You rely on ADC machine vision system technology to turn camera sensor data into digital information that drives fast decisions. In every machine vision system, your camera captures details that only a precise analog-to-digital converter can translate for ai and defect classification. The latest camera innovations, like HybridADC, deliver high resolution and speed. You see automatic defect classification raise classification accuracy to 91% in rice or 94% in corn with ai, as shown below:

| Application Area | Accuracy / Repeatability | Description / Notes |

|---|---|---|

| Rice quality inspection | ~91% | Online classification at over 1,200 kernels per minute |

| Corn kernel classification | 91% (whole), 94% (broken) | Classification rates for whole and broken corn kernels |

Your camera selection and vision system design now depend on ai-driven advances, camera sensor progress, and robust defect classification models. As you optimize, focus on how camera, ai, and classification work together in every adc machine vision system.

Key Takeaways

- ADCs convert camera sensor signals into digital data, enabling accurate image capture and processing in machine vision systems.

- High-speed and high-resolution ADCs improve image quality, helping detect small defects and support real-time inspection.

- AI and machine learning enhance ADC calibration and automatic defect classification, boosting accuracy and system performance.

- Combining the right camera, ADC, and AI models leads to faster, more reliable defect detection in industrial, robotic, and medical applications.

- Regular testing and AI-powered quality checks keep your machine vision system running smoothly and ensure consistent image quality.

ADC Machine Vision System

ADC Role in Image Capture

You start with a camera and an image sensor at the heart of every machine vision system. The image sensor, often a CCD or CMOS type, collects light and turns it into an analog signal. This signal holds all the details from the scene in front of your camera. To use this information, you need an adc to convert the analog signal into digital data. This step is essential for any adc machine vision system.

The adc sits between the image sensor and the rest of your vision system. It takes the analog output from the camera sensor and creates a stream of digital values. These values represent the brightness and color at each point in the image. You rely on this digital data for further processing, such as image analysis, defect detection, and classification.

Note: ADCs play a critical role in medical imaging, industrial inspection, and robotics. High repeatability and precision make adc-based systems ideal for tasks that require accurate image capture and analysis.

You see that adc machine vision system technology supports many industrial applications. For example:

- Industrial PCs with rugged casings protect your camera and adc hardware in harsh environments.

- Vision controllers connect your camera sensors to other devices, making sure data flows smoothly.

- Embedded systems like NVIDIA Jetson platforms help you process images quickly for robotics and autonomous vehicles.

- Cloud-based platforms let you scale up image processing for complex machine vision system tasks.

From Analog to Digital

The journey from light to digital image starts with your camera and image sensor. Here is how the process works:

- The camera lens focuses light onto the image sensor.

- The image sensor, using either CCD or CMOS technology, converts light into electrical charge.

- Each pixel in the image sensor stores a small amount of charge based on the light it receives.

- The adc reads the charge from each pixel and converts it into a digital value.

- The digital data forms the image, ready for processing by your machine vision system.

CMOS image sensors often include an adc in each pixel or column. This design allows for fast and parallel conversion of analog signals. You get higher speed and lower noise, which improves image quality. After conversion, the digital image goes through processing steps like noise reduction, color balance, and image enhancement.

You use adc machine vision system technology to achieve high accuracy in tasks like defect detection and quality control. In medical imaging, adc features help you detect subtle changes in brain tissue or tumors. Studies show that adc-based imaging provides high repeatability and precision, making it a trusted tool in clinical and industrial settings.

| Model | Training Accuracy (%) | Training AUC | Testing Accuracy (%) | Testing AUC | Testing Specificity (%) |

|---|---|---|---|---|---|

| SVM | 98.0 | 0.998 | 77.8 | 0.852 | 88.9 |

| MLR | 93.0 | 0.980 | 72.2 | 0.840 | 77.8 |

| ADA | 90.5 | N/A | 66.7 | 0.685 | 66.7 |

This table shows that machine learning models trained on adc features can achieve high accuracy in image classification tasks. You can trust adc machine vision system technology to deliver reliable results in both industrial and medical applications.

Tip: Always match your camera, image sensor, and adc to the needs of your application. The right combination ensures you get the best image quality and processing speed.

You should also understand the dual meaning of adc in this field. The first meaning is Analog-to-Digital Converter, which handles the conversion of analog signals from your camera sensors. The second meaning is Automatic Defect Classification, which uses digital image data and machine learning to find and classify defects. Both are essential for a modern machine vision system. You need a strong adc for accurate image capture and a robust classification model for reliable defect detection.

ADC Technical Factors

Speed and Resolution

You want your machine vision system to capture every detail. The speed and resolution of your adc decide how well your camera records an image. High-speed adcs let you process images quickly, which is important for real-time inspection. High resolution means your adc can capture more detail in each image. This helps you see small defects or features that matter for quality control.

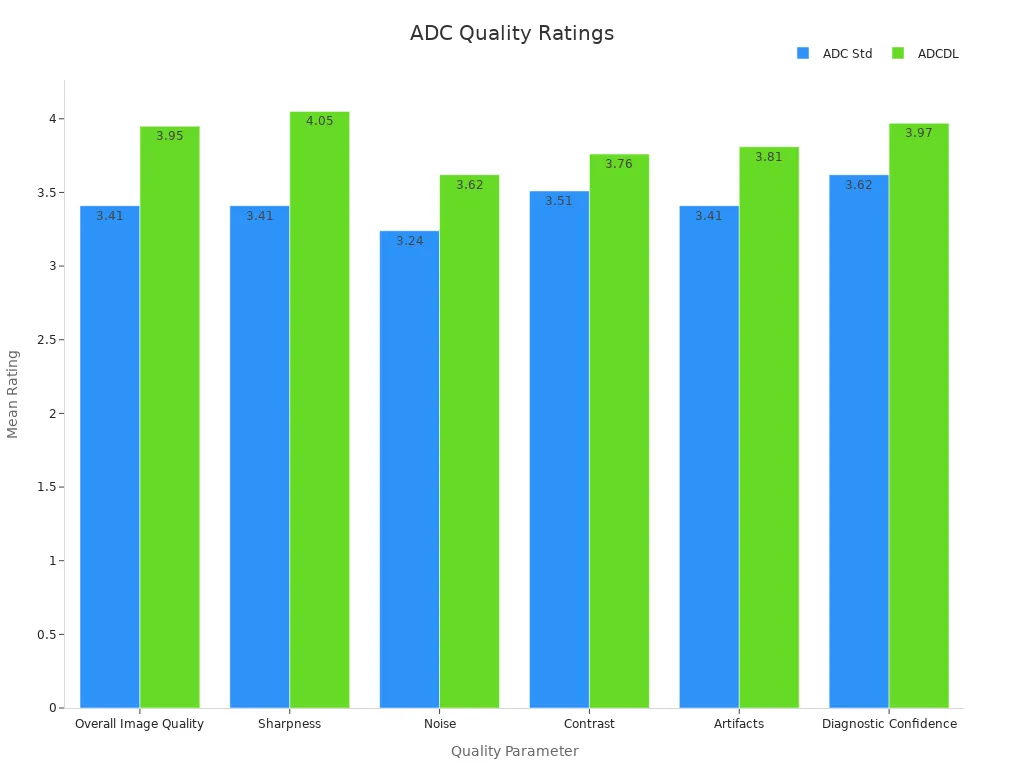

The table below shows how different adc setups affect image quality. Deep-learning adcs improve sharpness, noise, and diagnostic confidence compared to standard adcs. You can see that higher speed and resolution lead to better image processing and more reliable results.

| Image Quality Parameter | ADC Standard Mean (SD) | Deep-Learning ADC Mean (SD) | p-value | Inter-reader Reliability (r) |

|---|---|---|---|---|

| Overall Image Quality | 3.41 (0.59) | 3.95 (0.91) | <0.001 | 0.377 (ADCStd), 0.486 (ADCDL) |

| Sharpness | 3.41 (0.68) | 4.05 (0.91) | <0.001 | 0.671 (ADCStd), 0.615 (ADCDL) |

| Noise | 3.24 (0.64) | 3.62 (0.89) | <0.001 | 0.596 (ADCStd), 0.548 (ADCDL) |

| Contrast | 3.51 (0.83) | 3.76 (0.89) | <0.001 | 0.522 (ADCStd), 0.376 (ADCDL) |

| Artifacts | 3.41 (0.68) | 3.81 (0.93) | <0.001 | 0.474 (ADCStd), 0.300 (ADCDL) |

| Diagnostic Confidence | 3.62 (1.06) | 3.97 (1.04) | <0.001 | 0.743 (ADCStd), 0.668 (ADCDL) |

Noise and Signal Integrity

You need a clean signal for accurate image capture. Noise can hide important details in your image. Signal integrity affects how well your adc can turn the camera’s analog output into digital data. If your system has poor signal to noise ratio, you lose image quality and processing accuracy.

- Signal to noise ratio tells you how much useful image data you get compared to unwanted noise.

- Jitter and clock errors can distort your image, making it hard to spot defects.

- Good pcb layout and careful clock design help you keep noise low and signal integrity high.

You should always check the noise floor and bandwidth of your system. Limiting bandwidth to what your image needs helps reduce noise. High signal to noise ratio and strong signal integrity give you better dynamic range and quantum efficiency in your images.

SAR and In-Pixel ADCs

You can boost your camera’s performance with new adc designs. SAR adcs and in-pixel adcs are popular in modern image sensors. SAR adcs give you fast, accurate conversion for each image column. In-pixel adcs let you process signals right at the pixel, which speeds up image capture and reduces noise.

- SAR adcs, like a 10-bit 5 MS/s column adc, improve readout speed and accuracy.

- In-pixel adcs help with temperature compensation and noise suppression.

- Column adcs use less power and keep your camera cool, which helps with quantum efficiency and dynamic range.

These advances let you process images faster and with more detail. You get better quantum efficiency, higher dynamic range, and more reliable image processing for every application.

Machine Vision Technology and AI

Deep Learning for Defect Classification

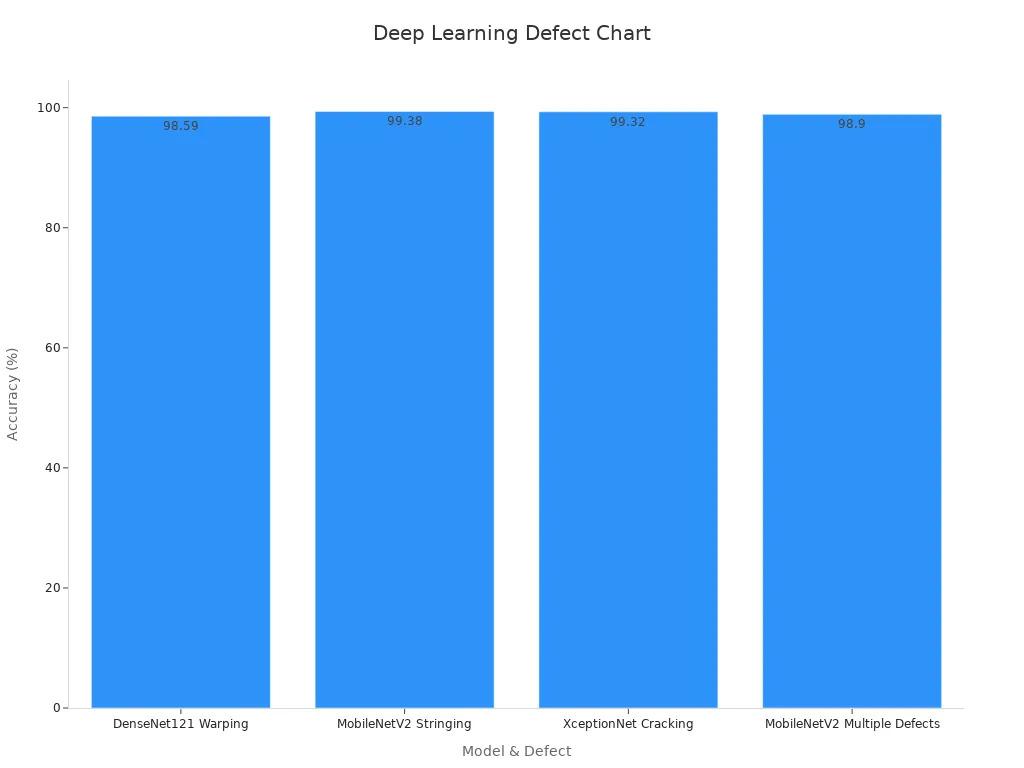

You see machine vision technology change quickly with the rise of ai and machine learning. Today, you use deep learning to improve automatic defect classification in your camera systems. When you train machine learning models on large sets of image data, you help your system spot even the smallest defects. Your camera captures each image, and the adc converts it for digital processing. Then, ai models analyze the image and make fast, accurate decisions.

Deep learning models like DenseNet121, MobileNetV2, and XceptionNet show high accuracy in defect classification. You can see their performance in the table below:

| Model | Defect Type | Accuracy (%) |

|---|---|---|

| DenseNet121 | Warping | 98.59 |

| MobileNetV2 | Stringing | 99.38 |

| XceptionNet | Cracking | 99.32 |

| MobileNetV2 | Multiple Defects | 98.90 |

You notice that these models reach almost perfect accuracy. This means your camera and adc, when combined with ai, can find defects that older systems might miss. The integration of ai with adc-based image processing also boosts inspection speed and traceability. The chart below shows how deep learning models outperform others in defect classification accuracy:

Tip: Use high-quality image data from your camera and adc to train your ai models. This helps your automatic defect classification system adapt to new defect types and keep improving.

ADC Calibration with Machine Learning

You want your adc to deliver the best image quality for every camera. Machine learning models now help you calibrate adc hardware for higher accuracy. When you use ai and machine learning for adc calibration, you see big improvements in signal quality and image processing.

Look at the table below to see how calibration with ai boosts adc performance:

| Metric | Before Calibration | After Calibration |

|---|---|---|

| Signal-to-Noise Ratio (SNDR) | 57.72 dB | 104.61 dB |

| Spurious-Free Dynamic Range (SFDR) | 59.77 dB | 152.64 dB |

| Effective Number of Bits (ENOB) | 8.79 bits | 17.08 bits |

You get a much cleaner signal and more accurate image data after calibration. This means your camera system can detect smaller defects and provide better automatic defect classification. You also see faster processing and more reliable results in your machine vision technology.

Note: Trained adc solutions with ai and machine learning give you a strong edge in industrial inspection. You can trust your camera, adc, and ai to deliver top performance in every image and every classification task.

Applications in Machine Vision Systems

Industrial Inspection

You see machine vision systems transform how factories check products. When you use a camera with a high-quality adc, you capture every detail of a product moving down the line. Inline inspection lets you spot defects in real time. For example, you can find cracks in glass bottles or scratches on metal sheets before they leave the factory. Your camera selection matters because the right sensor and adc combination gives you sharp images, even at high speeds. AI models then analyze each image and classify defects automatically. This process helps you reduce waste and improve product quality. Inline systems also keep your production running smoothly by catching problems early.

Robotics and Automation

You use machine vision to guide robots and automate tasks. A robot with a camera and adc can see its environment and make decisions quickly. For example, in a warehouse, a robot uses its camera to scan barcodes and sort packages. Inline vision systems help robots pick and place items with precision. The adc converts the camera’s analog signals into digital data, so the robot can process images fast. AI helps the robot recognize objects and avoid obstacles. You get faster operations and fewer errors when you combine camera, adc, and ai in your automation setup.

Medical Imaging

You rely on adc technology to improve medical image quality. In hospitals, doctors use cameras with advanced adcs to capture clear images of tissues and organs. AI helps analyze these images for signs of disease. Recent studies show how adc and ai work together to boost diagnostic accuracy:

- Researchers studied 486 patients across 62 hospitals to assess prostate MRI and adc map quality.

- They found that no single setting predicts adc image quality, so you need careful camera and adc setup.

- Deep learning models can predict adc map quality from other images, helping you check quality before scanning.

- Diagnostic figures show how different settings affect image quality and how to spot poor images.

- ADC maps help doctors find cancer, but they can show artifacts if the camera or adc setup is not right.

- AI-driven quality checks can alert you to problems during scanning, so you can fix issues and avoid repeat scans.

You see that the right camera, adc, and ai tools help you get the best medical images. This leads to better care for patients and more reliable diagnoses.

Tip: Always test your camera and adc setup before starting a new application. Inline checks and ai-powered analysis help you catch problems early and keep your system running at its best.

You power your machine vision system with both advanced ADC hardware and smart software. You select ADCs by comparing speed, resolution, and noise. The table below shows how different ADCs fit your needs:

| Model | Resolution (bits) | Max Speed (MSPS) | Noise (DNL, LSB) | Power (mW) | Best Use |

|---|---|---|---|---|---|

| AD9805 | 10 | 6 | ±0.25 | Low | General imaging |

| AD9814 | 14 | 6 | ±0.5 | Moderate | High-end imaging |

| AD9822 | 10 | 30 | ±0.5 | Moderate | High-speed scanning |

You boost results by combining ai with ADC calibration and automatic defect classification solutions. Ai helps you adapt to new challenges, improve image quality, and increase accuracy. Ai-driven systems let you spot defects, optimize settings, and keep your process efficient. You get the best performance when you balance technical choices with ai-powered analysis.

FAQ

What does ADC mean in machine vision?

ADC stands for Analog-to-Digital Converter. You use it to change signals from your camera sensor into digital data. In machine vision, ADC can also mean Automatic Defect Classification, which uses AI to spot and sort defects in images.

How does ADC speed affect image quality?

You need a fast ADC to capture images quickly. High speed lets you process more frames per second. This helps you see moving objects clearly and reduces blur. Slow ADCs can miss details or cause delays in your system.

Why is noise important in ADCs?

Noise can hide small details in your images. You want low noise in your ADC to get clear pictures. Less noise means your system can find tiny defects and make better decisions. Always check the noise level when you choose an ADC.

Can AI improve ADC performance?

Yes! You can use AI to calibrate your ADC and improve image quality. AI helps your system adjust settings for the best results. It also makes defect classification more accurate. This gives you better performance in real-world tasks.

See Also

Understanding How Machine Vision Systems Work In Automotives

How AI-Driven Vision Systems Are Revolutionizing Modern Industries

A Comprehensive Guide To Electronics-Based Machine Vision Systems

Exploring Essential Features And Advantages Of Medical Vision Systems

Demystifying Image Processing In Machine Vision Technologies Today