture, they can check up to 60 cherry tomatoes every second for quality. As industries such as automotive and food production demand higher safety and quality, computer vision machine vision system adoption continues to grow rapidly.

Key Takeaways

- Computer vision uses AI to help machines understand images in complex, changing environments, while machine vision relies on cameras and rule-based processing for fast, precise inspection in controlled settings.

- Machine vision systems improve factory productivity by inspecting parts quickly and accurately, reducing errors and downtime, and supporting tasks like quality control and robot guidance.

- Computer vision powers advanced applications like facial recognition, self-driving cars, and medical imaging by learning from data and making smart decisions in real time.

- Both systems boost efficiency, accuracy, and automation across industries such as manufacturing, healthcare, retail, and security, helping companies save costs and improve product quality.

- Starting with small pilot projects, choosing the right hardware, and involving stakeholders early can help businesses successfully adopt these technologies and overcome challenges like data quality and system integration.

What Is a Computer Vision Machine Vision System

Computer Vision Overview

Computer vision gives computers the ability to see and understand images or videos. This technology uses algorithms and models to analyze visual data, just like people use their eyes and brains. Computer vision can recognize faces, objects, and even actions in pictures or video streams. It helps with tasks such as facial recognition, self-driving cars, and medical image analysis. Since the 1950s, computer vision has grown with the help of deep learning and AI. These advances allow computers to interpret complex scenes and make decisions based on what they see.

The computer vision market is growing quickly. Recent reports show that the market could reach over $120 billion by 2035, with a growth rate of almost 20% each year. Most computer vision projects use on-premises systems for better data control and faster response times. The largest application area is facial recognition, which makes up more than a third of the market. Object detection is also growing fast, with a yearly growth rate of over 22%. Companies like Amazon, Google, Intel, and NVIDIA lead the way in this field.

Machine Vision Overview

Machine vision focuses on using cameras, sensors, and computers to inspect and measure objects in industrial settings. These systems work on production lines to check products for defects, measure parts, and guide robots. Machine vision systems use rule-based image processing, such as filtering and thresholding, to make quick decisions. They operate in controlled environments, like factories, where lighting and background stay the same.

Machine vision systems can inspect hundreds of parts every minute. They achieve over 99% accuracy in quality control, which helps reduce downtime by 25% and lowers the risk of costly errors. These systems rely on hardware components, including high-resolution cameras, special lighting, and vision processors. Performance is measured using metrics like accuracy, precision, recall, and F1 score. For example, a system might correctly classify 99.4% of inspected parts. Consistency is also important, so engineers use Gauge Repeatability and Reproducibility (Gauge R&R) tests to check if the system gives the same results every time.

Recent studies show that machine vision uses advanced statistical methods to improve inspection quality. These include pixel intensity analysis, size distribution estimation, and data drift detection. Machine learning models help the system adapt to new types of defects and changing conditions. Real-time monitoring and alerts keep inspection accuracy high and prevent missed defects.

Tip: Machine vision systems work best in environments where lighting, background, and object position stay the same. This helps the system make fast and accurate decisions.

Key Differences

While computer vision and machine vision share some technology, they serve different purposes. Machine vision is hardware-driven and focuses on speed and precision for specific tasks in controlled settings. It uses rule-based processing to inspect products quickly and accurately. Computer vision, on the other hand, uses advanced algorithms and AI to understand complex images and scenes. It can handle dynamic environments and perform tasks like facial recognition, object detection, and image segmentation.

| Feature | Machine Vision | Computer Vision |

|---|---|---|

| Main Use | Industrial inspection, quality control | Image understanding, recognition, AI |

| Environment | Controlled (factories, production lines) | Dynamic (real world, varied settings) |

| Processing | Rule-based, hardware-centric | Algorithm-driven, software-centric |

| Speed | Very high, real-time | Varies, can be slower with complex tasks |

| Flexibility | Task-specific, less adaptable | Highly adaptable, supports many tasks |

| Example Applications | Checking parts for defects, guiding robots | Facial recognition, self-driving cars, medical imaging |

Industrial reports highlight that machine vision systems dominate sectors like consumer electronics and food and beverage, with strong market shares and rapid growth. North America leads in adoption, especially in manufacturing. Machine vision reduces downtime and errors, while computer vision brings intelligence and adaptability to more complex tasks.

Both systems offer strong benefits, but choosing between them depends on the task. Machine vision excels in speed and reliability for repetitive jobs. Computer vision shines when tasks require understanding, learning, and adapting to new situations.

How Machine Vision Works

System Components

Machine vision systems rely on several core components to achieve high speeds and high accuracy. Cameras and image sensors capture detailed images of objects moving along production lines. These images go to computers or embedded vision systems for data processing. Burn-in-tested computers provide reliable operation during continuous inspection. Lighting design plays a key role in image capture, as strong and stable lighting ensures the system can detect defects even when light output drops over time. Calibration mechanisms adjust lighting automatically to maintain consistent image quality. Alert systems monitor hardware status and help prevent failures. Site acceptance testing checks that all hardware meets quality standards before the system starts operation. Smart camera-based vision systems combine cameras, processors, and software in one unit, making them compact and easy to install.

Image Processing

Image processing forms the heart of machine vision. The system uses rule-based analysis to inspect products for defects, measure dimensions, and guide robots. Modern machine vision systems use classification metrics like accuracy, precision, recall, and F1-score to evaluate how well they categorize images. Detection metrics such as Intersection over Union and mean Average Precision help measure object localization. Segmentation metrics like pixel accuracy and Dice coefficient assess how well the system separates different parts of an image. Continuous evaluation practices, such as monitoring data drift and real-time performance, keep the system reliable. Embedded vision systems process images on-device, which allows for fast inspection and tracking. This approach supports high speeds and high accuracy in materials inspection.

Types of Machine Vision Systems

Machine vision systems come in three main types: 1D, 2D, and 3D.

- 1D systems analyze information along a single line, making them ideal for materials inspection in industries like textiles or paper.

- 2D systems use area scan or line scan cameras to inspect flat surfaces and guide robots. These systems hold the largest market share because of their compatibility and widespread use.

- 3D systems capture depth information, allowing for complex inspection and tracking tasks, such as measuring object volume or shape. Industry reports show that 3D systems have the fastest growth rate, while 2D systems remain the most common. Embedded vision systems support all three types, offering compact design and fast data processing. Machine vision enables accurate inspection, tracking, and materials inspection across many industries.

Computer Vision in Action

AI and Pattern Recognition

Computer vision uses ai and machine learning to help computers understand images and videos. These systems can find patterns, recognize faces, and identify objects in real time. In many industries, computer vision supports image analysis and image processing for fast and accurate results. For example, deep learning models such as convolutional neural networks help with object recognition and image analysis. These models learn from thousands of images to spot differences and detect problems.

Performance metrics help measure how well ai systems work.

- Accuracy shows how often the system makes correct predictions.

- Precision focuses on the number of correct positive results.

- Recall measures how many actual positives the system finds.

- F1 Score combines precision and recall for a balanced view.

- Intersection over Union checks how well the system locates objects.

- Mean Absolute Error helps with tasks that need exact values.

- Confusion matrices and AUC give more details about performance.

The table below shows real-world examples of computer vision in action:

| Case Study | Description | Real-time Application | Impact |

|---|---|---|---|

| Hepta Airborne Drone Power Line Inspection | Drones with ai inspect 250 km of power lines in 5 minutes. | Real-time image capture and defect detection. | 3 million euros saved, 400% more defects found. |

| Darwin Edge Real-time Defect Detection | Deep learning finds defects on production lines. | Edge ai gives instant alerts. | Less manual inspection, fewer errors. |

| BMW Assembly Line Quality Control | ai spots assembly issues in real time. | Continuous quality monitoring. | High quality, less manual work. |

Complex Decision-Making

Computer vision systems use ai and machine learning for complex decision-making. These systems use image analysis and image processing to understand scenes and make choices. Cognitive computing lets them adapt, learn, and process data in real time. They use deep learning for image recognition, reinforcement learning for better strategies, and Bayesian networks for reasoning.

Some decision-making models include:

- Cognitive computing systems that interpret visual data.

- Personalization and adaptability for different users.

- Real-time data processing and learning from experience.

- Hybrid models where ai and humans work together.

Computer vision now helps in many fields. It supports autonomous vehicles, healthcare, manufacturing, finance, agriculture, and security. These systems improve diagnostics, monitor crops, manage inventory, and keep people safe. As ai and machine learning grow, computer vision will solve more problems and support better data analysis.

Applications and Benefits

Industrial Automation

Industrial automation relies on computer vision and machine vision to increase productivity and improve processes. In manufacturing, companies like General Motors have automated over 50% of their production workflows using machine vision systems. These systems handle automated inspection, counting, and sorting of products. Predictive maintenance uses visual data to find problems early, which reduces downtime and repair costs. Safety monitoring with computer vision helps lower workplace accidents by checking if workers follow safety rules. Many companies, such as Siemens, GE, Tesla, and Coca-Cola, use machine vision for assembly line monitoring and defect detection. Automated systems in manufacturing make operations faster and more reliable.

- Automated inspection reduces stockouts and overstock.

- Machine vision systems improve overall equipment effectiveness.

- Embedded vision systems support real-time monitoring.

Quality Control

Quality control in manufacturing depends on computer vision and machine vision systems. These systems inspect products for defects, measure parts, and ensure high product quality. A case study in brick manufacturing showed that computer vision reached 98.7% accuracy in finding critical defects. The same system reduced warranty claims by 92% and waste by 34%. Labor costs for quality control dropped by 68%, and production throughput increased by 27%. The company saved $1.2 million each year in warranty claims. Machine vision systems use high-resolution cameras, custom lighting, and machine learning models for real-time automated rejection. These systems help maintain high standards and improve brand reputation.

Note: Computer vision systems work best for high-speed inspection tasks that are hard for humans to perform.

Other Industries

Computer vision and machine vision also help in healthcare, retail, and security. In healthcare, human-in-the-loop machine vision systems reduce billing errors and improve diagnostic accuracy. In retail, embedded vision systems power self-checkout lanes and product recognition. Deep learning models in retail increase sales by 7.8% and profits by 8.1%. These systems also help visually impaired customers shop independently. In security, computer vision supports surveillance and access control. Machine vision systems make these industries more efficient and accurate.

Main Advantages

Computer vision and machine vision offer many advantages across industries:

| Advantage | Description |

|---|---|

| Efficiency | Automation of repetitive tasks increases productivity and reduces errors. |

| Accuracy | Computer vision algorithms often surpass human accuracy in image analysis. |

| Scalability | Frameworks like TensorFlow and PyTorch enable deployment on many devices. |

| Real-time Insights | Automated systems provide instant feedback for better decision-making. |

| Improved Quality | Better inspection leads to higher product quality and less waste. |

The AI in Computer Vision Market is growing fast, showing a compound annual growth rate of over 37%. Deep learning models process data quickly, making real-time decisions possible. Automated defect detection in manufacturing increases defect detection rates by 25% and reduces downtime by 30%. Machine vision and computer vision help manufacturing systems scale up and adapt to new challenges.

Challenges and Getting Started

Common Challenges

Many companies face several barriers when they try to use computer vision and machine vision systems.

- Legacy equipment often needs new hardware and software, which can be complex to install.

- Products may change in size, shape, or color, so algorithms must adapt quickly.

- These systems create large amounts of data, which require fast processing and storage.

- High initial costs and questions about return on investment can slow adoption.

- Workers may need special training to use and maintain the systems.

- Environmental factors like dust, poor lighting, or vibrations can affect accuracy and require frequent recalibration.

- Data quality issues, such as blurry images or cluttered backgrounds, can lower system performance.

- Privacy and security concerns arise, especially with facial recognition and surveillance.

Note: Real-world deployments often face challenges with data bias, lack of transparency in AI models, and the need for efficient real-time processing.

Choosing the Right System

Selecting the best computer vision or machine vision system depends on the specific needs of each business. Companies should define clear goals and involve all stakeholders early to avoid delays and extra costs.

- Consider the environment: controlled settings like manufacturing lines need different solutions than dynamic outdoor sites.

- Choose cameras, lenses, and lighting that match the application.

- Make sure the system can handle the required speed and accuracy.

- Check if the system can integrate with existing infrastructure and control systems.

- Look for specialized hardware and software that support real-time processing.

- Think about costs, including hardware, software, and training.

- Decide between on-premises or cloud deployment based on data sensitivity and speed needs.

A well-chosen system improves inventory tracking, quality control, and supply chain visibility. In manufacturing, machine vision helps with defect detection and predictive maintenance, while computer vision supports advanced analytics and safety monitoring.

Tips for Beginners

Getting started with computer vision and machine vision does not have to be overwhelming.

- Start with a small pilot project focused on high-priority equipment or processes.

- Use customizable solutions that can grow with your needs.

- Work with vendors who offer training and support.

- Communicate the benefits to your team to reduce resistance to change.

- Protect data with strong cybersecurity measures.

- Regularly monitor and validate system performance, especially during early deployment.

Predictive maintenance systems using machine vision can reduce downtime by up to 50% and cut maintenance costs by 25-30%. Industries like manufacturing, healthcare, and transportation have seen real-world success with these technologies. AI-powered computer vision systems improve accuracy and efficiency, making them valuable tools for many businesses.

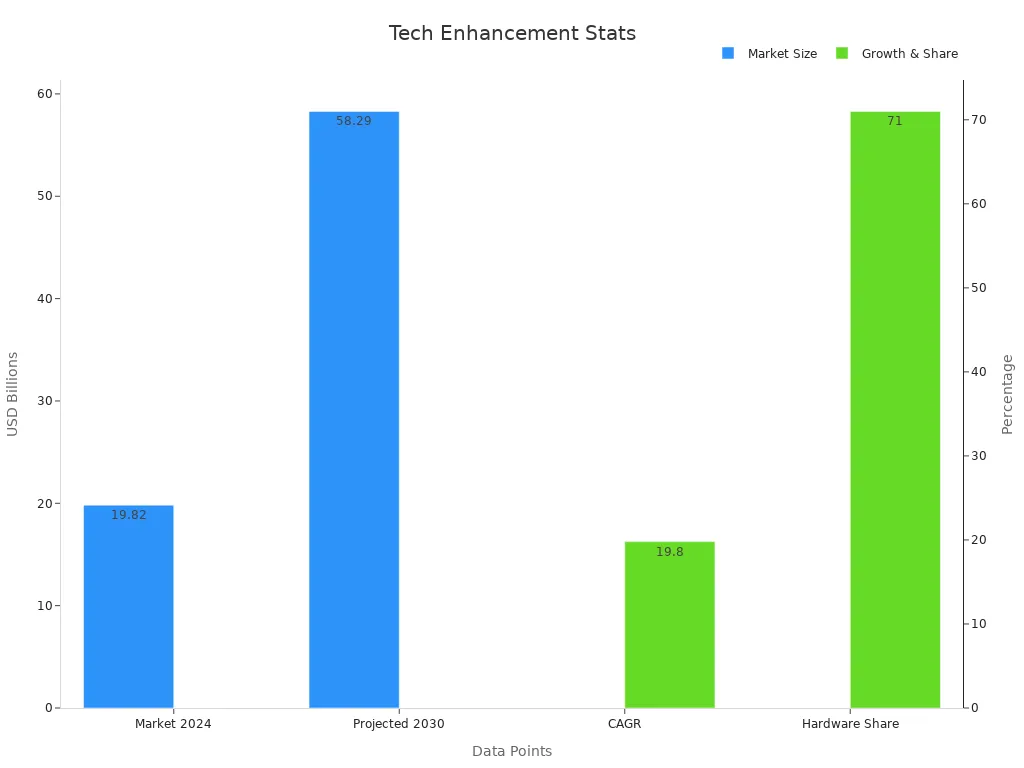

Computer vision and machine vision systems drive progress in many industries. These technologies boost efficiency, accuracy, and automation. The table below shows their growing impact:

| Aspect | Details |

|---|---|

| Market Size (2024) | USD 19.82 Billion |

| Projected (2030) | USD 58.29 Billion |

| Fastest Growth | Software, smart cameras |

| Top Application | Quality assurance, inspection |

Researchers predict rapid expansion as AI and deep learning improve. Many sectors, such as manufacturing and healthcare, will benefit from smarter, scalable systems. Anyone interested in technology can explore these tools to shape the future.

FAQ

What is the main difference between computer vision and machine vision?

Computer vision uses AI to understand images in many settings. Machine vision focuses on fast, rule-based inspection in factories.

Machine vision works best for repetitive tasks. Computer vision handles more complex problems.

Can machine vision systems work in outdoor environments?

Most machine vision systems work best indoors. Outdoor use can cause problems with lighting and background changes.

- Special cameras and software help some systems adapt to outdoor conditions.

How do companies measure the accuracy of these systems?

Companies use metrics like accuracy, precision, recall, and F1 score.

| Metric | What It Shows |

|---|---|

| Accuracy | Correct predictions |

| Precision | Correct positive cases |

| Recall | Found actual positives |

| F1 Score | Balance of both |

Are computer vision systems safe for privacy?

Computer vision systems can raise privacy concerns, especially with facial recognition.

Companies must follow privacy laws and protect personal data. They often use encryption and limit access to sensitive information.

See Also

Understanding Machine Vision Systems And Computer Vision Models

A Beginner’s Guide To Sorting Using Machine Vision Systems

An Overview Of Machine Vision Systems For Image Processing

Introduction To Metrology Using Machine Vision Systems Basics