Color space machine vision systems provide a major leap in accurate color detection compared to grayscale solutions. The table below highlights how different color spaces improve detection metrics over grayscale:

| Color Space | Relative Error | RMSE | SSIM |

|---|---|---|---|

| Grayscale | Baseline | Baseline | Baseline |

| RGB | Improved | Improved | Improved |

| LAB | Improved | Improved | Improved |

| HLS | Improved | Improved | Improved |

Color machine vision systems capture richer information, which allows vision applications to identify subtle differences in colors and achieve higher detection accuracy. Many industries rely on color machine-vision systems for critical tasks, such as:

- Ensuring product quality in automotive and electronics.

- Detecting packaging errors in food and pharmaceuticals.

- Maintaining color consistency in textiles and printing.

Color vision systems outperform manual inspection by providing reliable, repeatable color detection. Selecting the right color space can boost detection efficiency, making color machine vision essential for modern detection challenges.

Key Takeaways

- Color machine vision systems detect colors more accurately than grayscale systems by capturing detailed color information.

- Choosing the right color space, like HSV or LAB, improves detection accuracy and helps handle changes in lighting.

- A reliable color detection workflow includes quality image capture, proper color space conversion, and effective color thresholding.

- Color machine vision enhances quality control, sorting, and automation by reducing errors and increasing inspection speed.

- Proper lighting, regular calibration, and good hardware choices are essential to maintain consistent and precise color detection.

Color Space Machine Vision System

Why Color Space Matters

A color space machine vision system relies on several key components to achieve accurate detection. These systems use lighting, imaging sensors, lenses, computers, and specialized software. Lighting ensures that images remain consistent and clear. Imaging sensors, such as CCD or CMOS cameras, capture detailed images. Lenses focus the scene and determine the field of view. Computers process the image data, while software analyzes and controls the detection process.

Proper illumination and image acquisition form the foundation of any vision system. Without stable lighting, even the best color machine vision cannot deliver reliable detection results.

The choice of color space plays a critical role in detection performance. RGB color space is common, but it mixes color and brightness, making detection sensitive to lighting changes. HSV color space separates hue, saturation, and brightness, which helps the system detect colors more accurately, even when lighting varies. This separation allows for precise thresholding and improves detection reliability in real-world vision applications.

Grayscale vs. Color Machine Vision

Grayscale vision systems capture images using only shades of gray. These systems excel at detecting edges, shapes, and textures. They use less memory and process images quickly. However, grayscale systems cannot distinguish objects that differ only by color. For example, two objects with the same shape but different colors appear identical in grayscale.

Color machine vision systems capture images in multiple channels, such as RGB or HSV. This approach allows the system to analyze hue, saturation, and brightness. As a result, color vision systems can perform advanced detection tasks, such as sorting objects by color or verifying correct color connections in wiring. While color machine vision requires more computing power, it enables detection tasks that grayscale systems cannot handle.

A color space machine vision system provides the flexibility and accuracy needed for modern detection challenges. By capturing and analyzing color information, these systems outperform grayscale solutions in applications where color differentiation is essential.

Color Spaces in Machine Vision

RGB, HSL, LAB, HSV

Machine vision systems rely on different color spaces to analyze and detect colors accurately. Each color space has unique properties that make it suitable for specific image processing tasks. The most widely used color spaces in machine vision include rgb, hsv, and LAB. HSL, which stands for Hue, Saturation, and Lightness, is closely related to hsv and is also used in some applications.

| Color Space | Defining Properties | Usage in Machine Vision |

|---|---|---|

| RGB | Additive color model based on Red, Green, Blue components; each channel ranges from 0 to 255; represents colors as a 3D coordinate; device dependent; intuitive for display but less so for color analysis | Fundamental for image representation; initial format for most images; not ideal for color-based analysis tasks |

| HSV | Separates color into Hue (color type), Saturation (color purity), and Value (brightness); easier to define color ranges; more intuitive for color tracking | Widely used for tasks like color tracking and segmentation due to separation of chromatic content and brightness |

| Lab* | Perceptually uniform color space; L* encodes lightness; a* and b* encode color-opponent dimensions (green-red and blue-yellow); Euclidean distances correspond to perceived color differences; device independent | Valuable for color-based machine vision applications requiring perceptual color difference measurement |

The rgb color space forms the foundation for most digital images. It represents colors as combinations of red, green, and blue light. However, rgb is device dependent and does not match human color perception. This makes it less effective for tasks that require precise color discrimination.

The hsv color space separates hue, saturation, and value. Hue describes the type of color, saturation measures color intensity, and value represents brightness. This separation makes hsv ideal for color tracking and segmentation. Machine vision systems often use hsv to detect specific colors, even when lighting conditions change.

LAB, also known as CIELAB, is a perceptually uniform color space. It encodes lightness (L*) and two color-opponent dimensions (a* for green-red, b* for blue-yellow). LAB is device independent and matches human vision more closely. This makes LAB suitable for applications that require accurate color measurement and comparison, such as quality control.

Other color spaces, such as HSL, YUV, and RG Chromaticity, also play roles in machine vision. HSL is similar to hsv but uses lightness instead of value. YUV separates luminance from chrominance, which helps in video compression and broadcasting. RG Chromaticity focuses on color ratios, making it useful for certain scientific applications.

Tip: hsv color space is heavily used in computer vision for color tracking because it separates hue and saturation from brightness, making it easier to define color ranges.

Choosing the Right Color Space

Selecting the right color space is critical for achieving accurate and efficient color detection in machine vision. The choice affects how well the system can distinguish colors, how fast it processes images, and how robust it is to lighting changes.

- The required level of color accuracy and differentiation matters. Some applications need to detect subtle differences between colors, while others only need to separate broad color groups.

- Color crosstalk, or the overlap between color channels, can affect accuracy. This is important when distinguishing similar colors.

- Lighting conditions play a big role. Some color spaces, like hsv and LAB, handle changes in lighting better than rgb.

- The type of camera sensor and its sensitivity to light can influence which color space works best.

- The location of color space conversion, whether in the camera or on a computer, can impact processing speed and system design.

- Color enhancement and optimization features can help detect specific colors or deviations more effectively.

The rgb color space is simple and fast for image processing, but it is sensitive to lighting and device differences. hsv and LAB offer better separation of color information, which improves detection accuracy and robustness. For example, hsv separates brightness from color, making it less sensitive to shadows and lighting changes. LAB provides perceptual uniformity, so differences in LAB values match what people see.

Studies show that converting rgb images to hsv or LAB can improve detection accuracy and make systems more robust to lighting changes. Reducing color resolution or combining multiple color spaces can also speed up processing and reduce noise.

Note: The choice of color space depends on both the mathematical properties of the space and the environmental factors, such as lighting and camera calibration.

Color Detection Workflow

Color detection in machine vision follows a structured workflow. Each step builds on the previous one to ensure accurate detection and reliable results. The workflow includes image acquisition, color space conversion, and thresholding with analysis.

Image Acquisition

Image acquisition forms the foundation of any color detection system. High-quality images allow for precise detection and analysis. Machine vision systems use color cameras equipped with advanced sensors to capture images with millions of color levels. These cameras often use Color Filter Arrays, such as Bayer filters, to record red, green, and blue information in a single shot. This method supports high-speed detection but may reduce spatial resolution.

For applications that demand maximum detail, some systems use sequential acquisition. They capture separate images for each color channel using filters. This approach increases resolution and sensitivity but works best for slower processes.

Best practices for image acquisition include:

- Use robust libraries like OpenCV or Pillow for loading images and handling color space conversions.

- Convert images between formats, such as BGR to RGB or RGB to hsv, to optimize detection and segmentation.

- Resize images with interpolation methods to maintain quality and avoid distortion.

- Crop images to focus on relevant regions, ensuring consistent dimensions for stable processing.

- Normalize pixel values to balance brightness and color across images.

Adjusting camera gain for each color channel improves contrast between similar shades. This adjustment enhances color detection, especially when objects have subtle differences. Preprocessing steps, such as color shade-scale processing, help reduce noise and speed up detection. These steps are vital for high-speed production lines where accuracy and speed matter.

Calibration and lighting control play a critical role in image acquisition. Aligning all devices to the same illumination standard prevents color mismatches. Standardized lighting, especially with LED sources, ensures consistent color detection throughout the workflow.

Color Space Conversion

After acquiring images, the next step involves converting them into the most suitable color space for detection. The choice of color space affects how well the system can separate and analyze colors. Many systems start with rgb images but convert them to hsv or LAB for better detection performance.

OpenCV offers a popular method for color space conversion using the cv2.cvtColor function. This tool supports over 150 conversion types, such as BGR to hsv or BGR to Lab. Software-based algorithms like this provide flexibility and efficiency. Some systems use matrix transformations or lookup tables for faster conversions. Hardware-based solutions can handle real-time processing, which is important for live detection tasks.

| Conversion Method | Speed | Flexibility | Use Case |

|---|---|---|---|

| Software Algorithms | Moderate | High | General image processing |

| Matrix Transformations | Fast | Medium | Real-time detection |

| Lookup Tables | Very Fast | Low | Fixed color space conversions |

| Hardware Circuits | Fastest | Low | High-speed production lines |

Selecting the right conversion method involves balancing speed, accuracy, and computational resources. For example, converting to hsv separates hue, saturation, and value, making it easier to detect specific colors under changing lighting. LAB conversion provides perceptual uniformity, which helps in quality control and color analysis tools.

Thresholding and Analysis

Thresholding is the process of isolating specific colors or features in an image. This step is crucial for accurate color detection. The method chosen for thresholding depends on the color space. Thresholding in rgb is less reliable because the channels are highly correlated and sensitive to lighting changes. In contrast, thresholding in hsv or LAB improves robustness by separating chromatic features from intensity.

- hsv-based thresholding adapts to different lighting and background conditions. It allows the system to detect colors accurately, even with shadows or complex backgrounds.

- LAB thresholding matches human perception, making it ideal for quality inspection tasks.

- Automated thresholding techniques in hsv can segment small objects and handle diverse image qualities without labeled data.

Color segmentation uses these thresholding methods to separate objects based on their color. Advanced systems automatically determine the best block sizes for local thresholding. This approach suppresses shadows and adapts to varying image conditions, improving detection accuracy.

Analysis follows thresholding. The system measures color properties, checks for defects, and classifies objects. Reliable analysis depends on consistent calibration and lighting control. Regular calibration aligns all measurement devices and ensures that color detection remains accurate over time. Standardized lighting, especially with LED sources, maintains consistent results from one production stage to the next.

Frequent visual evaluations and employee training in color science support consistent detection. These practices reduce waste and improve product quality.

The workflow for color detection in machine vision combines careful image acquisition, precise color space conversion, and robust thresholding with thorough analysis. Each step ensures that detection remains accurate, efficient, and reliable in real-world applications.

Applications of Color Machine Vision

Quality Control

Color machine-vision systems play a vital role in quality control across many industries. In manufacturing, these systems perform automated quality control by inspecting products for defects, verifying assembly, and measuring dimensions with high precision. They detect even the smallest flaws that human inspectors might miss. These systems operate at high speed, maintaining production throughput and ensuring consistent inspections over long runs. Real-time applications allow immediate detection and correction of defects, reducing downtime and preventing faulty products from reaching customers. In the pharmaceutical sector, color machine-vision systems inspect packaging integrity, count pills, verify labels, and detect contaminants. This technology adapts to different lighting and material conditions, ensuring reliable inspections in diverse environments.

Color machine-vision systems eliminate human error in color assessment. They provide standardized inspections and detect subtle color inconsistencies, improving product quality and supporting brand reputation.

Sorting and Inspection

Sorting and inspection represent some of the most common applications for color machine-vision systems. These systems separate objects based on size, shape, color, or defects. In industrial settings, they inspect LCD panels, welds, and batteries, identifying irregularities that humans might overlook. For example, a system can sort apples from a multicolored background by classifying image regions and marking the largest apple for sorting. In electronics, color-based recognition distinguishes soldered from unsoldered joints, enabling fast and accurate classification. The integration of AI algorithms further enhances object detection, increasing yield and preventing defective products from reaching consumers. These applications demonstrate how color machine-vision systems improve inspection speed, accuracy, and reduce operating costs.

- Machine vision systems detect small defects with high-resolution imaging.

- Automated inspections maintain speed and quality.

- Consistent inspections avoid errors from human fatigue.

- Real-time data processing enables immediate corrective actions.

- Automation frees human operators for complex tasks.

- Systems perform diverse inspections, ensuring comprehensive quality control.

Robotics and Automation

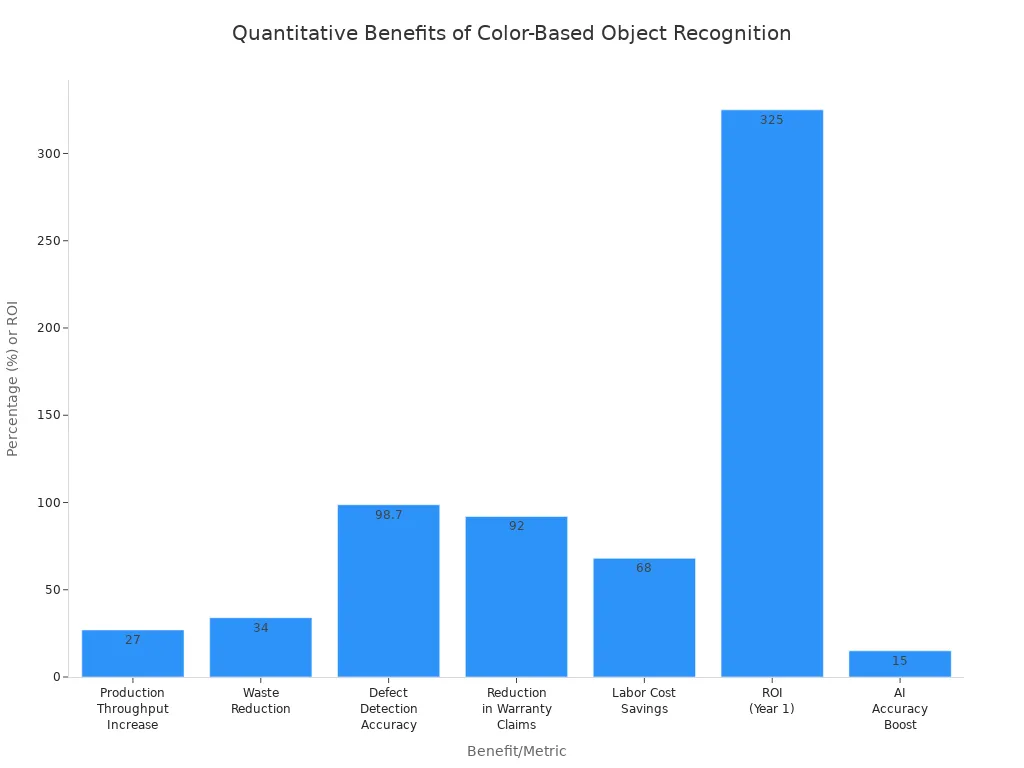

Robotics and automation rely on color machine-vision systems for advanced object detection and sorting. These systems use 2D and 3D cameras, sensors, and AI to identify, locate, and sort objects with high precision. Robots adapt to different products and environments, integrating seamlessly into manufacturing lines. The measurable benefits include increased production throughput, reduced waste, and improved defect detection accuracy.

| Benefit/Metric | Description/Result |

|---|---|

| Production Throughput Increase | 27% increase due to faster, more accurate sorting |

| Waste Reduction | 34% reduction in waste from fewer false positives |

| Defect Detection Accuracy | 98.7% accuracy, improving quality control |

| Reduction in Warranty Claims | 92% reduction, fewer defects reach customers |

| Labor Cost Savings | 68% reduction in quality control labor costs |

| Return on Investment (ROI) | 325% ROI within the first year, payback in 3.7 months |

| AI Integration Benefits | Up to 15% higher accuracy, faster processing, fewer false positives/negatives |

| Flexibility and Adaptability | Robots adapt to new products and environments |

Color machine-vision systems outperform human inspectors in speed and reliability. In electronics, AI-powered vision increased defect detection accuracy from 85% to 98% and reduced inspection time by 60%. In pharmaceuticals, machine vision inspected 300 vials per minute, tripling human speed. These systems operate without fatigue, process thousands of parts per minute, and adapt to new defect types, making them essential for modern object detection and real-time applications.

System Design Considerations

Lighting and Calibration

Lighting forms the backbone of any color reproduction system. Proper lighting ensures that the camera captures true colors, which is essential for accurate color detection. Different lighting techniques, such as ring, dome, or coaxial lighting, help reduce shadows and glare. For reflective surfaces, coaxial lighting minimizes unwanted reflections, making detection more reliable. Dome lighting provides even illumination, which helps the color reproduction system reveal subtle color differences.

Calibration aligns the camera and lighting setup to a standard. This process corrects for non-uniform illumination and sensor response variations. Regular calibration ensures that the color reproduction system maintains consistent color detection across all images. Environmental factors, such as temperature and humidity, can affect both lighting and sensor performance. High temperatures may reduce LED brightness, causing inconsistent detection results. Ambient light can also interfere with the color reproduction system, so using filters or adjusting exposure times helps maintain accuracy.

Tip: Frequent calibration and controlled lighting conditions keep the color reproduction system stable and improve detection reliability.

Color Separation Challenges

Separating similar colors remains a major challenge for any color reproduction system. Color aberrations, such as axial and transverse distortions, can cause focus issues and halos around objects. These distortions make color detection less accurate. Single-chip cameras often suffer from color crosstalk, which reduces the system’s ability to distinguish between close shades.

To overcome these challenges, engineers use special lenses, such as achromatic or apochromatic types, to reduce distortions. Three-CCD prism cameras offer higher color accuracy by minimizing crosstalk, though they increase system complexity. Selecting white LEDs with the right color temperature and high color rendering index improves the color reproduction system’s ability to reveal subtle differences. Software corrections can help, but hardware choices and frequent calibration remain the most effective solutions.

| Challenge | Solution |

|---|---|

| Color aberrations | Use achromatic/apochromatic lenses |

| Color crosstalk | Employ three-CCD prism cameras |

| Illumination inconsistency | Use high CRI LEDs and regular calibration |

| Environmental variability | Control temperature and ambient lighting |

A robust color reproduction system combines careful hardware selection, regular calibration, and optimized lighting to achieve precise color detection. These steps ensure the system can handle real-world detection tasks and maintain high accuracy.

Color space machine vision systems deliver high accuracy in color detection, reducing human error and inspection costs. These systems speed up detection, support real-time monitoring, and adapt to many applications. Recent advances in imaging, such as high-resolution cameras and AI-driven analysis, make color detection more reliable and accessible. For best results, users should match the detection method to their application and control lighting conditions. Future research will improve detection by combining color, texture, and 3D data, making these systems even more effective for industrial applications.

FAQ

What is color detection in machine vision?

Color detection in machine vision refers to the process where a system identifies and analyzes colors in digital images. The system uses sensors and algorithms to distinguish objects or features based on their color properties. This process improves accuracy in sorting, inspection, and quality control tasks.

Why do industries prefer color detection over grayscale analysis?

Industries choose color detection because it provides more information than grayscale analysis. Color detection helps systems identify subtle differences between products, detect defects, and ensure consistency. This advantage leads to higher accuracy and reliability in automated inspections and reduces the risk of human error.

How does lighting affect color detection accuracy?

Lighting plays a critical role in color detection. Inconsistent or poor lighting can cause errors in color detection results. Proper lighting ensures that the system captures true colors, which improves the reliability and repeatability of color detection in various environments.

Which color spaces are most effective for color detection?

RGB, HSV, and LAB color spaces are commonly used for color detection. HSV separates color from brightness, making it robust under changing lighting. LAB matches human vision, which helps in quality control. The choice depends on the application and required accuracy.

Can color detection systems adapt to different environments?

Yes, modern color detection systems can adapt to different environments. They use calibration, advanced sensors, and software adjustments to maintain accuracy. These systems handle changes in lighting, background, and object color, ensuring reliable color detection in diverse industrial settings.

Tip: Regular calibration and controlled lighting help maintain consistent color detection performance.

See Also

How Machine Vision Technology Enhances Defect Identification

Do Color Verification Technologies Boost Inspection Accuracy

A Detailed Look At Cameras Used In Machine Vision

Exploring Object Recognition Within Advanced Machine Vision Systems