Integrated AI-Powered Visual Inspection System

Automate inspection and optimize yield

with UnitX’s imaging, AI, and analytics

Imaging

Poor imaging is detrimental to inspection accuracy. Capture optimal 2D & 2.5D images with the OptiX- Software-Defined Imaging System

Versatility

lighting via software in minutes

independently controllable light sources

High speed

meter / sec fly capture

brighter vs. conventional light

lighting patterns / second

Training

Build better detection models faster with the CorteX AI management system– no AI experience needed

Sample Efficiency

images needed to train AI models

Threshold adjustability

adjustable attributes

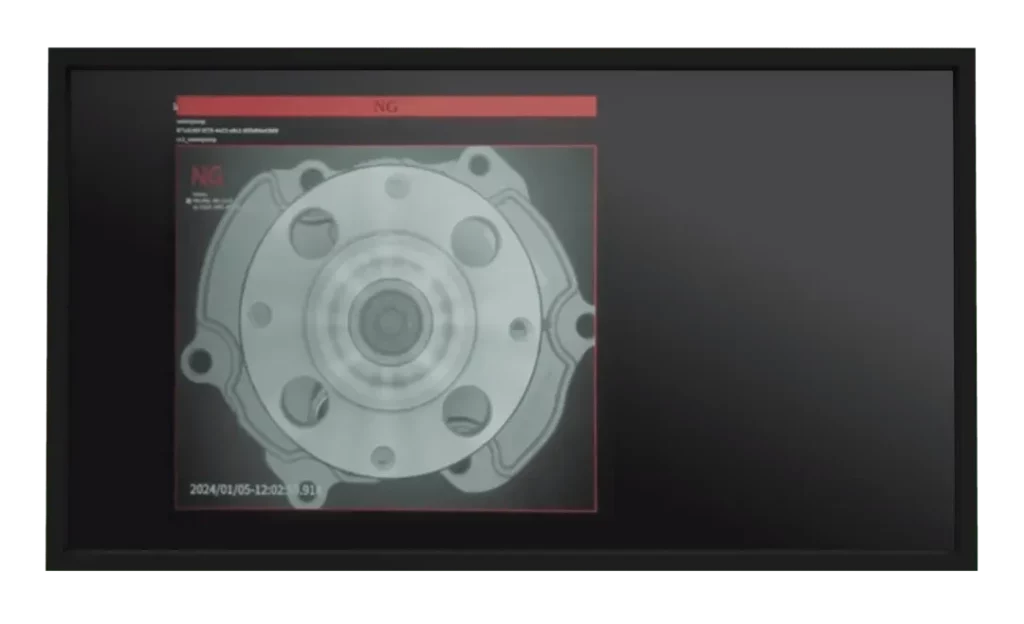

Detection

Manual inspection doesn’t scale. CorteX AI inference system automate inspection with high accuracty and speed

Accuracy

3 pixels needed for minimal pixel-level detection

for rotation variability

AI models adjust quickly to color changes

High speed

megapixels / sec inference speed

maximum detection throughput

integration with all major PLC, MES, and FTP systems

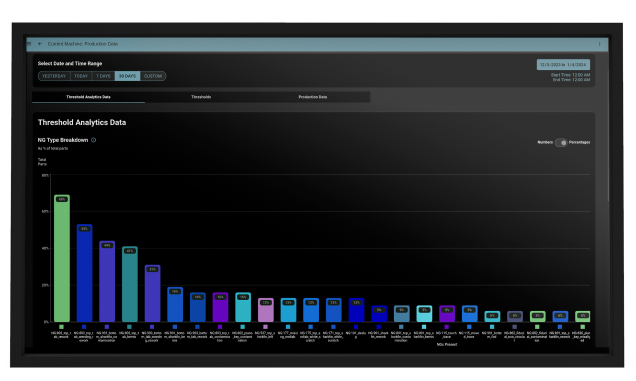

Analysis

Don’t let production issues hurt yield. Monitor production data with CorteX to identify production improvement opportunities

Visibility

Metrics in one place

Continuous improvement

reduced scrap with faster root cause analysis

reduced escape rate vs human operators

Not just defect detection. All-in-one inspection that provides:

UnitX AI Inspection

Solution Brief